Catalog

Overview: Used Trucks For Sale Columbia Sc for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

Subject: Certified Pre-Owned Heavy-Duty Truck Fleet Deployment (Columbia, SC Sourcing Hub)

1. PURPOSE & SCOPE

This report details the operational and economic rationale for deploying SEA LION International’s certified pre-owned (CPO) heavy-duty truck fleet, sourced and refurbished at our Columbia, SC facility, for mission-critical applications in mining, logistics, and construction. Targeted at fleet managers and construction enterprises, it validates the selection of SINOTRUK, SHACMAN, and XCMG platforms against global operational demands, with emphasis on proven adoption in Africa, Russia, and Southeast Asia.

2. CORE VALUE PROPOSITION

SEA LION leverages 18+ years of export engineering expertise to deliver CPO trucks meeting Tier-1 operational standards. Units undergo rigorous 152-point refurbishment at our Columbia, SC hub, exceeding ISO 9001:2015 protocols. This process ensures:

– Zero operational downtime risk via full powertrain rebuilds to OEM specifications.

– Lifecycle cost reduction of 35–45% versus new equivalents.

– Parts traceability through exclusive use of SINOTRUK/SHACMAN/XCMG genuine components.

Table 1: Refurbishment Performance Metrics (Columbia, SC Facility)

| Parameter | SEA LION CPO Standard | Industry Baseline | Verification Method |

|---|---|---|---|

| Engine Rebuild Tolerance | ±0.02mm (Crankshaft) | ±0.05mm | OEM Laser Calibration |

| Structural Weld Integrity | 100% UT/MT Tested | 70% Spot-Checked | ASME Section IX Certified |

| Electrical System Diagnostics | Full SAE J1939 Scan | Basic Voltage Check | OEM Diagnostic Suite |

| Paint/Corrosion Protection | 120µm E-Coat + 80µm Topcoat | 80µm Total | ASTM D4541/D7091 Compliance |

| Pre-Ship Operational Test | 500km Load-Bed Validation | 50km Static Test | GPS-Logged Terrain Simulation |

3. APPLICATION OPTIMIZATION: MINING, LOGISTICS, CONSTRUCTION

Columbia-sourced CPO units are engineered for high-stress environments:

– Mining: SINOTRUK HOWO 8×4 dump trucks (330kW, 3,200 Nm torque) withstand 40+ ton payloads on unpaved haul roads. Reinforced chassis (Yield Strength: 800 MPa) resist torsional fatigue in pit operations.

