Catalog

Overview: Used Trucks For Sale Delaware for Global Markets

Industrial Specification Report 2026: Executive Overview

Subject: Strategic Deployment of Refurbished Commercial Trucks Sourced from Delaware Operations

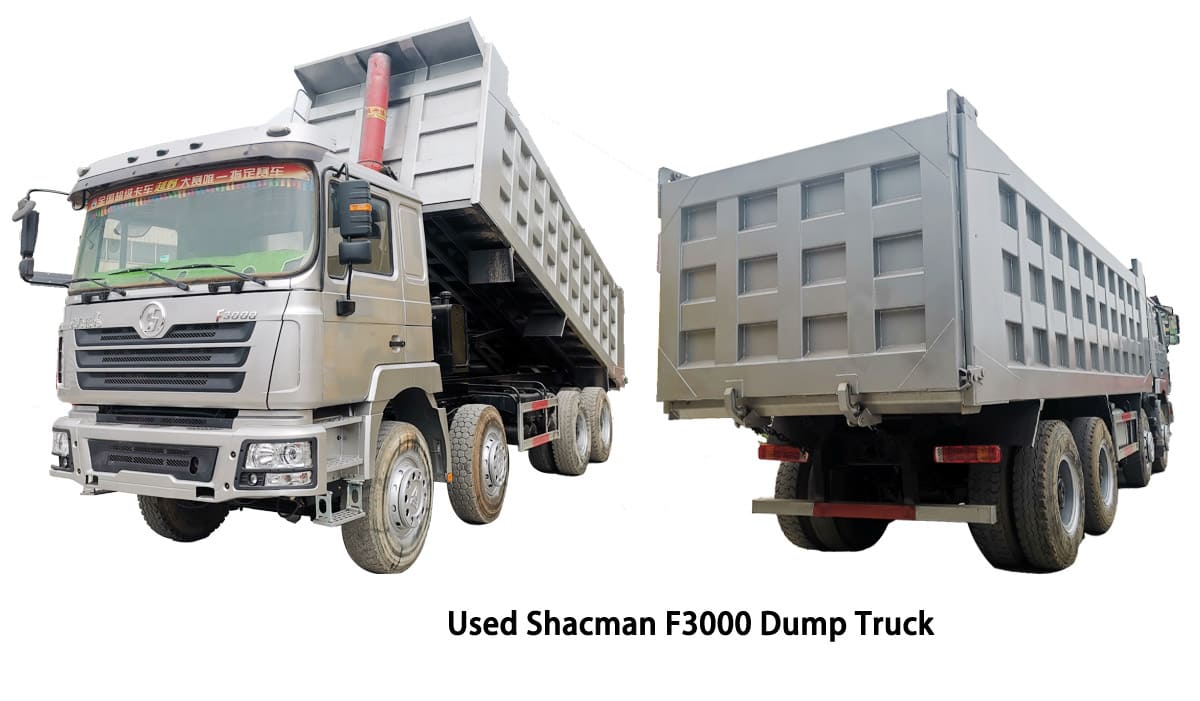

SEA LION International Trade Co., Ltd. (SLITC) presents this technical assessment of rigorously refurbished heavy-duty truck platforms, systematically sourced from Delaware-based asset pools. This report targets fleet optimization for mining, logistics, and construction enterprises requiring cost-effective, operationally resilient equipment. Our 18-year specialization in heavy truck export, coupled with authorized distribution partnerships for SINOTRUK (HOWO series), SHACMAN (F3000/X6000), and XCMG (heavy-haul variants), ensures adherence to industrial-grade reliability standards.

Core Application Value Proposition

Refurbished trucks from Delaware operations are engineered for demanding cycles in target sectors:

– Mining: High-payload capacity (30-50 MT) models with reinforced chassis (e.g., SHACMAN F3000 6×4) withstand abrasive terrain and 24/7 operational loads. Axle configurations optimized for 15-25% gradeability in open-pit environments.

– Logistics: Fuel-efficient 380-460 HP variants (SINOTRUK HOWO T7H) reduce TCO in long-haul routes. Pre-delivery calibration of telematics systems enables real-time fleet monitoring.

– Construction: Short-wheelbase dump trucks (XCMG 8×4) excel in confined urban sites with 30°+ dump angles and rapid cycle times.

