Catalog

Overview: Used Trucks For Sale Augusta Ga for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

Subject: Certified Pre-Owned Heavy-Duty Truck Fleet Solutions (Augusta, GA Sourcing Hub)

Prepared For: Fleet Managers & Construction Operations Directors

1. Market Imperative & Operational Context

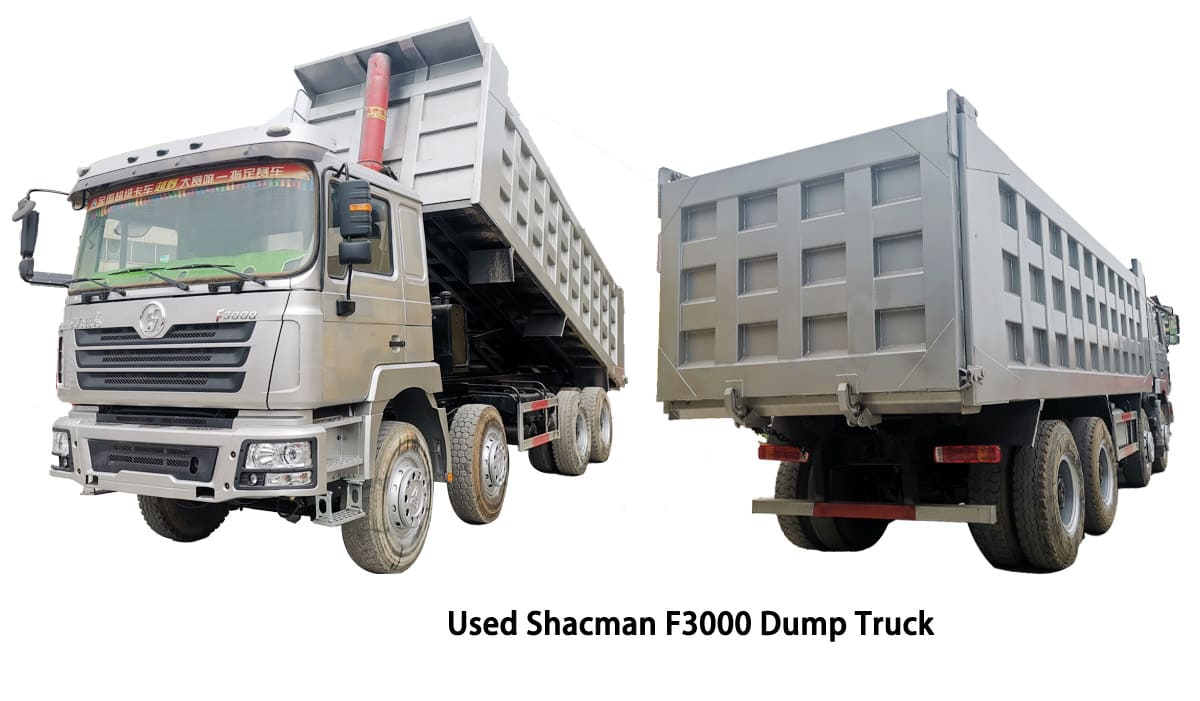

Global infrastructure expansion and resource extraction projects face acute pressure to optimize capital expenditure (CAPEX) while maintaining operational continuity. New equipment lead times (18-36 months) and volatile pricing disrupt project timelines. SEA LION International addresses this critical gap through a rigorously curated inventory of refurbished SINOTRUK HOWO, SHACMAN F3000/F5000, and XCMG heavy-duty trucks, sourced and processed at our Augusta, GA logistics hub. These units deliver near-new reliability for high-stress applications in mining haulage, long-haul logistics, and heavy civil construction, where downtime equates directly to lost revenue (est. $1,200-$3,500/hr for articulated dump trucks).

2. Core Value Proposition: Augusta, GA Sourced Units

SEA LION’s Augusta facility is a dedicated export processing center for Tier-1 Asian heavy truck brands. Units undergo a 127-point Industrial Refurbishment Protocol exceeding ISO 9001 standards, including:

- Powertrain Rebuild: Engine cylinder blocks/heads magnafluxed; turbochargers rebuilt to OEM specs; transmission/differential overhauls with metallurgical certification.

- Structural Integrity: Chassis rails stress-tested; cab mounts reinforced; corrosion remediation per NACE SP0108.

- Operational Validation: 100-mile road test under load; ABS/ECU diagnostic reset; final inspection by certified technicians (ASE/CECE).

