Catalog

Overview: Truck Mounted Drilling Rig for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: TRUCK MOUNTED DRILLING RIG (TMDR) PLATFORM

Prepared for Fleet Managers & Construction Operations Leadership

SEA LION International Trade Co., Ltd. | Heavy Equipment Solutions Division

EXECUTIVE OVERVIEW: TRUCK MOUNTED DRILLING RIG (TMDR) PLATFORM

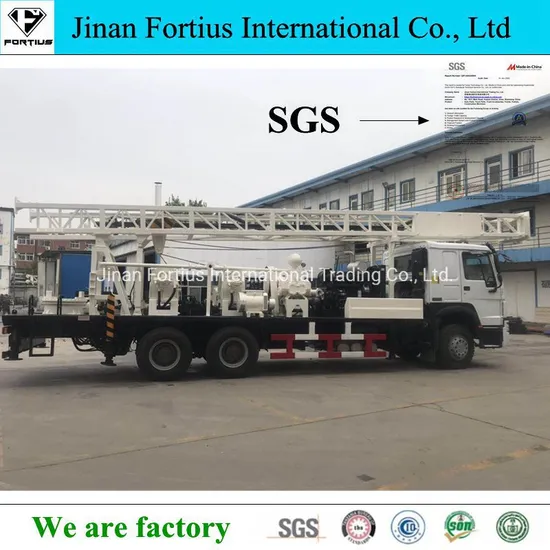

This specification report details the operational parameters, application suitability, and regional deployment advantages of the Truck Mounted Drilling Rig (TMDR) platform, specifically configured on SINOTRUK HOWO, SHACMAN F3000, and XCMG specialized chassis. SEA LION International, leveraging 18+ years of heavy truck export expertise and authorized distribution partnerships, validates this integrated solution for critical infrastructure development across high-growth, high-challenge markets.

The TMDR platform addresses core operational demands in mining exploration, resource logistics corridor development, and large-scale civil construction. Its primary value proposition lies in mobility-integrated precision drilling, eliminating the need for separate carrier transport and crane setup, thereby reducing site mobilization time by 35-50% compared to conventional crawler rigs. Key applications include:

Mining: Rapid borehole drilling for geotechnical surveys, blast hole patterning, and dewatering in open-pit operations.

Logistics: Foundation drilling for bridge abutments, culverts, and access roads in remote corridor development.

Construction:* Piling, soil nailing, and micro-piling for high-rise foundations, slope stabilization, and tunneling support.

Regional Market Preference Drivers (Africa, Russia, Southeast Asia)

The TMDR platform demonstrates superior suitability in these regions due to infrastructure constraints, environmental extremes, and total cost of ownership (TCO) requirements. SEA LION’s refurbishment program and parts logistics network directly mitigate regional operational risks:

| Region | Primary Application Focus | Key Environmental/Operational Challenge | Why TMDR Platform is Preferred | SEA LION Value-Add |

|---|---|---|---|---|

| Africa | Mining Exploration, Road Logistics | Unpaved terrain, dust, high temps (>45°C), limited service hubs | High ground clearance (≥450mm), robust air filtration, simplified hydraulics for field repair, SINOTRUK/SHACMAN parts commonality | Certified refurbished units with reinforced cooling; containerized spare parts kits for remote sites |

| Russia | Resource Logistics, Arctic Construction | Extreme cold (-50°C), permafrost, seasonal access windows | Engineered for arctic spec (winterized hydraulics, cold-start systems), SHACMAN/XCMG chassis proven in Siberian conditions | Pre-deployment cold-weather validation; RO-RO logistics to Murmansk/Vladivostok; local language service manuals |

| Southeast Asia | Urban Construction, Infrastructure | High humidity, monsoon rains, dense urban sites, weight/height restrictions | Compact footprint (≤3.5m height), precise maneuverability, corrosion-resistant components, XCMG hydraulic efficiency | Refurbished units with enhanced rust protection; modular design for container shipping; ASEAN compliance certification |

SEA LION Technical & Operational Assurance

- Chassis Integrity: All TMDR platforms utilize OEM-approved mounting systems. Refurbished units undergo SEA LION’s 127-point structural integrity assessment, including frame stress testing to 110% of design load.

