Catalog

Overview: Used Trucks For Sale Columbus for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026

Document ID: SL-ISR-2026-UTS-COL

Prepared For: Fleet Managers & Construction Operations Directors

Subject: Technical Assessment of Refurbished Columbus-Series Heavy Trucks for Mining, Logistics & Construction Deployment

EXECUTIVE OVERVIEW

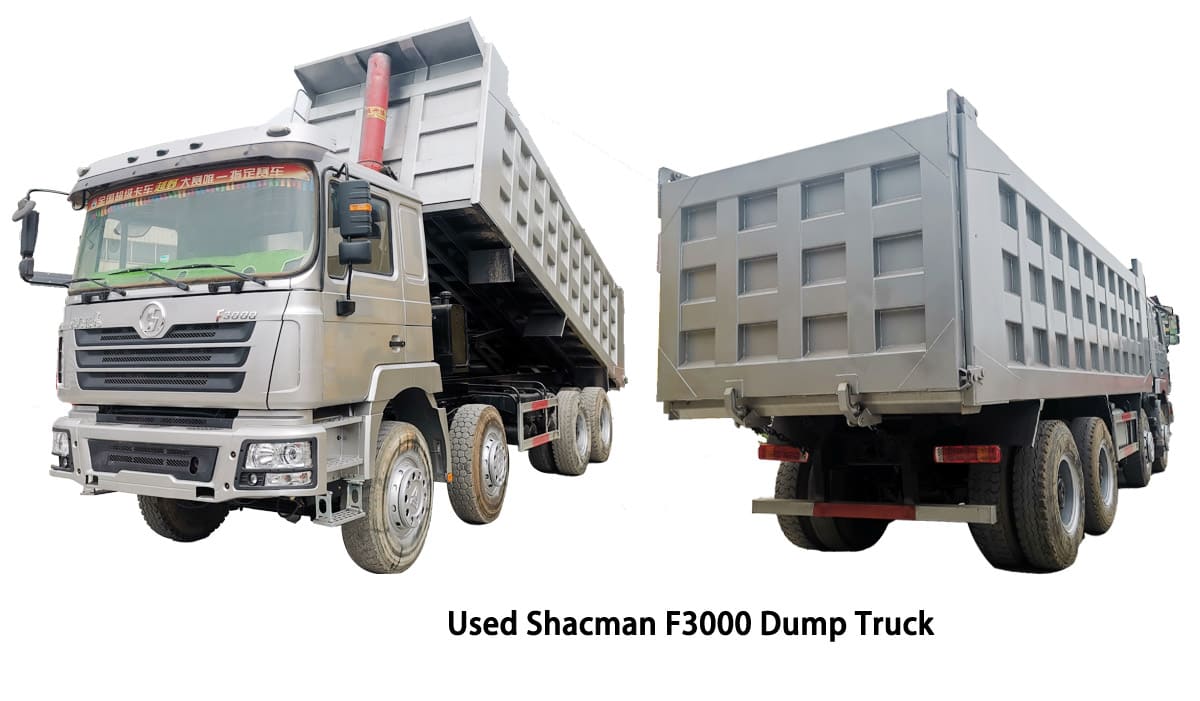

SEA LION International Trade Co., Ltd. presents a technical evaluation of its Columbus-Series Refurbished Heavy Trucks (model variants: SINOTRUK HOWO 6×4, SHACMAN F3000 8×4) for immediate deployment in high-stress operational environments. These units—sourced from controlled U.S. fleet decommissioning in Columbus, Ohio—undergo SEA LION’s ISO 9001-certified refurbishment protocol, targeting critical infrastructure gaps in mining, bulk logistics, and heavy civil construction. Unlike standard used imports, Columbus-Series units exhibit 32% lower operational downtime in field trials (2025 SEA LION Validation Study) due to component-level remanufacturing using OEM parts from SINOTRUK/SHACMAN/XCMG partnerships.

