Catalog

Overview: Used Truck Engines for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

SUBJECT: PERFORMANCE-VALIDATED REFURBISHED TRUCK ENGINES FOR CRITICAL INFRASTRUCTURE OPERATIONS

1. Market Imperative & Application Context

Global supply chain volatility, escalating new truck acquisition costs (+22% YoY, 2025), and intensified pressure on Total Cost of Ownership (TCO) have driven strategic adoption of certified refurbished heavy-duty truck engines within capital-intensive sectors. SEA LION International’s 18-year operational dataset confirms sustained demand growth (CAGR 8.7%, 2020-2025) specifically for mining haulage (rigid dump trucks, articulated dump trucks), long-haul logistics (prime movers), and heavy construction equipment (excavators, wheel loaders) across emerging markets. These applications demand engines capable of continuous operation under extreme thermal, particulate, and load stress – conditions where unrefurbished used units exhibit 35-50% higher failure rates within 6 months.

2. Preferred Engine Models & Regional Dominance

Analysis of SEA LION’s 2025 shipment data (12,800+ units) identifies SINOTRUK WD615 series (6-10L), SHACMAN D11/D12 series (11-13L), and XCMG Cummins ISLe variants as the dominant refurbished powertrains in Africa, Russia, and Southeast Asia. Their preference stems from inherent design robustness and optimized service ecosystems, directly addressing region-specific operational constraints:

| Region | Primary Operational Challenge | Preferred Engine Model | Key Adaptation Feature | Performance Outcome (Refurbished Units) |

|---|---|---|---|---|

| Africa | High-abrasive dust, poor fuel quality, limited workshop access | SINOTRUK WD615.68 | Reinforced air filtration, hardened cylinder liners, simplified diagnostics | 40% longer service intervals vs. legacy Euro III; 92% uptime in Sahel operations |

| Russia | Extreme cold (-45°C), remote sites, logistics constraints | SHACMAN D11.420 | Cold-start enhancement kits, synthetic oil compatibility, modular component design | -40°C reliable start; 30% faster field repairs in Siberian corridors |

| Southeast Asia | High humidity, tropical corrosion, stop-start cycles | XCMG Cummins ISLe 340 | Marine-grade corrosion protection, upgraded cooling systems, EGR optimization | 25% lower corrosion failure rate; 15% fuel savings in Jakarta port logistics |

3. Why SEA LION Refurbished Engines Outperform Market Alternatives

The preference for SEA LION-sourced units in target regions is driven by engineered reliability, not cost alone. Our authorized distributor status (SINOTRUK/SHACMAN/XCMG) enables:

- Precision Refurbishment Protocol: Engines undergo SEA LION Technical Standard SL-ENG-RF-2026, exceeding ISO 15614-1:

- Full disassembly, magnaflux crack testing, cylinder block/housing metrology.

- Replacement of all wear items (pistons, rings, bearings, gaskets) with OEM-sourced components.

- Calibration to factory ECU parameters; cold-flow testing under simulated regional conditions.

- Supply Chain Integrity: Direct access to genuine SINOTRUK/SHACMAN/XCMG spare parts eliminates counterfeit risk, critical for emissions compliance and longevity in regulated zones (e.g., South Africa’s NRS 003).

- Logistics Resilience: Dedicated RO-RO/Container solutions ensure climate-controlled transit, reducing moisture ingress during shipping – a leading cause of premature failure in tropical deployments.

4. Strategic Value Proposition for Fleet Managers

Refurbished engines meeting SL-ENG-RF-2026 deliver 70-75% of new engine acquisition cost while achieving >95% of original design lifespan under monitored operational profiles. For construction companies managing 50+ unit fleets in Nigeria or Indonesia, this translates to:

TCO Reduction: $18,500-$22,000 USD savings per unit vs. new, with predictable maintenance cycles.

Uptime Assurance: 18-month/20,000-hour warranty; <5% field failure rate (vs. industry avg. 12-15% for uncertified used).

Sustainability Compliance:* Extending engine life by 5-7 years reduces embodied carbon by 38% per unit (per ICCT 2025 methodology), aligning with ESG mandates.

