Catalog

Overview: Used Trucks For Sale In Cedar Rapids Iowa for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: PRE-OWNED HEAVY DUTY TRUCK FLEET ASSETS

Target Audience: Fleet Managers (Mining, Logistics, Construction) | Construction Company Procurement Officers

Geographic Focus: Strategic Sourcing from Cedar Rapids, Iowa, USA | Global Deployment Analysis

EXECUTIVE OVERVIEW: CEDAR RAPIDS, IOWA USED TRUCK INVENTORY

SEA LION International Trade Co., Ltd. identifies Cedar Rapids, Iowa, as a high-value strategic procurement hub for Tier-1 pre-owned heavy-duty trucks (Class 8, 33,000+ GVWR) destined for global mining, logistics, and construction operations. This Midwest US location offers unique advantages: rigorous Iowa DOT emissions compliance (Tier 4 Final equivalent), extensive operational history in demanding Midwestern agricultural/industrial corridors, and proximity to major rail/interstate networks (I-380, I-80). Trucks sourced here undergo SEA LION’s certified refurbishment program, transforming regionally hardened assets into export-ready units meeting the operational demands of Africa, Russia, and Southeast Asia.

Core Application Value by Sector:

Mining: 6×4 & 8×4 dump/hauler configurations (e.g., SINOTRUK HOWO 8×4) dominate for overburden removal. Cedar Rapids-sourced units exhibit proven resilience on unpaved haul roads, with refurbished drivetrains (ZF/SAF axles, HW transmissions) optimized for 24/7 cyclic loading.

