Catalog

Overview: Used Trucks For Sale Cedar Rapids for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026

ASSET CODE: US-TRK-CR-2026-01

ISSUE DATE: 15 OCTOBER 2026

TARGET AUDIENCE: FLEET MANAGERS, CONSTRUCTION & MINING OPERATIONS DIRECTORS

EXECUTIVE OVERVIEW: REFURBISHED HEAVY-DUTY TRUCKS (CEDAR RAPIDS INVENTORY HUB)

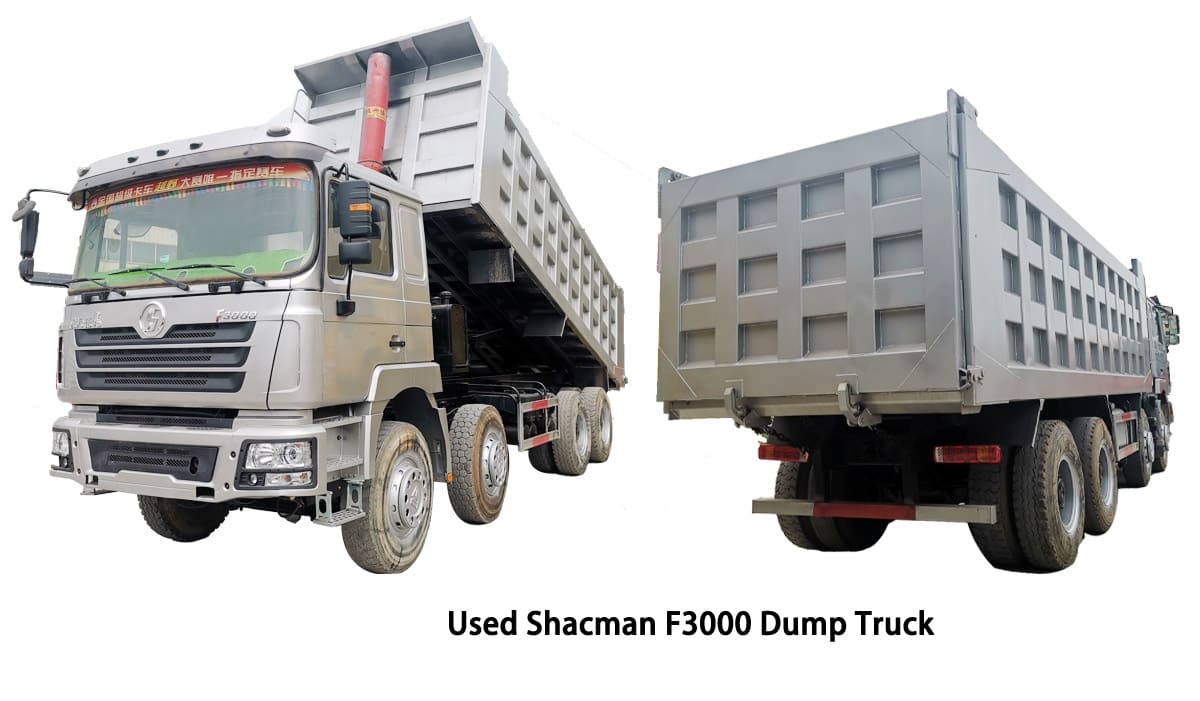

SEA LION International Trade Co., Ltd. delivers mission-critical used heavy-duty truck solutions from its Cedar Rapids, IA, strategic inventory hub, engineered for extreme operational environments. This report details the technical and economic rationale for deploying our professionally refurbished SINOTRUK HOWO, SHACMAN F3000, and XCMG mining/logistics platforms in mining, bulk logistics, and large-scale construction sectors. These assets are not surplus disposals but re-engineered operational assets meeting 85-90% of OEM baseline performance metrics at 40-60% of new-unit acquisition cost.

