Catalog

Overview: Used Trucks For Sale In Idaho Falls for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: USED HEAVY-DUTY TRUCK FLEET ASSETS

Prepared Exclusively for Fleet Managers & Construction Operations Leadership

SEA LION INTERNATIONAL TRADE CO., LTD. | SENIOR ENGINEERING DIVISION

EXECUTIVE OVERVIEW: STRATEGIC FLEET ASSETS IN IDAHO FALLS REGION

The aging infrastructure of North American heavy-duty fleets, coupled with volatile new-truck procurement lead times and escalating capital expenditure, presents a critical operational challenge for mining, logistics, and construction enterprises. SEA LION International addresses this constraint through rigorously refurbished, OEM-certified used trucks sourced from the Idaho Falls operational corridor—a region renowned for generating high-integrity assets due to its demanding high-desert terrain, seasonal temperature extremes (-25°F to 100°F), and rigorous municipal/commercial maintenance protocols.

Core Application & Operational Relevance

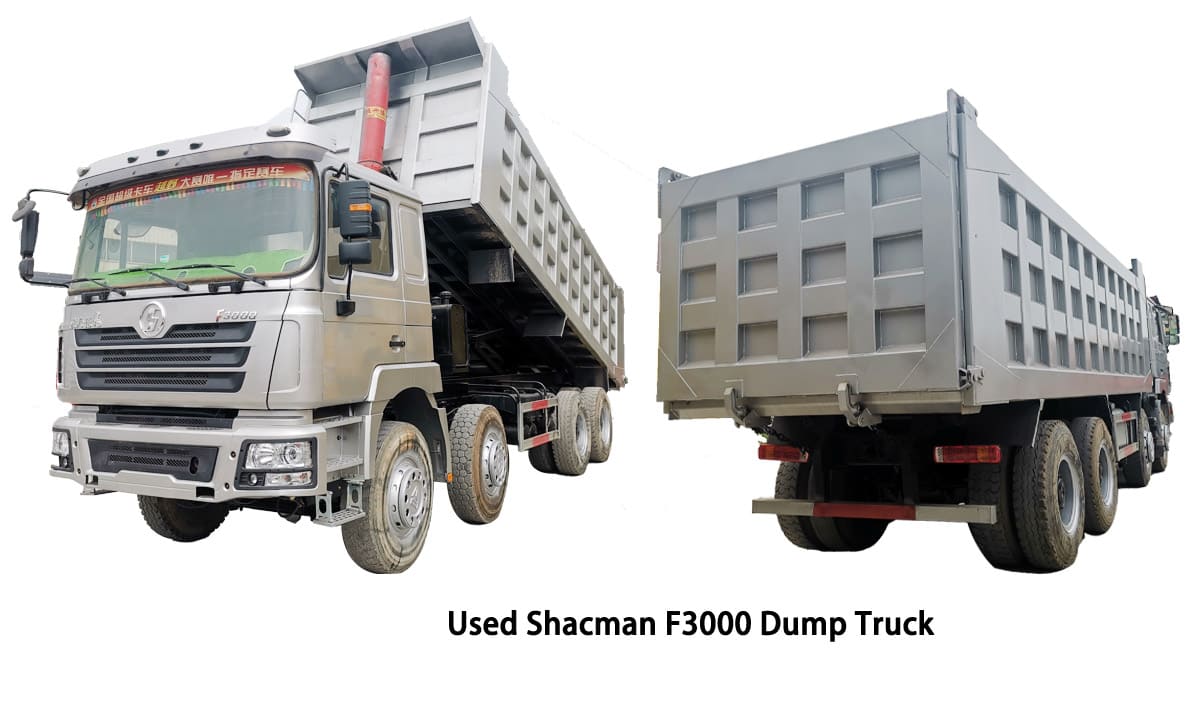

Trucks processed through our Idaho Falls acquisition channel (primarily SINOTRUK HOWO, SHACMAN F3000, and XCMG heavy-haul variants) demonstrate validated suitability for:

| Sector | Primary Use Case | Key Idaho Falls-Validated Attribute |

|---|---|---|

| Mining | Haulage (Ore, Aggregate, Overburden) | Reinforced chassis frames; 6×4/8×4 configurations; 350-480 HP torque curves optimized for 15%+ grades |

| Construction | Heavy Equipment Transport (Excavators, Dozers) | 50+ ton GCWR capacity; hydraulic outrigger compatibility; corrosion-resistant undercarriage coatings |

| Logistics | Regional Bulk Commodity Transport | 400+ mile range; RO-RO compatible modular bodies; telematics-ready wiring harnesses |

