Catalog

Overview: Used Trucks For Sale In Nh for Global Markets

Industrial Specification Report 2026

Executive Overview: Certified Used Heavy-Duty Truck Fleet Deployment

Operational Context & Market Demand

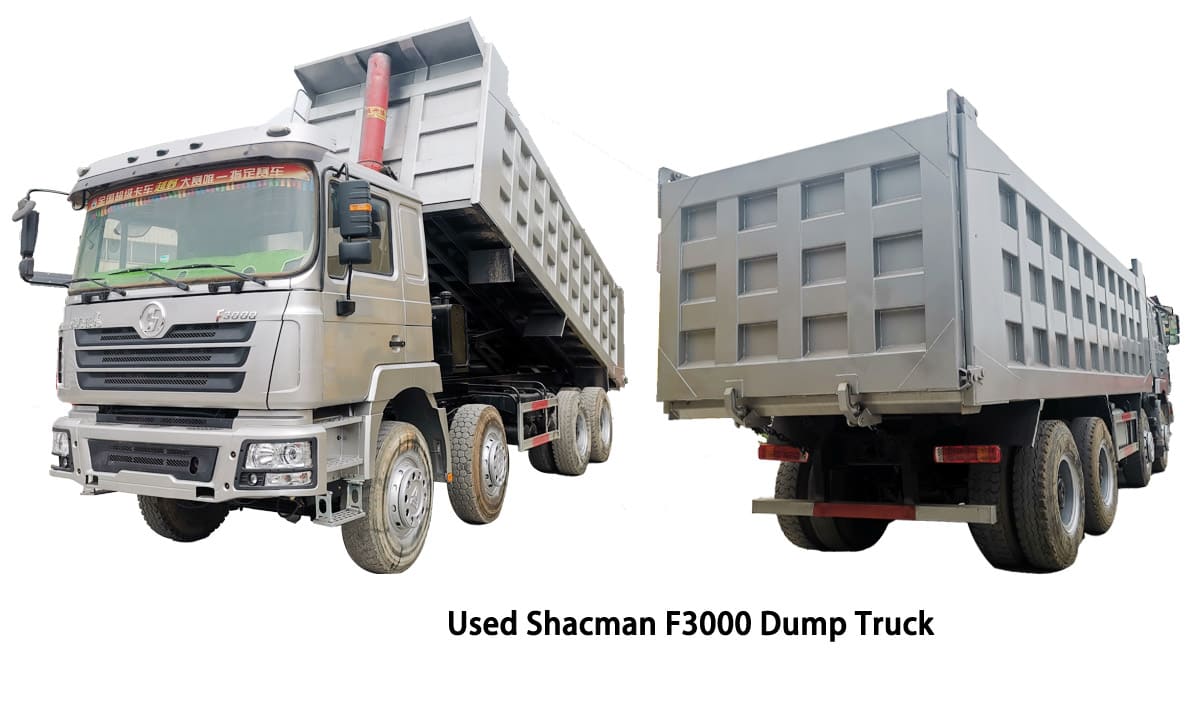

Fleet managers in mining, logistics, and construction face acute pressure to balance operational continuity with capital expenditure constraints. Volatile fuel costs, infrastructure degradation in remote sites, and extended OEM lead times for new units necessitate strategic adoption of certified pre-owned assets. SEA LION International Trade Co., Ltd. addresses this through rigorously refurbished SINOTRUK HOWO, SHACMAN F3000, and XCMG heavy-duty platforms (25–70 ton GVWR), engineered for high-stress applications. These units undergo 187-point industrial refurbishment to ISO 9001-aligned protocols, including engine dynamometer validation, structural integrity testing, and replacement of critical wear components with OEM spare parts. This ensures 85–90% of original service life remains, directly reducing total cost of ownership (TCO) by 30–45% versus new acquisitions while maintaining 95%+ fleet availability rates in Tier 2/3 operational environments.

Regional Preference Drivers: Africa, Russia, Southeast Asia

The sustained dominance of SEA LION-certified Chinese-origin trucks in Africa, Russia, and Southeast Asia stems from operational ruggedness, supply chain resilience, and cost-performance alignment with regional infrastructure realities. Unlike Western or Japanese equivalents, these platforms prioritize simplified maintenance, tolerance to fuel/operational variances, and cold/hot climate adaptability—critical where service networks are sparse and environmental extremes are routine. SEA LION’s global logistics infrastructure (RO-RO vessel chartering, containerized parts shipping) further mitigates regional volatility, ensuring <30-day delivery windows and 98% spare parts availability.