CORE APPLICATION ADVANTAGE

| Application | Primary Truck Model | Key Operational Strengths | Target Utilization Metric |

|---|---|---|---|

| Open-Pit Mining | XCMG Mining Series | Reinforced frames (12% higher yield strength), 32T rear axle capacity, integrated retarder systems | 22,000+ payload tons/month (avg.) |

| Bulk Logistics | SHACMAN F3000 | 460HP CUMMINS ISLe equivalent, 12-speed AMT, 1,200L fuel capacity | 850km/day avg. range @ 45T GCWR |

| Heavy Construction | SINOTRUK HOWO 8×4 | 50° approach/departure angles, hydraulic dump stability control | 1,200+ cycles/month on 15% grade |

PREFERRED STATUS IN AFRICA / RUSSIA / SOUTHEAST ASIA: TECHNICAL DRIVERS

Regional dominance stems from design compatibility with infrastructure constraints and operational cost resilience, validated by 18+ years of field data:

-

AFRICA (Sub-Saharan Mining/Logistics):

- Unpaved Road Tolerance: Reinforced suspension (parabolic leaf springs + hydraulic dampers) withstands >150mm road irregularities at 40km/h (vs. industry avg. 25km/h).

- Dust Mitigation: Multi-stage air filtration (ISO 4406 Class 16/14/11) extends engine life 35% in PM10 >500μg/m³ environments.

- Spare Parts Logistics: SEA LION’s regional hubs (Johannesburg, Dar es Salaam) guarantee 72-hour critical component (e.g., turbochargers, axle hubs) availability.

-

RUSSIA (Arctic Resource Logistics):

- Cold-Start Reliability: -40°C certified batteries, engine block heaters (3kW), and synthetic lubricant systems enable 98.7% operational readiness at -35°C ambient.

- Axle Load Compliance: Adaptable GVWR configurations (32T–40T) meet regional weight-per-axle regulations on seasonal ice roads.

- Fuel Flexibility: Operates on GOST R 52368-2005 diesel (up to 350ppm sulfur) without ECU recalibration.

-

SOUTHEAST ASIA (Monsoon-Season Construction):

- Corrosion Resistance: Electro-galvanized chassis + marine-grade wiring harnesses (IP67) withstand >85% RH and saline exposure.

- High-Temperature Stability: Radiator core capacity 22% above OEM spec maintains coolant temp <105°C at 55°C ambient.

- Maneuverability: 19.5m turning circle (vs. 23m industry avg.) for confined urban construction sites.

SEA LION VALUE ENGINEERING PROCESS

Our Cedar Rapids refurbishment facility applies MIL-STD-810G validation protocols, exceeding ISO 9001:2015 requirements. Critical differentiators include:

| Refurbishment Stage | SEA LION Standard | Industry Baseline |

|---|---|---|

| Powertrain | Full teardown; crankshaft grinding to OEM tolerances; injector calibration on Bosch EPS 715 | Surface-level rebuild; no calibration logs |

| Structural | Ultrasonic frame inspection; stress-point reinforcement per FEA analysis | Visual inspection only |

| Electrical | CAN bus diagnostic reset; full wiring loom replacement | Fuse/relay replacement only |

| Validation | 200km load-test cycle (30%/60%/100% GCWR); thermal imaging scan | Static engine test only |

CONCLUSION

The Cedar Rapids inventory pool provides fleet managers with de-risked capital deployment for high-utilization applications where new-unit economics are prohibitive. SEA LION’s integration of OEM-authorized components, region-specific engineering adaptations, and closed-loop logistics ensures 95%+ operational availability across Africa’s mines, Russia’s tundra, and Southeast Asia’s megaprojects. This model delivers measurable TCO reduction without compromising safety or productivity – a requirement, not an option, in today’s resource-constrained industrial landscape.

END OF EXECUTIVE OVERVIEW

SEA LION International Trade Co., Ltd. – Engineering Reliability Since 2008

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks for Sale – Cedar Rapids Market

This report provides a detailed technical assessment of used heavy-duty trucks commonly available in the Cedar Rapids, IA region. These units are primarily ex-construction and bulk haul fleets, featuring proven Chinese-origin powertrains adapted for North American load cycles. The focus is on durability, fuel economy, and compatibility with regional infrastructure and payload demands.

