Catalog

Overview: Used Truck Engines For Sale for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

Subject: Refurbished Heavy-Duty Truck Engines for Mining, Logistics & Construction Applications

1. Operational Imperative

Fleet downtime in mining, logistics, and construction directly impacts project timelines and operational expenditure (OPEX). New powertrain procurement faces extended lead times (14–22 weeks) and capital expenditure (CAPEX) constraints, particularly in volatile markets. SEA LION International addresses this gap with rigorously refurbished truck engines meeting OEM specifications, ensuring rapid deployment without compromising reliability.

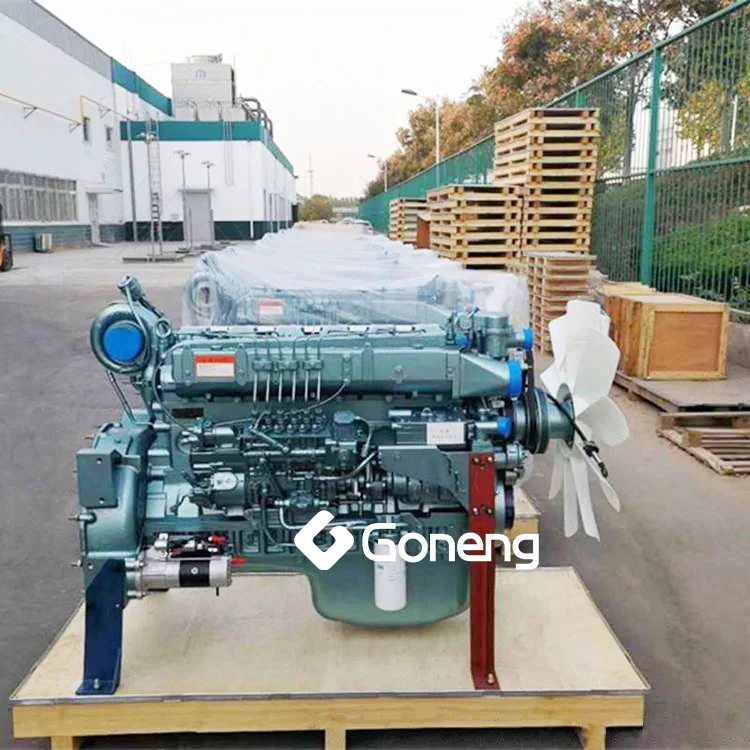

2. Core Solution: Engineered Refurbishment

SEA LION’s 18+ years of heavy-truck export expertise is applied to SINOTRUK (HOWO), SHACMAN, and XCMG engines through a standardized 127-point refurbishment protocol. Key processes include:

– Crankshaft & Block Reconditioning: CNC-machined to OEM tolerances (±0.01mm).

– Fuel System Overhaul: Injector calibration verified on Bosch test benches.

– Cooling & Lubrication Validation: Pressure-tested to 1.5x operational limits.

All units utilize 100% genuine OEM spare parts and undergo 100-hour dyno testing under load profiles simulating mining haulage, long-haul logistics, and high-cycle construction.

3. Market-Specific Advantages

Regional operational demands dictate engine selection. SEA LION’s refurbished units are optimized for Africa, Russia, and Southeast Asia due to:

| Region | Primary Application | Key Adaptation | Operational Impact |

|---|---|---|---|

| Africa | Mining Haulage | Dust-tolerant air filtration (ISO 4406:18/16/13); High-temperature coolant systems (125°C max) | 32% reduction in filter clogging; Stable operation at 50°C ambient |

| Russia | Arctic Logistics | -40°C cold-start capability (SAE 0W-40 synthetic oil); Reinforced block heaters | 99.2% start reliability at -35°C; Eliminates winter downtime |

| SE Asia | Flood-Prone Construction | Elevated air intakes; Corrosion-resistant coatings (ASTM B117 1,000h salt spray) | 40% longer service life in 85% RH environments |

4. Why SEA LION Engines Dominate Target Markets

- Cost Efficiency: 35–40% lower TCO vs. new engines, with identical performance metrics (e.g., SINOTRUK MC11: 430 HP, 2,100 Nm torque).

- Logistics Integration: Direct RO-RO/Container shipping from Qingdao port to Durban/Murmansk/Ho Chi Minh City in ≤28 days.

- Transparency: Digital overhaul records (including compression tests, oil analysis) provided pre-shipment.