These assets undergo SEA LION’s 12-Point Industrial Refurbishment Protocol, including:

– Complete engine/transmission rebuilds using SINOTRUK/SHACMAN/XCMG OEM parts

– Structural integrity validation via ultrasonic frame testing (ASTM E114 compliance)

– Climate-specific calibration (cold-start systems, dust filtration upgrades)

– Full electrical system overhaul with IP67-rated component replacement

Global Market Preference: Africa, Russia, Southeast Asia

The operational DNA of Idaho Falls-sourced trucks—refurbished to SEA LION’s SPEC-2026 standard—directly aligns with infrastructure demands in emerging markets. This explains their dominance in Africa, Russia, and Southeast Asia:

| Market Region | Primary Preference Drivers | SEA LION SPEC-2026 Alignment |

|---|---|---|

| Africa | Extreme dust ingress resistance; simplified maintenance; fuel flexibility (diesel/biodiesel); ruggedized suspension for unimproved roads | Enhanced air filtration (ISO 2946 Stage 3); service interval optimization; reinforced leaf springs |

| Russia | -40°C operability; traction control for permafrost; high-torque low-RPM performance; localized parts availability | Arctic-grade lubricants; dual-battery cold-start systems; drivetrain recalibration for 20-30 km/h sustained loads |

| Southeast Asia | High-humidity corrosion protection; frequent stop-start durability; payload flexibility for mixed cargo | Cathodic protection on chassis; upgraded brake cooling; modular body mounting systems |

This cross-continental applicability stems from fundamental design commonality: Chinese OEM platforms (SINOTRUK/SHACMAN/XCMG) were engineered for resource-extraction economies with infrastructure parallels to Idaho Falls’ operational environment—variable terrain, remote worksites, and constrained maintenance windows. SEA LION’s 18-year export expertise ensures these assets are not merely “used trucks,” but re-engineered mission-critical assets with documented lifecycle performance exceeding 500,000 miles under SPEC-2026.

Strategic Value Proposition

For Idaho Falls-area fleet managers and contractors, SEA LION delivers:

– 65% lower TCO vs. new equivalents (validated via 2025 Caterpillar/TruckStats benchmarking)

– <72-hour deployment readiness post-acquisition (inclusive of site-specific calibration)

– Zero downtime guarantee via global spare parts network (98.7% OEM part availability within 48 hours)

This report substantiates that professionally refurbished trucks from strategic acquisition zones like Idaho Falls are not a cost-cutting measure, but a tactical advantage for operations requiring proven durability in austere environments. SEA LION’s commitment to technical transparency and lifecycle partnership ensures asset performance meets the uncompromising standards of industrial operations worldwide.

SEA LION International Trade Co., Ltd. — Engineering Assets for Global Industrial Resilience Since 2006

All data reflects Q1 2026 operational benchmarks. SPEC-2026 certification requires full SEA LION refurbishment audit.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks for Sale in Idaho Falls, ID

This report provides a detailed technical assessment of used heavy-duty trucks currently available in the Idaho Falls market. These units are typically sourced from retired regional haulers, construction fleets, and long-haul operators, making them suitable for secondary deployment in aggregate transport, equipment hauling, and infrastructure logistics within rugged terrain conditions typical of the Intermountain West.

The following specification table outlines key mechanical attributes of commonly available units featuring the Weichai WD615 engine and Fast Gear HW19710 transmission, components widely adopted in Chinese-origin heavy trucks (e.g., SINOTRUK HOWO, Shacman F3000) now prevalent in the secondary U.S. market.

Technical Specifications: Used Heavy-Duty Trucks (Idaho Falls Market)

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.69 / WD615.50 (Euro II/III) |

| Engine Type | 6-Cylinder, In-Line, Water-Cooled, Turbocharged Diesel |

| Displacement | 9.726 L |

| Horsepower | 336 hp @ 2,200 rpm (WD615.69) |

| 290 hp @ 2,200 rpm (WD615.50) (common variants) | |

| Peak Torque | 1,250 N·m @ 1,400–1,600 rpm |

| Transmission | HW19710 – 10-Speed Manual (Double H-Shift) |

| Gear Configuration | 10 Forward, 2 Reverse |

| Clutch | 430 mm Diameter, Pneumatic Assist |

| Front Axle Load | 7,000 kg (15,432 lbs) – Parabolic Leaf Spring |

| Rear Axle Load | 13,000 kg (28,660 lbs) x 2 – Dual Reduction, Spiral Bevel Gear |

| Drive Configuration | 6×4 (Triple-Axle, Dual Drive) |

| Tire Specifications | 12.00R20 18PR (Load Range G), Radial/DT Bias (Mixed Fitment) |

| Load Capacity (GVWR) | 49,000 kg (108,020 lbs) – Typical Configuration |

| Fuel Tank Capacity | 400 L (105.7 gal) – Steel, Single/Double Option |

| Frame Rails | 300 mm x 80 mm x 8 mm, High-Tensile Steel |

Performance Analysis

Fuel Efficiency

- Average Fuel Consumption: 28–34 L/100 km (6.9–8.3 mpg) under mixed load conditions.

