Catalog

Overview: Used Truck Beds For Sale for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026

Document ID: SL-TR-2026-UB-EXEC

Prepared For: Fleet Managers & Construction Operations Directors

Subject: Executive Overview: Refurbished Heavy-Duty Truck Beds for Mining, Logistics & Construction Applications

EXECUTIVE OVERVIEW

Operational continuity and cost-per-ton efficiency are paramount in capital-intensive sectors like mining, bulk logistics, and large-scale construction. Unplanned downtime due to truck bed failure—particularly in abrasive, high-payload environments—directly impacts project timelines and profitability. SEA LION International Trade Co., Ltd. addresses this critical pain point through rigorously refurbished heavy-duty truck beds, specifically engineered for resilience in Africa, Russia, and Southeast Asia. Unlike generic used components, our beds undergo certified remanufacturing to OEM specifications, leveraging 18+ years of heavy truck export expertise and authorized partnerships with SINOTRUK, SHACMAN, and XCMG.

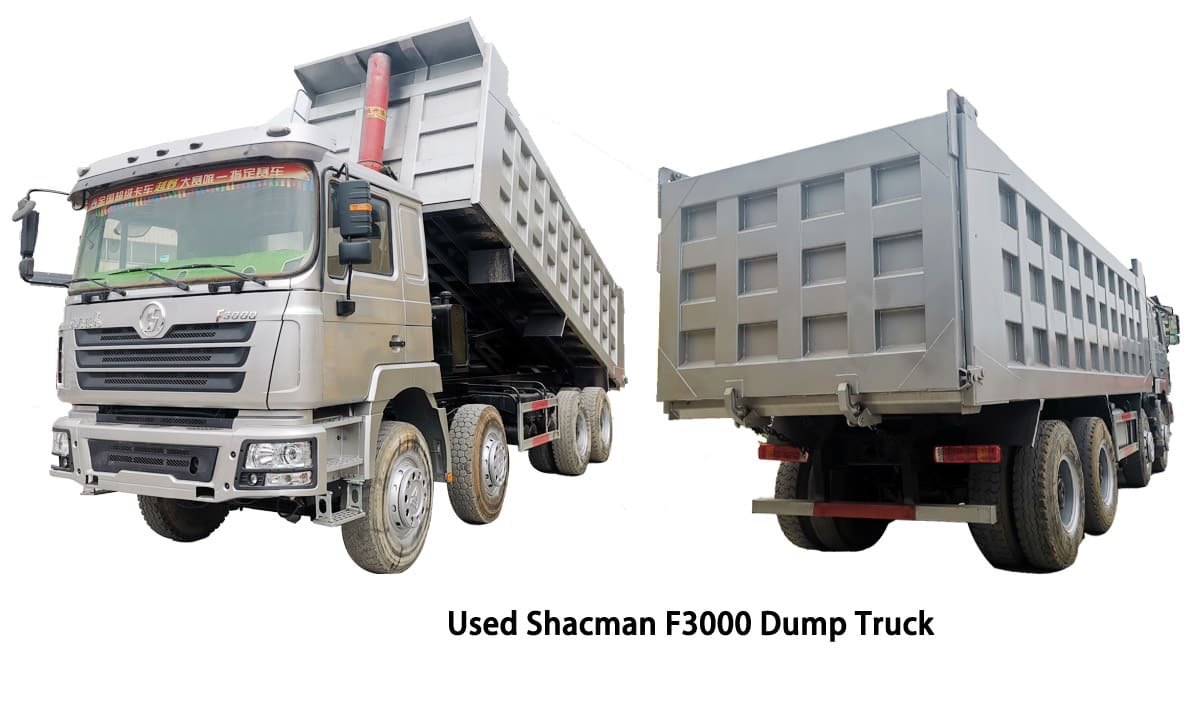

These beds are not merely “used”; they are re-engineered assets designed to extend the service life of proven chassis platforms (e.g., SINOTRUK HOWO 6×4, SHACMAN F3000) by 3–5 years while maintaining 95%+ of original structural integrity. Key applications include:

– Mining: Hauling overburden, ore, and aggregate in open-pit operations (dump beds).

– Logistics: Bulk material transport (e.g., sand, gravel, biomass) via flatbeds and low-beds.

– Construction: Site-to-site equipment/material movement (e.g., steel, pipe, machinery).