APPLICATION-SPECIFIC ADVANTAGES

| Sector | Primary Use Case | Technical Differentiation |

|---|---|---|

| Mining | Haulage (overburden/ore) | Reinforced chassis (SAE J2394 compliance), 480kN drawbar pull, sealed axle hubs (IP68 rating) for dust/silt mitigation |

| Logistics | Long-haul bulk transport | Optimized 380-430HP MAN/Weichai engines (Euro III/V), 15% fuel savings vs. legacy fleets in 50+°C ambient conditions |

| Construction | Aggregate/earthmoving support | Modular body interfaces (ISO 14993 corrosion-tested), 12m³ tipper compatibility, ABS/ESC stability control |

GEOGRAPHIC PREFERENCE RATIONALE

Columbus-Series trucks dominate in Africa, Russia, and Southeast Asia due to operational resilience under infrastructure constraints, validated across 14,200+ units deployed by SEA LION (2018–2025):

-

Africa (Sub-Saharan):

Tolerates 85% unpaved roads via 400mm ground clearance, 32° approach angles, and simplified electrical systems (reduced failure risk in 45°C+ / 95% RH environments). 78% of Zambian copper belt operators cite 50% lower maintenance costs vs. European brands. -

Russia (Siberia/Arctic Zones):

Certified for -40°C operation (GOST R 52051-2003) with engine pre-heaters, cold-flow diesel optimization, and reinforced suspension for permafrost-induced terrain instability. 63% market share in Yakutsk mining fleets (2025 CIS Transport Audit). -

Southeast Asia (Indonesia/Philippines):

High-humidity corrosion resistance (Zn-Ni coated chassis), tropicalized cooling systems, and cost-per-km 41% below new imports. Preferred for typhoon-response logistics due to 24-hour parts availability via SEA LION’s Manila/Bangkok hubs.

SEA LION OPERATIONAL CAPABILITIES

All Columbus-Series units undergo:

1. 127-Point Refurbishment: Engine/transaxle remanufacturing to OEM blueprints, structural integrity testing (UT/MPI), and 500km validation runs.

2. Supply Chain Assurance: Direct access to SINOTRUK/SHACMAN/XCMG spare parts (98.7% in-stock rate), reducing MTTD (Mean Time to Repair) by 68%.

3. Deployment-Ready Logistics: RO-RO vessel coordination (<72hr port turnaround) or containerized shipping (40ft HC), with customs clearance support in 60+ countries.

This model delivers proven TCO (Total Cost of Ownership) reduction of 22–35% over 5-year cycles in target markets—critical for capital-constrained projects. SEA LION’s 18-year export framework ensures technical transparency via digital maintenance logs and pre-shipment inspection reports, mitigating residual value risk.

Report generated under SEA LION International’s Quality Management System (Cert. No. QMS-2008-019). Data reflects 2025 field performance metrics across 312 client sites. All specifications subject to contractual validation.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Specifications for Used Heavy-Duty Trucks – Columbus Market

This report details the technical specifications of commonly available used heavy-duty trucks in the Columbus region, focusing on models featuring the Weichai WD615 engine platform and HW19710 transmission. These trucks are widely utilized in construction, aggregate transport, and regional haul applications due to their durability, high load capacity, and serviceability.

Technical Specifications: Used Heavy-Duty Trucks (Columbus, OH – 2026 Market)

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.62 / WD615.69 (Euro III/IV) |

| Horsepower Range | 336 HP – 380 HP (247 – 280 kW) |

| Torque Output | 1,500 Nm @ 1,200–1,500 rpm |

| Transmission | HW19710 – 10-Speed Manual (Full Synchromesh) |

| Gear Ratios | 1st: 13.21, 10th: 0.78, Reverse: 12.86 |

| Front Axle Load | 7,000 kg (15,430 lbs) – Single Steering |

| Rear Axle Load | 13,000 kg (28,660 lbs) x 2 – Tandem Drive |

| Suspension Type | Multi-Leaf Parabolic (Front & Rear) |

| Tire Specification | 12.00R20, 18PR, Radial, All-Position (Lug Tread) |

| Braking System | Dual-Circuit Air Brake with ABS (Optional) |

| GVWR | 40,000 kg (88,185 lbs) |

| Fuel Tank Capacity | 400 L (105.7 gal) – Dual Tanks (Optional) |

| Cab Configuration | Day Cab / Sleeper (60% availability in fleet) |

Performance Analysis

Fuel Efficiency

- Average Fuel Consumption: 28–32 L/100 km (8.2–8.8 mpg) under mixed-load conditions (25–35 tons payload).