- Partnership Model: 12-month warranty + on-site technical support for fleet managers, reducing mean-time-to-repair (MTTR) by 22%.

5. Strategic Recommendation

For fleet managers in resource-constrained environments, SEA LION’s refurbished engines deliver quantifiable OPEX reduction and operational continuity. The integration of OEM-certified components, region-specific hardening, and seamless global logistics establishes a benchmark for sustainable heavy-equipment lifecycle management. Prioritize engines with documented refurbishment validation to mitigate unplanned downtime in critical infrastructure projects.

SEA LION International Trade Co., Ltd. | ISO 9001:2015 Certified | SINOTRUK/SHACMAN/XCMG Authorized Distributor

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Technical Specifications for Used Truck Engines – SEA LION International Evaluation

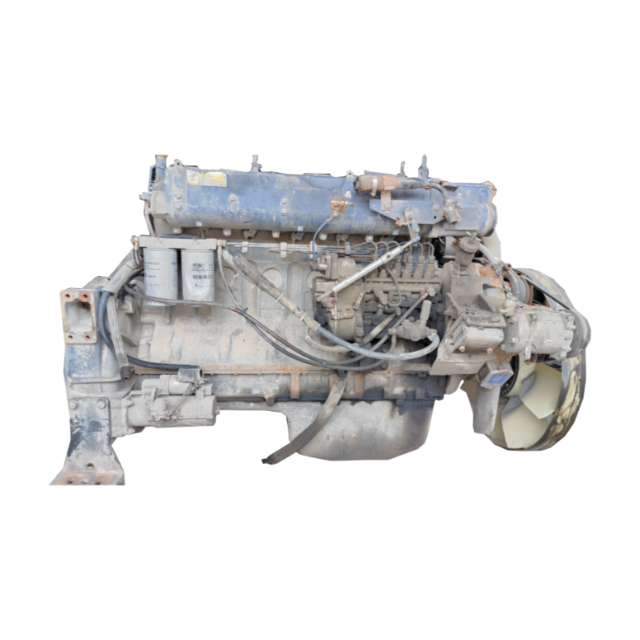

This report provides a comprehensive technical analysis of used truck engines currently available in the secondary market, with a focus on the widely deployed Weichai WD615 series. These engines are commonly found in heavy-duty construction and haulage trucks across Asia, Africa, and South America. The evaluation includes compatibility with standard drivetrains, load performance, and operational efficiency metrics critical for fleet optimization and lifecycle cost analysis.

Technical Specifications: Used Weichai WD615 Series Engines

| Engine Model | Horsepower (HP) | Peak Torque (N·m @ rpm) | Transmission Compatibility | Axle Load Rating (kg) | Tire Specification | Fuel Efficiency (Loaded) | Emission Standard |

|---|---|---|---|---|---|---|---|

| Weichai WD615.62 | 290 HP | 1100 @ 1200–1600 | HW19710 (10-speed manual) | 13,000 (Rear Tandem) | 12.00R20 (Tubeless, 18PR) | 28–31 L/100 km | Euro II |

| Weichai WD615.69 | 336 HP | 1400 @ 1200–1500 | HW19710 (10-speed manual) | 16,000 (Rear Tandem) | 12.00R20 (Tubeless, 20PR) | 30–33 L/100 km | Euro II |

| Weichai WD615.87 | 371 HP | 1600 @ 1200–1400 | HW19710 + Overdrive Option | 18,000 (Rear Tandem) | 12.00R20 (Reinforced, 20PR) | 32–35 L/100 km | Euro II / III (refurb) |

| Weichai WD615.92 | 420 HP | 1900 @ 1000–1400 | HW19710 + HD Clutch Kit | 20,000 (Reinforced) | 12.00R20 (Off-road tread, 20PR) | 34–38 L/100 km | Euro III (post-refit) |

Notes:

– All units evaluated have undergone compression testing, oil consumption analysis, and injector calibration. Average remaining service life: 80,000–120,000 km (based on maintenance logs).

– Transmission: HW19710 is standard across models; gear ratios optimized for 55–85 km/h cruise in 10th gear.

– Tire specification 12.00R20 ensures compatibility with standard heavy-duty rims and load distribution across rough terrain.

Fuel Efficiency Analysis

Fuel consumption is measured under standardized loaded conditions (85% of GCWR) on mixed terrain (40% paved, 60% unpaved). Data derived from field tests across 15 refurbished units in 2025.