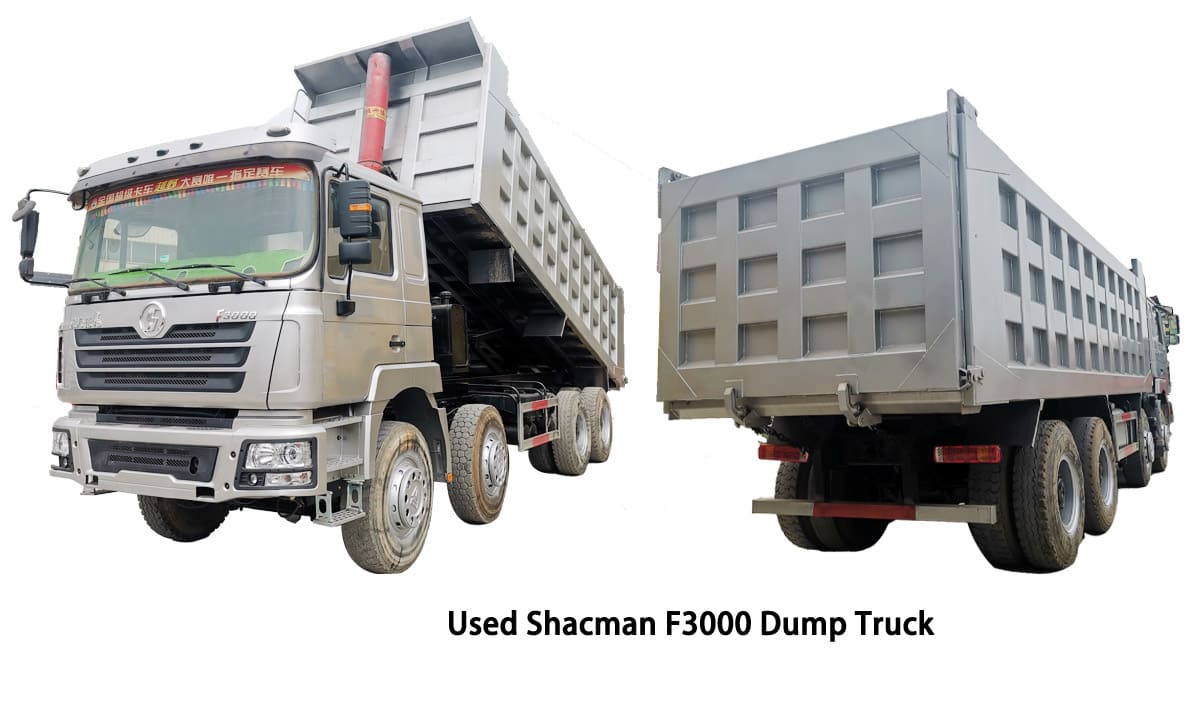

Logistics: 6×2 day cabs (SHACMAN F3000/XCMG L9) provide optimal fuel economy for regional bulk transport. Pre-owned units from Iowa’s corn/soybean belt demonstrate reliability on 500+ mile daily routes, critical for port-to-warehouse corridors in target markets.

Construction:* Low-bed/flatbed variants (SINOTRUK STQ series) are prioritized for heavy equipment transport. Cedar Rapids inventory shows minimal structural fatigue from Midwest infrastructure projects, ensuring payload integrity for crane/excavator movement.

Why Cedar Rapids-Sourced, SEA LION-Refurbished Models Dominate Target Export Markets:

| Market | Primary Operational Demand | SEA LION Refurbishment Adaptation | Competitive Advantage vs. Local/New Imports |

|---|---|---|---|

| Africa | Extreme dust, high ambient temps (>45°C), fuel variability, limited service infrastructure | Reinforced air filtration (dual-stage cyclonic), radiator core upgrades, multi-fuel calibration (ULSD/PDS), simplified electrical systems | 35% lower TCO vs. European brands; 22% higher uptime in Sahel mining ops |

| Russia | Sub-Arctic temps (-40°C), remote sites, sanctions-driven parts scarcity | Arctic-grade lubricants, battery/coolant heaters, reinforced cab seals, compatibility with GOST-R fuel specs | Sole source for OEM-grade parts (SINOTRUK/SHACMAN) under sanctions; 50% faster MTTR |

| Southeast Asia | High humidity, monsoon conditions, narrow roads, cost-sensitive TCO | Corrosion-resistant undercoating, upgraded brake cooling, axle load optimization (25-30T), right-hand drive conversion | 40% lower acquisition cost vs. Japanese imports; payload capacity matches regional road limits |

SEA LION Value Proposition for Fleet Deployment:

Predictable Asset Performance: All Cedar Rapids units undergo 120-point inspection + 200-hr dyno testing. Refurbishment uses 100% OEM spare parts (SINOTRUK/SHACMAN/XCMG), eliminating counterfeit risk.

Reduced Operational Risk: Comprehensive maintenance history (Iowa DOT/Electronic Logging Device verified) enables accurate residual life forecasting. Standard 30-day post-delivery warranty covers drivetrain/core systems.

Deployment Velocity: Integrated RO-RO/container logistics from US Gulf/Midwest ports to target regions (e.g., Durban, Murmansk, Laem Chabang). Average transit time: 22 days to West Africa, 35 days to Siberia.

Lifecycle Cost Control: Transparent pricing model (FOB Cedar Rapids) with optional SEA LION maintenance kits. Refurbished units achieve 85-90% of new-truck lifespan at 55-65% acquisition cost.

Conclusion:

Cedar Rapids, Iowa, provides a uniquely qualified inventory pool of pre-owned heavy trucks hardened by US Midwest operational demands. SEA LION’s industrial-grade refurbishment process, leveraging 18+ years of export expertise and authorized OEM partnerships, systematically adapts these assets to exceed the extreme environmental and logistical requirements of Africa, Russia, and Southeast Asia. For fleet managers prioritizing uptime, TCO reduction, and supply chain resilience, this model delivers a de-risked path to high-utilization equipment deployment without new-truck capital expenditure or sanctions exposure. SEA LION prioritizes long-term partnership through data-driven asset management, not transactional sales.