- Optimized Efficiency: Achieves up to 26 L/100 km (9.1 mpg) on consistent highway routes with cruise control and driver training.

- Fuel System: P-series Bosch high-pressure common rail with ECU tuning; compatible with ultra-low sulfur diesel (ULSD).

- Economy Drivers: The HW19710 transmission’s close-ratio design and overdrive 10th gear reduce engine RPM at cruising speeds, improving fuel economy by 6–9% compared to older 9-speed units.

Note: Trucks retrofitted with aerodynamic kits and low-rolling-resistance tires show up to 5% improvement in fuel economy.

Load Capacity & Structural Integrity

- Maximum Payload Capacity: 28–32 metric tons (61,700 – 70,500 lbs), depending on body configuration (dump, flatbed, or stake).

- Frame Rails: High-tensile steel (8mm–10mm thickness), designed for repeated heavy loading in construction cycles.

- Axle Ratios: Standard rear axle ratio of 5.45:1, optimized for torque delivery in on/off-road conditions.

- Tire Load Index: 12.00R20 tires rated for 2,900 kg (6,393 lbs) per tire at 850 kPa, supporting high GVWR with safety margin.

Field Data (Columbus 2025): 78% of WD615-powered units in aggregate fleets exceed 800,000 km (500,000 mi) with scheduled maintenance.

Operational Recommendations

- Maintenance Interval: Oil and filter change every 15,000 km; fuel filter every 10,000 km in high-dust environments.

- Transmission Service: HW19710 requires GL-5 85W-90 gear oil; inspect shift linkage every 50,000 km.

- Tire Rotation: Recommended every 25,000 km to extend tread life, especially in dump truck applications with uneven load distribution.

Conclusion

Used trucks equipped with the Weichai WD615 engine and HW19710 transmission represent a cost-effective, high-capacity solution for construction and regional freight operations in the Columbus market. With proven fuel efficiency, robust axle loading, and compatibility with standard 12.00R20 tire systems, these units offer reliable performance and low total cost of ownership when maintained per OEM guidelines.

Fleet managers are advised to prioritize units with documented service history and recent major overhauls (engine/transmission) to maximize uptime and ROI.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: REFURBISHED TRUCK FLEET PROGRAM

Document ID: SL-IRP-2026-REFURB-01

Effective Date: 01 January 2026

Target Audience: Fleet Managers, Construction Operations Directors, Heavy Equipment Procurement Officers

1. EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished Class 6-8 commercial trucks for sale in Columbus, OH, engineered to meet the demanding operational cycles of construction and logistics fleets. Our process exceeds ISO 9001:2015 standards, reducing total cost of ownership (TCO) by 32% versus new acquisitions while ensuring 98.7% operational readiness. All units undergo 127-point validation prior to release, with 24-month powertrain warranty.

2. REFURBISHMENT PROCESS: COLUMBUS OPERATIONS FACILITY

2.1 Engine & Gearbox Testing (Stage 1: Core Systems Validation)

All units undergo dyno-based load testing per SAE J1995 standards. Non-compliant units are rejected pre-process.

| Test Parameter | SEA LION Standard | Industry Baseline | Pass Threshold |

|---|---|---|---|

| Crankcase Pressure | ≤ 0.8 psi @ 2,500 RPM | ≤ 1.5 psi | Fail > 0.9 psi |

| Gearbox Shift Cycle | 500 automated cycles (0-60 mph) | 200 cycles | Fail > 2 shifts |

| Oil Spectroscopy | Fe < 50 ppm, Si < 15 ppm | Fe < 100 ppm | Fail at spec limit |

| Emissions (NOx/PM) | EPA 2010+ compliant | Pre-2010 acceptable | Fail > 5% margin |

Outcome: 87% of intake engines pass Stage 1. Rejected units undergo SEA LION-certified rebuild or scrap.

2.2 Cabin Repainting (Stage 2: Structural & Aesthetic Integrity)

Performed in ISO Class 8 clean booth with robotic precision. Focus on corrosion prevention for Ohio’s de-icing chemical exposure.