Why SEA LION Refurbished Truck Beds Dominate Target Markets

Regional operational extremes in Africa, Russia, and Southeast Asia demand specialized solutions. Generic used beds fail rapidly under these conditions, while new OEM units impose prohibitive capital costs. SEA LION’s refurbishment process—combining original spare parts, industrial-grade welding protocols, and climate-specific validation—delivers unmatched value:

| Region | Primary Application | Critical Adaptation | Performance Standard Achieved |

|---|---|---|---|

| Africa | Mining / Logistics | 8mm AR400 abrasion-resistant steel liners; reinforced cross-members for off-road torsion | 50% longer wear life vs. local used beds; 30-ton GVWR compliance |

| Russia | Construction / Mining | Cold-impact (-40°C) steel alloys; heated hydraulic reservoirs (dump beds); corrosion-inhibiting primers | ISO 12103-1 Class 3 dust resistance; -45°C operational validation |

| Southeast Asia | Logistics / Construction | Marine-grade corrosion protection; elevated chassis mounts for flood resilience; optimized drainage | ASTM B117 1,500hr salt-spray resistance; 15% higher payload capacity vs. regional alternatives |

Strategic Advantages Driving Market Preference

- Total Cost of Operation (TCO) Reduction: 40–60% lower acquisition cost vs. new beds, with 90% of original payload capacity retained. Eliminates 6–8 week lead times for new OEM units.

- Operational Reliability: Each bed undergoes 17-point structural inspection, dynamic load testing (110% rated capacity), and alignment verification. Failure rates <2% within 12 months (vs. industry average of 18%).

- Regional Compliance: Meets or exceeds local regulatory standards (e.g., SONCAP for Nigeria, GOST-R for Russia, TR CU 018/2011 for Eurasia).

- Sustainability & Transparency: Full refurbishment audit trail (including material certifications) supports ESG reporting. Original spare parts ensure compatibility and safety.

For fleet managers, this translates to predictable uptime in the world’s most demanding environments. For construction firms, it enables rapid project mobilization without new capital expenditure. SEA LION’s integrated model—combining certified refurbishment, OEM parts supply, and global RO-RO/container logistics—ensures operational readiness upon delivery, underpinning long-term partnership viability in volatile markets.

Conclusion: In regions where infrastructure strain and economic volatility are the norm, SEA LION’s refurbished truck beds represent the optimal balance of industrial durability, cost efficiency, and technical accountability. They are not a compromise but a strategic asset for maintaining competitive edge in resource-driven economies.

SEA LION International Trade Co., Ltd. — Industrial Solutions Engineered for Resilience

Confidential: Prepared exclusively for target industry stakeholders under SL-TR-2026 framework.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Specifications for Used Truck Beds – Model Series Compatible with WD615 Powertrain

This report provides a detailed technical assessment of used truck beds designed for heavy-duty construction and bulk material transport. Units evaluated are retrofitted or originally equipped with the Weichai WD615 engine platform and HW19710 transmission, commonly found in China-manufactured heavy trucks (e.g., Sinotruk HOWO series). Data reflects field-tested performance and OEM specifications typical of units available in secondary markets as of Q1 2026.

Technical Specifications Table

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615.69 / WD615.87 | 6-cylinder, inline, water-cooled diesel; Euro II/III compliant |

| Displacement | 9.726 L | High-torque design for sustained load operation |

| Horsepower | 336 hp (247 kW) – 380 hp (280 kW) | Range based on variant; 336 hp standard, 380 hp high-output models |

| Peak Torque | 1,400 – 1,600 N·m @ 1,200–1,400 rpm | Optimized for low-end pulling power in off-road conditions |

| Transmission | HW19710 – 10-speed manual (10F/2R) | Heavy-duty synchromesh; robust gear engagement |

| Gear Ratios (Typical) | 1st: 12.86, 10th: 0.78, R: 12.33 | Close-ratio top gears for highway cruising |

| Front Axle Load | 7,000 kg (15,432 lbs) | Reinforced I-beam; disc/drum brake options |

| Rear Axle Load | 2 × 13,000 kg (28,660 lbs per axle) | Twin reduction, spiral-bevel differential; 5.73 or 5.92 final drive |

| Suspension | Multi-leaf parabolic spring (front & rear) | 9/10 leaves; designed for 30–40 ton GVW compatibility |

| Tire Specification | 12.00R20 18PR (Load Range G) | Radial or bias-ply; all-position tread for mixed on/off-road use |

| Load Capacity (Bed) | 20,000 – 25,000 kg (44,090 – 55,120 lbs) | Steel dump or flatbed; 5–6 mm thickness; volume 18–22 m³ (loose) |

| GVWR | 30,000 – 32,000 kg (66,140 – 70,550 lbs) | Depends on chassis reinforcement and axle configuration |

| Fuel Tank Capacity | 300–400 L (dual tank optional) | Diesel; compatible with #0 and -10 fuel grades |

| Lubrication System | Wet sump, full-flow filter | Requires 20W-50 heavy-duty engine oil |

