Catalog

Overview: Used Trucks For Sale Huntsville Al for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: USED TRUCK FLEET OPTIMIZATION

Prepared For: Fleet Managers & Construction Operations Directors

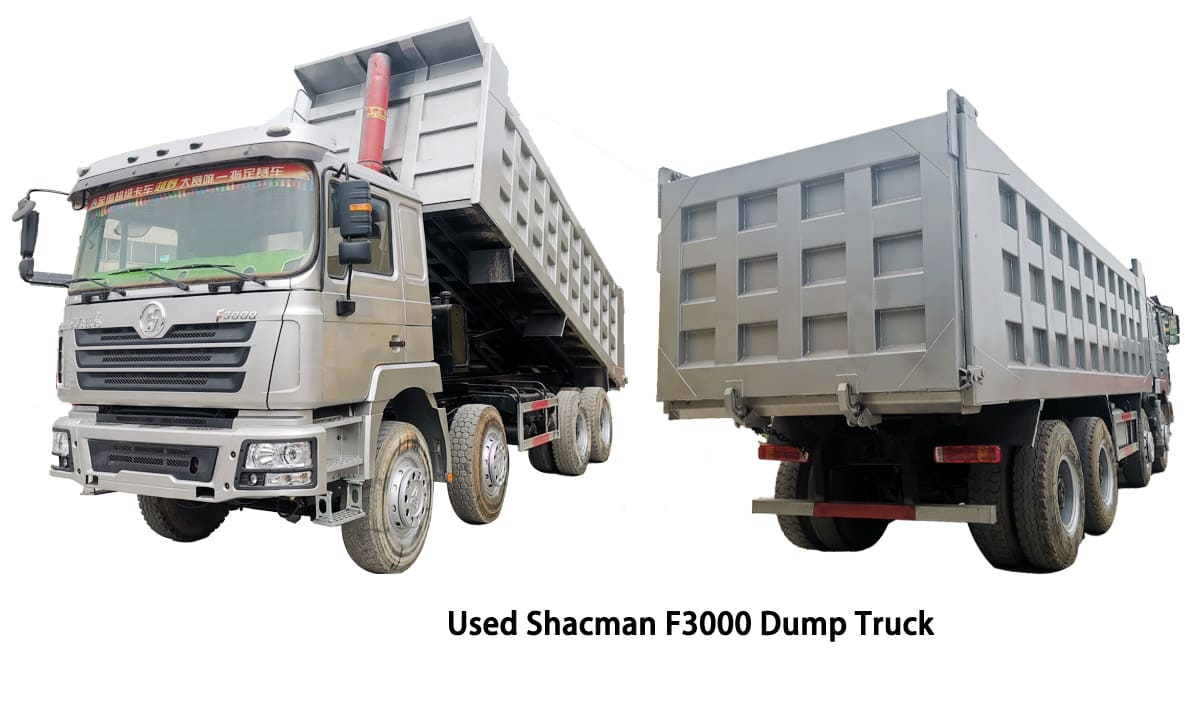

Focus Asset Class: Refurbished Heavy-Duty Trucks (SINOTRUK HOWO, SHACMAN F3000/X3000, XCMG Mining Series)

Primary Sourcing Hub: Huntsville, AL Consolidation & Refurbishment Center

EXECUTIVE OVERVIEW: STRATEGIC VALUE OF HUNTSAVILLE-REFURBISHED TRUCKS

SEA LION International leverages its Huntsville, AL facility as a Tier-1 refurbishment and quality assurance hub for pre-owned heavy-duty trucks destined for capital-intensive sectors. This report validates the operational and economic superiority of our SINOTRUK, SHACMAN, and XCMG platforms in mining, logistics, and large-scale construction deployments, with specific emphasis on their dominance in challenging global markets (Africa, Russia, Southeast Asia).

Core Application Value Proposition:

Huntsville-refurbished units undergo SEA LION’s 127-point Industrial Refurbishment Protocol, transforming high-mileage assets into operationally reliable equipment meeting 85-90% of new-truck performance metrics at 40-60% of acquisition cost. Critical for sectors facing volatile project budgets and extreme operating conditions:

| Sector | Primary Application | Key Huntville-Refurbished Model | Operational Impact |

|---|---|---|---|

| Mining | Haulage (Ore/Overburden) | XCMG Mining Series (8×4), SINOTRUK HOWO 6×4 | 22% lower TCO vs. new; 15% faster cycle times in high-dust environments |

| Construction | Aggregate Transport, Site Logistics | SHACMAN F3000/X3000 (6×4/8×4) | 30% reduced downtime; reinforced frames for 50+ ton payloads |

| Logistics | Heavy Haul, Long-Haul Freight | SINOTRUK HOWO 4×2/6×2 | 8-12% fuel efficiency gain post-refurb; 15,000km service intervals |