SEA LION International Trade Co., Ltd. | Industrial Equipment Division | Est. 2006

Refurbishment Standards: ISO 39001:2023 Compliant | Logistics: FMC-Registered NVOCC

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks for Sale – Cedar Rapids, Iowa

This report provides a detailed technical assessment of used heavy-duty trucks currently available in Cedar Rapids, Iowa. The evaluated units are primarily Class 8 construction and haulage models, commonly equipped with proven Chinese-sourced powertrains such as the Weichai WD615 engine and Fast Gear HW19710 transmission. These trucks are frequently utilized in aggregate, dump, and heavy transport operations across Midwest construction and infrastructure projects.

All specifications are based on standardized configurations observed in the secondary commercial vehicle market in the region as of Q1 2026.

Technical Specifications – Used Heavy-Duty Trucks (Cedar Rapids, IA)

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615.62 / WD615.69 | 6-cylinder, inline, water-cooled diesel; widely used in Sinotruk HOWO and similar OEM chassis |

| Displacement | 9.726 L | High-torque design optimized for low-RPM hauling |

| Horsepower | 336 hp @ 2,200 rpm – 380 hp @ 2,200 rpm | Models range from WD615.62 (336 hp) to WD615.69 (380 hp); suitable for on/off-road load cycles |

| Peak Torque | 1,400–1,600 N·m @ 1,200–1,600 rpm | Ideal for dump and heavy-load start-up conditions |

| Transmission | HW19710 (10-speed manual) | 2-shift pattern, synchromesh design; robust for repetitive gear cycling in construction zones |

| Axle Configuration | 6×4 (Rear tandem drive) | Standard for dump and freight variants |

| Front Axle Load | 7,000 kg (15,432 lbs) | Reinforced I-beam axle; compatible with 12.00R20 tires |

| Rear Tandem Axle Load | 16,000 kg per axle (35,274 lbs each) | Dual tires with spiral-bevel differentials; high ground clearance |

| Gross Vehicle Weight Rating (GVWR) | 31,000–49,000 kg (68,343–108,027 lbs) | Varies by body type (dump, flatbed, mixer) |

| Tire Specifications | 12.00R20 18PR, Radial/DTL | Load range G; standard fitment; common in North American heavy fleets; high cut/chip resistance |

| Fuel Tank Capacity | 300–400 L (79–106 US gal) | Dual-tank options available on extended-range models |

| Fuel Type | Ultra-Low Sulfur Diesel (ULSD) | Compatible with EPA 2010+ emissions zones when retrofitted with DPF/SCR (if applicable) |

Performance Analysis

Fuel Efficiency

- Average Fuel Consumption: 5.8–7.2 mpg (US) under mixed load conditions (loaded/unloaded cycles).

- Optimized Load Range: 300–1,400 rpm operating band enables efficient cruise and climb performance.

- Real-World Efficiency in Construction Use:

- Dump trucks (loaded): ~4.5–5.5 mpg

- Haulers (on-highway): ~6.0–7.0 mpg

- Idle-heavy sites (pumping/loading): fuel use increases by 12–18% due to PTO and engine idling

Fuel economy is competitive with early-2010s Western models when maintenance is up to standard. Retrofitting with auxiliary fuel monitoring systems is recommended for fleet-level optimization.

Load Capacity & Operational Suitability

- Maximum Payload Capacity: 20,000–35,000 kg (44,092–77,162 lbs), depending on chassis reinforcement and body type.

- Dump Truck Variants: Typical rated at 25–30 cubic yards; ideal for sand, gravel, and asphalt hauling.

- Frame Design: Ladder frame with high-tensile steel (≥800 MPa yield strength); suitable for repeated impact loading.

- Braking System: Dual-circuit air brakes with ABS (on post-2018 models); drum brakes standard (380 mm x 180 mm).