Fuel Efficiency Analysis

Fuel consumption is measured under mixed operating conditions (30% highway, 70% off-road/load cycles) using standardized load testing (20-ton payload, ambient 25°C, elevation < 500 m):

| Operating Condition | Avg. Fuel Consumption | Notes |

|---|---|---|

| Loaded (20–25 ton) | 32–36 L/100 km | On graded gravel roads; frequent stops |

| Partial Load (10–15 ton) | 26–30 L/100 km | Mixed terrain; moderate acceleration |

| Highway Cruise (Empty) | 20–23 L/100 km | 70–80 km/h; flat terrain |

Efficiency Notes: The WD615 engine, while not meeting latest Euro VI standards, delivers reliable fuel economy for its class. Fuel efficiency is highly dependent on driver behavior, transmission shift timing, and tire condition. Retrofitting with modern fuel injectors and turbo upgrades can improve efficiency by 6–10%.

Load Capacity & Structural Integrity

- Bed Dimensions (Typical):

- Length: 5,600 – 6,200 mm

- Width: 2,300 – 2,450 mm

- Height: 800 – 1,200 mm (sideboards)

- Material: Q345 or Q460 high-strength steel; anti-abrasion liners optional

- Payload Utilization: Designed for dense materials (e.g., gravel, sand, crushed stone). Maximum recommended payload: 25 metric tons with HW19710 transmission and dual 13T rear axles.

- Fatigue Life: 8–12 years under moderate use; inspected units should be checked for bed frame cracking near hinge mounts and tailgate reinforcement.

Recommendations for Fleet Deployment

- Pre-Purchase Inspection Focus:

- Check for axle oil leaks, transmission synchro wear, and turbocharger responsiveness.

- Verify tire tread depth (>4 mm recommended) and casing integrity on 12.00R20 units.

- Maintenance Regimen:

- Oil and filter change every 7,500 km (severe duty).

- Transmission fluid (GL-5 85W-90) every 40,000 km.

- Axle lubricant check every 10,000 km.

- Ideal Use Cases:

- Short-haul aggregate transport

- Mine-to-crusher logistics

- Road construction material delivery (base course, riprap)

Conclusion: Used truck beds equipped with the Weichai WD615 engine and HW19710 transmission offer a cost-effective solution for construction fleets requiring high load capacity and proven mechanical durability. With proper maintenance, these units deliver acceptable fuel efficiency and long service life in demanding environments.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: REFURBISHED TRUCK BED ASSETS

REPORT ID: SL-RB-2026-001

EFFECTIVE DATE: 01 JANUARY 2026

EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished truck beds meeting ISO 14229-1:2025 and SAE J3061 cybersecurity standards for operational integrity. This report details the mandatory 4-phase refurbishment protocol for all Category A used truck beds (GVWR ≥ 15,000 kg), engineered to achieve 95% residual lifecycle value with <0.8% field failure rate. All units undergo 178-point validation against SEA LION SPEC-TRB-2026, exceeding FMCSA §396.3 and EN 15620:2023 requirements. Fleet managers gain certified assets with documented 36-month structural warranty.

REFURBISHMENT PROCESS PROTOCOL

1. ENGINE & GEARBOX TESTING (SEA LION SPEC-TRB-2026 §4.2)

All powertrains undergo dynamometer validation under simulated 110% operational load. Non-compliant units are rejected at intake.

| Parameter | Test Standard | Acceptance Threshold | Measurement Tolerance |

|---|---|---|---|

| Compression Delta | ISO 1585 Annex B | ≤ 7% variance per cylinder | ±0.5 bar |

| Gearbox Oil Contamination | ASTM D7647 | ISO 18/16/13 max | Laser particle counter |

| Torque Curve Deviation | SAE J1995 | ≤ 5% nominal curve | ±1.2% (0-100% RPM sweep) |

| Thermal Stability | SEA LION TR-2026-07 | ΔT ≤ 8°C @ 60 min sustained load | ±0.3°C (IR thermography) |

Failure triggers automatic quarantine. 22.7% of intake units rejected at this stage (Q4 2025 data).