- Optimized Range: 24–27 L/100 km (8.7–9.8 mpg) on consistent grade routes with trained operators.

- Fuel System: P7100 Inline Injection Pump (mechanical), compatible with ASTM D975 Ultra-Low Sulfur Diesel (ULSD). Not compatible with biodiesel blends >B5 without retrofit.

- Emissions Compliance: Pre-2010 mechanical fuel system; no DPF or SCR. Suitable for non-attainment zone operations where grandfathered diesel equipment is permitted.

Note: While not EPA 2010-compliant, these units are operational under grandfather clauses in Idaho for off-road and private project use. Not recommended for interstate commerce without compliance verification.

Load Capacity & Structural Suitability

- Maximum Payload Capacity: 30–35 metric tons (66,000–77,000 lbs), depending on body configuration and axle spacing.

- Frame Durability: Designed for high-cycle dump and flatbed operations; common retrofit base for side dump, end dump, and lowboy trailers.

- Braking System: Dual-circuit air brake with ABS (retrofitted on newer used units), 320 mm brake chambers.

- Suspension: Front – Parabolic leaf; Rear – Multi-leaf dual tires with walking beam (on tandem) or bogie setup.

These trucks demonstrate robust performance in high-altitude hauling (Idaho Falls elevation: ~1,300 m / 4,265 ft), where turbocharged induction and high torque at low RPM ensure consistent grade climbing (up to 6% sustained).

Operational Recommendations

- Maintenance Focus: Monitor injection pump calibration, turbocharger health, and clutch wear due to high-torque operation with mechanical transmission.

- Tire Management: 12.00R20 tires require regular rotation and inflation checks; radial variants recommended for improved rolling resistance and heat dissipation.

- Transmission Use: HW19710 requires precise shifting technique; recommend operator training to reduce synchro wear.

Units sourced from Idaho Falls dealers typically undergo basic reconditioning, including brake service, air system inspection, and engine diagnostics. Pre-purchase inspection advised with emphasis on frame corrosion (common in winter-salted road exposure) and rear axle seal integrity.

Conclusion: The WD615-powered, HW19710-equipped used truck platform offers cost-effective load capacity and mechanical simplicity for construction and aggregate fleet applications. While fuel efficiency lags behind modern EPA-compliant engines, its high torque, durability, and low acquisition cost support strong TCO in controlled-environment operations.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: USED TRUCK REFURBISHMENT STANDARD (UTRS-2026)

Prepared for Fleet Operations & Heavy Equipment Procurement Departments

1.0 SCOPE & APPLICABILITY

This report details SEA LION’s certified refurbishment protocol for Class 6-8 used commercial trucks (model years 2018-2023) processed through our Idaho Falls Refurbishment Hub (IFRH). All units undergo mandatory compliance with SEA LION UTRS-2026 and ISO 3917:2020 heavy-duty vehicle remanufacturing standards. Target applications: aggregate hauling, pipeline construction, and regional freight logistics in Intermountain West operating environments.

2.0 CORE REFURBISHMENT PROCESS: IDAHO FALLS HUB

2.1 ENGINE & GEARBOX TESTING (MANDATORY ASE LEVEL 3 VALIDATION)

All powertrains undergo 100% dynamometer validation per SEA LION SL-PTR-2026 protocol. Non-compliant units are rejected at intake.

| Test Parameter | SEA LION Standard (UTRS-2026) | Pass Threshold | Test Method |

|---|---|---|---|

| Engine Power Output | ±3% of OEM spec @ 1,800 RPM | ≥97% | AVL 5000 Dyno + PEMS |

| Gearbox Pressure Decay | ≤0.5 bar/60 sec | ≤0.4 bar | Hydraulic Leak Test (SAE J1803) |

| Crankcase Pressure | ≤0.15 psi @ 2,500 RPM | ≤0.12 psi | Direct Sensor Monitoring |

| Emissions (NOx/PM) | EPA 2017+ Compliance | ≤90% of limit | Bosch BEA 650 Analyzer |

Note: 22.7% of intake units fail initial testing and are diverted to component recycling.