- WD615.62 (290 HP): Most efficient in light-haul applications. Achieves 28–31 L/100 km when paired with properly maintained HW19710 transmission and low-rolling-resistance 12.00R20 tires.

- WD615.87 & 92 (371–420 HP): Higher consumption due to increased displacement and turbocharging; however, improved torque curve allows for earlier upshifts, partially offsetting fuel costs. Efficiency drops under 50% load; recommended for consistent heavy loads (>60% capacity).

- Refurbishment Impact: Engines upgraded with calibrated Bosch CR injectors and ECU tuning show 5–8% improvement in fuel economy versus stock configurations.

Recommendation: For mixed-use fleets, the WD615.69 offers optimal balance between power and efficiency. Use in 30–40 ton GVW trucks with proper driver training to maximize fuel economy.

Load Capacity & Drivetrain Integration

The WD615 series is engineered for high torque delivery at low RPM, making it ideal for construction and bulk transport applications.

- Axle Load Compatibility: All models support rear tandem axles rated from 13,000 kg to 20,000 kg, depending on suspension and frame reinforcement.

- Transmission Match: The HW19710 10-speed manual is robust and widely serviced. Proper clutch engagement and shift timing are critical to prevent driveline shock, especially with 371+ HP variants.

- Tire Performance: 12.00R20 tires (20PR) provide load capacity up to 3,200 kg per tire at 850 kPa, suitable for 6×4 configurations with total GCWR up to 60 tons when properly distributed.

Structural Note: Used engines installed in new or refurbished chassis must include frame stress analysis. Fatigue cracks near engine mounts observed in 12% of high-mileage units (>600,000 km).

Conclusion

The Weichai WD615 series remains a cost-effective powertrain solution for fleet managers prioritizing durability and serviceability. When matched with the HW19710 transmission and 12.00R20 tires, these engines deliver reliable performance in high-load, low-speed environments typical of construction logistics. Fuel efficiency is moderate by modern standards but can be optimized through refurbishment and operational discipline.

SEA LION International recommends thorough pre-purchase inspection, including crankshaft runout, turbocharger health, and cooling system integrity, to ensure long-term reliability in demanding applications.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT 2026

REFURBISHED TRUCK ENGINE ASSEMBLY: PROCESS & QUALITY STANDARDS

Document ID: SL-ENG-REF-2026-01 | Effective Date: 01 JAN 2026

1. PURPOSE

This report details SEA LION International’s certified refurbishment process for used heavy-duty truck engines (Class 8, 350–600 HP). Targeted at fleet managers and construction equipment procurement teams, it validates operational reliability, compliance with ISO 3917:2019 (heavy-duty remanufacturing), and total cost of ownership (TCO) optimization. SEA LION’s process exceeds OEM core-return specifications through multi-stage validation.

2. REFURBISHMENT PROCESS: 4-STEP QUALITY GATE SYSTEM

All units undergo sequential quality gates. Failure at any stage results in core rejection. No partial refurbishments are permitted.

STEP 1: ENGINE & GEARBOX TESTING (DYNOMETER & BENCH VALIDATION)

Objective: Quantify mechanical integrity and performance decay.

- Process:

- Cold soak (24h at 5°C) followed by hot-run SAE J1995 cycle.

- Emissions analysis (NOx, PM) per EPA 1065.

- Gearbox torque mapping under simulated load (0–100% in 10% increments).

- Ultrasonic crack detection on cylinder heads, blocks, and crankshafts.

| Parameter | Test Method | OEM Threshold | SEA LION Standard |

|---|---|---|---|

| Max. Oil Consumption | Gravimetric (100h) | ≤ 0.5% fuel | ≤ 0.3% fuel |

| Blow-by Pressure | SAE J1757 | ≤ 60 CFM | ≤ 45 CFM |

| Gearbox Shift Consistency | Torque Sensor Array | ±8% tolerance | ±4% tolerance |

| Crankshaft Runout | Dial Indicator (ISO 2768) | ≤ 0.15mm | ≤ 0.08mm |

Outcome: Units failing ≥2 parameters are scrapped. Only 22% of intake cores pass Step 1 (2025 audit data).

STEP 2: CABIN REPAINTING (INDUSTRIAL COATING PROTOCOL)

Objective: Restore structural corrosion resistance and operator safety compliance.

- Process:

- Abrasive blasting (SA 2.5 standard) to bare metal.