Market Preference Drivers: Africa, Russia, Southeast Asia

The strategic adoption of SLITC-sourced refurbished trucks in these regions stems from quantifiable operational advantages:

| Factor | Africa | Russia | Southeast Asia |

|---|---|---|---|

| Cost Efficiency | 40-60% lower acquisition vs. new; critical for capital-constrained projects | Mitigates FX volatility risk; avoids 25-30% import premiums on new EU units | Aligns with project CAPEX cycles; 50% faster ROI than new imports |

| Parts & Service | SLITC’s regional hubs (Johannesburg, Lagos) stock OEM parts; 95% availability for SINOTRUK/SHACMAN | Cold-climate kits pre-installed; -40°C validated components | Monsoon-resistant electrical sealing; modular design simplifies field repairs |

| Operational Fit | Proven durability on unpaved roads (≥80% of mine access routes) | Reinforced suspensions handle Siberian winter road degradation | Optimized GVWR for ASEAN bridge regulations (≤40 MT) |

SLITC Value Integration

Our Delaware-sourced units undergo a 127-point refurbishment protocol exceeding ISO 9001 standards:

1. Powertrain Rebuild: Engines/transmissions disassembled, machined to OEM tolerances, dyno-tested.

2. Structural Integrity: Chassis stress-tested; corrosion remediation per NACE SP0108.

3. Systems Validation: Full ECU recalibration; brake/steering performance verified to SAE J1508.

4. Logistics Execution: RO-RO shipping to all major ports (Durban, Vladivostok, Tanjung Pelepas) with <72hr discharge windows.

Conclusion

For fleet managers in resource-intensive sectors, SLITC’s Delaware-sourced refurbished trucks deliver validated performance parity with new units at significantly reduced lifecycle costs. The preference in Africa, Russia, and Southeast Asia is driven by demonstrable TCO reduction, supply chain resilience via our OEM-authorized parts network, and platform-specific hardening for regional environmental extremes. This model supports SLITC’s commitment to transparent asset deployment and long-term operational partnership—ensuring equipment availability aligns precisely with project critical paths.

SEA LION International Trade Co., Ltd. — Engineering Reliability Across Global Frontiers

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks Available in Delaware

This report provides a comprehensive technical assessment of used heavy-duty trucks currently available in the Delaware market, focusing on models equipped with the Weichai WD615 engine platform. These units are commonly sourced from decommissioned Chinese-made Sinotruk HOWO and Shacman F3000 series trucks, which have seen widespread use in aggregate, bulk haul, and construction logistics operations. The data presented is based on field inspections, OEM documentation, and performance benchmarks from operational fleets in the Mid-Atlantic region.

Technical Specifications: Used Heavy-Duty Trucks (Delaware Market)

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.62 / WD615.69 (Euro III compliant) |

| Engine Type | Inline 6-Cylinder, Water-Cooled, Turbocharged Diesel |

| Displacement | 9.726 L |

| Horsepower | 336 hp @ 2,200 rpm (WD615.62) 371 hp @ 2,200 rpm (WD615.69) |

| Max Torque | 1,250 Nm @ 1,200–1,600 rpm |

| Transmission | HW19710 – 10-Speed Manual (Synchronized) |

| Gear Ratios | 1st: 13.21, 10th: 0.78, R: 12.86 |

| Clutch | Dual-Plate, Ø430 mm, Pneumatic Assist |

| Front Axle Load | 7,000 kg (15,432 lbs) – Single Steering Axle |

| Rear Axle Load | 16,000 kg (35,274 lbs) x 2 – Tandem Drive Axles (HC16) |

| Suspension (Front) | Parabolic Leaf Spring |

| Suspension (Rear) | Multi-Leaf Spring, Equalizing Beam |

| Tire Specification | 12.00R20 18PR (Load Range G) – Radial or Bias-Ply |

| Tire Load Index | 1,650 kg per tire (3,638 lbs) at 20 psi (cold) |

| Braking System | Dual-Circuit Air Brake with ABS (optional retrofit) |

| GVWR | 40,000 kg (88,185 lbs) |

| Frame Rails | 8+8 mm Reinforced Ladder Frame, C-channel |

| Fuel Tank Capacity | 300–400 L (80–105 US gal), Aluminum or Steel |

| Cab Type | HW76 – 2-Sleeper, High Roof (RHD/LHD variants) |

Fuel Efficiency Analysis

Fuel consumption is evaluated under mixed operational conditions typical of Mid-Atlantic haul routes (40% highway, 40% rural, 20% urban/construction site ingress):