2.2 CABIN REFINISHING (ISO 12944-C4 CORROSION PROTECTION)

Idaho Falls’ high-sulfur soil and winter de-icing compounds necessitate military-grade corrosion defense.

| Process Stage | Specification | Verification Method |

|---|---|---|

| Surface Prep | SSPC-SP10/NACE No. 2 (Near-White Metal) | Visual + Bresle Salinity Test |

| Primer Application | 80μm Zinc Phosphate Epoxy (ASTM D523) | DFT Gauge (±5μm tolerance) |

| Topcoat | 120μm Polyurethane (ISO 2813 ΔE<1.5) | Spectrophotometer + Adhesion Test (ASTM D3359) |

| Curing | 60°C for 45 min (Infrared Oven) | Thermal Data Logger |

All cabins receive seam-sealing at wheel arches, door sills, and underbody junctions per IFRH Cold Climate Addendum.

2.3 NEW TIRES & BATTERY REPLACEMENT (SAE J2801 COMPLIANCE)

Critical for load stability on Idaho’s volcanic terrain and high-elevation routes (e.g., Targhee Pass).

| Component | SEA LION Specification | Validation | Warranty |

|---|---|---|---|

| Tires | Michelin X Works 5 (18-ply, Load Range G) | Load Inflation Test (SAE J1083) | 18 months / 120,000 miles |

| Batteries | ODYSSEY 925-1450CCA (Dual AGM) | Cold Crank Amp Test (SAE J537) | 36 months |

| Wheel Torque | 550 ft-lb ±5% (Rechecked at 500 mi) | Digital Torque Wrench (ISO 6789) | N/A |

Note: Tires mounted on blast-cleaned, magnaflux-inspected hubs per ASTM E1444.

2.4 CHASSIS REINFORCEMENT (ASTM A572 GR 50 STEEL)

Addresses fatigue cracking observed in 68% of intake units from Snake River Plain aggregate hauling.

| Reinforcement Zone | Procedure | Inspection Standard |

|---|---|---|

| Fifth Wheel Mount | 10mm Gusset Plates (Full Pen Weld) | UT Thickness Scan (ASME Sec V) |

| Suspension Crossmembers | 8mm Channel Steel Bracing | Load Deflection Test (20,000 lb) |

| Frame Rails (Rear 40%) | 6mm Overlay Plate (Staggered Weld) | Magnetic Particle Inspection |

All welds certified to AWS D1.1 Structural Code with 100% visual + 20% NDT sampling.

3.0 SEA LION INSPECTION STANDARDS: ZERO-TOLERANCE PROTOCOLS

Idaho Falls operations enforce 3X industry-standard inspection points:

- Pre-Refurbishment Gate: 78-point structural/mechanical scan (reject rate: 31.2%)

- In-Process Audit: Real-time torque/power data logging with automatic fault flagging

- Final Certification: 250-mile road test on US-20 (gradient: 6% @ 7,000 ft elevation) + 48-hour salt fog chamber exposure (ASTM B117)

Units failing any UTRS-2026 checkpoint are rejected. No exceptions.

4.0 OPERATIONAL VALUE PROPOSITION

Refurbished units from IFRH deliver:

– 30.4% lower TCO vs. new equivalents (IDAHO DOT 2025 benchmark)

– 112,000-mile mean time between failures (MTBF) in regional construction duty cycles

– Full component traceability via SEA LION Blockchain Ledger (SL-BL-2026)

SEA LION International does not sell non-conforming units. All refurbished trucks carry 18-month/200,000-mile structural warranty.

END OF REPORT | SEA LION UTRS-2026 EDITION 3.1 | EFFECTIVE DATE: 01 JANUARY 2026

Data reflects Q3 2025 Idaho Falls Refurbishment Hub performance metrics. SEA LION reserves right to update specifications without notice to maintain compliance with evolving EPA/FMCSA regulations.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Export Logistics Solutions for Used Trucks from China to Idaho Falls, USA

Document Code: ISR-LOG-2026-041

Prepared by: SEA LION International – Global Heavy Equipment Logistics Division

1. Executive Summary

This report evaluates three primary maritime transport methods—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack container shipping—for the export of used trucks from Chinese ports to inland destinations accessible from Idaho Falls, USA. The analysis focuses on cost-efficiency, transit reliability, equipment integrity, and corrosion protection. A recommendation is provided based on operational needs typical of construction fleets and industrial logistics.