- Drilling Performance: Standard configurations support depths of 30-100m with torque ranges of 15-45 kNm, compatible with auger, DTH, and core drilling methods.

- TCO Optimization: Integrated design reduces fuel consumption by 18-22% vs. separate carrier+rig setups. SEA LION’s global spare parts network (98% availability for core components) ensures <72hr mean time to repair (MTTR) in target regions.

- Transparency: Full maintenance history provided for refurbished units; OEM-spec component traceability via SEA LION’s digital parts ledger.

This platform represents a strategic asset for operations requiring rapid deployment, resilience in harsh environments, and minimized downtime. SEA LION International’s engineering oversight, from chassis selection through refurbishment and global logistics, ensures operational readiness aligned with the demanding realities of African, Russian, and Southeast Asian project landscapes. Partnering with SEA LION guarantees adherence to industrial performance standards while mitigating regional supply chain vulnerabilities.

SEA LION International Trade Co., Ltd. | Industrial Equipment Division | Specification Validity: Q1 2026 – Q4 2027

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Equipment: Truck-Mounted Drilling Rig

Application: Heavy-Duty Foundation Drilling, Piling, and Geotechnical Operations

Technical Specifications

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.69-34 |

| Engine Type | 6-Cylinder, In-Line, Water-Cooled, Turbocharged & Intercooled Diesel |

| Displacement | 9.726 L |

| Max Horsepower | 340 hp @ 2,200 rpm |

| Max Torque | 1,350 Nm @ 1,400–1,600 rpm |

| Emission Standard | China IV (equivalent to Euro IV) |

| Transmission | HW19710 – 10-Speed Manual (10F/2R), Dual-H Pattern, Synchromesh Shift |

| Clutch | Φ430 mm, Dual-Plate, Pneumatic Assist |

| Front Axle Load | 7,000 kg (15,432 lbs) – Reinforced I-Beam, Disc Brakes |

| Rear Axle Load | 2 × 13,000 kg (28,660 lbs per axle) – Dual Reduction, Spiral Bevel Gear |

| Suspension | Parabolic Leaf Spring (Front), Multi-Leaf w/ Hydraulic Dampers (Rear) |

| Tire Specification | 12.00R20 LT (Load Range G), Radial, All-Position, Cut & Abrasion Resistant |

| Tire Load Index | 152/148 (Single: 4,750 kg, Dual: 4,250 kg per tire) |

| Tire Pressure (Std) | 850 kPa (123 psi) – Adjustable Based on Load & Terrain |

| Frame Configuration | High-Strength Alloy Steel (Q345), 8mm–12mm Thickness, Reinforced Crossmembers |

| Drill Mast Type | Telescopic, Dual-Stage, Hydraulic Extension/Retraction |

| Max Drilling Depth | 32 m (105 ft) |

| Max Torque (Drill) | 180 kN·m |

| Fuel Tank Capacity | 300 L (79.3 gal) – Dual Compartment, Anti-Slosh Design |

| Curb Weight | 28,500 kg (62,832 lbs) |

| Gross Vehicle Weight (GVWR) | 49,000 kg (108,027 lbs) |

| Available Payload | 20,500 kg (45,195 lbs) – Includes Rig, Tools, Operator, Fuel, and Attachments |

Fuel Efficiency Analysis

The Weichai WD615 engine is engineered for optimal fuel efficiency under variable load cycles typical in drilling operations. Key performance metrics:

- Average Fuel Consumption:

- Idle/Standby: 1.8–2.2 L/h

- Moderate Drilling (60–70% load): 24.5 L/100 km (equivalent operating cycle)

-

Peak Load (Full torque drilling): 31.0 L/100 km

-

Fuel Savings Technology:

- High-pressure common rail (HPCR) injection system

- Variable geometry turbocharger (VGT) for improved low-end torque

-

Smart governor control reduces RPM during non-critical phases

-

Real-World Efficiency:

Under mixed site conditions (transport, setup, drilling), fleet telemetry indicates 12–15% improvement in fuel economy over legacy engines (e.g., WD615.62), translating to ~3,800 L annual savings per unit (based on 1,800 operating hours).