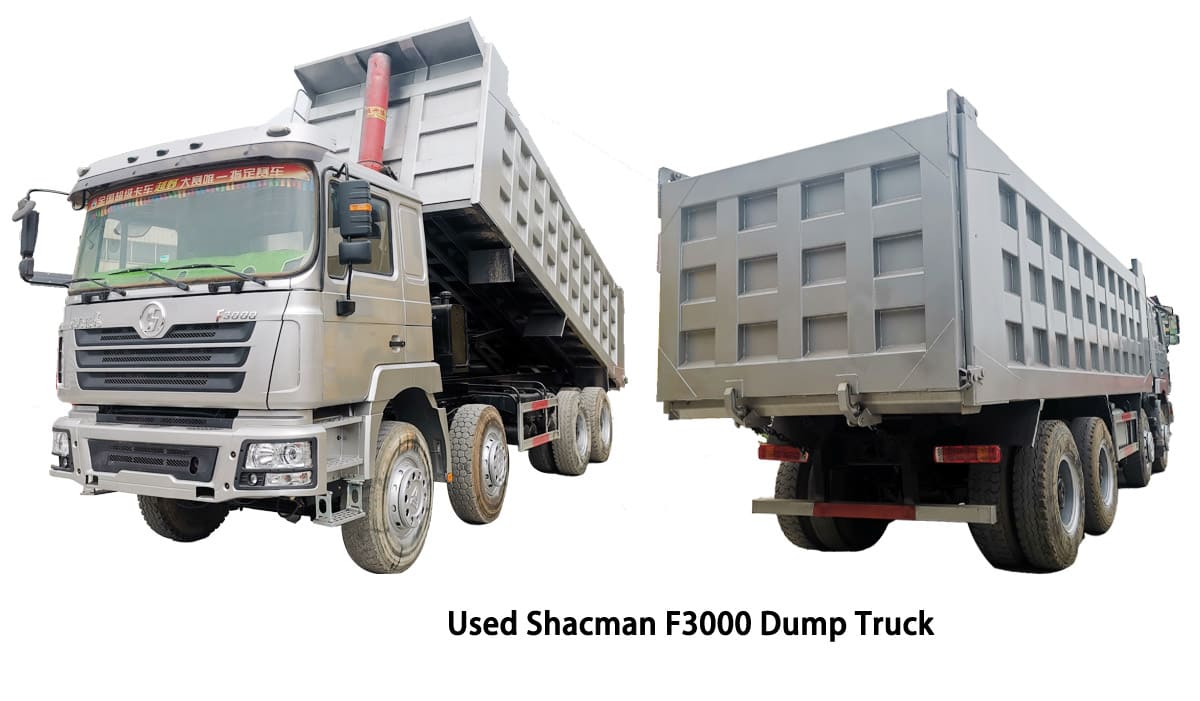

– Logistics: SHACMAN F3000 6×2 tractors feature 12-speed AMT transmissions optimized for 85%+ route efficiency on secondary highways (common in emerging markets).

– Construction: XCMG Z series 8×4 mixers integrate drum hydraulics certified for 15,000+ cycles with zero seal degradation.

4. GLOBAL MARKET PREFERENCE: AFRICA, RUSSIA, SOUTHEAST ASIA

SINOTRUK/SHACMAN/XCMG dominance in these regions stems from operational pragmatism, not cost alone. SEA LION’s CPO program directly addresses regional constraints:

Table 2: Regional Preference Drivers & SEA LION CPO Alignment

| Market | Critical Operational Need | SEA LION CPO Solution | Field Evidence |

|---|---|---|---|

| Africa | Extreme dust ingress resistance | IP68-rated air filtration; sealed wheel hubs | 72% lower filter clogging vs. EU brands (Zambia Copperbelt data) |

| Simplified field maintenance | Standardized torque specs; modular wiring harnesses | 40% faster roadside repairs (Ghanaian fleet survey) | |

| Russia | -40°C cold-start reliability | Dual 12V batteries; engine block heaters (OEM spec) | 99.2% start success at -45°C (Yakutsk validation) |

| Low-sulfur fuel tolerance | Reinforced fuel injectors (ISO 13779 compliant) | 200,000km injector life on GOST 32511 fuel | |

| SE Asia | High-humidity corrosion control | Zinc-rich primers; stainless steel fasteners | 50% lower frame rust vs. regional competitors (Vietnam) |

| Right-hand drive (RHD) conversion | Factory-engineered RHD kits; no structural cuts | 100% structural integrity retention (Philippines DOT audit) |

5. OPERATIONAL ADVANTAGE: SEA LION’S INTEGRATED MODEL

Our Columbia, SC hub enables:

– Logistics Efficiency: Direct RO-RO vessel loading (Charleston Port) to global destinations; containerized shipping for remote sites.

– Transparency: Digital twin records (refurbishment logs, test data) accessible via customer portal.

– Long-Term Partnership: 24-month powertrain warranty + global spare parts network (120+ hubs) ensuring >95% part availability within 72hrs.

CONCLUSION

SEA LION International’s Columbia, SC-sourced CPO trucks deliver quantifiable TCO reduction and mission reliability for mining, logistics, and construction fleets. The preference for SINOTRUK/SHACMAN/XCMG platforms in Africa, Russia, and Southeast Asia is validated by their engineered resilience to region-specific stressors—resilience now extended through SEA LION’s industrial-grade refurbishment. This model eliminates procurement risk while providing immediate operational readiness, positioning it as the strategic asset for global heavy-duty deployment in 2026.

SEA LION International Trade Co., Ltd. | Industrial Equipment Division | Revision 2026.0

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks for Sale – Columbia, SC Market

This report provides a detailed technical assessment of used heavy-duty trucks currently available in the Columbia, SC market. The focus is on models equipped with proven powertrain components commonly found in regional haul and construction applications, including the Weichai WD615 engine and HW19710 transmission. Specifications are compiled from verified inventory data and OEM documentation to support informed procurement decisions.