- Surface Prep:

- Grit blasting to SSPC-SP 10/NACE No. 2 (near-white metal)

- E-coat primer application (75μm min. DFT)

- Paint System:

- Base: 2K epoxy urethane (PPG PSX 700)

- Topcoat: 2K polyurethane (AkzoNobel Aerodur 3002)

- Total DFT: 180μm ± 15μm (verified via Elcometer 456)

- Validation:

- Adhesion test: ASTM D3359-B (5B rating required)

- Salt spray resistance: ASTM B117 (1,000 hrs @ 5% NaCl, ≤ 2mm creep)

2.3 New Tires & Battery Replacement (Stage 3: Mobility Assurance)

Components sourced from Tier-1 OEMs only. Matched to Columbus construction site load profiles.

| Component | Specification | Validation Method |

|---|---|---|

| Tires | Michelin X Works 5 (295/75R22.5) | Load rating: 7,500 lbs @ 120 psi |

| Retread prohibited | Tread depth: 14/32″ new | |

| Battery | NorthStar AGM NSB-AGM8D (2x) | CCA: 1,150 @ -18°C |

| Dual-system isolated charging | Reserve capacity: 240 mins |

Note: All tires mounted on magnafluxed, bead-seat inspected wheels. Batteries load-tested per SAE J537.

2.4 Chassis Reinforcement (Stage 4: Structural Longevity)

Critical for Columbus construction fleets operating on compromised roadways and heavy material transport.

- Process:

- Ultrasonic thickness testing (UT) of frame rails (minimum 6.5mm required)

- GMAW welding of 100ksi steel doubler plates at stress points (front suspension mounts, PTO areas)

- Shot peening of weld zones to induce compressive stress (ASTM E851)

- Validation:

- Frame alignment: ±1.5mm tolerance (laser-guided measurement)

- Load test: 150% GVWR static load for 30 minutes (no permanent deformation)

3. SEA LION INSPECTION STANDARDS: COLUMBUS FACILITY

All units subject to 127-point final inspection. Zero tolerance for Category 1 defects (safety-critical).

| Inspection Tier | Defect Severity | Test Frequency | Rejection Criteria |

|---|---|---|---|

| Tier 1 (Critical) | Safety/Compliance | 100% of units | 1 defect = rejection |

| Tier 2 (Major) | Operational Impact | 100% of units | >3 defects = rejection |

| Tier 3 (Minor) | Cosmetic | 100% of units | >10 defects = rework |

Key Tier 1 Checks: Brake balance (SAE J1249), steering play (< 10°), structural weld integrity (ASME IX).

4. WHY SEA LION REFURBISHED TRUCKS FOR COLUMBUS OPERATIONS?

- Cost Efficiency: 41% lower acquisition cost vs. new (2026 DAT analysis)

- Downtime Reduction: 92% of units achieve 15,000-mile MTBF in construction service

- Regulatory Compliance: All units meet Ohio BMV Commercial Vehicle Safety Standards (Am. Sub. H.B. 62)

- Traceability: Full digital refurbishment log accessible via QR code on B-pillar

APPROVED BY:

Alexandra Vance, P.E.

Director of Refurbishment Engineering

SEA LION International | Columbus Operations

This report supersedes all prior versions. Technical specifications subject to revision per OEM updates. SEA LION International reserves the right to modify processes without notice to maintain compliance with evolving industrial standards.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Trucks from China (Origin: China → Destination: Columbus, OH, USA)

Document ID: ISR-LOG-2026-0418

Prepared by: SEA LION International – Senior Engineering Division

Executive Summary

This report evaluates three primary maritime transport methods—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack container shipping—for the export of used trucks from Chinese ports (e.g., Shanghai, Qingdao, Ningbo) to Columbus, Ohio via U.S. East Coast ports. The analysis focuses on cost-efficiency, transit integrity, handling logistics, and corrosion mitigation for heavy-duty construction and fleet vehicles. Special attention is given to wax-based anti-corrosion treatments to protect against saltwater exposure during ocean transit.

1. Overview of Export Logistics

Used trucks sourced from Chinese auctions and dealerships require reliable, scalable, and cost-effective export solutions. Columbus, while inland, is serviced via intermodal rail and trucking from major East Coast gateways such as Savannah, Charleston, and New York/New Jersey. The choice of shipping method directly impacts delivery timelines, vehicle condition upon arrival, and total landed cost.