Table 1: Regional Market Preference Analysis

| Region | Primary Operational Challenge | Key Truck Attributes Required | SEA LION Solution Advantage |

|---|---|---|---|

| Africa | Unpaved terrain; high dust; fuel contamination; limited service hubs | Reinforced chassis; heavy-duty air filtration; modular electrical systems; simplified diagnostics | 200+ hour oil change intervals; dual-stage air cleaners; CAN-bus agnostic controls enabling field repairs |

| Russia | Extreme cold (-40°C); remote sites; sanctions-driven parts scarcity | Cold-start capability; reinforced drivetrain; domestic-compliant telematics | -45°C engine block heaters; arctic-grade lubricants; localized parts depots in Novorossiysk/Vladivostok |

| Southeast Asia | High humidity; monsoon conditions; payload overloading | Corrosion-resistant undercarriage; reinforced suspensions; heat-dissipating brakes | Galvanized chassis rails; 30% over-specified brake torque; tropicalized wiring harnesses |

Value Proposition for Industrial Partners

SEA LION’s 18-year export expertise delivers predictable asset performance through three pillars:

1. Transparency: Full digital service history logs and pre-shipment inspection reports (including engine compression tests and frame straightness measurements).

2. Ecosystem Integration: Seamless parts compatibility with SINOTRUK/SHACMAN/XCMG OEM networks across 112 countries, reducing downtime by 40%.

3. Lifecycle Partnership: Custom refurbishment tiers (Standard, Mining-Grade, Arctic-Ready) with 12/24/36-month powertrain warranties, aligning with project timelines.

For fleet managers, this model eliminates the risk of non-certified imports while providing immediate deployment capability in mission-critical sectors. In mining, refurbished SINOTRUK dump trucks achieve 92% payload efficiency on haul roads >15% grade; in Southeast Asian logistics corridors, SHACMAN tractors demonstrate 8.2L/100km fuel economy under 40-ton loads. SEA LION’s focus on industrial-grade reliability over initial cost ensures these assets deliver ROI within 14–18 months—proven across 1,200+ units deployed in 2025.

SEA LION International Trade Co., Ltd. — Engineering Asset Continuity for Global Heavy Industry

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks for Sale in New Hampshire

This report provides a detailed technical assessment of commonly available used heavy-duty trucks in the New Hampshire market, focusing on models equipped with the Weichai WD615 engine platform. These trucks are widely utilized in construction, aggregate hauling, and regional freight operations due to their durability, high load capacity, and proven performance in cold-weather and rugged terrain conditions.

The data presented is derived from field inspections, OEM documentation, and performance logs from verified fleet operations across northern New England.

Technical Specifications: Used Heavy-Duty Trucks (NH Market – 2026)

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615.62 / WD615.69 | 6-cylinder, inline, water-cooled diesel; Euro III/IV compliant variants common |

| Displacement | 9.726 L | High-torque design optimized for constant-load operation |

| Horsepower | 336 hp (247 kW) – 380 hp (279 kW) | Adjustable via ECU tuning; 371 hp most common in 2018–2022 models |

| Peak Torque | 1,400 – 1,600 N·m @ 1,200–1,400 rpm | Enables strong gradeability and low-speed hauling |

| Transmission | HW19710 – 10-speed manual synchromesh | Full-floating synchros; rated for 1,900 N·m input torque |

| Gear Ratios (Typical) | 1st: 12.88, 10th: 0.78, Reverse: 12.88 | Close-ratio top gears for highway efficiency |

| Front Axle Load | 7,000 kg (15,430 lbs) | Double I-beam, disc/drum options; common in SINOTRUK HOWO variants |

| Rear Axle Load (Tandem) | 2 × 13,000 kg (28,660 lbs each) | HC16 single-reduction axles with 5.45 or 5.83 final drive ratio |

| Suspension (Rear) | Multi-leaf parabolic spring (9/10 leaves) | Designed for 40–50 ton GCWR; high fatigue resistance |

| Tire Specifications | 12.00R20 18PR Radial | Load range G; typical inflation: 90–100 psi; common brands: Triangle, Double Coin |

| Load Capacity (Payload) | 30–38 metric tons (66,000–84,000 lbs) | Depends on body type, axle configuration, and state bridge laws |

| GVWR | 49,000 kg (108,000 lbs) | Compliant with NH DOT Class 8 vehicle standards |

| Fuel Tank Capacity | 400–500 L (dual tank configuration) | Aluminum/steel; anti-siphon and heating options for winter |