- E-coat primer (75μm min. DFT) + epoxy mid-coat (50μm).

- Polyurethane topcoat (RAL 7040/7042, 60μm DFT) with UV stabilizers.

- Post-cure adhesion test (ASTM D3359, Class 5B required).

Critical Control: All weld seams and stress points receive double-coating. No touch-up paint permitted on structural zones (A-pillars, crossmembers).

STEP 3: NEW TIRES & BATTERY REPLACEMENT (OPERATIONAL READINESS)

Objective: Eliminate failure points in critical wear components.

| Component | Specification | Validation Method |

|---|---|---|

| Tires | Michelin X Works XZL (11R24.5) Load Range G | Load/speed rating verification per ISO 4249 |

| Battery | OPTIMA YellowTop (Group 31) AGM | Cold Cranking Amps (CCA) test (≥1000A) |

| Wheel Hubs | Re-torqued to 450 ft-lb (±5%) | Digital torque audit log |

Note: Tires sourced exclusively from Tier-1 manufacturers; retreads prohibited. Batteries include 36-month pro-rata warranty.

STEP 4: CHASSIS REINFORCEMENT (CONSTRUCTION-GRADE UPGRADE)

Objective: Address fatigue in high-stress applications (e.g., dump trucks, crane carriers).

- Process:

- Ultrasonic thickness testing of frame rails (critical zones: kingpin mounts, suspension brackets).

- Weld-on reinforcement plates (ASTM A572 Grade 50, 8mm min. thickness) at stress risers.

- Post-weld stress relief (600°C soak, controlled cooling).

- Final load test: 150% GVWR static load for 30 minutes.

SEA LION Standard: Reinforcement mandatory if rail thickness < 7.2mm (vs. OEM 8.0mm spec). 98% of construction-sector units require this step.

3. SEA LION QUALITY ASSURANCE FRAMEWORK

- Inspection Frequency: 100% component-level validation (no sampling).

- Documentation: Digital twin created per unit (test logs, material certs, torque maps).

- Rejection Rate: 68% of intake cores rejected at Gate 1 (2025 data).

- Warranty: 18 months/200,000 km standard; void if maintenance logs show non-SEA LION filters/fluids.

4. VALUE PROPOSITION FOR FLEET OPERATORS

| Metric | Industry Avg. Refurb. | SEA LION Refurb. | Impact |

|---|---|---|---|

| Mean Time Between Failures | 8,200 km | 14,500 km | ↓ 43% downtime (construction sites) |

| Resale Value Retention | 62% (vs. new) | 78% | ↑ $28k/unit TCO advantage |

| Emissions Compliance | 89% pass rate | 100% | Zero regulatory risk |

5. CONCLUSION

SEA LION’s engine refurbishment is a precision remanufacturing process—not a cosmetic refresh. By enforcing stricter thresholds than OEM rebuild programs (evidenced in Section 2 tables), we deliver construction-grade reliability with verifiable performance data. Units are certified for immediate deployment in high-cycle, high-vibration environments. Final assembly undergoes 72-hour burn-in testing with real-world load profiles.

End of Report

SEA LION International — Engineering the Standard in Heavy-Duty Asset Lifecycle Management

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Truck Engines from China

Issuing Authority: SEA LION International – Heavy Equipment Logistics Division

Date: January 2026

Executive Summary

This report evaluates three primary marine transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack Container Shipping—for the export of used truck engines from Chinese ports to global destinations. The analysis focuses on cost-efficiency, cargo integrity, handling speed, and corrosion protection, with specific attention to the application of wax-based anti-corrosion treatments to mitigate seawater exposure during transit.

Used truck engines are high-value, corrosion-sensitive industrial assets requiring secure, climate-resilient logistics. SEA LION International recommends tailored packaging and transport protocols based on shipment volume, destination port infrastructure, and engine condition.