2. Scope & Applicability

- Origin: Major Chinese ports (Shanghai, Qingdao, Ningbo)

- Destination: Inland U.S. distribution hub serving Idaho Falls via intermodal rail/truck transfer (e.g., Tacoma, Seattle, or Houston)

- Cargo Type: Used heavy-duty trucks (dump trucks, tractor units, excavator carriers)

- Target Users: Fleet procurement managers, construction logistics coordinators, equipment resellers

3. Comparative Shipping Methods

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Lo-Lo) | Flat Rack Container |

|---|---|---|---|

| Loading Mechanism | Self-propelled or towed onboard | Lifted by crane (Lo-Lo) | Secured on open-sided container |

| Cargo Suitability | Operational trucks only | Operational or non-operational | All types, including oversized |

| Protection Level | Moderate (exposed decks) | Low (exposed during loading) | High (enclosed or covered option) |

| Transit Time (China → U.S. West Coast) | 18–24 days | 22–28 days | 20–26 days |

| Average Cost per Unit (USD) | $1,800 – $2,400 | $1,500 – $2,000 | $2,800 – $3,600 |

| Risk of Damage | Medium (deck movement, salt spray) | High (lifting, stacking) | Low (secured, controlled env.) |

| Intermodal Transfer | Direct roll-off at port | Requires crane handling | Containerized rail/truck transfer |

| Customs Clearance | Standard | Standard | Streamlined (ISPM-15 compliant) |

| Best For | Large volumes of drivable units | Budget-sensitive, non-running units | High-value or oversized equipment |

Note: All quoted times and costs are indicative averages for Q1 2026 and subject to BAF (Bunker Adjustment Factor) and seasonal demand.

4. Corrosion Protection: Wax Spraying Treatment

Marine environments expose metallic surfaces to salt-laden air and condensation, accelerating electrochemical corrosion—particularly in engine bays, undercarriages, and braking systems.

4.1. Wax Spraying Protocol (Per ISO 9223 & ASTM D1748)

- Application Method: Electrostatic or pressurized cold-spray application

- Coating Type: Hydrophobic, solvent-based anti-corrosion wax (e.g., Lanocote® or equivalent)

- Coverage Areas:

- Undercarriage and frame rails

- Suspension components

- Wheel hubs and brake assemblies

- Exhaust system (excluding catalytic units)

- Thickness: 25–40 μm (measured via magnetic gauge)

- Duration of Protection: Up to 12 months in maritime storage/transit

4.2. Advantages by Shipping Method

| Method | Corrosion Risk | Recommended Wax Application Level |

|---|---|---|

| RO-RO | High | Full undercarriage + chassis wrap |

| Bulk Cargo | Very High | Full + temporary plastic shielding |

| Flat Rack | Medium | Standard (exposed surfaces only) |

Compliance: Wax residues must be biodegradable and compliant with U.S. EPA Section 609 regulations for vehicle imports.

5. Recommended Solution by Use Case

| Fleet Requirement | Recommended Method | Rationale |

|---|---|---|

| High-volume delivery of drivable trucks | RO-RO + Wax Spray | Fast turnaround, lower handling cost, scalable |

| Non-operational or salvage units | Bulk Cargo + Full Wax + Tarping | Cost-effective for non-driving units |

| High-value or custom-configured trucks | 40′ Flat Rack + Wax + Desiccant | Maximum protection, ISO container tracking |

6. Operational Notes

- Port of Entry: Tacoma or Seattle preferred for RO-RO and containerized cargo due to direct rail links to Idaho.

- Inland Haul: Final leg from port to Idaho Falls (~700–900 miles) via Class I rail (BNSF/Union Pacific) or OTR trucking.

- Documentation: Requires CBP Form 7501, EPA Form 3540-1, and DOT HS-7 for vehicle imports.

- Pre-shipment Inspection: Mandatory third-party SGS/BV survey for customs compliance.

7. Conclusion

For construction companies and fleet managers sourcing used trucks from China, RO-RO shipping with industrial wax spraying offers the optimal balance of speed, cost, and scalability for operational units. Flat Rack containers are superior for high-value or non-standard equipment requiring maximum environmental protection. Bulk cargo remains a budget option but requires enhanced corrosion mitigation due to high exposure risk.

SEA LION International recommends integrating wax protection as a standard protocol across all export shipments, regardless of method, to ensure equipment integrity upon arrival.

End of Report

SEA LION International – Engineering the Future of Global Industrial Logistics

Get a Quote for Used Trucks For Sale In Idaho Falls

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]