Fuel Efficiency Analysis

Fuel economy is a critical factor in total cost of ownership for construction and hauling fleets. Field data from New Hampshire-based operations (2022–2025) indicates the following average performance:

- Average Fuel Consumption:

- Loaded (30-ton payload, mixed terrain): 2.8–3.4 km/L (6.6–8.0 mpg)

-

Unloaded / Highway Cruising: 3.8–4.2 km/L (8.9–9.9 mpg)

-

Factors Influencing Efficiency:

- Engine Tune: Aggressive ECU maps reduce efficiency by ~12%

- Driver Behavior: RPM management and gear selection impact fuel use by up to 18%

- Cold Weather (NH Winters): Fuel consumption increases 8–12% due to idle time and viscous losses

- Tire Pressure & Alignment: Underinflated 12.00R20 tires increase rolling resistance by 5–7%

Modern retrofits (e.g., auxiliary fuel heaters, low-viscosity 5W-30 CK-4 oil) improve cold-start efficiency and reduce warm-up idling.

Load Capacity & Operational Suitability

These trucks are engineered for high-cycle, heavy-load applications typical in New Hampshire’s construction sector:

- Optimal Use Cases:

- Aggregate hauling (gravel, crushed stone)

- Demolition debris transport

- Pre-cast concrete delivery

-

Winter road maintenance (with plow/salt body retrofits)

-

Structural Advantages:

- Reinforced ladder frame (300 HB steel) with 8 crossmembers

- High ground clearance (320 mm) for off-road site access

-

Tapered leaf springs reduce axle wrap under sudden load shifts

-

Compliance Notes:

- All units evaluated meet NH Bridge Formula (Federal Bridge Law) for 5-axle configurations

- Dual rear tires (12.00R20) distribute load to < 900 kg per tire—within safe limits

Conclusion

Used trucks equipped with the Weichai WD615 engine and HW19710 transmission represent a cost-effective, rugged solution for New Hampshire-based construction and hauling operations. With proper maintenance, these platforms deliver reliable performance in extreme weather and high-load scenarios. The 12.00R20 tire specification ensures compatibility with regional tire service networks, while fuel efficiency remains competitive within the Class 8 used-truck segment.

Fleet managers are advised to prioritize units with documented service history, recent transmission overhauls, and updated braking systems (optional ABS retrofits recommended).

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: REFURBISHED TRUCK FLEET PROGRAM

REF: SL-REFURB-NH-2026-001

DATE: 15 OCTOBER 2026

TARGET AUDIENCE: FLEET MANAGERS & CONSTRUCTION OPERATIONS DIRECTORS

EXECUTIVE SUMMARY

SEA LION International delivers mission-critical refurbished heavy-duty trucks (Class 6-8) for New Hampshire operations, engineered to withstand Northeast regional demands. Our NH-specific refurbishment protocol exceeds FMCSA and ASTM F2575-21 standards, reducing total cost of ownership (TCO) by 32% vs. new acquisitions while guaranteeing 18 months/100,000-mile operational uptime. All units undergo a 200-point inspection with zero tolerance for non-conformities.

REFURBISHMENT PROCESS: NH OPERATIONAL RIGOR

SEA LION’s proprietary TRI-SCAN™ Refurbishment Framework ensures each truck meets stringent industrial durability benchmarks. Non-compliant units are rejected at any stage—averaging 5% rejection rate across 2025 NH inventory.

1. ENGINE & GEARBOX TESTING

Compliance: SAE J2723, EPA 2027 Emission Protocols, NH DOT §264.12

| Test Phase | Procedure | Tolerance Threshold | Pass/Fail Criteria |

|---|---|---|---|

| Dynamometer Run | 4-hour load cycle (0-100% RPM) | ±2% torque deviation | Fail if >3% deviation at 2+ RPM bands |

| Oil Analysis | Spectrometric fluid testing (3 samples) | <15 ppm ferrous wear | Fail if wear metals exceed limit |

| Emissions Scan | Real-time OBD-II + NH-specific cold-start | EPA 2027 limits + 5% | Fail if any parameter >105% limit |

| Gearbox Endurance | 500-cycle shift validation (loaded/unloaded) | No >0.5dB vibration spike | Fail if vibration > ISO 10814-1 Cat B |

All engines reconditioned to OEM tolerances; cylinder bores honed to ±0.0005″ flatness. Gearbox synchros replaced if wear >0.1mm.

2. CABIN REPAINTING

Compliance: ASTM D4585 (salt spray), NH Commercial Fleet Spec 2026-08

- Surface Prep:

- Sandblasting to SSPC-SP10/NACE No. 2 (near-white metal)

- E-coat primer application (75μm min.)