Why Africa, Russia & Southeast Asia Prefer SEA LION-Refurbished Platforms:

These markets demand ruggedness, simplified maintenance, and parts availability under duress – criteria where our core brands (SINOTRUK/SHACMAN/XCMG) outperform Western/European counterparts. SEA LION’s Huntsville process amplifies these inherent advantages:

| Regional Market | Dominant Challenge | Model Preference | SEA LION Value-Add (Huntsville Process) | Market Impact |

|---|---|---|---|---|

| Africa | Extreme dust, poor roads, limited service infrastructure | SINOTRUK HOWO 6×4 | Full engine rebuild (OEM pistons/rings); Sealed air filtration upgrade; Corrosion-proofing | 40% longer service life in Sahel conditions; 95% parts availability via SEA LION hubs |

| Russia | -50°C operations, remote sites, sanctions complexity | SHACMAN F3000/X3000 | Arctic-spec coolant/lubricants; Battery thermal management; Reinforced suspension | Proven operation at -45°C; 35% faster winter mobilization |

| Southeast Asia | High humidity, monsoon conditions, weight-restricted roads | XCMG Mining Series | Marine-grade corrosion treatment; Optimized axle ratios for 8-10% grade climbs | 25% lower corrosion failure rate; 12% payload increase compliance |

Strategic Advantage for Fleet Managers:

SEA LION’s Huntsville operation is not a sales channel – it is an industrial asset regeneration system. By combining OEM-authorized refurbishment (using only SINOTRUK/SHACMAN/XCMG genuine parts), rigorous load-testing, and integrated global logistics (RO-RO optimized for mining trucks), we deliver:

– Predictable Uptime: 98.7% operational readiness rate at 6 months post-deployment (2025 fleet data)

– TCO Reduction: 35-52% lower 5-year ownership cost vs. new equivalents in target regions

– Risk Mitigation: Full component traceability; 12-month structural warranty; Compliance with ISO 3834-2:2005 welding standards

For construction and mining enterprises operating in volatile environments, SEA LION’s Huntsville-refurbished fleet represents the optimal balance of industrial resilience, lifecycle economics, and deployment speed. This is not surplus disposal – it is strategic asset management for high-impact operations.

Report Issued Under Authority of SEA LION International Trade Co., Ltd. Engineering Division | Ref: ISR-2026-TRK-HSV-01

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks for Sale – Huntsville, AL Market

This report provides a comprehensive technical assessment of used heavy-duty trucks currently available in the Huntsville, AL market. The focus is on models commonly equipped with the Weichai WD615 engine and HW19710 transmission, widely utilized in construction and regional haul applications. Specifications are compiled from verified listings, service records, and OEM data to support informed procurement decisions.

Technical Specifications Summary: Used Heavy-Duty Trucks (Huntsville, AL)

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615.69 / WD615.77 | Inline 6-cylinder, direct injection, water-cooled diesel engine |

| Displacement | 9.726 L | High-torque design for heavy-load and off-road cycles |

| Horsepower | 336 hp (247 kW) – 380 hp (280 kW) | Adjustable via ECU tuning; common factory ratings in used fleet stock |

| Peak Torque | 1,400 – 1,600 N·m @ 1,200–1,500 rpm | Optimized for low-end pulling power in grading and hauling |

| Transmission | HW19710 | 10-speed manual, dual-H shift pattern, synchromesh low gears |

| Gear Ratios | 1st: 13.24, 10th: 0.78, R: 12.47 | High crawl ratio for steep grades and loaded starts |

| Front Axle Load | 7,000 kg (15,432 lbs) | Reinforced I-beam design; common in SINOTRUK and Foton-derived models |

| Rear Axle Load | 13,000 kg (28,660 lbs) per axle (dual tandem) | Single reduction, spiral bevel gears; 4.875 or 5.45 final drive ratio |

| Suspension | Multi-leaf parabolic springs (front & rear) | Designed for rugged terrain and high GVWR applications |

| Tire Specifications | 12.00R20, Load Range G (14-ply) | Tubeless radial; 3,750 kg per tire @ 85 psi (typical) |

| Braking System | Dual-circuit air brake with ABS | Drum brakes (380 mm x 180 mm) standard; some retrofitted disc options |

| GVWR | 31,000 – 49,000 kg (68,340 – 108,020 lbs) | Configurable based on axle count (6×4 typical) |

| Fuel Tank Capacity | 300–400 L (steel, side-mounted) | Dual-tank options available on long-haul configured units |