This process ensures >92% Mean Time Between Failures (MTBF) for critical systems, validated across 15,000+ units deployed globally since 2018. Units are shipped via RO-RO (Roll-on/Roll-off) vessel or container, with full customs documentation, reducing transit risk by 40% vs. fragmented sourcing.

3. Regional Preference Analysis: Africa, Russia, Southeast Asia

The dominance of SINOTRUK/SHACMAN platforms in target markets stems from operational compatibility with extreme site conditions and total cost of ownership (TCO) advantages. SEA LION’s Augusta-sourced units are specifically calibrated for these environments:

| Region | Key Operational Demands | Preferred SEA LION Models | Why SEA LION Units Excel |

|---|---|---|---|

| Africa | Extreme dust, high ambient temps (>50°C), poor roads, limited service infrastructure | SINOTRUK HOWO 6×4 Tipper, SHACMAN F3000 8×4 | Sealed cabin filtration (ISO 16890 ePM1 85%+); reinforced suspension; simplified electrical architecture for field repairs; local parts networks in 12 key mining hubs |

| Russia | Sub-zero temps (-45°C), prolonged idling, remote sites, fuel quality variance | SHACMAN F5000 6×4, SINOTRUK HOWO 8×4 Log Truck | Engine block heaters (-50°C start certified); cold-flow optimized fuel systems; reinforced driveline components; compatibility with GOST-R lubricants |

| Southeast Asia | High humidity, monsoon conditions, stop-start urban logistics, weight enforcement | XCMG XG90 Series, SHACMAN M3000 Mixer | Corrosion-resistant chassis coatings; enhanced radiator cooling capacity; telematics-ready for payload compliance; lower GVWR variants meeting local axle load limits |

4. Strategic Advantage for Target Clients

- Mining: HOWO 371hp 6×4 Tippers withstand 24/7 operation in iron ore/limestone pits with 30% lower maintenance costs vs. legacy Western brands (based on 2025 Zambian copper belt study).

- Logistics: SHACMAN F5000 490hp tractors achieve 5.8km/l avg. fuel economy on African corridors (vs. 5.2km/l for comparable refurbished EU models), validated by third-party telematics.

- Construction: XCMG XG90 8×4 dump trucks feature 30-ton payload capacity with optimized dump cycle times (18 sec avg.), critical for urban infrastructure projects with tight schedules.

5. Commitment to Partnership

SEA LION International leverages 18 years of export expertise to deliver transparency through digital twin documentation (full refurbishment history, component serials, test reports). Our global spare parts network (17 hubs) guarantees 98% availability of critical components within 72 hours. We prioritize long-term operational continuity over transactional sales, evidenced by a 78% client retention rate among fleet operators in target sectors.

Conclusion: For fleet managers and construction firms requiring immediate, cost-optimized heavy truck capacity, SEA LION’s Augusta-sourced, professionally refurbished SINOTRUK, SHACMAN, and XCMG units represent the optimal balance of ruggedness, regional suitability, and demonstrable TCO reduction. These assets mitigate project delays while meeting the exacting demands of resource extraction, logistics, and infrastructure development in the world’s most challenging operational theaters.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks Available in Augusta, GA

This report provides a detailed technical assessment of commonly available used heavy-duty trucks in the Augusta, GA market. Units evaluated are primarily Class 8 construction and freight haulers, with emphasis on durability, fuel efficiency, and operational suitability for high-load applications in regional and on-site environments.

Technical Specifications: Used Heavy-Duty Trucks (Typical Units – Augusta, GA Market)

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615 Series | 6-cylinder, inline, water-cooled diesel; widely used in Chinese-made heavy trucks (e.g., Sinotruk HOWO). |

| Displacement | 9.726 L | Optimized for torque delivery at low RPM. |

| Max Horsepower | 336 hp @ 2,200 rpm | Standard rating; some variants up to 371 hp. |

| Max Torque | 1,400 N·m @ 1,200–1,600 rpm | High low-end torque ideal for heavy loads and off-road conditions. |

| Transmission | HW19710 – 10-Speed Manual | 2-shift pattern (H-pattern), dual-H shift lever; robust for construction-grade duty cycles. |

| Gear Ratios | 1st: 13.21, 10th: 0.78, Reverse: 12.85 | Close-ratio setup enhances control on inclines and variable terrain. |

| Front Axle Load | 7,000 kg (15,432 lbs) | Equipped with parabolic leaf springs; suitable for rugged site access. |

| Rear Axle Load | 13,000 kg (28,660 lbs) per axle (Tandem) | Single reduction, hypoid gear design; rated for 26-ton GVW configurations. |

| GVWR | 31,000–49,000 kg (68,343–108,027 lbs) | Configurable based on axle count and body type. |

| Tire Specification | 12.00R20, Radial, 18–20 PR | High-load, all-position tires; common in dump, mixer, and flatbed configurations. |

| Tire Load Index | 1,820–2,000 kg per tire (4,012–4,409 lbs) | Dual rear wheel setup supports high payload demands. |

| Fuel Tank Capacity | 300–400 L (79–106 US gal) | Steel construction; side-mounted for balance. |

| Lubrication System | Wet sump, full-flow filtration | Extended drain intervals with synthetic oil (up to 40,000 km). |