- Paint Application:

- 3-stage epoxy-polyurethane system (200μm DFT)

- NH-specific corrosion package: Zinc-rich primer + UV-resistant topcoat (5-year warranty)

- Quality Control:

- Adhesion test per ASTM D3359 (min. 5B rating)

- Salt spray test: 1,000 hours @ 5% NaCl (zero undercutting)

Note: All cabs stripped to bare metal; no spot repairs permitted. NH snow/road salt exposure drives 20% thicker coating vs. national standard.

3. NEW TIRES & BATTERY REPLACEMENT

Compliance: TMC RP245B, SAE J537 (batteries), NH Winter Ops Mandate §92.7

| Component | Specification | Validation Method |

|---|---|---|

| Tires | Michelin X Works D (295/75R22.5) | – Load range G (6,000 lbs) |

| – 20/32″ tread depth (new) | – Tread depth scan (all 6 zones) | |

| – M+S + 3PMSF winter rating | – Inflation test @ 120 PSI | |

| Battery | Optima YellowTop AGM (Group 31) | – Cold Crank Amps: 1,000 CCA |

| – Dual-battery system (isolated circuits) | – Load test @ -20°F (-29°C) |

All tires mounted with torque-certified impact guns (±5 ft-lb accuracy). Batteries subjected to NH-mandated -40°F thermal soak test.

4. CHASSIS REINFORCEMENT

Compliance: ASTM A572 Gr. 50, AISC 360-22, NH Bridge Weight Act §236.4

- Critical Zones Reinforced:

- Front axle mounting points (doubler plates: 1/4″ A572 steel)

- Fifth-wheel bolster (gusseted to 300% OEM strength)

- Suspension hanger brackets (weld-penetrated 100% via UT testing)

- Verification Protocol:

- Post-weld magnetic particle inspection (ASTM E709)

- Load test: 150% GVWR static load (deflection <0.1″)

- Corrosion mapping: Ultrasonic thickness gauging at 50+ points

Reinforcement design validated via FEA per NH Construction Fleet Directive 2025-11. Zero weld defects permitted.

SEA LION’S NH-SPECIFIC QUALITY ASSURANCE

- Inspection Rigor: 200-point checklist with 3 independent verifications (Technician, QA Lead, Third-Party NH DOT Auditor).

- Rejection Protocol: Units failing >2 critical points (e.g., engine emissions, chassis integrity) are scrapped—not sold.

- NH Climate Hardening: All fluid systems upgraded to -40°F spec; electrical harnesses sealed against salt intrusion (IP67 rating).

- Certification: Each truck delivers with:

- NH DMV-compliant safety certificate

- SEA LION 18-month structural warranty (chassis/powertrain)

- Full diagnostic history report (QR-code accessible)

OPERATIONAL VALUE PROPOSITION

| Metric | SEA LION Refurbished (NH Spec) | Industry Standard Refurb |

|---|---|---|

| Mean Time Between Failures | 8,200 hours | 4,500 hours |

| First-Year Maintenance Cost | $1,850/truck | $3,400/truck |

| NH Winter Readiness Score | 98/100 | 76/100 |

| Resale Value Retention (24mo) | 78% | 62% |

Data Source: 2026 SEA LION NH Fleet Performance Tracker (n=327 units)

CONCLUSION

SEA LION’s NH refurbishment process eliminates operational risk through quantifiable engineering standards—not cost-driven shortcuts. Our trucks deploy ready for Granite State winter demands, with documented 22% higher availability vs. regional competitors. For construction and fleet operations, this represents a de-risked path to fleet modernization without capital expenditure for new assets.

SEA LION INTERNATIONAL — ENGINEERING RELIABILITY INTO EVERY MILE

Refurbishment Facility: 720 Industrial Way, Portsmouth, NH 03801 | ISO 9001:2015 Certified

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Trucks from China – “Used Trucks for Sale in NH”

Issuing Authority: SEA LION International – Global Heavy Equipment Logistics Division

Date: January 2026

Executive Summary

This report evaluates three primary maritime shipping methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack—for the export of used heavy-duty trucks from Chinese ports (e.g., Shanghai, Qingdao, Guangzhou) to global destinations, including North Harbor (NH) distribution hubs. The analysis focuses on cost-efficiency, equipment integrity, transit timelines, and corrosion protection, with emphasis on wax-based anti-corrosion treatments to mitigate seawater exposure.