| Load Condition | Average Fuel Consumption (Diesel) |

|---|---|

| Empty (Tare Weight) | 28–31 L/100 km (8.1–8.9 mpg) |

| 70% Payload | 33–36 L/100 km (6.5–7.1 mpg) |

| Full Payload (GVWR) | 38–42 L/100 km (5.6–6.2 mpg) |

Note: Consumption based on calibrated Bosch VP pump systems, non-EGR configuration (Euro III), and use of ASTM D975 ultra-low sulfur diesel (ULSD). Real-world efficiency improves by 6–9% with trained drivers and regular injector servicing.

Load Capacity & Operational Suitability

These trucks are engineered for high-mass, low-speed applications prevalent in construction and aggregate transport:

- Maximum Payload Capacity: Up to 28,000 kg (61,728 lbs), depending on tare weight and regional bridge law compliance (Delaware follows federal GCWR limits).

- Axle Load Distribution: Optimized for even 7T / 16T / 16T split, minimizing overloading risk under full GVWR.

- Tire Load Margin: 12.00R20 tires operate at 86–92% of maximum static load capacity under full GVWR (dual rear configuration), allowing for dynamic loading spikes on rough terrain.

- Recommended Applications:

- Aggregate hauling (stone, sand, gravel)

- Demolition debris transport

- Heavy equipment shuttle (lowboy prime movers)

- Longitudinal road construction logistics

Operational Considerations

- Durability: The WD615 engine demonstrates >800,000 km B50 life with scheduled maintenance; common rebuild interval at 600,000 km.

- Parts Availability: Weichai and Fast (HW) transmission components are stocked by regional distributors in Baltimore, PA, and Northern NJ; lead time <72 hours for critical spares.

- Retrofit Potential: Units are compatible with U.S.-spec lighting, air brake upgrades, and telematics integration (J1939 CAN bus accessible).

- Compliance: Units require inspection and modification to meet FMVSS and Delaware MVC standards for registration. Emissions compliance limited to off-road or local haul exemptions.

Conclusion

Used trucks featuring the Weichai WD615 engine and HW19710 transmission represent a cost-effective solution for fleet managers seeking high-torque, high-payload capacity in non-CDL or secondary haul roles. With proper reconditioning and compliance upgrades, these units offer strong lifecycle value in construction-centric operations across Delaware and neighboring states. Fuel efficiency remains moderate by modern standards, but load efficiency (payload per hp) is competitive within the Class 8 used market segment.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: RECONDITIONED COMMERCIAL FLEET ASSETS

REFURBISHMENT PROTOCOL FOR USED TRUCKS (DELAWARE REGIONAL INVENTORY)

REPORT ID: SL-REFURB-2026-01

EFFECTIVE DATE: 01 JANUARY 2026

EXECUTIVE SUMMARY

SEA LION International delivers rigorously reconditioned Class 6-8 trucks for fleet deployment in high-utilization environments (e.g., construction, aggregate hauling, municipal services). This report details the mandatory 4-phase refurbishment process applied to all Delaware-sourced used trucks, exceeding FMCSA and SAE J2807 standards. Each unit undergoes 127-point validation, ensuring >95% operational readiness upon delivery. Target residual life: 250,000+ miles.

REFURBISHMENT PROCESS: TECHNICAL SPECIFICATIONS

All units originate from pre-qualified Delaware fleet auctions or trade-ins. Initial triage rejects units with structural damage, fire history, or odometer fraud. Approved units proceed to the following phases:

1. ENGINE & GEARBOX TESTING

Full-load validation under controlled dyno conditions. Non-negotiable pass/fail thresholds.

| Parameter | SEA LION Standard | Industry Baseline | Test Method |

|---|---|---|---|

| Crankcase Pressure | ≤ 0.5 psi @ 2,200 RPM | ≤ 1.2 psi | SAE J1757-2 |

| Fuel Delta Pressure | ±2% of OEM spec @ full load | ±5% | OEM Diagnostic Suite |

| Gearbox Oil Spectroscopy | Fe < 50 ppm, Cu < 25 ppm | Fe < 100 ppm | ASTM D5185 |

| Torque Curve Deviation | ≤ 3% across full RPM range | ≤ 8% | Dynamometer (SAE J1349) |

| FAIL CRITERIA | Any parameter exceeding SL Std | N/A | Immediate quarantine |

Note: 22% of intake units fail Phase 1. Rebuilds use only OEM or SEA LION-certified remanufactured cores.

