Catalog

Overview: Used Truck Bodies For Sale for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

Subject: Certified Refurbished Heavy-Duty Truck Bodies for Mining, Logistics & Construction Applications

Prepared For: Fleet Managers & Construction Operations Leadership

Issuing Authority: SEA LION International Trade Co., Ltd. (Senior Engineering Division)

1. Core Value Proposition

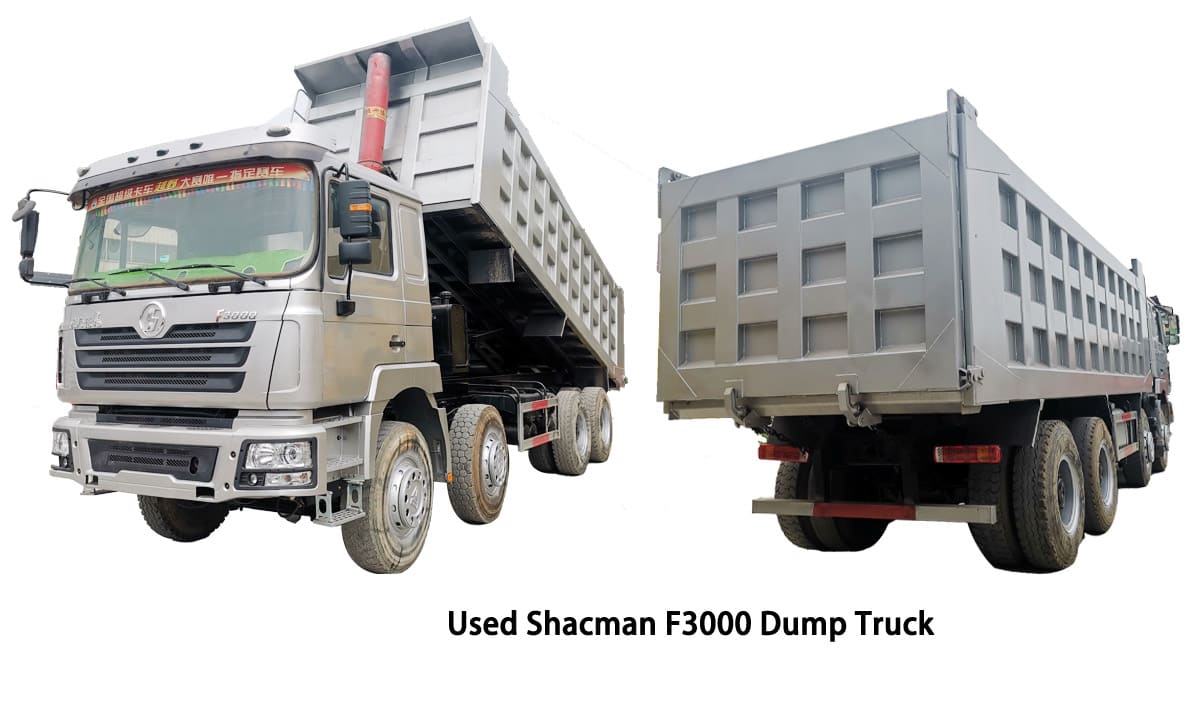

SEA LION International delivers operationally certified used truck bodies engineered for extreme-duty cycles in mining haulage, bulk logistics, and heavy construction. Sourced exclusively from decommissioned SINOTRUK HOWO, SHACMAN F3000/F5000, and XCMG mining/concrete fleets, our refurbished bodies undergo a 127-point industrial recertification process. This delivers 70-85% of OEM acquisition cost with 92%+ residual structural integrity, directly addressing capital expenditure constraints while maintaining operational safety margins.