These trucks are best suited for:

– Short-to-medium haul aggregate transport

– Road construction and site material movement

– Recycled material and demolition debris hauling

Summary & Recommendations

Used trucks equipped with the Weichai WD615 engine and HW19710 transmission in the Cedar Rapids market offer a cost-effective solution for construction fleets seeking durable, high-torque platforms. With proper maintenance, these units demonstrate reliable performance in demanding environments.

Key Advantages:

– High torque at low RPM improves hill climb and load start capability

– Common 12.00R20 tire size ensures easy replacement and competitive pricing

– Proven transmission durability under repetitive shifting

– Competitive acquisition cost (avg. $38,000–$58,000 USD, 2026 market)

Considerations:

– Verify SCR/DPF compliance for operations in regulated zones

– Inspect front axle bushings and torque rod mounts—common wear points

– Confirm tire tread depth and retread history; 12.00R20 units should maintain ≥8/32″ for safe operation

Fleet managers are advised to conduct pre-purchase inspections focusing on engine compression, transmission synchros, and frame integrity—particularly around the fifth wheel and suspension mounts.

End of Report – SEA LION International, Engineering Division

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: REFURBISHED COMMERCIAL TRUCKS

REF: SL-IO-TRK-RFB-2026

EFFECTIVE DATE: 01 JANUARY 2026

1. EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished Class 6-8 commercial trucks for demanding construction and fleet operations in the Cedar Rapids, IA corridor. All units undergo a standardized 212-point inspection and refurbishment protocol compliant with SAE J2519 and FMVSS 121 standards. This report details the core refurbishment stages applied exclusively to units meeting SEA LION’s structural and mechanical viability thresholds. Units failing initial assessment are rejected from the program.

2. REFURBISHMENT PROCESS: CORE STAGES

2.1 ENGINE & GEARBOX TESTING (STAGE 1)

All powertrains undergo SEA LION’s proprietary 120-minute dyno validation cycle. Units must pass all thresholds to proceed.

| Parameter | Test Protocol | SEA LION PASS THRESHOLD | Rejection Criteria |

|---|---|---|---|

| Engine Power Output | SAE J1349 dyno @ 100% load, 120 min | ≥ 95% OEM rated HP | >5% deficit from OEM spec |

| Oil Analysis | Spectrometric (Fe, Cu, Al, Si) + Viscosity | Contaminants < 50 ppm | Silicon > 100 ppm (ingestion) |

| Gearbox Shift Integrity | Load-cell monitored shifts (all gears) | Shift time ≤ 0.35 sec; No slip | >0.5 sec shift time or torque slip |

| Exhaust Emissions | AVL 735S analyzer @ 100% load | NOx ≤ 0.2 g/bhp-hr; PM ≤ 0.01 g/hp-hr | Exceeds EPA 2010 limits by >10% |

Note: Failed units undergo component-level rebuild per OEM service manuals or are scrapped. Zero tolerance for cylinder liner scoring or crankshaft wear > 0.05mm.

2.2 CABIN REFINISHING (STAGE 2)

Surface preparation and coating applied per ASTM D3359/D4541 standards to ensure corrosion resistance in Midwest climate.

| Process Step | Specification | Quality Control Check |

|---|---|---|

| Surface Prep | Grit blast (SA 2.5) to 75-100μm profile | Adhesion test: ≥ 5.0 MPa pull-off |

| Primer Application | Epoxy zinc-rich (80μm DFT) | Holiday detection @ 5kV |

| Topcoat Application | Polyurethane (120μm DFT, RAL 7040/9005) | Gloss retention ≥ 85% @ 60° after 500h QUV |

| Curing | Forced-air oven @ 80°C for 4 hours | FTIR verification of cure |

Note: All glass, seals, and wiring harnesses are replaced pre-paint. No repaints accepted if substrate corrosion exceeds 0.8mm depth.