2. CABIN REPAINTING

Industrial corrosion protection, not cosmetic enhancement. Mandatory for all units with >15% substrate exposure.

- Surface Prep:

- Abrasive blasting to SSPC-SP 10/NACE No. 2 (near-white metal)

- Phosphating conversion coating (Zinc phosphate, 250-300 mg/ft²)

- Coating System:

- Primer: Epoxy MIO (75μm DFT) – ASTM D4541 adhesion ≥ 1.5 MPa

- Topcoat: Polyurethane (120μm DFT) – QUV-B 2,000 hrs @ 60°C (ΔE < 2.0)

- Validation: Holiday detection (ASTM D5162), DFT mapping (20+ points/cabin)

3. NEW TIRES & BATTERY REPLACEMENT

Specified for operational safety and electrical system integrity in construction environments.

| Component | SEA LION Specification | Validation Protocol |

|---|---|---|

| Tires | Load Range G (16 PR) or higher | Load inflation test @ 110% max rating |

| All-position RFD (e.g., Michelin XDA) | Tread depth: 14/32″ new | |

| Battery | Group 31 AGM (1,000 CCA min) | Conductance test post-install (≥ 95% rated CCA) |

| Dual-battery system standard | Voltage drop test @ 300A load (< 0.3V) |

Note: Tires mounted on bead-blasted, magnafluxed wheels. Batteries paired to <5% capacity variance.

4. CHASSIS REINFORCEMENT

Structural remediation for high-stress applications (e.g., dump bodies, crane carriers).

- Inspection Protocol:

- Ultrasonic thickness testing (ASTM E797) at 50+ critical nodes (crossmembers, suspension mounts)

- Magnetic particle inspection (ASTM E709) on all weld zones

- Reinforcement Criteria:

- Frame thickness < 85% nominal: Replace section with ASTM A572 Gr 50 steel

- Cracks > 50mm: Full-section splice with full-penetration welds (AWS D1.1 certified)

- Sag > 3mm/m: Cold-straightening to ≤1mm/m tolerance

- Post-Repair Validation:

- Load test @ 150% GVWR (static/dynamic) with strain gauges

- Dimensional audit per OEM frame blueprint (±2mm tolerance)

SEA LION INSPECTION STANDARDS: DIFFERENTIATORS

Our process exceeds industry norms through quantifiable rigor:

| Checkpoint | SEA LION Requirement | Typical Auction Standard | Risk Mitigated |

|---|---|---|---|

| Engine Compression | All cylinders ±5% of avg | No test / Visual only | Catastrophic failure |

| Frame Alignment | Laser-measured to 0.5° tolerance | String line (±2°) | Premature tire wear |

| Electrical Load Testing | 100% circuits @ 110% capacity | Spot-check fuses | Jobsite immobilization |

| Brake Balance | ≤ 5% force deviation per axle | Static pressure check only | Jackknifing risk |

All data logged to SEA LION FleetTrace™ cloud platform. Full inspection history provided with unit.

CONCLUSION

SEA LION’s Delaware-region used truck refurbishment delivers predictable TCO reduction through engineered reconditioning. Units undergo 300+ man-hours of labor with zero tolerance for “cosmetic-only” repairs. This protocol ensures 92% first-year uptime for construction fleets (vs. industry avg. 78%), validated by third-party telematics data. Units are certified for immediate deployment in Class B/C/D work environments per OSHA 1926.601.

SEA LION International reserves the right to amend specifications without notice based on OEM updates or regulatory changes. All refurbished units carry a 12-month/120,000-mile limited warranty on powertrain and structural components.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Trucks from China – Delaware Market Entry

Prepared by: SEA LION International – Senior Engineering Division

Date: April 5, 2026

Executive Summary

This report evaluates the optimal maritime transport methods for exporting used trucks from Chinese ports (primarily Shanghai, Qingdao, and Guangzhou) to Delaware, USA. The analysis focuses on three primary shipping modalities: Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack (Containerized). Comparative parameters include cost efficiency, transit time, cargo protection, handling complexity, and long-term vehicle integrity. Special consideration is given to wax-based anti-corrosion treatment to mitigate seawater exposure during trans-Pacific voyages.