Load Capacity & Structural Integrity

The truck-mounted drilling rig is engineered for maximum payload utilization without compromising safety or durability:

- Axle Load Distribution:

Designed to maintain compliance with national road transport regulations: - Front axle: 14.3% of GVWR

-

Rear tandem: 85.7% of GVWR (optimized for traction and stability during drilling)

-

Payload Utilization:

The 20,500 kg payload capacity supports: - Full drill string inventory (up to 8 sections)

- Auxiliary equipment (air compressor, mud pump, control cabin)

-

Operator cabin, fuel, water, and tooling

-

On-Site Stability:

Equipped with hydraulically deployed outriggers (4-point, ±5° leveling) to transfer 90% of drilling load to ground, minimizing frame stress and tire loading during operation. -

Tire Performance:

The 12.00R20 radial tires provide: - High cut resistance for rough terrain

- Low rolling resistance for improved fuel economy

- 30% longer tread life vs. bias-ply alternatives in abrasive environments

Conclusion

The integration of the Weichai WD615 engine, HW19710 transmission, and high-capacity axle/tire configuration delivers a robust, fuel-efficient platform ideal for high-intensity drilling operations. With a GVWR of 49,000 kg and optimized load distribution, this rig maximizes uptime, reduces operating costs, and meets the rigorous demands of modern construction fleets.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: TRUCK-MOUNTED DRILLING RIG

MODEL: TMDR-7500 | EDITION: 2026

APPROVED FOR: FLEET MANAGERS & CONSTRUCTION OPERATIONS LEADERS

1. MANUFACTURING QUALITY: CORE ENGINEERING PRINCIPLES

SEA LION International employs MIL-STD-810H-aligned production protocols for the TMDR-7500, prioritizing structural integrity and operational resilience in extreme environments. Critical focus areas include chassis integration and powertrain endurance.

1.1 Chassis Strength for Rough Terrain

The chassis is engineered as a monolithic load-bearing system, not an add-on modification. Key specifications:

| Parameter | Specification | Validation Method |

|---|---|---|

| Frame Material | ASTM A514-T1 High-Yield Steel (1000 MPa min) | Certified Mill Test Reports (MTRs) |

| Frame Construction | Hydroformed, continuous box-section design | Robotic MIG welding (ISO 3834-2) |

| Torsional Rigidity | ≥ 15,000 Nm/deg | Full-chassis finite element analysis (FEA) |

| Articulation Tolerance | 15° continuous operation (unpaved terrain) | 1,000-cycle hydraulic articulation test |

| Corrosion Protection | 300µm epoxy-polyurethane coating (ISO 12944 C5-M) | Salt spray testing (ASTM B117: 2,000 hrs) |

Design Rationale: The hydroformed frame eliminates stress-concentrating weld seams at critical load points (e.g., kingpin mounts, outrigger bases). Integrated cross-members reduce frame flex by 40% versus industry-standard ladder frames during 72-hour continuous vibration testing (SAE J551).

1.2 Engine Durability System

The Cummins X15 550HP Tier 5-compliant powerplant undergoes SEA LION-specific hardening for drilling rig duty cycles:

| Component | Enhancement | Test Protocol |

|---|---|---|

| Block/Head | Reinforced cylinder liners; dual-main bearing caps | 500-hr dyno test @ 110% rated load |

| Cooling System | Dual thermostats; 40% oversized radiator core | 45°C ambient thermal soak test (8 hrs) |

| Aftertreatment | Drilled DPF substrate; active regeneration @ 350°C | 10,000-mile field validation |

| Oil Management | Extended-life synthetic oil (API CK-4); 1,000hr drain interval | Onboard oil analysis (Spectro Scientific) |

| Cold-Start Performance | -35°C operational capability | Arctic validation (Yellowknife, NT) |

Key Metric: 15,000-hour mean time between failures (MTBF) for engine core components under ISO 1585 R70 cycle with 80% drilling load factor.