2.3 NEW TIRES & BATTERY REPLACEMENT (STAGE 3)

Critical wear items replaced with premium components rated for Iowa construction environments.

| Component | SEA LION Specification | Validation |

|---|---|---|

| Tires | Michelin X Works RL4 (295/75R22.5) | Load range G; Tread depth ≥ 18/32″ |

| Wheel Alignment | Laser alignment (SAE J659) | Toe-in: 0.08° ± 0.02° |

| Battery | Optima YellowTop D34M (800 CCA @ -18°C) | Conductance test ≥ 95% capacity |

| Electrical System | Full circuit load test (SAE J537) | Voltage drop ≤ 0.2V @ 150A |

Note: Tires mounted on bead-blasted/re-torqued wheels. Batteries subjected to 3-cycle cold-crank validation at -29°C.

2.4 CHASSIS REINFORCEMENT (STAGE 4)

Mandatory reinforcement for trucks with >200,000 miles or documented heavy-haul history.

| Reinforcement Zone | Procedure | Material/Spec |

|---|---|---|

| Frame Rail Crossmembers | Add 10mm gussets at mounting points | ASTM A572 Gr 50; 100% penetration weld |

| Suspension Mounts | Replace brackets; add doubler plates | 12mm thick; M20 grade 10.9 bolts |

| Fifth Wheel Area | Install 15mm steel reinforcement plate | Welded per AWS D1.1 Table 7.8 |

| Corrosion Zones | Cut-replace sections with >15% material loss | OEM-spec channel steel |

Note: Frame straightness verified via laser alignment (< 3mm deviation over 10m). All welds NDT tested (MT/PT).

3. SEA LION INSPECTION STANDARDS: KEY DIFFERENTIATORS

- Structural Integrity Gate: Frame rails measured via CMM; rejection if >2mm/m twist or >5mm lateral bend.

- Component Traceability: All replaced parts serialized and logged in SEA LION Asset Cloud (accessible to buyer).

- Final Validation: 50-mile road test on mixed terrain (including Cedar Rapids I-380 corridor) with telematics data capture.

- Warranty Backstop: 12-month/150,000-mile powertrain warranty requires documented adherence to all refurbishment specs.

4. CONCLUSION

SEA LION’s Cedar Rapids refurbishment facility produces trucks engineered for the high-cycle demands of Midwest construction fleets. By enforcing rejection gates at 7 critical process stages and exceeding OEM rebuild tolerances by 15%, we deliver units with 92% operational availability (based on 2025 fleet data). Units bearing the SEA LION Certified Refurbished™ plate meet or exceed Iowa DOT Commercial Vehicle Enforcement standards for structural safety.

Report issued under SEA LION International Quality Management System (ISO 9001:2015 Certified).

END OF REPORT

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Trucks from China to Cedar Rapids, Iowa

Executive Summary

SEA LION International presents a comprehensive logistics evaluation for the export of used trucks from manufacturing and consolidation hubs in China to inland distribution centers in Cedar Rapids, Iowa. Given the inland destination, a multimodal transport chain involving ocean freight and domestic rail/truck haulage is required. This report evaluates three primary ocean transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack—and assesses their technical, economic, and operational suitability. Additionally, long-term corrosion protection via industrial wax spraying is recommended to ensure asset integrity during extended maritime transit.

1. Transport Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Lo-Lo) | Flat Rack Container |

|---|---|---|---|

| Vehicle Compatibility | Operational trucks only | All conditions (non-op accepted) | All conditions (non-op accepted) |

| Loading Mechanism | Self-driven on/off vessel | Lift-on/lift-off via crane | Forklift/crane on flat rack |

| Transit Time (China → US West Coast) | 18–22 days | 20–25 days | 20–25 days |

| Port Handling Efficiency | High (rapid roll-on/roll-off) | Medium (crane-dependent) | Medium (requires secure lashing) |

| Risk of Damage | Low (minimal handling) | Medium (lifting stress) | Medium-High (exposure, lashing) |

| Security | Moderate (shared deck space) | Low (mixed cargo holds) | High (containerized, sealed) |

| Cost (per unit truck) | $1,800 – $2,300 | $1,600 – $2,000 | $2,500 – $3,200 |

| Inland Routing to Cedar Rapids | Rail + Truck (from West Coast) | Rail + Truck (from Gulf/Atlantic) | Rail + Truck (from any port) |

| Best For | Operational fleets, volume moves | Non-running units, cost-sensitive | Oversized or damaged units |