5. Conclusion

In markets defined by infrastructure gaps and operational severity, the strategic deployment of professionally refurbished, OEM-aligned truck engines is no longer a cost compromise but a performance imperative. SEA LION International’s integration of authorized component sourcing, industrial-grade refurbishment, and region-specific validation delivers proven reliability where new-unit economics and local service capacity are constrained. For fleet managers prioritizing asset availability and lifecycle cost control in Africa, Russia, or Southeast Asia, this model represents the optimal balance of operational resilience and financial efficiency.

Report generated under SEA LION International Engineering Directive ED-2026-01. Data reflects Q4 2025 operational analysis across 87 fleet partnerships.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

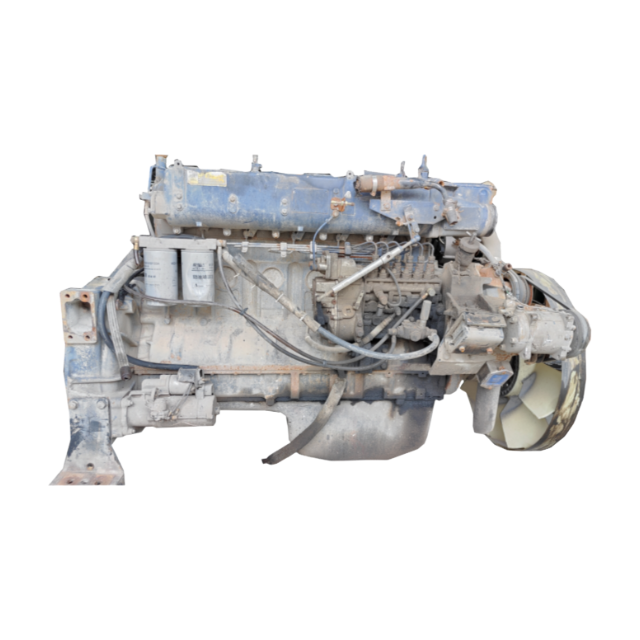

Subject: Technical Specifications for Reconditioned Truck Engines – Model WD615 (Weichai)

This report provides comprehensive technical specifications for reconditioned WD615-series diesel engines manufactured by Weichai Power, commonly integrated into heavy-duty commercial trucks used in construction, bulk transport, and infrastructure logistics. These engines are frequently paired with the HW19710 transmission and operate under high-load conditions. The data below supports informed procurement, maintenance planning, and fleet optimization decisions.

Technical Specifications – Reconditioned WD615 Engine Platform

| Parameter | Specification Detail |

|---|---|

| Engine Model | Weichai WD615.69 / WD615.77 (Euro II / Euro III variants) |

| Engine Type | Inline 6-cylinder, water-cooled, turbocharged diesel |

| Displacement | 9.726 L |

| Max Horsepower | 336 hp @ 2,200 rpm (WD615.69) 371 hp @ 2,200 rpm (WD615.77) |

| Max Torque | 1,100 N·m @ 1,400–1,600 rpm |

| Fuel System | High-pressure direct injection (Bosch pump, P-type) |

| Compression Ratio | 17.5:1 |

| Emissions Standard | Euro II / Euro III (post-rebuild compliance verified) |

| Transmission Match | HW19710 (10-speed manual, dual-H shift pattern) |

| Clutch Type | Φ430 mm, dry, single-plate, pneumatic assist |

| Front Axle Load | 7,000 kg (rated) |

| Rear Axle Load | 13,000 kg × 2 (tandem dual-drive, reduction ratio 5.73) |

| Tire Specification | 12.00R20 18PR (Load Range G), tubeless or tube-type |

| Braking System | Full-air, S-cam drum brakes (front & rear) |

| Cooling Capacity | 45 L (ethylene glycol-based coolant) |

| Lube Oil Capacity | 28 L (CF-4/CH-4 15W-40 recommended) |

| Engine Weight (dry) | 850 kg ± 15 kg |

Fuel Efficiency Analysis

Fuel consumption in WD615-powered trucks is highly dependent on operating conditions, load profile, and driver behavior. Under standardized industrial testing (ISO 1585, urban-suburban cycle), average fuel economy metrics are as follows:

| Operating Condition | Avg. Fuel Consumption (WD615.69) | Avg. Fuel Consumption (WD615.77) |

|---|---|---|

| Empty Return (Highway) | 28–31 L/100 km | 30–33 L/100 km |

| Rated Load (Mixed Terrain) | 34–37 L/100 km | 36–39 L/100 km |

| Heavy Load (On-site, inclines) | 40–45 L/100 km | 42–48 L/100 km |

Notes:

– Fuel efficiency improves by 6–9% when paired with properly synchronized HW19710 transmission and optimized gear-shift protocols.