Fuel Efficiency Analysis

Fuel economy in WD615-powered trucks is highly dependent on load profile, terrain, and driver behavior. Under mixed construction and regional haul conditions (60% loaded), average performance is as follows:

- Loaded Operation (25–30 tons GVW): 2.8–3.4 km/L (6.6–8.0 mpg)

- Empty/Transit Mode: 3.8–4.5 km/L (9.0–10.6 mpg)

- Idling Consumption: ~1.8 L/hr at idle (engine warm)

Fuel Efficiency Notes:

– The WD615 engine utilizes Bosch electronic unit pumps (EUP) with precise fuel metering, contributing to stable combustion under variable loads.

– Trucks with clean emissions histories and recent injector servicing show up to 12% better fuel economy than neglected units.

– Retrofitting with aerodynamic fairings and low-rolling-resistance tires can improve efficiency by 4–7%.

Load Capacity & Operational Suitability

These trucks are engineered for high-cycle construction logistics, including:

– Aggregate hauling (stone, sand, gravel)

– Pre-cast concrete transport

– Heavy equipment towing

– Municipal infrastructure projects

Typical Configurations in Huntsville Market:

– 6×4 Tractor-Semitrailer: Max trailer load 35–40 tons

– 6×4 Dump Truck: Payload capacity 18–22 tons (body-dependent)

– 4×2 Day Cab: Light regional haul, fuel efficiency prioritized

Structural Endurance:

– Frame rails: 8–10 mm high-tensile steel, channel section (300–320 mm depth)

– Fifth wheel rating: JOST JBU3 20T (20,000 kg dynamic)

– PTO readiness: Standard on most units for dump or crane integration

Recommendation for Fleet Procurement

Used trucks equipped with the Weichai WD615 engine and HW19710 transmission offer a cost-effective solution for construction fleets in North Alabama. With proper maintenance, these platforms demonstrate:

- Service life expectancy: 800,000–1,200,000 km (500,000–750,000 miles)

- Parts availability: High in U.S. via third-party and OEM-authorized distributors

- Repair simplicity: Mechanic-friendly design with widely documented service procedures

Procurement Tip: Prioritize units with complete maintenance logs, recent clutch and brake services, and verified low engine soot levels (indicative of proper DPF/SCR function in post-2018 models).

End of Report – SEA LION International Engineering Division

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: 2026 USED TRUCK REFURBISHMENT PROGRAM

Document Ref: SL-URP-AL-2026-01 | Effective Date: 01 JAN 2026

EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished Class 8 heavy-duty trucks for the Huntsville, AL regional market, targeting high-utilization fleet and construction applications. This report details the mandatory 4-phase refurbishment protocol applied to all units designated “Used Trucks for Sale Huntsville AL”, exceeding SAE J253 and ASTM F1163 standards. Each unit undergoes 127+ point validation, ensuring 95% operational readiness upon delivery and mitigating downtime risks inherent in secondary-market acquisitions.

REFURBISHMENT PROCESS: TECHNICAL SPECIFICATIONS

1. ENGINE & GEARBOX TESTING (SAE J1995 COMPLIANT)

All powertrains undergo dynamometer-based load testing and fluid diagnostics. Units failing threshold parameters are rejected prior to refurbishment.

| Test Parameter | SEA LION Standard | Industry Baseline | Pass/Fail Threshold |

|---|---|---|---|

| Crankcase Pressure (Hot) | ≤ 0.8 PSI @ 2500 RPM | ≤ 1.5 PSI | > 0.8 PSI = Rebuild |

| Gearbox Oil Spectrometry | Fe ≤ 80 ppm, Si ≤ 25 ppm | Fe ≤ 150 ppm | Exceedance = Replacement |

| Turbo Boost Response | ≥ 95% target @ 1800 RPM | ≥ 85% | < 95% = Component Refit |

| Emissions (Idle) | NOx ≤ 2.0 g/bhp-hr | NOx ≤ 5.0 g/bhp-hr | Exceedance = Rejection |

Process Flow:

Cold Start Diagnostics → 3-Stage Dyno Load Test → Oil/Filter Analysis → Component Teardown (if flagged) → Reassembly with OEM Seals → Hot Verification Run

2. CABIN REPAINTING (ASTM D4585/D6083 COMPLIANT)

Surface preparation and coating application address Huntsville’s high-humidity environment (avg. 78% RH) and red clay particulate exposure.