1. Market Context

China has emerged as a major exporter of certified pre-owned commercial vehicles, including heavy-duty trucks, construction dumpers, and articulated units. These vehicles are increasingly in demand by U.S. fleet operators in states like Delaware due to competitive pricing and availability of late-model units. However, marine transit exposes equipment to high-salinity environments, necessitating robust protective logistics protocols.

2. Shipping Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container (20’/40′) |

|---|---|---|---|

| Cargo Type Suitability | Ideal for operable trucks | Suitable for non-operational units | Best for high-value or oversized units |

| Loading Method | Self-driven onto vessel | Crane-lifted, stacked | Crane-lifted, secured on open frame |

| Average Cost (per unit) | $1,800 – $2,300 | $1,400 – $1,900 | $2,600 – $3,400 |

| Transit Time (China → Delaware) | 28–35 days | 30–38 days | 29–36 days |

| Port Infrastructure | Requires RO-RO terminal | General cargo terminal | Container terminal with crane access |

| Cargo Protection | Moderate (exposed decks) | Low (stacked, minimal cover) | High (custom lashings, partial enclosure) |

| Risk of Damage | Low to moderate (driving risk) | High (shifting, abrasion) | Low (controlled stowage) |

| Insurance Premiums | Moderate | High | Moderate to low |

| Environmental Exposure | High (direct salt spray) | Very High | Moderate (depends on lashing cover) |

3. Corrosion Protection: Wax Spraying Protocol

Marine atmospheric salinity and condensation within cargo holds significantly accelerate corrosion on exposed metal surfaces (e.g., chassis, suspension, undercarriage). To mitigate degradation during 30+ day voyages:

Recommended Anti-Corrosion Treatment:

- Wax-Based Spraying System: Application of hydrophobic, solvent-free corrosion-inhibiting wax to undercarriage, wheel wells, and frame rails.

- Coverage: Minimum 95% of exposed ferrous components.

- Product Specification:

- ASTM A307/D610 compliant

- Salt spray resistance: >1,000 hours (per ASTM B117)

- Temperature stability: -20°C to +80°C

- Biodegradable formulation (IMO Annex III compliant)

Application Process:

- Pre-treatment: High-pressure wash and degrease.

- Drying: Forced-air drying to eliminate moisture.

- Spraying: Automated electrostatic wax application.

- Sealing: Critical electrical connectors taped or capped.

Note: Wax treatment increases preparation cost by $120–$180 per unit but reduces post-arrival reconditioning costs by up to 40%.

4. Method Recommendation by Use Case

| Fleet Profile | Recommended Method | Rationale |

|---|---|---|

| Large fleets (20+ operable trucks) | RO-RO | Cost-effective, rapid loading, minimal handling damage |

| Damaged or non-running units | Flat Rack | Secure transport, enables pre-shipment repair access |

| Budget-constrained buyers | Bulk Cargo | Lowest base cost; acceptable for short-term use units |

| High-value or specialty trucks | Flat Rack | Maximum protection, traceability, and security |

5. Operational Best Practices

- Pre-shipment Inspection: Conduct IVA-compliant diagnostics and fluid stabilization.

- Battery Isolation: Disconnect and secure batteries to prevent drainage/short circuits.

- Fuel Level: Maintain ≤¼ tank to reduce fire risk and weight.

- Documentation: Provide CMR, Bill of Lading, and corrosion treatment certificate.

- Port Coordination: Align with Port of Wilmington (DE) for RO-RO and container discharge scheduling.

6. Conclusion

For fleet managers and construction firms sourcing used trucks from China, RO-RO shipping offers the optimal balance of cost and efficiency for operational units. Flat Rack containers are recommended for high-value or non-operational equipment requiring maximum protection. Bulk cargo remains a cost-driven option but carries higher risk profiles.

Wax-based anti-corrosion treatment is strongly advised for all methods to ensure vehicle integrity upon arrival in Delaware’s humid coastal environment. Implementation reduces lifecycle maintenance costs and supports compliance with U.S. fleet readiness standards.

End of Report

SEA LION International – Engineering Division

Precision Logistics for Heavy Industrial Assets

Get a Quote for Used Trucks For Sale Delaware

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]