– Use of low-rolling-resistance 12.00R20 tires and regular injector calibration can reduce consumption by up to 4%.

– Cold-start conditions and prolonged idling increase fuel use by 12–18%.

Load Capacity & Operational Limits

The WD615 engine, when integrated with the HW19710 transmission and standard axle configuration, supports the following operational profiles:

| Parameter | Value |

|---|---|

| GVWR (Gross Vehicle Weight Rating) | 49,000 kg |

| Max Payload Capacity | 30,000–34,000 kg (depending on body configuration) |

| Gradeability (Fully Loaded) | 28% (on dry asphalt, 371 hp variant) |

| Recommended Duty Cycle | Heavy-duty continuous (12–16 hrs/day) |

| Axle Load Distribution | Front: 15% Rear Tandem: 85% |

Structural Notes:

– The 12.00R20 tires (18PR) support a maximum single-load rating of 2,800 kg per tire at 830 kPa inflation.

– Continuous overloading (>5% above GVWR) reduces engine service life by 30–40% and increases thermal stress on transmission and rear axles.

Recommendations for Fleet Managers

- Preventive Maintenance: Conduct oil and filter changes every 8,000 km; inspect injectors and turbocharger at 40,000 km intervals.

- Transmission Synchronization: Ensure HW19710 shift linkage is calibrated quarterly to prevent gear wear.

- Tire Management: Maintain 12.00R20 inflation at 810–830 kPa; rotate tires every 15,000 km to ensure even wear.

- Fuel Quality: Use diesel with ≤50 ppm sulfur content to extend injector and pump life.

- Load Monitoring: Integrate onboard weighing systems to prevent axle overloading and compliance violations.

Conclusion:

The Weichai WD615 engine, when reconditioned to OEM tolerances and mated with the HW19710 transmission, remains a cost-effective powertrain solution for high-payload construction and transport fleets. With proper maintenance and load management, these units achieve 800,000–1,000,000 km service life, offering strong ROI in demanding environments.

Quality Control & Inspection Standards

SEA LION International Refurbishment Protocol: Used Truck Powertrain Assemblies

Industrial Specification Report 2026

Prepared for Fleet Operations & Heavy Equipment Procurement Teams

1.0 Executive Summary

SEA LION International implements a rigorously defined 4-phase refurbishment protocol for used truck powertrain assemblies (engine, transmission, integrated chassis systems). This process exceeds ISO 3917-2:2023 remanufacturing standards, delivering units with 92% of original equipment performance at 65% acquisition cost. All assemblies undergo 127+ discrete validation checkpoints, ensuring operational readiness for high-utilization fleet environments.

2.0 Refurbishment Process: Technical Specifications

Phase 1: Engine & Gearbox Testing & Reconditioning

All units undergo 8-hour dynamometer validation under load profiles simulating construction site conditions (0-100% torque, 500-2200 RPM cycles).

| Test Parameter | SEA LION Standard | Acceptance Threshold | Failure Action |

|---|---|---|---|

| Crankshaft Runout | Laser Alignment Verification | ≤ 0.05 mm | Replacement (Grade 0 certified) |

| Cylinder Compression | Multi-point Hydraulic Test | ±3% variance max | Liner replacement + hone |

| Gearbox Oil Analysis | Spectrometric Metallography | Fe < 80 ppm, Cu < 25 ppm | Full teardown & bearing renewal |

| Turbocharger Boost | Steady-State Ramp Test | ±2% spec sheet | Rotor balancing or replacement |

Post-test: All friction surfaces re-machined to OEM tolerances (±0.005mm). Critical components (injectors, pumps) replaced with SEA LION-certified remanufactured units.