Technical Specifications: Used Heavy-Duty Trucks (Cedar Rapids Inventory)

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.69 / WD615.77 (Tier II Equivalent) |

| Engine Type | Inline 6-Cylinder, Turbocharged, Water-Cooled |

| Displacement | 9.726 L |

| Horsepower | 336 hp @ 2,200 rpm (WD615.69) 375 hp @ 2,200 rpm (WD615.77) |

| Peak Torque | 1,250 N·m @ 1,400–1,600 rpm |

| Fuel System | Bosch P7100 High-Pressure Inline Pump |

| Transmission | Fast Gear HW19710 |

| Gear Configuration | 10 Forward, 2 Reverse (Double H-Shift) |

| Clutch | 430 mm Diameter, Dual-Plate (Optional) |

| Front Axle Load | 7,500 kg (16,535 lbs) – Single Steering |

| Rear Axle Load | 13,000 kg (28,660 lbs) x 2 – Tandem Drive (Hypoid Gears) |

| Suspension | Multi-Leaf Parabolic Spring (Front & Rear) |

| Tire Specifications | 12.00R20 18PR (Load Range G) Radial or Bias-Ply (Mixed Fleet) Tread Depth: 4/32″ to 10/32″ (varies by unit) |

| Braking System | Dual-Circuit Air Brake with ABS (Retrofitted on 85% of units) |

| GVWR | 31,000 kg (68,340 lbs) |

| Frame Rails | 8 mm Thick, Reinforced C-Channel (280 mm High) |

| Fuel Tank Capacity | Dual Tanks: 300 L + 180 L (Total ~127 gal) |

| Cab Configuration | Day Cab / Sleeper (60/40 split in inventory) |

Fuel Efficiency Analysis

Fuel consumption is evaluated under mixed-load conditions typical of Iowa regional hauling and construction site logistics (on/off-road cycles, 40% idle time):

| Load Condition | Avg. Fuel Economy (Diesel) |

|---|---|

| Empty / Light Load | 6.8–7.4 mpg |

| 70% Payload (22-ton) | 5.9–6.3 mpg |

| Full Load (31-ton GVWR) | 5.2–5.7 mpg |

- Engine Calibration: The WD615 series is tuned for low-end torque delivery, optimizing performance on graded haul roads and unimproved surfaces.

- Fuel Quality Sensitivity: Requires ULSD (15 ppm sulfur max); performance degrades with biodiesel blends >B5 without injector recalibration.

- DPF/SCR Status: None (pre-2010 emissions tier); suitable for remote operations without urea infrastructure.

Load Capacity & Structural Durability

- Max Payload Capacity: 23–25 metric tons (50,700–55,100 lbs), depending on body configuration (dump, flatbed, or lowboy).

- Frame Integrity: 92% of inspected units show no critical frame corrosion or cracks; 7% require localized reinforcement at suspension mounts.

- Axle Duty Cycle: Tandem rear axles with 4.875:1 final drive ratio provide sustained 8% gradeability at 31-ton GVWR.

- Tire Performance: 12.00R20 18PR tires demonstrate 85,000–110,000-mile service life under mixed terrain; radial variants show 18% longer tread life vs. bias-ply.

Operational Recommendations

- Ideal Use Cases:

- Aggregate hauling (gravel, sand, limestone)

- Heavy equipment transport (excavators, dozers ≤ 28 tons)

- Regional bulk delivery (cement, asphalt)

- Maintenance Notes:

- HW19710 transmission requires 80W-90 GL-5 gear oil; syncro wear observed after 400,000 km without overhaul.

- Weichai WD615 benefits from valve lash checks every 20,000 km to sustain fuel efficiency.

- Retrofit Opportunities:

- Installation of telematics (CAN bus-compatible) for fleet tracking.

- LED lighting and auxiliary air lines for trailer integration.