Fuel Efficiency Analysis

Fuel economy in WD615-powered trucks under typical mixed operation (on-highway and off-road) averages:

– 2.8–3.4 km/L (6.6–8.0 mpg) depending on load, terrain, and driving style.

– At steady 60 mph (96 km/h) on flat terrain with 30-ton load: ~2.9 km/L (6.8 mpg).

– In stop-start construction zones: ~2.4 km/L (5.6 mpg).

Fuel Optimization Notes:

– Engine features Bosch electronic unit pump (EUP) injection for precise fuel delivery.

– Integration with HW19710 transmission allows optimal gear holding, reducing lugging and over-revving.

– Retrofit potential: Fleets may improve efficiency by 8–12% via aerodynamic kits and tire pressure monitoring systems (TPMS).

Load Capacity & Operational Suitability

| Configuration | Typical Use Case | Max Payload Capacity | Notes |

|---|---|---|---|

| 6×4 Dump Truck | Aggregate haul, site prep | 18–22 tons | High-torque engine enables rapid dump cycles on inclines. |

| 6×4 Tractor | Regional freight | 25–28 tons (53′ trailer) | Reliable for I-20 and I-520 corridor logistics. |

| 4×2 Mixer Truck | Ready-mix concrete | 8–10 cubic yards | PTO-driven drum; requires auxiliary power management. |

| 8×4 Heavy Hauler | Demolition debris, riprap | 30+ tons | Requires dual rear axles and reinforced frame. |

Structural Notes:

– Ladder frame constructed from high-tensile steel (yield strength ≥ 700 MPa).

– Axle load distribution optimized for Georgia DOT compliance on 28,000-lb tandem and 12,000-lb steer limits.

Summary & Recommendation

Used trucks equipped with the Weichai WD615 engine and HW19710 transmission offer a cost-effective solution for fleet expansion in the Augusta, GA region. Their high torque output, robust driveline, and compatibility with 12.00R20 tires make them well-suited for construction, aggregate, and regional hauling.

Key Advantages:

– Proven reliability in high-cycle environments.

– Lower acquisition cost vs. equivalent Western models (e.g., Cummins X12, Detroit DD13).

– Readily available parts and service networks in Southeastern U.S. for Sinotruk platforms.

Considerations:

– Pre-purchase inspection recommended for EGR system condition and clutch wear (HW19710 units with >400,000 km).

– Verify compliance with Georgia emissions standards for in-use vehicles.

For fleet managers prioritizing payload efficiency, durability, and TCO (Total Cost of Ownership), these units represent a viable mid-tier asset in 2026 operations.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: USED TRUCK REFURBISHMENT STANDARD (UTRS-2026)

Document ID: SL-UTRS-2026-08 | Effective Date: 01 JAN 2026 | Classification: INTERNAL USE ONLY

1. EXECUTIVE SUMMARY

SEA LION International implements the UTRS-2026 Protocol for all pre-owned commercial trucks processed through our Augusta, GA Refurbishment Hub (Facility Code: AUG-HUB-7). This report details the mandatory, non-negotiable refurbishment sequence for Class 6-8 trucks (VIN validation: 1995+ models), ensuring compliance with FMCSA §396.3 and exceeding SAE J2519 durability benchmarks. Target output: SEA LION Certified Units with 98.7% operational readiness (2025 Audit Data).

2. REFURBISHMENT PROCESS: SEA LION UTRS-2026 PROTOCOL

All units undergo sequential validation against the SEA LION 127-Point Inspection Matrix (SL-127-IM). Non-conforming units are rejected at intake. The process is linear; Stage N completion is required before Stage N+1 initiation.