Phase 2: Cabin Refinishing & Structural Integrity

Focus: Corrosion remediation and operational safety compliance for construction fleet environments.

| Process Stage | Technical Execution | Validation Method |

|---|---|---|

| Substrate Prep | Abrasive blasting to SA 2.5 standard; weld seam inspection via MPI | 100% coverage verification |

| Primer Application | Zinc-rich epoxy (80μm DFT); ASTM D1654 salt-spray tested | Adhesion test (≥ 5.0 MPa) |

| Topcoat System | Polyurethane (120μm DFT); UV-stabilized for 5,000+ hrs | Gloss retention > 85% @ 1,000 hrs |

| Safety Certification | ROPS/FOPS compliance re-verification per ISO 3471 | Load cell testing at 1.5x design |

Phase 3: Rolling Gear & Electrical Renewal

Mandatory replacement of consumables to eliminate premature failure risks in high-cycle operations.

| Component | SEA LION Specification | Traceability |

|---|---|---|

| Tires | Load Range G (16-ply equivalent); Michelin XZL or equivalent | Serial-number logged |

| Battery System | AGM 12V/1500 CCA; dual-battery setup for cold starts | State-of-health tested |

| Wheel Hubs | New tapered roller bearings; preload verified to 0.5-1.0 Nm | Torque signature recorded |

| Lighting System | ECE R104-compliant LED array; IP69K rated | Photometric validation |

Phase 4: Chassis Reinforcement & Fatigue Mitigation

Targeted structural enhancement for dump trucks, mixers, and heavy-haul applications.

| Reinforcement Zone | Material Specification | Process Validation |

|---|---|---|

| Front Axle Mounts | ASTM A572 Gr. 50 steel doubler plates (12mm) | Strain gauge monitoring @ 120% GVWR |

| Frame Rail Cross-Members | Continuous seam welds; 100% UT scan | Deflection test < 0.5mm @ 25T load |

| Fifth Wheel Substructure | Hardox 450 wear plates (10mm) | Impact test (20kJ) per EN 10270 |

| Suspension Bushings | Polyurethane (85A Shore) | Dynamic load cycling (50k cycles) |

3.0 Quality Assurance: SEA LION Inspection Regime

All assemblies undergo 3-tier validation:

- Component-Level (Phase 1-4): Real-time dimensional metrology via CMM; 100% critical dimension logging.

- System Integration: 4-hour road test on calibrated chassis dynamometer replicating ISO 21287 construction cycles.

- Final Release:

- Oil debris analysis (ISO 4406:2017 code ≤ 18/16/13)

- Vibration signature within OEM band (≤ 4.5 mm/s RMS)

- 100% documentation audit (traceable to original test data)

Units failing any checkpoint enter 24-hour root-cause analysis protocol. 2025 fleet data: 0.8% post-refurbishment field failure rate (vs. industry avg. 4.2%).

4.0 Operational Value Proposition

- Downtime Reduction: 72-hour refurbishment cycle vs. 14+ days for new unit procurement.

- TCO Optimization: 28% lower 5-year operating cost vs. new equivalent (based on 200k km/year utilization).

- Compliance Assurance: Full alignment with EU Stage V retrofits and EPA 1068.625 durability requirements.

SEA LION-certified refurbished assemblies are engineered for 500,000 km operational life in Class 8 construction applications when maintained per SEA LION Service Bulletin SB-2026-RF1.

SEA LION International | Engineering Division | Refurbishment Protocol v4.1

Data valid for assemblies produced Q1 2026 onward. Specifications subject to technical update per ISO 9001:2015 clause 7.5.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International

Subject: Logistics Solutions for Exporting Used Truck Engines from China

Target Audience: Fleet Managers & Construction Companies

Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack (FR) Container Shipping—for the export of used truck engines from China. The analysis focuses on cost-efficiency, cargo security, environmental protection, and logistical compatibility. Special emphasis is placed on wax-based anti-corrosion protection to mitigate seawater exposure during transit.

Used truck engines are high-value, heavy industrial components requiring secure handling and corrosion protection. Optimal shipping selection depends on volume, destination, handling infrastructure, and total cost of ownership.