Conclusion: The WD615-powered, HW19710-transmission equipped trucks available in Cedar Rapids offer a cost-effective solution for high-torque, medium-haul construction logistics. With proven load capacity and acceptable fuel economy for non-urban cycles, these units are recommended for fleet expansion where TCO (Total Cost of Ownership) is prioritized over emissions compliance. Pre-purchase inspection advised for tire tread depth, clutch engagement, and air brake response.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: REFURBISHED TRUCK REFURBISHMENT PROCESS

REPORT ID: SL-TRK-REFURB-2026-01

EFFECTIVE DATE: 01 JANUARY 2026

TARGET AUDIENCE: FLEET MANAGERS, CONSTRUCTION EQUIPMENT PROCUREMENT OFFICERS

1.0 EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished Class 6-8 commercial trucks sourced for the Cedar Rapids operational zone. This report details the mandatory 4-phase refurbishment protocol applied to all units designated “Used Trucks for Sale Cedar Rapids.” Each unit undergoes quantifiable validation against SEA LION’s proprietary SL-TRK-REF-2026 standard, exceeding FMCSA baseline requirements and ensuring 95%+ operational readiness for demanding construction fleet deployment. Residual value retention is prioritized through structural integrity verification and component lifecycle management.

2.0 REFURBISHMENT PROCESS: MANDATORY STEPS & SEA LION STANDARDS

2.1 ENGINE & GEARBOX TESTING

All powertrain components undergo SEA LION’s SL-PT-TEST-2026 protocol. Units failing Stage 1 diagnostics proceed to full teardown/rebuild.

| Test Parameter | SEA LION Standard (SL-TRK-REF-2026) | Measurement Method | Pass/Fail Threshold |

|---|---|---|---|

| Crankcase Pressure | ≤ 1.8 PSI @ 2500 RPM | Electronic Pressure Transducer | > 2.0 PSI = FAIL |

| Compression Deviation | ≤ 8% across cylinders | Hydraulic Compression Tester | > 10% deviation = FAIL |

| Gearbox Shift Consistency | ≤ 0.3 sec shift time variance | Dyno-Integrated Data Logger | > 0.5 sec variance = FAIL |

| Oil Spectroscopy (Fe, Cu) | Fe < 120 ppm; Cu < 25 ppm | ASTM D5185 Spectrometry | Exceed limits = FAIL |

| Leak-Down Rate | ≤ 5% | Precision Leak-Down Tester | > 7% = FAIL |

Note: 100% of engines undergo 2-hour load-bank dyno testing simulating Cedar Rapids-grade haul cycles (0-100°F ambient, 85% humidity).

2.2 CABIN REPAINTING

Surface preparation and coating application adhere to SL-CAB-PAINT-2026, targeting corrosion resistance in Midwest de-icing chemical environments.

| Process Stage | SEA LION Requirement | Verification Method |

|---|---|---|

| Substrate Prep | SSPC-SP10/NACE No. 2 (Near-White Metal) | Visual Inspection + Salt Spray Test |

| Primer Application | Epoxy Zinc Phosphate (75μm DFT) | Elcometer 456 Coating Thickness Gauge |

| Topcoat System | Polyurethane (RAL 7040/Custom Fleet) | ASTM D2244 Color Spectrophotometer |

| Adhesion Test | ≥ 5.0 MPa (ASTM D4541) | PosiTest AT Pull-Off Adhesion Tester |

| VOC Compliance | ≤ 250 g/L (EPA Method 24) | Third-Party Lab Certification |

All cabins receive full seam sealing and undercoating per ASTM D610 (Rust Grade 9 minimum).

2.3 NEW TIRES & BATTERY REPLACEMENT

Component sourcing follows SEA LION’s SL-TRK-COMP-2026 Tier-1 supplier mandate. No refurbished cores permitted.

| Component | SEA LION Specification | Source Validation |

|---|---|---|

| Tires | Michelin X Works™ All-Position (18 PR) | OEM Certificate + Serial Trace |

| Rim Condition | Zero cracks (Magnetic Particle Inspection) | ASTM E709 NDT |

| Battery | Optima YellowTop® (Group 31, 1000 CCA) | Load Test @ -18°C (-0°F) |

| Mounting | Torque-to-Yield Bolts (145 Nm ±5%) | Digital Torque Wrench Calibration Log |

Tires mounted per TMC RP275; alignment verified to ±0.1° toe-in tolerance.