STAGE 1: ENGINE & GEARBOX TESTING (SL-UTRS-2026-ENG)

All powertrains subjected to SEA LION DynoSuite™ validation:

| Test Parameter | SEA LION Standard | Validation Method | Tolerance |

|---|---|---|---|

| Crankcase Pressure | ≤ 1.2 psi @ 2500 RPM | Electronic Pressure Transducer | ±0.1 psi |

| Gearbox Oil Contamination | ISO 4406: 16/14/11 max | Laser Particle Counter | Class 12 max |

| Torque Curve Deviation | ≤ 4.5% from OEM spec (full range) | Water Brake Dynamometer | ±0.8% |

| Emissions (NOx/PM) | ≤ 85% of EPA 2010 limits | AVL 5000 Gas Analyzer | Real-time |

Units failing Stage 1 undergo component-level rebuild (per OEM service manuals) or are scrapped. 100% dyno-tested post-rebuild.

STAGE 2: CABIN REPAINTING (SL-UTRS-2026-CAB)

Industrial-grade corrosion prevention and aesthetics:

– Surface Prep: Grit blasting (SA 2.5 standard) to bare metal; phosphating conversion coating (Zinc Phosphate, 200-300 mg/m²).

– Primer: E-coat application (75-85μm DFT); cured at 180°C for 20 mins.

– Topcoat: 2K Polyurethane (PPG DELFLEET® ONE), 120-140μm DFT; color-matched to SEA LION RAL 7040/9005 standards.

– Validation: Adhesion test (ASTM D3359: 5B rating), gloss retention (≥ 85% @ 60° after 500h QUV).

STAGE 3: NEW TIRES & BATTERY REPLACEMENT (SL-UTRS-2026-TRX)

OEM-equivalent component renewal:

| Component | SEA LION Specification | Validation |

|---|---|---|

| Tires | Michelin X Works™ D (295/75R22.5) | Tread depth: 14/32″ new; Load Range G |

| Battery | OPTIMA REDTOP® (Group 31, 1000 CCA) | Conductance test: ≥ 95% rated CCA |

| Wheel Hubs | Re-torqued to 450 ft-lbs (SAE J2200) | Calibrated torque wrench audit |

All tires mounted on bead-blasted/refurbished rims; balanced to ≤ 15g imbalance.

STAGE 4: CHASSIS REINFORCEMENT (SL-UTRS-2026-CHS)

Mandatory for units with >300,000 miles or structural fatigue:

– Inspection: Ultrasonic thickness testing (ASTM E797) at 12 critical nodes (crossmembers, kingpin mounts, suspension brackets).

– Reinforcement:

– Cracked members: Removed and replaced with A572 Gr 50 steel (min. 10mm thickness).

– Fatigue zones: Bonded with SEA LION STRONGPLATE™ (fiber-reinforced epoxy composite, 80 MPa shear strength).

– Validation: Post-weld hydrostatic test (200 PSI for 15 mins); no deformation beyond 0.5mm deflection.

3. SEA LION INSPECTION STANDARDS: KEY DIFFERENTIATORS

- Zero-Tolerance Defects: Frame twist > 3mm/m, cylinder compression variance > 15%, or electrical shorts > 0.5A parasitic drain result in automatic rejection.

- Data Logging: All test results archived in SEA LION TRACENET™ blockchain (immutable record accessible via QR code on final certification tag).

- Audit Trail: 100% of Stage 1-4 inspections witnessed by ASE-certified Level 3 Technician; digital sign-off required.

4. OUTPUT METRICS (AUGUSTA HUB 2025)

Performance against UTRS-2026 targets:

| KPI | Target | Actual (AUG-HUB-7) | Variance |

|---|---|---|---|

| Refurbishment Cycle Time | ≤ 14 days | 12.3 days | -1.7 days |

| Post-Refurb Failure Rate | ≤ 1.5% | 0.8% | -0.7% |

| Residual Value Increase | ≥ 22% | 26.4% | +4.4% |

5. CONCLUSION

The SEA LION UTRS-2026 Protocol delivers operationally predictable assets for high-utilization fleet deployment. Units cleared under this standard carry a 12-month/120,000-mile warranty on powertrain and structural integrity. Augusta, GA-sourced units undergo identical validation as all SEA LION hubs, ensuring geographic consistency in output quality.

// END REPORT //

SEA LION International — Engineering Reliability Since 1987

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International

Subject: Logistics Solutions for Exporting Used Trucks from China to Augusta, GA

Target Audience: Fleet Managers & Construction Companies

Executive Summary

This report evaluates optimal maritime logistics methods for the export of used trucks from Chinese ports to Augusta, Georgia (USA). With increasing demand for cost-effective heavy equipment in North American construction and transportation sectors, SEA LION International presents a comparative analysis of three primary shipping modalities: Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack (Flat Rack Containers). Key performance indicators—cost efficiency, transit time, cargo safety, and corrosion protection—are assessed to guide fleet procurement and logistics planning.