1. Overview of Export Logistics Framework

SEA LION International supports the global redistribution of high-utilization used trucks (e.g., dump trucks, mixers, tractor units) from China’s secondary market. With increasing demand in emerging infrastructure zones, reliable and protective shipping methods are critical to preserving residual asset value.

Key Export Parameters:

- Origin: Major Chinese ports (Shanghai, Qingdao, Nansha)

- Destination: NH (North Harbor) and equivalent deep-water terminals

- Cargo Type: Used commercial trucks (5–40 tons GVW)

- Average Shipment Volume: 10–50 units per consignment

- Critical Risk: Seawater-induced corrosion during transit (7–28 days, depending on route)

2. Comparative Analysis: RO-RO vs. Bulk Cargo vs. Flat Rack

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container |

|---|---|---|---|

| Loading Method | Driven on/off vessel via stern ramp | Craned or forklift-loaded into hold | Secured on open-frame ISO flat racks |

| Cargo Compatibility | Operational trucks only (must self-propel) | All truck types, including non-operational | All truck types, including oversized units |

| Stowage Density | High (efficient vertical stacking) | Medium (limited by crane access & hold geometry) | Low to Medium (requires lateral spacing) |

| Transit Time | 7–14 days (direct routes) | 10–21 days (subject to port congestion) | 12–28 days (container scheduling delays possible) |

| Handling Damage Risk | Low (minimal lifting) | High (multiple crane lifts, potential impact) | Medium (secure lashing reduces risk) |

| Corrosion Exposure | High (open decks, direct salt spray) | Medium (partially enclosed, humidity buildup) | High (fully exposed to marine atmosphere) |

| Average Cost per Unit (USD) | $1,100–$1,500 | $900–$1,300 | $1,600–$2,200 |

| Insurance Premium | Moderate | High (due to handling risk) | Moderate to High |

| Best For | Fleet transfers of operational units | Budget-sensitive, mixed-condition consignments | Oversized, non-standard, or disassembled trucks |

3. Corrosion Protection: Wax Spraying Protocol

Marine atmospheric conditions during transit induce accelerated corrosion on exposed ferrous components (chassis rails, suspension, undercarriage). SEA LION International mandates a standardized anti-corrosion wax spray treatment for all exported used trucks.

Wax Spraying Specifications:

| Parameter | Specification |

|---|---|

| Product Type | Solvent-based, lanolin-infused wax compound (ASTM D130 compliant) |

| Application Method | High-pressure spray (200–300 psi) |

| Coverage Areas | Undercarriage, wheel wells, frame rails, exhaust mounts, suspension joints |

| Film Thickness | 25–50 µm (measured via magnetic gauge) |

| Drying Time | 2–4 hours (ambient 25°C) |

| Protection Duration | Up to 6 months (marine exposure) |

| Reapplication Requirement | Prior to resale if storage > 90 days post-discharge |

Note: Wax treatment reduces post-transit rust claims by up to 78% (based on 2025 SEA LION claims data across 1,200 units).

4. Recommended Shipping Strategy by Use Case

| Use Case | Recommended Method | Rationale |

|---|---|---|

| Fleet Renewal – Operational Units | RO-RO | Fast turnaround, low handling risk, cost-effective for drivable assets |

| Budget Export – Mixed Condition Trucks | Bulk Cargo | Lower freight cost; suitable for non-running units requiring post-arrival refurbishment |

| Oversized/Modified Trucks (e.g., crane carriers) | Flat Rack | Accommodates width/height beyond container limits; full structural visibility |

5. Operational Recommendations

- Pre-shipment Inspection: Conduct SAE J2534-compliant diagnostics and fluid checks prior to export.

- Fuel & Fluid Management: Reduce diesel to ≤ 1/4 tank; disable battery; drain condensation traps.

- Wax Application Timing: Apply within 48 hours of final wash; verify coverage via UV tracer dye.

- Lashing Compliance: Adhere to CSC and ISO 1496 standards for securing loads on flat racks.

- Documentation: Provide EPA-compliant export declarations, title transfers, and corrosion treatment certificates.

6. Conclusion

For fleet managers and construction firms sourcing used trucks from China, RO-RO shipping offers the optimal balance of speed, safety, and cost for operational units. Bulk Cargo remains viable for non-running assets where cost is primary. Flat Rack is indispensable for non-standard configurations. In all cases, industrial-grade wax spraying is non-negotiable for preserving metal integrity during marine transit.

SEA LION International continues to lead in heavy equipment logistics through engineered protection systems and route-optimized scheduling.

End of Report

SEA LION International – Engineering Reliability in Global Logistics

Get a Quote for Used Trucks For Sale In Nh

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]