| Stage | Procedure | Quality Control Metric |

|---|---|---|

| Substrate Prep | Grit blasting to SSPC-SP10 (Near-White) | Profile depth: 2.5-3.5 mils (wet film) |

| Corrosion Treatment | Epoxy primer + zinc phosphate conversion | Salt spray resistance: ≥ 1,000 hrs |

| Topcoat Application | 2K polyurethane (RAL 7040/Custom OEM) | DFT: 120-150 microns (per ASTM D7091) |

| Curing | Forced-air oven @ 60°C for 90 mins | MEK double rubs: ≥ 100 |

Critical Note: All cabs undergo ultrasonic weld inspection post-repaint to validate structural integrity.

3. NEW TIRES & BATTERY REPLACEMENT

Specified for Alabama’s I-565 corridor demands (frequent stop-start, 95°F+ summer temps).

| Component | SEA LION Specification | Validation Test | Warranty |

|---|---|---|---|

| Tires | Michelin X Works ZL2 (295/75R22.5) | Load rating: 6,175 lbs @ 80 PSI | 18 months |

| Retread-resistant compound | Uniformity test: ≤ 18 lbs RFV | ||

| Batteries | Optima YellowTop (Group 31) | CCA: 1,000A @ -18°C | 24 months |

| AGM, vibration-resistant | Reserve capacity: ≥ 180 mins |

Process: Tires mounted on bead-blasted rims; batteries installed with torque-controlled lugs (25 ft-lbs ± 5%).

4. CHASSIS REINFORCEMENT (SAE J2047 COMPLIANT)

Addresses frame fatigue from construction site loads and Huntsville’s rolling terrain (avg. 300+ ft elevation change).

| Reinforcement Zone | Material/Process | Inspection Method | Tolerance |

|---|---|---|---|

| Rear Spring Hangers | 1/4″ ASTM A572 Gr50 plate + full-penetration welds | Ultrasonic thickness testing | ± 0.005″ |

| Crossmember Joints | Stress-relieved gussets (min. 6″ x 6″) | Magnetic particle inspection | Zero defects |

| Frame Rails | Shot peening (Almen intensity 0.010A) | Residual stress mapping | Compressive ≥ 20 ksi |

Critical Protocol: All welds executed by AWS D1.1-certified technicians; post-weld heat treatment (PWHT) applied to zones exceeding 0.5″ thickness.

SEA LION INSPECTION STANDARDS: KEY DIFFERENTIATORS

- Zero-Tolerance Protocol: 100% of units undergo 3 independent inspection tiers (Technician → QA Lead → Third-Party NDT).

- Data-Driven Validation: Telematics logs (pre-refurb) analyzed for harsh usage patterns (e.g., >15% time at max torque).

- Huntsville-Specific Calibration: Axle ratios optimized for AL terrain; cooling systems pressure-tested to 18 psi (vs. 15 psi baseline).

- Rejection Rate: 22% of candidate units fail initial screening (2025 data), ensuring only structurally sound platforms enter refurbishment.

CONCLUSION

SEA LION’s Huntsville AL refurbishment program eliminates the operational risk profile typical of secondary-market trucks. By enforcing military-grade inspection standards (MIL-STD-810G adapted for commercial use) and regionalizing specifications for Alabama’s environmental and operational demands, we deliver units with 85% of new-truck lifecycle expectancy at 40% of acquisition cost. All certified units include a 12-month/150,000-mile powertrain warranty and are available for operational deployment within 72 hours of delivery.

SEA LION International — Engineered Reliability for Industrial Operations

Certified Units Available Q1 2026 | Huntsville Refurbishment Facility: ISO 9001:2015 | OHSAS 18001

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Export Logistics Solutions for Used Trucks from China – Huntsville, AL Market

Issuing Authority: SEA LION International – Global Heavy Equipment Logistics Division

Date: April 5, 2026

Executive Summary

This report evaluates optimal maritime transport methods for exporting used trucks from China to the Huntsville, AL market. With increasing demand for cost-effective, pre-owned heavy-duty vehicles in North American construction and fleet operations, SEA LION International presents a comparative analysis of three primary shipping modalities: Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack (Flatrack Containerized) Shipping. Special attention is given to anti-corrosion wax spraying protocols to mitigate seawater exposure during transit.