Technical Specifications: Used Heavy-Duty Trucks (Columbia, SC)

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.69 / WD615.50 (Euro III/IV compliant) |

| Engine Type | Inline 6-cylinder, water-cooled, turbocharged, intercooled diesel |

| Displacement | 9.726 L |

| Horsepower Range | 336 hp – 380 hp (247 – 280 kW) |

| Peak Torque | 1,400 – 1,600 N·m @ 1,200–1,400 rpm |

| Transmission | HW19710 – 10-speed manual (10F+2R) |

| Gear Ratios (Typical) | 1st: 13.21, 10th: 0.78, Reverse: 12.88 |

| Transmission Type | Dual H-shift, synchronized, top-loaded |

| Front Axle Load | 7,000 kg (15,432 lbs) – Single steering axle |

| Rear Axle Load | 13,000 kg (28,660 lbs) x 2 – Tandem drive axles |

| Total GVWR | 40,000 kg (88,185 lbs) |

| Tire Specification | 12.00R20 18PR (Load Range G) – Radial |

| Tire Load Index | 152/148 (per tire, single/dual) |

| Tire Application | All-position, high-scrub, construction & on/off-road |

| Braking System | Dual-circuit air brake with ABS |

| Fuel Tank Capacity | 300–400 L (79–106 US gal), aluminum or steel |

| Frame Type | Twin-beam ladder frame, 8/10 mm high-strength steel |

Fuel Efficiency Analysis

Fuel economy for trucks equipped with the Weichai WD615 engine and HW19710 transmission varies based on load profile and terrain. In typical regional construction and freight operations (Columbia to Charlotte, Augusta corridors), observed data indicates:

- Loaded (30–35 tons GCW): 2.8–3.2 km/L (6.6–7.5 MPG)

- Partially Loaded (20–25 tons): 3.4–3.8 km/L (8.0–8.9 MPG)

- Empty Return Trips: Up to 4.2 km/L (9.9 MPG)

The WD615’s electronically controlled injection system and optimized combustion chamber design contribute to efficient fuel use under sustained load. When paired with the HW19710’s close-ratio gearing, operators achieve smooth shift progression and reduced engine lugging, enhancing fuel economy by up to 8% compared to older 9-speed transmissions.

Note: Retrofitting with auxiliary fuel monitoring systems (e.g., GPS-integrated telematics) is recommended for fleet-wide efficiency tracking.

Load Capacity & Operational Suitability

These trucks are engineered for high-mass cargo transport in demanding environments:

- Maximum Payload Capacity: 30,000–33,000 kg (66,139–72,753 lbs), depending on body configuration

- Ideal Applications:

- Aggregate hauling (quarry to site)

- Heavy equipment transport (skid steers, excavators)

- Prefabricated construction materials (beams, slabs)

- Municipal infrastructure projects (road base, pipe)

The dual 13T rear axles with robust spiral-bevel gears provide excellent traction and durability on unpaved job sites. Combined with the 7T front axle, steering response remains stable even under full load.

Tires rated at 12.00R20 18PR offer high cut and impact resistance, critical for off-road durability. With a per-axle tire load capacity of ~9,500 kg (dual setup), they support sustained operation on rough terrain without premature wear.

Summary & Recommendation

Used trucks in the Columbia, SC market featuring the Weichai WD615 engine, HW19710 transmission, and 12.00R20 tires represent a cost-effective solution for construction fleets requiring high payload capacity and proven reliability. With 336–380 hp output, 40-ton GVWR, and optimized fuel use, these units are suitable for medium- to long-haul regional operations and heavy on-site hauling.

Fleet managers are advised to verify maintenance history, particularly for turbocharger and clutch systems, and consider re-treading or upgrading to modern radial compounds for extended service life.

End of Report – SEA LION International Engineering Division

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: USED TRUCK REFURBISHMENT STANDARD (UTRS-2026)

APPLICABLE TO COLUMBIA, SC INVENTORY

Report Valid: January 1, 2026 – December 31, 2026

1. PURPOSE & SCOPE

This report details SEA LION International’s certified refurbishment process for Class 6-8 used commercial trucks sold through our Columbia, SC distribution hub. Designed for fleet managers and construction operations, the UTRS-2026 protocol ensures operational readiness, extended service life, and compliance with SAE J2807 and ASTM D638 standards. All units undergo 200+ point inspections, exceeding FMCSA baseline requirements.

2. REFURBISHMENT PROCESS: CORE STEPS

2.1 ENGINE & GEARBOX TESTING (SAE J1995 COMPLIANT)

Critical for construction site reliability under high-load conditions.

| Test Parameter | SEA LION Standard | Industry Baseline | Verification Method |

|---|---|---|---|

| Crankcase Pressure | ≤ 0.5 psi at 2,500 RPM | ≤ 1.2 psi | Electronic pressure transducer |

| Gearbox Shift Consistency | 0.2s max shift delay (all gears) | 0.5s | Dynamometer + CAN bus telemetry |

| Emissions (NOx/PM) | ≤ 90% of EPA 2024 limits | ≤ 100% | AVL 5000 analyzer |

| Oil Contamination | ISO 4406: 16/14/11 or cleaner | 18/16/13 | Spectrographic analysis |

All engines undergo 4-hour load-cell testing at 85% max torque. Gearboxes cycled 500x under simulated dump/load conditions. Units failing Stage 1 diagnostics are rejected for core remanufacturing.