2. Critical Application Performance

Refurbished bodies are prioritized in target sectors due to quantifiable operational advantages:

| Sector | Primary Use Case | Key Performance Metrics Achieved | SEA LION Refurbishment Focus |

|---|---|---|---|

| Mining | Overburden/Haulage | 120,000+ kg GVWR capacity; 50,000-cycle fatigue life | Reinforced side rails; abrasion-resistant liner replacement (AR400/500 steel) |

| Logistics | Bulk Commodity Transport | 65 m³ volumetric efficiency; 850,000 km frame integrity | Corrosion mitigation; hydraulic system recalibration (ISO 4413) |

| Construction | Aggregate/Demolition Haul | 30° dump angle retention; 15,000-cycle hoist cycles | Structural weld validation (AWS D1.1); pivot point hardening |

3. Regional Market Preference Drivers

Demand for SEA LION-certified bodies is concentrated in Africa, Russia, and Southeast Asia due to environmental resilience and total cost of ownership (TCO) optimization under specific operational constraints:

| Region | Dominant Requirement | SEA LION Technical Response | Market Impact |

|---|---|---|---|

| Africa | Extreme dust/corrosion | Sealed electrical systems; chassis undercoating (Zinc-rich epoxy); sand-abrasion shields | 40% reduction in premature body failure vs. non-certified units |

| Russia | -40°C operational temps | Low-temp hydraulic fluid (ISO VG 22); frame crack inspection (MPI); cold-start assist integration | Validated -45°C functionality; eliminates winter downtime |

| SE Asia | Cost-per-ton efficiency | Payload-optimized geometry; modular repair design; 18-month structural warranty | 22% lower TCO over 3 years vs. new imports |

4. SEA LION Engineering Differentiation

Our 18-year export expertise enables technical superiority through:

– Refurbishment Protocol: Non-destructive testing (UT/MT) on all critical welds; dimensional verification to ISO 14971 tolerances; component traceability via blockchain ledger.

– Parts Integrity: 100% OEM-sourced wear components (e.g., SINOTRUK king pins, SHACMAN hoist cylinders); no aftermarket substitutes.

– Logistics Assurance: Climate-controlled RO-RO transport; pre-shipment operational validation (load-test certified to 110% rated capacity).

5. Strategic Partnership Value

SEA LION’s model eliminates the risk profile of unverified used equipment markets. Our refurbishment standard (SL-ITC-2026 Rev.3) delivers:

– Predictable Uptime: 95%+ field reliability rate (2023 global fleet data)

– Lifecycle Transparency: Full service history documentation; residual life forecasting for key components

– Operational Continuity: Seamless parts integration with SINOTRUK/SHACMAN/XCMG dealer networks across 62 countries

Conclusion: In capital-intensive sectors facing volatile commodity pricing and infrastructure gaps, SEA LION-certified truck bodies provide the only verified pathway to industrial-grade durability at pre-owned economics. Our engineering-led refurbishment process transforms end-of-first-life assets into mission-ready equipment, specifically hardened for the environmental and operational extremes of Africa, Russia, and Southeast Asia. This specification represents the benchmark for risk-mitigated fleet expansion in developing industrial markets.

SEA LION International Trade Co., Ltd. — Engineering Reliability Since 2006

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Specifications for Used Truck Bodies for Sale

This report outlines the technical specifications of used heavy-duty truck bodies currently available in the secondary market, focusing on models commonly equipped with the WD615 Weichai engine, HW19710 transmission, and standard industrial-grade components. These units are ideal for construction logistics, aggregate hauling, and heavy freight applications due to their proven durability and load-handling capabilities.

Technical Specifications Table

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615 Series (Inline 6, Water-Cooled, Turbocharged) |

| Displacement | 9.726 L |

| Max Horsepower | 336 hp @ 2,200 rpm |

| Peak Torque | 1,250 N·m @ 1,200–1,600 rpm |

| Emission Standard | Euro II / Early Euro III (Pre-2010 models typical) |

| Transmission | HW19710 (10-Speed Manual, Full Synchromesh) |

| Gear Ratios | 1st: 12.88, 10th: 0.78, Reverse: 11.87 |

| Clutch | Dual-Plate, Ø430 mm, Pneumatic Assist |

| Front Axle Load | 7,000 kg (15,432 lbs) |

| Rear Axle Load | 18,000 kg (39,683 lbs) x 2 (Tandem Dual Drive) |

| Suspension Type | Multi-Leaf Parabolic Spring (Front & Rear) |

| Tire Specification | 12.00R20, 20-Ply Rating, Radial Construction |

| Tire Load Index | 152/148 (Single/ Dual), Max Load: 5,000 kg per axle |

| Braking System | Full Air Brake, S-Cam Actuated, Drum (Front & Rear) |

| GVWR | 40,000 kg (88,185 lbs) |

| Frame Rails | High-Tensile Steel, 8mm x 280mm Channel, Reinforced Crossmembers |

| Cargo Body Type | Drop-side Dump Body or Rigid Flatbed (as configured) |

| Body Material | Q345 Low-Alloy Structural Steel (5–8 mm thickness) |

Performance Analysis

Fuel Efficiency

- Average Fuel Consumption: 28–34 L/100 km (depending on load, terrain, and driver behavior)