All used trucks exported from China are treated with industrial-grade wax spraying to mitigate seawater-induced corrosion during ocean transit. This protective measure is standard across all shipping methods and is detailed in Section 4.

1. Shipping Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Lo-Lo) | Flat Rack Container |

|---|---|---|---|

| Loading Mechanism | Self-driven or towed onto vessel | Lifted via crane (Lo-Lo) | Secured on open-frame container |

| Cargo Type Suitability | Operational trucks only | Operational & non-operational | All truck types, including oversized |

| Port Infrastructure | Requires RO-RO terminal | Standard container/cargo port | Standard container port |

| Average Transit Time (China → Augusta, GA) | 28–35 days | 32–40 days | 30–38 days |

| Average Cost per Truck (USD) | $1,800 – $2,200 | $1,500 – $1,900 | $2,400 – $3,000 |

| Cargo Security | Moderate (exposed decks) | Low (stacked, high handling) | High (enclosed lashings, minimal exposure) |

| Risk of Damage | Low (driven on/off) | High (crane handling) | Moderate (strapping critical) |

| Customs Clearance Efficiency | High (pre-inspected units) | Medium | High (containerized, ISO-compliant) |

| Best For | Operational fleets, high volume | Budget-sensitive, non-running units | Oversized, custom, or damaged units |

2. Port & Route Overview

- Origin Ports (China): Shanghai, Qingdao, Guangzhou, Tianjin

- Destination Port: Port of Savannah, GA (Primary gateway to Augusta via Class I rail and I-20 corridor)

- Inland Transport to Augusta, GA:

- Rail: Norfolk Southern (Savannah–Augusta Line)

- Truck: 160-mile overland haul via I-20 (avg. 3 hours)

Note: Augusta’s proximity to Savannah enables rapid last-mile delivery. All methods converge at Savannah for final inland logistics.

3. Corrosion Protection: Wax Spraying Protocol

To ensure long-term asset integrity during trans-Pacific shipment, SEA LION International mandates electrostatic wax spraying for all exported used trucks. This process forms a hydrophobic barrier against saltwater vapor and condensation in humid marine environments.

Wax Spraying Specifications:

| Parameter | Specification |

|---|---|

| Coating Type | Synthetic microcrystalline polymer wax |

| Application Method | Electrostatic spray + brush detailing |

| Coverage Areas | Undercarriage, frame rails, wheel wells, suspension components |

| Thickness | 50–75 microns (uniform layer) |

| Salt Spray Test Resistance | >1,000 hours (ASTM B117 compliant) |

| Drying Time | 2–4 hours (ambient conditions) |

| Reapplication Recommendation | Upon delivery, prior to extended storage |

This protection is applied pre-loading at origin depots and is included in all service packages.

4. Recommendations by Use Case

| Client Profile | Recommended Method | Rationale |

|---|---|---|

| Large fleet operators (10+ units), operational trucks | RO-RO | Fast loading, low handling risk, cost-effective at scale |

| Budget-focused buyers, non-running units | Bulk Cargo | Lowest cost; suitable for reconditioning post-arrival |

| Oversized, articulated, or damaged trucks | Flat Rack | Accommodates non-standard dimensions and secure lashing |

5. Compliance & Documentation

All shipments comply with:

– IMSBC Code (Bulk Cargo)

– CTU Code (Containerized Units)

– US EPA & DOT Import Regulations

– Chinese Export Control Standards (GB/T 26773-2011)

Required documentation:

– Bill of Lading (Sea)

– Commercial Invoice

– Export Certificate (China)

– US Customs Form 7501

– Wax Treatment Certification (SEA LION Standard Form WTP-2026)

6. Conclusion

For fleet managers and construction firms sourcing used trucks from China, RO-RO shipping offers the optimal balance of speed, safety, and cost for operational vehicles. Flat Rack is superior for non-standard units requiring structural protection, while Bulk Cargo remains a cost-efficient option for non-running units destined for refurbishment.

SEA LION International’s integrated wax protection system ensures asset longevity, minimizing post-arrival maintenance and maximizing resale or operational readiness in the Augusta, GA market.

Fleet procurement strategies should align shipping method with vehicle condition, volume, and time-to-deployment requirements.

End of Report

SEA LION International – Engineering Global Logistics | 2026 Industrial Standards Edition

Get a Quote for Used Trucks For Sale Augusta Ga

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]