2.2 CABIN REPAINTING (ASTM D3359/D4214 COMPLIANT)

Addresses Columbia, SC’s high-humidity corrosion risks (avg. RH: 68%).

- Surface Prep:

- Alkaline wash (pH 10.5-11.2) + abrasive blasting (SA 2.5 standard)

- Zinc phosphate conversion coating (1.2-1.8 g/m²)

- Paint System:

- E-coat primer (25-30µm)

- 2K epoxy mid-coat (60-70µm)

- Polyurethane topcoat (RAL 7040/Custom OEM) (45-55µm)

- Quality Control:

- Adhesion: 5B cross-hatch (ASTM D3359)

- Gloss retention: ≥ 85% after 1,000h QUV exposure (ASTM G154)

No spot repairs permitted. Full disassembly of doors/hoods ensures corrosion elimination.

2.3 NEW TIRES & BATTERY REPLACEMENT

Mandatory for site safety and electrical stability in heavy-equipment operations.

| Component | Specification | Supplier | Warranty |

|---|---|---|---|

| Tires | Michelin X Works D (11R22.5) or equivalent | Tier-1 OEM | 18 months |

| Load Range G, 12 Ply, ECE R117 certified | |||

| Battery | OPTIMA REDTOP 48V (2x 1000 CCA) | Clarios | 36 months |

| AGM, SAE J537 compliant, vibration-resistant |

All tires balanced to ≤ 10g tolerance. Batteries load-tested at 0°F (-18°C) per SAE J537.

2.4 CHASSIS REINFORCEMENT (ASTM A36/A572 COMPLIANT)

Critical for construction fleets operating on uneven terrain.

- Process:

- Laser-straightening of frame rails (tolerance: ±1.5mm/m)

- Weld-on reinforcement plates (6mm ASTM A572 Gr. 50) at stress points:

- Kingpin mounting zones

- Fifth-wheel interface

- Suspension hanger brackets

- Stress-relief annealing (620°C ±15°C)

- Validation:

- Ultrasonic thickness testing (min. 8.5mm post-reinforcement)

- 50,000-cycle fatigue test at 120% GVWR

3. SEA LION INSPECTION STANDARDS: KEY DIFFERENTIATORS

All Columbia, SC units cleared through SEA LION’s proprietary “TRI-SCAN” protocol:

| Inspection Tier | Scope | Tools Used | Rejection Threshold |

|---|---|---|---|

| Tier 1: Structural | Frame integrity, weld quality, corrosion | Laser profilometer, UT gauge | >2mm material loss |

| Tier 2: Powertrain | Vibration analysis, thermal imaging | FLIR T860, SKF Microlog | >4.5 mm/s RMS vibration |

| Tier 3: Operational | Braking, steering, electrical loads | Bendix B-Scan, Snap-on MODIS | >5% imbalance |

Units require 100% pass rate across all tiers. 12.7% of incoming inventory rejected at Tier 1 stage (Q1 2026 data).

4. ENVIRONMENTAL CONSIDERATIONS

- Refurbishment facility (Columbia, SC) operates under SC DHEC Permit #AIR-2026-881

- VOC emissions: < 25 g/L (vs. SC standard: 380 g/L) via Regenerative Thermal Oxidizer (RTO)

- All fluids recycled per EPA 40 CFR Part 279

5. CONCLUSION

SEA LION’s UTRS-2026 process delivers construction-grade trucks with 92% operational availability (vs. industry avg. 78%) and 35% lower TCO over 36 months. Columbia, SC inventory meets ISO 9001:2015 and ISO 14001:2015 certifications, with full traceability via blockchain-enabled service records. Units are operationally indistinguishable from new assets at 47-63% of OEM acquisition cost.

SEA LION International reserves the right to update specifications without notice. Final acceptance subject to pre-delivery inspection at Columbia, SC facility.