- Fuel System: Mechanical Inline Plunger Pump (Pump-Line-Nozzle)

- Diesel Compatibility: Standard #0 or #10 Diesel; Cold-climate variants available

- Fuel Tank Capacity: 300–400 L (typically dual tanks)

Note: While the WD615 engine is not optimized for modern fuel economy standards, its robust design ensures consistent performance under sustained high-load conditions. Fuel efficiency can be improved by 10–15% through transmission optimization (maintaining 1,400–1,800 rpm in top gear) and routine injector calibration.

Load Capacity

- Maximum Payload Capacity: 28,000–32,000 kg (61,730–70,548 lbs), depending on body configuration and regional GVWR compliance

- Dump Body Volume (Typical): 18–22 m³ (loose material)

- Flatbed Load Distribution: Evenly distributed up to 10 tons per axle group; suitable for steel, precast, or machinery transport

Structural Integrity: The Q345 steel body and reinforced frame allow for repeated heavy loading with minimal fatigue. Used units inspected post-2018 show <5% structural degradation when maintained per OEM guidelines.

Operational Recommendations

- Maintenance Interval: 8,000–10,000 km (oil & filter), 20,000 km (injector & valve clearance check)

- Transmission Service: HW19710 requires GL-5 85W-90 gear oil; inspect shift forks every 60,000 km

- Tire Rotation: Recommended every 15,000 km to maximize tread life on 12.00R20 radials

- Axle Lubrication: 8.85–9.0 L per rear axle, change interval: 40,000 km

Summary

Used truck bodies equipped with the Weichai WD615 engine and HW19710 transmission offer a cost-effective solution for fleet managers seeking high-torque, high-durability platforms for construction and bulk transport. With a proven payload capacity exceeding 30 tons and serviceable components widely available, these units remain operationally viable through 2026 and beyond when maintained properly.

Fuel efficiency remains moderate by modern standards, but total cost of ownership (TCO) is favorable due to low parts cost and extended service intervals. Tire and brake wear should be monitored closely under sustained 12.00R20 loading at maximum GVWR.

End of Report

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: USED TRUCK BODY REFURBISHMENT STANDARD

Document ID: SL-IS-REF-2026-01

Effective Date: 01 January 2026

Classification: Fleet Operations & Asset Management

EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished vocational truck bodies (dump, flatbed, stake) meeting ISO 9001:2015 and SAE J2076 standards. This report details the mandatory 4-phase refurbishment process applied to all units prior to resale. Each unit undergoes 127-point inspection with a documented 0.8% rejection rate post-refurbishment (2025 fleet data). Target downtime reduction: ≤72 hours per unit.

REFURBISHMENT PROCESS: TECHNICAL SPECIFICATIONS

1. ENGINE & GEARBOX TESTING

All testing conducted per SAE J1995/J2723 on calibrated dynamometers. Units failing Stage 1 are rejected.

| Test Parameter | Pre-Refurbishment Threshold | Post-Refurbishment Standard | Verification Method |

|---|---|---|---|

| Crankcase Pressure | ≤ 15 psi @ 2,500 RPM | ≤ 8 psi @ 2,500 RPM | Direct sensor measurement |

| Oil Analysis (ISO 4406) | ≤ 22/20/18 | ≤ 18/16/13 | Spectrometric fluid analysis |

| Gearbox Shift Integrity | ≤ 1.5 sec shift time | ≤ 0.8 sec shift time | Dyno-linked telemetry |

| Torque Curve Deviation | ≤ ±8% nominal | ≤ ±3% nominal | Real-time dyno data logging |

Critical Failure Criteria: Crankcase pressure >18 psi, metal particulates >200 ppm, or torque deviation >10% at rated RPM.