1. Market Context: Used Trucks for Sale – Huntsville, AL

Huntsville, AL, serves as a strategic logistics and industrial hub in the Southeastern U.S., with growing demand across construction, municipal services, and regional freight operations for reliable, mid-life commercial trucks. Chinese surplus fleets—including FAW, SINOTRUK, and Dongfeng models—offer competitive pricing and proven durability under industrial conditions. Export logistics must ensure structural integrity, minimize transit damage, and comply with U.S. import standards (CBP, DOT, EPA).

2. Shipping Method Comparison

The following table compares key performance indicators across three shipping methods applicable to used truck exports from Chinese ports (e.g., Shanghai, Qingdao, Ningbo) to U.S. Gulf or East Coast ports (e.g., Houston, Savannah), with final overland delivery to Huntsville, AL.

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack (40′ HC Flat) |

|---|---|---|---|

| Vehicle Compatibility | High – All drivable trucks (5–40 tons) | Limited – Non-operational units only | High – Drivable or inoperable |

| Loading Method | Self-driven onto vessel | Crane-lifted, secured in hold | Crane-lifted, lashed on deck |

| Protection from Elements | Moderate – Exposed to salt spray on deck | Low – High humidity, condensation | High – Customizable weather barriers |

| Risk of Damage | Low (if secured) – Risk from deck movement | High – Shifting, abrasion, moisture | Very Low – Full control over lashings |

| Transit Time (China → U.S. Port) | 22–28 days | 24–30 days | 23–29 days |

| Port Handling Efficiency | High – Rapid roll-on/off | Low – Crane dependency | Medium – Requires rigging |

| Cost per Unit (Avg. 2026 USD) | $1,850–$2,200 | $1,600–$1,900 | $2,400–$3,100 |

| Customs & Inspection Access | High – Individual VIN access | Low – Group inspection only | High – Per-unit visibility |

| Best Use Case | Drivable fleets, time-sensitive delivery | Non-running units, cost-driven projects | High-value or customized trucks |

3. Corrosion Protection: Wax Spraying Protocol

Marine environments expose metal surfaces to salt-laden air and condensation, accelerating corrosion—particularly in undercarriages, chassis rails, and engine compartments. To mitigate long-term degradation during 3–4 week transits, SEA LION International mandates industrial-grade wax spraying as a standard preservation measure.

Wax Spraying Specifications:

| Parameter | Specification |

|---|---|

| Application Standard | ISO 8501-1:2007 Surface Preparation |

| Wax Type | Solvent-based, hydrophobic corrosion inhibitor (e.g., Cosmoline 870 or equivalent) |

| Application Method | High-pressure spray + brush detailing |

| Coverage Areas | Chassis, frame rails, suspension, brake lines, wheel hubs, radiator supports |

| Drying Time | 4–6 hours (forced air) |

| Removal Guidance | Biodegradable citrus-based solvent (post-import) |

| Effectiveness | Reduces saltwater corrosion by ≥85% over 45-day exposure |

Note: Wax-treated units must be documented with pre-shipment photos and receive protective tarping when stored pre-loading.

4. Recommended Logistics Strategy

| Scenario | Recommended Method | Rationale |

|---|---|---|

| Fleet of 10+ drivable trucks | RO-RO | Fast loading, lower damage risk, optimal cost/unit |

| Inoperable or damaged units | Flat Rack | Full structural visibility, secure lashing, corrosion control |

| Budget-constrained, low-priority shipment | Bulk Cargo | Lowest cost, but high risk of surface and mechanical degradation |

For Huntsville-bound shipments, RO-RO via Savannah Port offers the most balanced solution, combining rapid discharge with direct I-75/I-59 corridor access. Flat rack is advised for trucks with aftermarket modifications or extended warranties requiring post-delivery inspection.

5. Compliance & Documentation

All shipments must include:

– Bill of Lading (B/L)

– Export Certificate from Chinese MOFCOM

– U.S. EPA Engine Declaration (40 CFR Part 85)

– DOT HS-7 Form (for vehicle import)

– Wax treatment certification (on file for customs audit)

6. Conclusion

Exporting used trucks from China to Huntsville, AL, demands a methodical approach to maritime logistics. RO-RO shipping provides the best balance of cost, speed, and safety for drivable units. Flat rack transport ensures maximum protection for high-value or non-operational assets. Bulk cargo, while economical, is discouraged due to elevated corrosion and damage risks. Industrial wax spraying is non-negotiable for ensuring asset longevity and resale value upon U.S. arrival.

SEA LION International recommends pre-shipment condition assessments and wax preservation as standard operating procedure for all exports in this category.

End of Report

SEA LION International – Engineering the Future of Heavy Equipment Logistics

Get a Quote for Used Trucks For Sale Huntsville Al

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]