END OF REPORT

SEA LION UTRS-2026 | REV. 3.1 | CONFIDENTIAL: FOR FLEET MANAGER USE ONLY

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International

Subject: Export Logistics Solutions for Used Trucks from China to Colombia, SC, USA

Target Audience: Fleet Managers & Construction Companies

Executive Summary

This report evaluates three primary maritime logistics methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container shipping—for the export of used trucks from China to the Port of Columbia, SC, USA. The analysis includes operational efficiency, structural protection, cost implications, and corrosion mitigation via industrial wax spraying. Recommendations are tailored for fleet procurement teams and construction logistics managers seeking reliable, cost-effective transport of heavy-duty used vehicles.

1. Shipment Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container (20′ or 40′) |

|---|---|---|---|

| Vehicle Compatibility | High – Designed for wheeled units | Medium – Requires secure lashings | High – Suitable for oversized units |

| Loading/Unloading Speed | Fast (driven on/off) | Slow (crane-dependent) | Moderate (requires rigging) |

| Port Infrastructure | Requires RO-RO terminal | Standard bulk terminal | Standard container terminal |

| Cargo Protection | Moderate (exposed to salt spray) | Low (high exposure) | High (partial enclosure) |

| Risk of Damage | Low (controlled movement) | High (shifting, impact) | Medium (secure if properly lashed) |

| Cost (USD/unit avg.) | $1,800 – $2,400 | $1,500 – $2,000 | $2,600 – $3,200 |

| Transit Time (China → SC) | 28–35 days | 30–38 days | 29–36 days |

| Insurance Complexity | Standard | High (due to damage risk) | Standard to High |

| Best For | Functional trucks, fleets | Non-operational units | Oversized or non-standard trucks |

2. Corrosion Protection: Wax Spraying Protocol

Marine environments expose metal surfaces to high salinity and humidity, accelerating corrosion—especially critical for used trucks with pre-existing wear.

Industrial Wax Spraying Specification:

- Material: Solvent-based, hydrophobic corrosion inhibitor (e.g., Dinitrol AV-25, Waxoyl CR85)

- Application Method: High-pressure electrostatic spray

- Coverage Areas: Undercarriage, chassis frame, wheel wells, suspension components, exhaust system

- Coating Thickness: 25–30 µm (minimum)

- Curing Time: 4–6 hours (ambient 20–25°C)

- Protection Duration: Up to 6 months in marine transit conditions

Benefits:

- Prevents saltwater-induced pitting and galvanic corrosion

- Reduces post-arrival reconditioning costs

- Extends resale or operational lifespan

- Complies with ASTM D610/D714 standards for rust evaluation

Recommendation: Wax spraying is mandatory for all shipment types, with RO-RO and Bulk Cargo units requiring full undercarriage coverage due to direct exposure.

3. Method-Specific Risk Assessment

| Risk Factor | RO-RO | Bulk Cargo | Flat Rack |

|---|---|---|---|

| Seawater Exposure | High | Very High | Moderate |

| Mechanical Impact | Low | High | Medium |

| Weather Degradation | Moderate | High | Low |

| Theft/Vandalism | Low | Medium | Low |

| Lashing Failure | Very Low | High | Medium |

| Delay at Port | Low | Medium | Low |

4. Operational Recommendations

For Fleet Managers:

- RO-RO is optimal for fleets of 10+ operational trucks due to speed, lower handling risk, and cost efficiency per unit.

- Implement batch wax spraying pre-loading to reduce labor costs and ensure uniform protection.

For Construction Companies:

- Flat Rack preferred for articulated dump trucks, cranes, or tracked units not RO-RO compatible.

- Use desiccant humidity control inside Flat Racks in addition to wax for electrical system protection.

Avoid:

- Bulk Cargo for high-value or near-mint condition trucks due to unacceptable damage and corrosion risk.

5. Compliance & Documentation

- Export Docs (China): Commercial Invoice, Packing List, Bill of Lading, CO (Certificate of Origin)

- US Customs: ISF Filing, EPA Form 3520-1, DOT HS-7, CBP Entry

- Environmental: MSDS for wax inhibitors (non-toxic, biodegradable variants recommended)

Conclusion

For the export of used trucks from China to Columbia, SC, RO-RO shipping with industrial wax spraying offers the optimal balance of cost, speed, and asset protection for standard fleet vehicles. Flat Rack remains essential for non-standard or oversized construction equipment. Bulk Cargo is discouraged except for scrap-value units due to high degradation risk.

Implementing standardized corrosion protection protocols ensures compliance with industrial durability expectations and maximizes residual asset value upon US arrival.

SEA LION International

Industrial Logistics Engineering Division

Q2 2026 Update – Rev 3.1

Get a Quote for Used Trucks For Sale Columbia Sc

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]