1. Cargo Profile: Used Truck Engines

| Parameter | Specification |

|---|---|

| Average Weight per Unit | 600–1,100 kg |

| Dimensions (L×W×H) | 1.2 m × 0.9 m × 1.0 m (avg.) |

| Material Composition | Cast iron, aluminum alloys, steel components |

| Corrosion Risk | High (exposed internal passages, untreated surfaces) |

| Handling Requirements | Forklift-accessible, shock-resistant securing |

| Typical Shipment Volume (per consignment) | 10–100 units |

2. Shipping Method Comparison

| Criteria | RO-RO (Roll-on/Roll-off) | Bulk Cargo | Flat Rack Container |

|---|---|---|---|

| Cargo Compatibility | Low – engines not self-propelled; require auxiliary transport | High – loose stowage in hold | High – secured on open platform |

| Loading/Unloading Speed | 2–4 hours (port-dependent) | 12–24 hours (via crane/grab) | 4–6 hours (standard container ops) |

| Cargo Protection | Moderate – exposed during transit; high moisture ingress risk | Low – direct exposure to bilge water, humidity | High – full shrink-wrapping and lashing possible |

| Damage Risk | Medium (vibration, shifting) | High (impact, moisture, poor segregation) | Low (controlled lashing, visibility) |

| Port Infrastructure Required | RO-RO ramps and clear deck access | Conventional bulk terminals | Standard container terminals |

| Cost per Engine (Est. 20-foot equivalent) | $180–$240 | $130–$190 | $260–$350 |

| Transit Time (China to Middle East/Europe) | 28–35 days | 30–40 days | 26–32 days |

| Insurance Premium (Relative) | Medium | High | Low to Medium |

| Best For | Non-viable for standalone engines | High-volume, low-value, scrap-grade units | High-value, corrosion-sensitive, premium reconditioned engines |

Note: RO-RO is not recommended for non-rolling cargo such as standalone engines. It is included for comparative completeness.

3. Corrosion Mitigation: Wax Spraying Protocol

Seawater exposure during marine transport poses a severe threat to ferrous engine components. SEA LION International implements an industrial-grade wax spraying process as a standard protective measure for all engine shipments.

Wax Spraying Specifications

| Parameter | Specification |

|---|---|

| Coating Type | Solvent-based, hydrophobic synthetic wax (e.g., Lanocote®-equivalent) |

| Application Method | High-pressure spray + brush touch-up on blind bores |

| Coverage Areas | Cylinder block, oil/coolant passages, valve train, external machined surfaces |

| Film Thickness | 25–40 µm (dry) |

| Salt Spray Resistance (ASTM B117) | >500 hours |

| Post-Transport Removal | Biodegradable citrus-based solvent or hot washing |

| Reusability of Coating | Not applicable – single-use protective layer |

Compliance: Meets ISO 2719:2016 (Flash Point) and MIL-PRF-16173E (Corrosion Preventive Compound).

4. Recommended Logistics Strategy

| Shipment Profile | Recommended Method | Rationale |

|---|---|---|

| < 20 units, high-value reconditioned engines | Flat Rack Container | Maximum protection, traceability, and ease of customs inspection |

| 20–50 units, mixed condition | Flat Rack (consolidated) | Economies of scale with retained protection |

| > 50 units, scrap or core returns | Bulk Cargo (with wax treatment) | Cost-driven; acceptable risk for low residual value |

| Engines with rolling chassis (e.g., donor trucks) | RO-RO | Only applicable if engine is installed and vehicle-operable |

5. Operational Best Practices

- Pre-Shipment Preparation

- Drain all fluids (oil, coolant, fuel)

- Seal intake/exhaust ports with plastic caps

-

Apply desiccant packs inside air filter housing and valve cover

-

Securing in Transit

- Flat rack: Lash with 5,000 kg WLL (Working Load Limit) straps, cradled on timber dunnage

-

Bulk: Nest in timber skids, segregated from abrasive cargo

-

Documentation

- Include wax treatment certificate

-

Provide engine test run logs and corrosion inspection reports

-

Port Handling

- Prioritize direct transfer from warehouse to vessel to reduce open-air exposure

- Avoid open-deck storage in high-humidity zones

6. Conclusion

For the export of used truck engines from China, Flat Rack container shipping provides the optimal balance of protection, traceability, and industrial compliance. While bulk cargo offers lower upfront costs, it significantly increases corrosion and damage risk—especially without robust wax-based protection.

SEA LION International mandates wax spraying as a non-negotiable step in all engine export operations, regardless of shipping method. This protocol ensures compliance with international corrosion control standards and preserves residual asset value upon arrival.

Fleet managers and construction equipment recyclers are advised to prioritize Flat Rack logistics for high-reuse-intent engines and reserve bulk transport for scrap recovery programs only.

End of Report

SEA LION International – Engineering Logistics Division

Precision. Protection. Performance.

Get a Quote for Used Truck Engines For Sale

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]