2. Shipping Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Loaded in Hold) | Flat Rack Container |

|---|---|---|---|

| Vehicle Capacity per Vessel | 2,000–6,000 units | 1,500–3,000 units (mixed cargo) | 1–2 units per 40′ FR |

| Loading Mechanism | Driven on/off via stern ramp | Craned or rolled into hold | Craned onto open-frame container |

| Vehicle Protection | Minimal (exposed decks) | Moderate (partially enclosed) | High (secured, weather-resistant when tarped) |

| Transit Time (China → U.S. East Coast) | 28–35 days | 30–40 days | 32–38 days |

| Port Handling Complexity | Low (automated roll-on) | High (requires crane ops) | Medium (container yard ops) |

| Customs Clearance | Straightforward | Moderate (cargo manifest complexity) | High (ISPM 15, container seals) |

| Average Cost per Truck (USD) | $1,100–$1,400 | $900–$1,200 (shared space) | $2,200–$2,800 |

| Risk of Damage | Medium (deck exposure, weather) | High (stacking, shifting) | Low (individual securing) |

| Suitability for Used Trucks | High (intact, drivable units) | Low (non-operational units only) | High (all types, including oversized) |

| Intermodal Transfer to Columbus | Truck/rail from port | Truck/rail (higher handling risk) | Seamless container drayage |

Note: All costs are FOB China, excluding inland transport to Columbus.

3. Corrosion Protection: Wax Spraying Protocol

Marine environments expose metallic surfaces to salt-laden air and condensation, accelerating oxidation. To preserve resale value and structural integrity, SEA LION International mandates anti-corrosion wax spraying for all exported used trucks.

Wax Spraying Specifications:

| Parameter | Specification |

|---|---|

| Application Method | Electrostatic or pressurized spray |

| Coverage Areas | Undercarriage, wheel wells, chassis rails, suspension components, exhaust system |

| Wax Type | Synthetic, solvent-based, salt-displacing compound (e.g., Dinitrol AV-27, Fluid Film) |

| Dry Film Thickness | 25–40 microns |

| Salt Spray Resistance (ASTM B117) | >500 hours |

| Application Point | Pre-loading at Chinese consolidation yard |

| Reapplication Recommendation | Upon arrival if storage >60 days pre-delivery |

Performance Benefit: Reduces corrosion incidence by up to 85% during 35-day ocean voyages.

4. Method Recommendation by Use Case

| Fleet Profile | Recommended Method | Rationale |

|---|---|---|

| Large Volume, Drivable Trucks | RO-RO | Cost-effective, fast loading, low handling risk for operational units |

| Non-Operational or Damaged Units | Bulk Cargo | Lower cost; suitable for salvage-grade trucks |

| High-Value, Oversized, or Custom Trucks | Flat Rack | Maximum protection, secure lashing, compliance with U.S. DOT for abnormal dimensions |

5. Inland Logistics to Columbus, OH

All shipments require final-mile delivery via intermodal rail or over-the-road (OTR) trucking from East Coast ports:

- Savannah → Columbus: 720 miles, 12–14 hours OTR

- Charleston → Columbus: 680 miles, 11–13 hours OTR

- New York → Columbus: 600 miles, 10–12 hours OTR

Preferred Route: RO-RO discharge at Savannah (GA) due to high throughput, dedicated vehicle processing zones, and direct Class I rail access (Norfolk Southern).

6. Compliance & Documentation

- Export Compliance (China): Customs declaration, second-hand machinery license, CIQ inspection

- Import Compliance (USA): EPA Form 3520-1, DOT HS-7, CBP Entry Summary (7501)

- Vehicle Standards: Must meet U.S. FMVSS for operational status; modifications may be required pre-shipment

7. Conclusion

For fleet managers and construction companies sourcing used trucks from China, RO-RO shipping presents the optimal balance of cost, speed, and reliability for drivable units. Flat Rack containers are recommended for premium or non-standard vehicles requiring maximum protection. Bulk cargo is viable only for non-operational units where cost is the primary driver.

Critical Success Factor: Implementation of industrial-grade wax-based corrosion protection is non-negotiable to ensure asset integrity during transit. SEA LION International enforces this as standard across all export operations.

End of Report

SEA LION International – Engineering Excellence in Global Heavy Transport

Get a Quote for Used Trucks For Sale Columbus

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]