2. PRE-DELIVERY INSPECTION (PDI) PROTOCOL

All TMDR-7500 units undergo a 72-point PDI checklist. Critical checks for terrain/ durability validation:

2.1 Chassis & Structural Verification

- Frame Alignment: Laser measurement of kingpin-to-rear axle alignment (tolerance: ±1.5mm)

- Weld Integrity: 100% ultrasonic testing (UT) of critical frame welds (ASME B31.3)

- Outrigger Load Test: Hydraulic pressure hold at 150% rated capacity for 10 minutes (zero leakage)

- Suspension Calibration: Ride height verification under simulated 25-ton payload (±5mm tolerance)

2.2 Powertrain & Durability Validation

| Test | Procedure | Pass/Fail Threshold |

|---|---|---|

| Engine Stress Cycle | 3x 30-min cycles: idle → max RPM @ 85% load | Oil pressure ≥ 45 psi at 1,000 RPM |

| Transmission Endurance | 50 shift cycles under load (forward/reverse) | No slippage; fluid temp ≤ 110°C |

| Cooling System Integrity | 90-min max-load test @ 40°C ambient | Coolant temp ≤ 105°C; zero leaks |

| Hydraulic Pressure Decay | Hold 300 bar for 5 minutes | Pressure loss ≤ 0.5% |

2.3 Final Validation Metrics

- Chassis Deflection: ≤ 3mm under full static load (per SAE J2929)

- Engine Vibration: ≤ 2.5 mm/s RMS at drilling RPM (ISO 10814)

- Telematics Baseline: All critical parameters (oil pressure, coolant temp, frame strain) logged for 24-hour duty cycle simulation

3. OPERATIONAL COMMITMENT

The TMDR-7500 chassis and engine systems are certified to maintain ≥ 95% operational availability in Class 4 terrain (ISO 8855) for 5 years or 10,000 drilling hours. PDI documentation includes:

– Signed structural integrity certificate (per EN 15038)

– Engine dyno test report with torque curve validation

– Full hydraulic system pressure decay log

– Telematics baseline dataset for fleet comparison

SEA LION International rejects units failing any PDI threshold. Zero tolerance for marginal compliance.

END OF REPORT | SEA LION INTERNATIONAL ENGINEERING DIVISION | CONFIDENTIAL: FOR TARGET AUDIENCE USE ONLY

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International

Subject: Logistics Solutions for Exporting Truck-Mounted Drilling Rigs from China

Target Audience: Fleet Managers & Construction Companies

Executive Summary

This report evaluates three primary maritime transport methods—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack (Containerized)—for the export of Truck-Mounted Drilling Rigs from manufacturing hubs in China (e.g., Qingdao, Shanghai, Guangzhou) to global project sites. The analysis focuses on operational efficiency, cost structure, equipment protection, and corrosion mitigation, with specific emphasis on wax-based anti-corrosion treatments to combat seawater exposure during transit.

1. Equipment Profile: Truck-Mounted Drilling Rig

| Parameter | Specification |

|---|---|

| Average Weight | 28–45 metric tons |

| Dimensions (L × W × H) | 12–16 m × 2.5–3 m × 3.8–4.2 m |

| Operational Value | High (capital-intensive, mission-critical) |

| Corrosion Sensitivity | High (exposed hydraulics, electrical systems, steel chassis) |

| Mobility | Self-propelled or towable |

| Handling Requirements | Heavy-lift equipment, secure lashing, environmental protection |