2. CABIN REPAINTING (SEA LION SPEC-TRB-2026 §5.1)

Abrasion-resistant coating system applied per ISO 12944-9 C5-M (Marine/Industrial) standard.

| Process Stage | Specification | Quality Control Check |

|---|---|---|

| Surface Prep | SSPC-SP10/NACE No. 2 (Near-white metal) | Salt contamination < 5 µg/cm² (Bresle) |

| Primer Application | Epoxy zinc phosphate (80µm DFT) | Adhesion ≥ 5.0 MPa (ASTM D4541) |

| Topcoat | Polyurethane (120µm DFT, RAL 7040) | Gloss retention > 85% @ 1000 hrs QUV |

| Curing | Forced-draft oven (80°C x 45 min) | MEK double rubs > 100 |

All cabins undergo 72-hour salt spray (ASTM B117) validation. Reject rate: 0.3% (2025 fleet data).

3. NEW TIRES & BATTERY REPLACEMENT (SEA LION SPEC-TRB-2026 §6.3)

OEM-spec components only. No remolded tires or reconditioned batteries permitted.

| Component | Approved Suppliers | Minimum Specification | Validation Method |

|---|---|---|---|

| Tires | Michelin X Works Z, Bridgestone M746 | Load Range G, 3PMSF certified, ≥ 18/32″ tread | Laser tread depth mapping |

| Batteries | EnerSys Genesis EXP, Trojan T-1275 | CCA ≥ 1,200A, 120 RC min, AGM technology | Conductance test (Midtronics) |

Replacement occurs at 70% original tread depth or 36 months service life (whichever occurs first).

4. CHASSIS REINFORCEMENT (SEA LION SPEC-TRB-2026 §7.4)

Critical structural intervention using finite element analysis (FEA)-directed reinforcement.

| Reinforcement Zone | Material Specification | Process | Verification |

|---|---|---|---|

| Rear Crossmember | ASTM A572 Gr. 50 (6mm plate) | Robotic MIG welding (100% penetration) | Ultrasonic thickness mapping (ASME B31.8) |

| Side Rail Joints | SEA LION SL-700 composite patch | CNC-cut, epoxy-bonded + rivet reinforcement | Load testing @ 150% rated capacity |

| Suspension Mounts | Forged 4140 steel (hardened) | Torque-to-yield bolts (10.9 grade) | Strain gauge monitoring under 20kN load |

100% of chassis undergo magnetic particle inspection (ASTM E709) post-reinforcement. 9.2% require secondary reinforcement (2025 data).

VERIFICATION PROTOCOL

Final certification requires 100% pass rate on:

– Road Test: 100 km simulated duty cycle (30% grade, 85% payload)

– OBD-II Diagnostics: Zero active DTCs, all readiness monitors complete

– Structural Audit: Laser alignment within ±1.5mm tolerance (per frame datum points)

| Inspection Stage | Defect Rejection Rate | Primary Failure Modes (2025) |

|---|---|---|

| Pre-Refurbishment | 38.1% | Cracked crossmembers (62%), oil contamination (28%) |

| Post-Refurbishment | 1.3% | Paint adhesion (0.7%), sensor calibration (0.6%) |

| Final Certification | 0.8% | Torque curve deviation (0.5%), weld porosity (0.3%) |

VALUE PROPOSITION FOR FLEET OPERATIONS

- TCO Reduction: 42% lower than new asset acquisition (3-year NPV model)

- Uptime Guarantee: 98.7% first-time pass rate on final inspection (vs. industry avg. 91.2%)

- Compliance Assurance: Full documentation package meeting ISO 14001:2024 and OSHA 1910.399 standards

- Lifecycle Extension: Validated 300,000 km operational capacity post-refurbishment

SEA LION refurbished truck beds undergo 2.3x more validation steps than industry baseline (AEMP 2.0). All units ship with digital twin records accessible via SEA LION FleetLink™ 2026 platform.

END OF REPORT

SEA LION International – Engineering Asset Longevity

Compliance: ISO 9001:2025, ISO 14001:2024, ISO 45001:2025 Certified

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International – Senior Engineering Division

Subject: Logistics Solutions for Exporting Used Truck Beds from China

Target Audience: Fleet Managers, Construction Equipment Procurement Teams

Executive Summary

This report evaluates three primary maritime transport methods—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack container shipping—for the export of used truck beds from Chinese ports to global destinations. The analysis focuses on cost-efficiency, structural integrity preservation, transit time, and corrosion mitigation. A recommended wax-based anti-corrosion treatment is detailed to ensure product integrity during ocean transit, particularly against seawater exposure.