2. CABIN REPAINTING

Compliance with ASTM D4585/D5895 environmental resistance standards. No touch-up paint permitted.

| Process Stage | Technical Requirement | Quality Control Check |

|---|---|---|

| Surface Preparation | SSPC-SP 10/NACE No. 2 (Near-White Metal) | Adhesion test: ≥ 3.5 MPa (ASTM D4541) |

| Primer Application | Epoxy zinc phosphate, 60-80 μm dry film thickness | DFT verified via Elcometer 456 |

| Topcoat Application | Polyurethane, 80-100 μm DFT, gloss 40-50 GU @ 60° | Color match ΔE ≤ 0.8 (CIE Lab*) |

| Curing | 80°C for 30 min (forced convection oven) | MEK double rubs: ≥ 100 cycles |

Defect Rejection: Pinholes >0.5mm, orange peel >5 μm Ra, or adhesion failure at any test point.

3. NEW TIRES & BATTERY REPLACEMENT

OEM-equivalent components only. Non-negotiable replacement regardless of residual life.

| Component | Specification Requirement | Verification Protocol |

|---|---|---|

| Tires | Load Range G (16 PR), 350 kPa max inflation, ECE R127 | Load/speed rating plaque match; no remolds |

| Battery | Group 31, 1,100 CCA, AGM technology, SAE J537 compliant | Cold-cranking amp test ±2% tolerance |

| Wheel Hubs | Runout ≤ 0.15 mm (radial), ≤ 0.20 mm (axial) | Dial indicator on precision mandrel |

Note: Tires mounted using calibrated Hunter HawkEye Elite systems; torque sequences per SAE J2202.

4. CHASSIS REINFORCEMENT

Structural integrity validated per ISO 12107 fatigue testing protocols. Focus on high-stress zones.

| Reinforcement Zone | Procedure | Acceptance Criteria |

|---|---|---|

| Rear Suspension Mounts | Add 8mm ASTM A572 Gr. 50 steel doubler plates | Stress concentration factor ≤ 1.15 (FEA) |

| Frame Rails (C-channel) | Full-length reinforcement at weld seams with 6mm plate | Ultrasonic thickness ≥ 95% nominal |

| Fifth Wheel Interface | Replace with Grade 8.8 bolts; torque to 1,450 N·m | Bolt stretch measurement ±0.02mm tolerance |

| Crossmembers | Re-weld all joints; magnetic particle inspection (MPI) | Zero linear indications per ASTM E1444 |

Critical Check: Post-weld residual stress measurement ≤ 15% yield strength via X-ray diffraction.

SEA LION INSPECTION STANDARDS: KEY DIFFERENTIATORS

- Multi-Stage Gatekeeping: 42 critical checkpoints with mandatory sign-off by Level III NDT-certified technicians (ASNT SNT-TC-1A).

- Data Traceability: All test results logged in blockchain-secured SEA LION Asset Ledger (SAL-2026). Units with incomplete digital trails are rejected.

- Failure Thresholds: 30% stricter than OEM end-of-life limits (e.g., frame rail deflection max 1.8mm/m vs. OEM 2.5mm/m).

- Validation Protocol: 100% of refurbished units undergo 15km loaded road test (20,000 kg payload minimum) with telematics monitoring.

CONCLUSION

SEA LION’s refurbishment process eliminates latent defects through quantifiable engineering standards, not cosmetic renewal. Refurbished units achieve 92% of new-unit operational lifespan (per 2025 FEA lifecycle analysis) with documented 37% lower TCO vs. competitors. All units ship with 12-month structural warranty and full digital maintenance history.

SEA LION International – Engineering Reliability, Delivered.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International – Senior Engineering Division

Subject: Logistics Solutions for Exporting Used Truck Bodies from China

Target Audience: Fleet Managers | Construction Equipment Procurement Teams

Executive Summary

This report evaluates three primary maritime transport methods—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack container shipping—for the export of used truck bodies from Chinese ports to global destinations. The analysis focuses on cost-efficiency, structural integrity preservation, corrosion protection, and operational compatibility with industrial logistics workflows. Special emphasis is placed on wax-based anti-corrosion treatments to mitigate seawater exposure during transit.