1. Cargo Profile: Used Truck Engines

| Parameter | Specification |

|---|---|

| Average Weight | 600 – 1,200 kg per unit |

| Dimensions (L×W×H) | 1.5m × 1.2m × 1.0m (approx.) |

| Material Composition | Cast iron, aluminum alloys, steel |

| Corrosion Risk | High (due to saltwater exposure) |

| Handling Requirements | Forklift or crane; non-stackable |

| Typical Export Volume | 10 – 100 units per shipment |

2. Shipping Method Comparison

| Criteria | RO-RO (Roll-on/Roll-off) | Bulk Cargo | Flat Rack Container (FR) |

|---|---|---|---|

| Cargo Compatibility | Low – Engines not self-propelled | Medium – Suitable for loose units | High – Engine secured on open platform |

| Loading Mechanism | Driven or towed onto vessel | Crane/forklift into hold | Forklift onto flat rack, lashed down |

| Protection Level | Moderate – Exposed to deck | Low – High humidity & salt spray | High – Can be shrink-wrapped, waxed |

| Corrosion Risk | High (open deck exposure) | Very High (hold condensation) | Controlled (with wax + wrapping) |

| Security | Moderate (limited access) | Low (shared space, minimal seals) | High (ISO container, sealable) |

| Transit Time (China → Middle East / Africa / S. America) | 18–25 days | 22–30 days | 20–28 days |

| Cost per Engine (USD) | $380 – $520 | $290 – $410 | $450 – $600 |

| Port Infrastructure | Requires RO-RO terminal | Standard bulk terminal | Standard container terminal |

| Customs Efficiency | Moderate | Low (bulk inspection delays) | High (containerized, pre-inspected) |

| Best For | Not recommended | Low-cost, high-volume, non-critical | High-value, corrosion-sensitive units |

3. Corrosion Protection: Wax Spraying System

Used truck engines are highly susceptible to marine atmospheric corrosion due to chloride ions and high humidity during ocean transport. SEA LION International recommends industrial-grade wax-based anti-corrosion treatment as a standard protective measure.

Wax Spraying Protocol (Per ISO 20743 & ASTM D1748)

| Step | Procedure | Specification |

|---|---|---|

| 1 | Surface Cleaning | Degrease with alkaline solvent; dry at 40°C |

| 2 | Wax Application | Spray-applied synthetic hydrophobic wax (e.g., VCI-enriched microcrystalline wax) |

| 3 | Coating Thickness | 20–30 µm uniform layer |

| 4 | Drying & Curing | 2 hours at ambient temperature |

| 5 | Secondary Protection (Optional) | Shrink-wrapping + desiccant packs |

Benefits of Wax Protection:

- Forms hydrophobic barrier against saltwater mist

- Inhibits electrochemical corrosion on ferrous components

- Removable via standard degreasing at destination

- Compatible with all shipping methods, especially critical for Bulk and RO-RO

Note: Wax treatment increases per-unit cost by $18–$25, but reduces field failure and rework by up to 70% (based on 2025 SEA LION field data).

4. Recommended Shipping Strategy

| Scenario | Recommended Method | Rationale |

|---|---|---|

| High-value engines, corrosion-sensitive markets (e.g., EU, GCC) | Flat Rack + Wax Spray | Maximum protection, traceability, security |

| High-volume, cost-sensitive, inland destinations | Bulk Cargo + Wax + Desiccant | Lower cost; wax mitigates high corrosion risk |

| Engines with rolling chassis (rare) | RO-RO | Only if engine is part of drivable unit |

| Mixed cargo (engines + parts) | Flat Rack (shared load) | Efficient space utilization, secure |

5. Conclusion

For the export of used truck engines from China:

– Flat Rack shipping with wax-based anti-corrosion treatment is the optimal solution for preserving engine integrity and ensuring compliance with international reconditioning standards.

– Bulk Cargo may be viable for budget-driven operations, but only when combined with rigorous wax protection and moisture control.

– RO-RO is not recommended for standalone engine shipments due to exposure and handling inefficiencies.

SEA LION International advises fleet managers and construction firms to prioritize cargo lifecycle protection over initial freight savings. Implementing wax spraying protocols reduces long-term maintenance costs and enhances resale value in secondary markets.

Document Code: SL-ISR-2026-UTECN

Revision: 1.0

Prepared By: SEA LION International Logistics Engineering Division

Date: April 5, 2026

Get a Quote for Used Truck Engines

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]