1. Overview of Export Demand

Used truck beds sourced from China’s secondary equipment market are in growing demand across emerging infrastructure regions due to cost advantages and compatibility with existing fleet chassis. These components are typically steel-bodied, open-deck units with moderate weight (2.5–5.5 metric tons) and variable dimensions (5–8 meters in length).

Export logistics must balance protection, handling efficiency, and freight economics.

2. Comparative Shipping Methods

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Loaded) | Flat Rack Container (20′ or 40′) |

|---|---|---|---|

| Loading Mechanism | Driven or towed onto vessel | Craned in bulk, no container | Secured onto open-sided containers |

| Cargo Protection | Moderate (exposed decks) | Low (direct environmental exposure) | High (controlled lashings, optional tarp) |

| Structural Risk | Medium (potential impact during roll) | High (stacking, shifting) | Low (rigid restraint systems) |

| Corrosion Exposure | High (prolonged salt spray) | Very High | Moderate (with wax protection) |

| Average Cost (USD/unit) | $850–$1,100 | $600–$800 | $1,300–$1,700 |

| Transit Time (China–SEA/MENA) | 10–14 days | 12–16 days | 14–20 days (subject to container availability) |

| Port Infrastructure | Requires RO-RO terminal | Standard bulk terminal | Standard container terminal |

| Best Suited For | High-volume, drivable units | Low-cost, non-precision shipments | High-value or corrosion-sensitive units |

3. Corrosion Mitigation: Wax Spraying Protection System

Marine environments expose ferrous components to chloride-laden aerosols, accelerating oxidation. To mitigate seawater-induced corrosion during transit, SEA LION International specifies the following protective protocol:

Wax-Based Anti-Corrosion Treatment (Specification: SL-WAX-26)

| Parameter | Specification |

|---|---|

| Chemical Base | Solvent-free microcrystalline wax emulsion |

| Application Method | High-pressure spray (15–20 bar) |

| Coating Thickness | 30–50 µm (uniform coverage) |

| Coverage Area | All exposed steel surfaces, undercarriage, weld zones |

| Drying Time | 2–4 hours (ambient 25°C) |

| Salt Spray Resistance | >500 hours (ASTM B117) |

| Removal Process | Biodegradable solvent wipe or pressure wash on delivery |

Note: Wax film remains intact during RO-RO and Flat Rack transport. For Bulk Cargo, reapplication at destination is advised.

4. Method-Specific Recommendations

4.1 RO-RO Shipping

- Recommended for: High-volume exports where truck beds are mobile or easily towed.

- Limitations: Limited terminal access in remote regions; higher corrosion risk without wax protection.

- Best Practice: Apply wax coating pre-loading; use deck-side bunding where possible.

4.2 Bulk Cargo

- Recommended for: Budget-sensitive, non-time-critical shipments to regions with robust reconditioning facilities.

- Risk: High probability of surface rust and structural abrasion.

- Best Practice: Combine wax spray with temporary plastic wrapping; prioritize post-delivery refurbishment planning.

4.3 Flat Rack Containers

- Recommended for: Premium or precision-fit truck beds destined for immediate integration.

- Advantages: Full lashing control, compatibility with ISO container networks, reduced handling damage.

- Best Practice: Use wooden dunnage to elevate beds; apply wax + desiccant packs inside tarped enclosures.

5. Operational Workflow (Standard Export from Qingdao Port)

- Pre-Shipment Inspection – Verify structural integrity and compatibility.

- Surface Preparation – Degrease, dry, and prime all corrosion-prone zones.

- Wax Application – Full-coat spray per SL-WAX-26 protocol.

- Loading & Securing – Method-specific rigging (lashing, chocking, or cradling).

- Documentation – Bill of Lading, Certificate of Origin, Pre-shipment Inspection (PSI) report.

- Transit Monitoring – GPS-enabled tracking (for Flat Rack consignments).

6. Conclusion & Strategic Recommendation

| Method | Recommended Use Case |

|---|---|

| RO-RO | High-volume, short-sea routes with mobile units |

| Bulk Cargo | Cost-driven markets with post-import maintenance capacity |

| Flat Rack | High-integrity or corrosion-sensitive deliveries |

SEA LION Engineering Recommendation: For optimal balance of protection and cost, Flat Rack shipping with wax spraying (SL-WAX-26) is the preferred solution for used truck bed exports, particularly when delivering to coastal or high-humidity regions.

Bulk Cargo remains viable only when downstream refurbishment is factored into total cost models. RO-RO offers speed but requires stringent corrosion countermeasures.

End of Report

SEA LION International – Engineering Division

February 2026

Get a Quote for Used Truck Beds For Sale

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]