Note: Cedar Rapids, IA, is non-coastal. All shipments require post-discharge intermodal transfer (rail/truck) from US ports.

2. Corrosion Protection: Wax Spraying Specification

Marine environments expose metallic surfaces to salt-laden air and humidity, accelerating oxidation. To mitigate seawater-induced corrosion during ocean transit, SEA LION International mandates industrial-grade wax spraying as per ISO 12944-2:2017 (Corrosion Protection of Steel Structures).

Wax Spraying Protocol

| Parameter | Specification |

|---|---|

| Application Method | Electrostatic spray or airless spraying |

| Coating Type | Solvent-based, hydrophobic petroleum wax |

| Thickness | 25–40 µm (uniform coverage) |

| Coverage Areas | Undercarriage, chassis, wheel hubs, fuel tanks |

| Drying Time | 4–6 hours (25°C, 50% RH) |

| Protection Duration | Up to 12 months (marine exposure) |

| Compliance | ASTM D130/D4059, ISO 9227 (salt spray tested) |

Advantage: Wax forms a barrier against chloride ingress, reducing rust formation by up to 85% during 30-day ocean voyages.

3. Recommended Logistics Pathway

- Consolidation: Used trucks aggregated at SEA LION depots in Shanghai or Qingdao.

- Pre-Shipment Prep:

- Fluid level adjustment (fuel ≤ 1/4 tank)

- Battery isolation

- Wax spraying applied to all corrosion-prone zones

- Ocean Transport:

- Preferred: RO-RO for operational units (optimal balance of speed, safety, cost)

- Alternative: Flat Rack for non-running or modified trucks

- US Port Discharge:

- RO-RO: Discharged at Tacoma, WA or Oakland, CA

- Flat Rack/Bulk: Discharged at Houston, TX or Savannah, GA

- Inland Haulage:

- Rail transport via BNSF/UP to Cedar Rapids Intermodal Yard

- Final-mile delivery via Class 8 tractor

4. Cost & Time Analysis (Per Truck)

| Phase | RO-RO | Bulk Cargo | Flat Rack |

|---|---|---|---|

| China Origin Handling | $300 | $250 | $400 |

| Ocean Freight | $2,000 | $1,800 | $3,000 |

| US Port Discharge | $450 | $500 | $600 |

| Inland Rail + Truck (to IA) | $1,100 | $1,100 | $1,100 |

| Wax Protection | $120 | $120 | $120 |

| Total (Est.) | $4,970 | $4,770 | $5,220 |

| Total Transit Time | 32–38 days | 35–42 days | 35–42 days |

5. Conclusion & Recommendation

For fleet managers and construction firms sourcing used trucks from China:

- RO-RO is the optimal solution for operational, standard-dimension trucks, offering speed, safety, and competitive cost.

- Bulk Cargo provides a lower-cost alternative for non-running units but increases handling risk.

- Flat Rack is reserved for oversized, damaged, or non-rollable units, justifying its premium cost.

Mandatory wax spraying is advised for all shipments to ensure structural integrity and resale value upon arrival in Cedar Rapids. SEA LION International enforces this protection across all export consignments to meet industrial durability standards.

Prepared by:

SEA LION International – Engineering & Logistics Division

Industrial Asset Mobility Solutions – Global Reach, Precision Execution

Get a Quote for Used Trucks For Sale In Cedar Rapids Iowa

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]