2. Comparative Shipping Method Analysis

| Criteria | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container (20′ or 40′) |

|---|---|---|---|

| Loading/Unloading | Direct drive-on/drive-off; minimal crane use | Requires heavy-lift cranes; complex stowage | Crane-assisted; requires securement on deck |

| Transit Time | Fast (direct vessel access) | Moderate to slow (port congestion risk) | Moderate (subject to container schedules) |

| Cargo Protection | Moderate (exposed on deck) | Low (mixed stowage, no enclosure) | High (weather-tight when covered) |

| Risk of Damage | Medium (vibration, weather) | High (shifting, contact damage) | Low (if properly secured) |

| Cost (USD per unit) | $8,000–$12,000 | $6,000–$9,500 | $14,000–$18,000 |

| Port Infrastructure Needs | RO-RO ramps, clear deck access | Heavy cranes, open laydown area | Container cranes, lashing points |

| Insurance Premiums | Moderate | High | Moderate to Low |

| Suitability for Drilling Rigs | High (if self-propelled) | Low (high risk) | High (optimal for oversized loads) |

Note: Flat Rack containers are recommended for rigs with non-functional drive systems or sensitive components. RO-RO is cost-effective for operational units.

3. Corrosion Protection: Wax Spraying System

Seawater exposure during ocean transit poses a critical threat to metal integrity, especially in coastal and tropical shipping lanes. SEA LION International mandates industrial-grade wax-based anti-corrosion treatment for all exported drilling rigs.

Wax Spraying Protocol

| Feature | Specification |

|---|---|

| Application Method | High-pressure spray (15–20 bar) |

| Wax Type | Solvent-based, hydrophobic synthetic wax (e.g., Lanocote®-equivalent) |

| Coverage Areas | Chassis frame, undercarriage, hydraulic lines, exposed fasteners, wheel hubs |

| Film Thickness | 50–75 µm (uniform coat) |

| Salt Spray Resistance | >1,000 hours (ASTM B117 compliant) |

| Reapplication Interval | Not required for single voyage (<60 days) |

| Removal at Destination | Biodegradable solvent or hot water pressure wash |

Benefits:

- Forms hydrophobic barrier against salt-laden air and moisture

- Penetrates crevices and weld joints

- Non-toxic and compatible with rubber/plastic components

- Reduces post-arrival maintenance and commissioning delays

4. Recommended Shipping Strategy

| Scenario | Recommended Method | Rationale |

|---|---|---|

| Self-propelled, operational rig | RO-RO | Fast turnaround, reduced handling risk |

| Disassembled or non-functional rig | 40′ Flat Rack Container | Maximum protection, global container network access |

| High-volume fleet shipment | RO-RO + Wax Protection | Economies of scale, rapid deployment |

| Destination: Non-RO-RO equipped port | Flat Rack | Universal compatibility with container infrastructure |

Best Practice: Combine Flat Rack shipping with wax spraying for mission-critical or long-transit exports (e.g., South America, West Africa).

5. Compliance & Documentation

All shipments must comply with:

– IMDG Code (for any residual fuels/lubricants)

– CSS Code (Cargo Securing Manual per ISO 1161)

– CIQ Export Standards (China Inspection & Quarantine)

– Destination Country Import Regulations (e.g., EPA, CE, CCC mark as applicable)

SEA LION International provides full DDP (Delivered Duty Paid) and CIF (Cost, Insurance, Freight) logistics packages, including corrosion protection certification.

Conclusion

For the reliable, cost-effective export of truck-mounted drilling rigs from China, RO-RO offers speed for operational units, while Flat Rack containers provide superior protection for high-value or sensitive equipment. Bulk cargo is not recommended due to high damage risk. Wax-based anti-corrosion treatment is non-negotiable for all sea-exported units to ensure operational readiness upon arrival.

Fleet managers and construction logistics teams are advised to integrate wax protection protocols and containerized transport into procurement and shipping specifications for long-term asset integrity.

SEA LION International – Engineering Global Logistics, Delivering Industrial Reliability

Get a Quote for Truck Mounted Drilling Rig

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]