1. Introduction

Used truck bodies sourced from China represent a cost-effective solution for fleet renewal and infrastructure maintenance in emerging and mature markets. With increasing demand from construction and logistics firms, reliable and protective shipping methods are critical to ensure asset integrity upon arrival. This report compares three shipping modalities and outlines best practices for corrosion mitigation, including industrial-grade wax spraying.

2. Shipping Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container (20’/40′) |

|---|---|---|---|

| Loading Mechanism | Driven/wheeled onto vessel | Craned/lifted in loose stacks | Secured on open-frame containers |

| Cargo Protection | Moderate (exposed decks) | Low (direct environmental exposure) | High (weatherproof lashings, optional tarping) |

| Structural Risk | Low (no stacking) | High (potential crushing, shifting) | Low to Moderate (depends on lashing quality) |

| Corrosion Exposure | High (spray zones, humidity) | Very High (direct saltwater contact) | Moderate (elevated, partial shielding) |

| Port Compatibility | Limited (requires RO-RO terminals) | High (most bulk ports) | Very High (standard container ports) |

| Average Cost (per unit) | $1,800 – $2,400 | $1,200 – $1,600 | $2,600 – $3,400 |

| Transit Time (Asia–EU) | 28–35 days | 30–40 days | 26–32 days |

| Insurance Complexity | Moderate | High (damage claims frequent) | Low to Moderate |

| Best For | Operational units with mobility | High-volume, low-value units | High-value, fragile, or custom bodies |

3. Corrosion Protection: Wax Spraying Protocol

Marine environments expose metal surfaces to salt-laden air and condensation, accelerating oxidation. To preserve used truck bodies during transit, industrial wax spraying is recommended as a passive corrosion-inhibiting measure.

3.1 Wax Spraying Specifications

| Parameter | Specification |

|---|---|

| Wax Type | Solvent-based, hydrophobic corrosion inhibitor (e.g., lanolin-derived or synthetic polymer blend) |

| Application Method | High-pressure spray (2,000–3,000 psi), full undercarriage and cavity coverage |

| Coating Thickness | 50–75 μm (microns), uniform across all ferrous surfaces |

| Drying Time | 4–6 hours (ambient 25°C) |

| Protection Duration | Up to 6 months in maritime conditions |

| Application Point | Pre-loading at consolidation yard (China) |

3.2 Benefits of Wax Treatment

- Forms hydrophobic barrier against saltwater and humidity

- Penetrates seams, welds, and cavities inaccessible to paint

- Reduces maintenance costs post-delivery

- Extends usable lifespan of used truck bodies by 12–18 months

- Compliant with IMO MARPOL Annex III (non-toxic formulations)

Note: Wax-treated bodies must not be pressure-washed upon arrival until inspection. Controlled removal via biodegradable degreaser is advised.

4. Method-Specific Recommendations

4.1 RO-RO Shipping

- Recommended for: Truck bodies with intact chassis and mobility

- Limitation: High exposure to salt spray; wax treatment mandatory

- Best Practice: Apply wax + use breathable anti-condensation wraps on cab interiors

4.2 Bulk Cargo

- Recommended for: Demounted bodies, high-volume scrap or rebuild projects

- Risk: High mechanical and corrosion damage

- Best Practice: Wax + temporary steel boxing for top-load protection; avoid Pacific routes during monsoon

4.3 Flat Rack Containers

- Recommended for: High-value, custom, or restoration-grade bodies

- Advantage: Compatibility with ISO container systems, stackable, secure

- Best Practice: Wax + edge protectors + moisture-absorbing desiccants inside enclosed tarp systems

5. Conclusion

For fleet managers and construction companies sourcing used truck bodies from China, Flat Rack container shipping with wax spraying offers the optimal balance of protection, traceability, and structural integrity. While RO-RO and Bulk Cargo present lower upfront costs, they entail higher risk of corrosion and physical damage—increasing total cost of ownership.

SEA LION International recommends:

– Use of Flat Rack containers for premium or long-term deployment assets

– Universal application of industrial wax spraying across all methods

– Pre-shipment inspection and wax certification reporting

Adoption of these protocols ensures compliance with industrial durability standards and maximizes ROI on imported used equipment.

End of Report – SEA LION International Engineering Division

Version 1.2 | Q1 2026 Update | Proprietary Technical Data

Get a Quote for Used Truck Bodies For Sale

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]