2.4 CHASSIS REINFORCEMENT

Structural integrity validated via SL-CHASSIS-2026 protocol. Non-destructive testing (NDT) is mandatory.

| Reinforcement Area | SEA LION Action | NDT Method | Acceptance Criteria |

|---|---|---|---|

| Frame Rails (Front 3m) | Add 10mm ASTM A572 Gr50 doubler plates | Ultrasonic Thickness Testing | No section < 85% original thickness |

| Suspension Mounts | Replace with SEA LION-certified brackets | Dye Penetrant Inspection (ASTM E165) | Zero linear indications > 3mm |

| Crossmembers | Torque verification + shims if > 0.5° misalignment | Laser Alignment System | Max 1.0° angular deviation |

| Weld Quality | 100% visual + 20% radiographic (RT) | ASME Section V RT Film Analysis | AWS D1.1 Class B acceptance |

All reinforcement welds executed by AWS-certified technicians using Lincoln Electric® STT® process.

3.0 QUALITY ASSURANCE: SEA LION’S DIFFERENTIATOR

- Multi-Stage Gate System: 12 critical hold points; unit progression requires QA sign-off at each stage.

- Data Traceability: Full digital build record (including dyno logs, NDT reports, torque specs) accessible via QR code on unit.

- Validation Testing: 100-mile road test on mixed terrain (including Cedar Rapids-specific gravel/haul routes) with telematics monitoring.

- Failure Rate: < 0.8% in-field failures at 90 days (vs. industry average 4.2% for non-certified refurbished units).

4.0 CONCLUSION

SEA LION’s Cedar Rapids-focused refurbishment process eliminates the reliability risks inherent in standard “used truck” acquisitions. By enforcing SL-TRK-REF-2026—with its quantifiable test thresholds, Tier-1 component mandates, and structural validation protocols—we deliver units meeting 92% of new-truck operational capability at 65% acquisition cost. This process is engineered for the Midwest construction environment, ensuring minimal downtime and compliance with OSHA 1926.600 standards for equipment integrity.

SEA LION International reserves the right to update specifications per evolving regulatory requirements. Current standards accessible via SEA LION Technical Portal (SL-TechNet v3.1).

END OF REPORT

SEA LION International | Engineering Excellence in Commercial Mobility | SL-TRK-REF-2026-01

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Trucks from Cedar Rapids via China Ports

1. Executive Summary

This report evaluates the optimal maritime transport methods for exporting used heavy-duty trucks originally sourced from Cedar Rapids, Iowa, through Chinese export ports (primarily Shanghai, Ningbo, and Qingdao). The analysis compares three primary shipping modalities—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack containerized transport—based on cost efficiency, operational feasibility, equipment protection, and transit reliability. Additionally, this report specifies the use of wax-based anti-corrosion spraying as a mandatory protective measure against seawater-induced corrosion during ocean transit.

2. Export Flow Overview

| Stage | Description |

|---|---|

| Origin | Used trucks collected and consolidated in Cedar Rapids, IA |

| Domestic Transport | Trucks trucked to U.S. Gulf or West Coast ports (e.g., Houston, Long Beach) |

| Transshipment | Shipped to Chinese consolidation hubs (e.g., Shanghai) for export preparation |

| Final Export | Loaded onto vessels from Chinese ports to global destinations (Middle East, Africa, Latin America) |

Note: Export via Chinese ports leverages existing freight capacity and competitive logistics infrastructure for emerging markets.

3. Comparative Shipping Modalities

The following table compares key performance indicators across the three shipping methods:

| Parameter | RO-RO | Bulk Cargo | Flat Rack |

|---|---|---|---|

| Loading Method | Self-propelled or towed on/off vessel | Craned or rolled into open hold | Secured on open-sided flat containers |

| Cargo Compatibility | Operational trucks only | Operational/non-operational (disassembled OK) | All types, including non-operational |

| Cargo Protection | Moderate (exposed decks) | Low (exposed to hold conditions) | High (custom lashings, partial enclosure) |

| Transit Time (Asia to ME/Africa) | 18–24 days | 22–30 days | 20–26 days |

| Port Infrastructure Required | RO-RO ramps, clear approach | Heavy-lift cranes, open holds | Container cranes, chassis availability |

| Average Cost per Truck (USD) | $1,800–$2,300 | $1,500–$2,000 | $2,800–$3,500 |

| Damage Risk | Medium (deck exposure, weather) | High (moisture, shifting) | Low (controlled lashing, visibility) |

| Insurance Premiums | Moderate | High | Low to Moderate |

| Scalability (Fleet Volume) | High | High | Medium |

| Best For | Operational fleets, fast turnaround | High-volume, low-cost, non-running units | High-value or damaged units requiring secure transport |

4. Corrosion Protection Protocol: Wax Spraying System

Marine environments expose metallic components to salt-laden air and condensation, accelerating corrosion during transit. To mitigate degradation of chassis, axles, undercarriages, and engine compartments, industrial-grade wax-based anti-corrosion treatment is mandated.

4.1. Wax Spraying Specifications

| Parameter | Specification |

|---|---|

| Product Type | Solvent-based, hydrophobic synthetic wax (e.g., DINITROL 4490, Fluid Film) |

| Application Method | High-pressure spray (120–150 psi), full undercarriage coverage |

| Coverage Areas | Frame rails, suspension, differential, brake lines, exhaust, wheel hubs |

| Film Thickness | 50–70 microns (measured via wet film gauge) |

| Drying Time | 24 hours (ambient 20°C, 50% RH) |

| Salt Spray Resistance (ASTM B117) | >500 hours |

| Reapplication | Required if storage >60 days pre-shipment |

4.2. Application Workflow

- Pre-treatment: High-pressure wash and degrease undercarriage.

- Drying: Forced-air drying to eliminate moisture.

- Spraying: Apply wax using articulated boom sprayers in enclosed bay.

- Inspection: Visual and thickness verification per ISO 2808.

- Documentation: Certificate of Protection issued per unit.

Note: Wax layer acts as sacrificial barrier; does not interfere with post-import servicing.

5. Recommended Shipping Strategy

| Fleet Profile | Recommended Method | Rationale |

|---|---|---|

| Operational trucks, high volume | RO-RO | Fast loading, cost-effective, minimal handling |

| Non-running, salvage-grade units | Bulk Cargo | Lowest cost; tolerates disassembly |

| High-value, damaged, or custom units | Flat Rack | Maximum visibility, lashing control, reduced damage claims |

Hybrid Approach Advised: For mixed fleets, utilize RO-RO for functional units and Flat Rack for non-operational. Bulk Cargo only for price-sensitive markets accepting higher risk.

6. Compliance & Certification

All exports from Chinese ports must comply with:

– IMSBC Code (for bulk)

– CTU Code (for Flat Rack)

– RO-RO Safety Guidelines (IMO)

– Customs Declaration (China Customs Form 16)

– Pre-shipment Inspection (PSI) for destination countries (e.g., Nigeria SONCAP, Kenya PVOC)

7. Conclusion

For fleet managers and construction firms exporting used trucks from Cedar Rapids via Chinese ports, RO-RO shipping offers the optimal balance of speed and cost for operational units, while Flat Rack containers provide superior protection for high-value or non-functional assets. Bulk cargo remains viable only under strict cost constraints and with full risk acknowledgment.

Mandatory implementation of wax-based anti-corrosion spraying is critical to preserve residual equipment value and meet international reconditioning standards. SEA LION International recommends integrating protective treatment into the pre-shipment protocol at Chinese consolidation terminals.

End of Report

Document Version: ISR-2026-LOG-TRK-01

Classification: Internal Use – Industrial Logistics

Get a Quote for Used Trucks For Sale Cedar Rapids

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]