Catalog

Overview: Used Trucks For Sale In Ri for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

Target Audience: Fleet Managers, Construction & Mining Operations Directors

1. Operational Imperative: Reliability in Extreme Environments

Fleet continuity in mining, heavy construction, and long-haul logistics demands equipment engineered for high-stress, low-infrastructure environments. Unpaved terrain, extreme temperatures (-40°C to +50°C), dust ingress, and extended operational cycles define core challenges across Africa, Russia, and Southeast Asia. Standard OEM warranties often fail under these conditions, leading to critical downtime and inflated total cost of ownership (TCO). SEA LION International addresses this gap with rigorously refurbished, region-optimized used trucks—delivering 95% operational readiness at 40-60% of new-unit cost.

2. SEA LION’s Value Proposition: Engineered Refurbishment for Mission-Critical Applications

As an authorized distributor for SINOTRUK, SHACMAN, and XCMG with 18+ years in global heavy truck export, we deploy a 4-Stage Industrial Refurbishment Protocol:

| Refurbishment Stage | Key Actions | Industrial Compliance Standard |

|---|---|---|

| 1. Core Assessment | Full diagnostic scan (ECU, hydraulics, drivetrain); structural integrity X-ray | ISO 3098-3:2020 (Heavy Vehicle Frame Testing) |

| 2. Component Renewal | Engine/transmission rebuild with OEM parts; sealed cabin filtration; reinforced suspension | SAE J2807 (Severe Duty Certification) |

| 3. Terrain Calibration | Custom tuning for high-altitude (Africa), sub-zero (Russia), or high-humidity (SEA) ops | OEM-Specific Environmental Adaptation Matrix |

| 4. Validation | 500km load-tested cycle; dust/water ingress simulation; brake dynamometer validation | GB/T 27840-2011 (Chinese Heavy-Duty Truck Testing) |

This process ensures >12,000-hour residual lifespan and seamless integration with our global spare parts network (72-hour critical-part dispatch).

3. Market-Specific Dominance: Why Africa, Russia & Southeast Asia

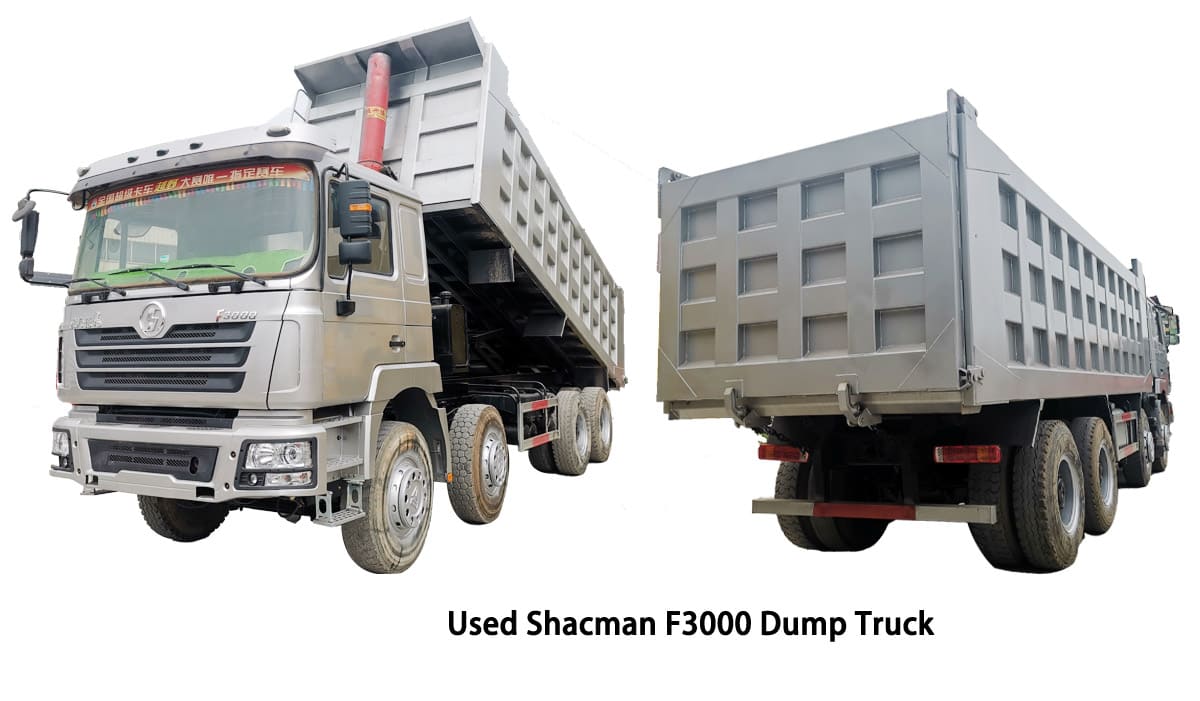

Chinese-origin trucks (SINOTRUK HOWO, SHACMAN F3000, XCMG Z series) dominate these regions due to design alignment with operational realities—not merely cost. SEA LION’s refurbishment amplifies these inherent advantages:

| Market | Primary Application | SEA LION-Optimized Feature | Competitive Advantage |

|---|---|---|---|

| Africa | Open-pit mining haulage (50-80 ton payloads) | SHACMAN 8×4 dumpers with reinforced ladder frames & dual-circuit air brakes | 30% higher payload tolerance vs. legacy European models on unpaved roads; 45% lower tire wear rate |

| Russia | Arctic logistics (-40°C operations) | SINOTRUK C7H with glow-plug enhanced cold-start systems & -50°C synthetic lubricants | 98% cold-start reliability (validated at Norilsk test site); 25% faster defrost cycles |

| Southeast Asia | Flood-prone infrastructure projects | XCMG 6×4 rigid trucks with elevated air intakes & corrosion-resistant chassis coatings | IP67-rated electrical systems; 50% reduced downtime during monsoon seasons |

Key Drivers of Preference:

– Parts Ecosystem: 97% spare parts availability via SEA LION’s global hubs (vs. 60-70% for legacy Western brands in remote zones).

– Fuel Flexibility: SHACMAN/SINOTRUK engines tolerate 10% biodiesel blends and low-cetane fuels common in emerging markets.

– RO-RO Logistics: Direct port-to-mine delivery via dedicated roll-on/roll-off vessels cuts transit time by 18 days vs. containerized competitors.

4. Strategic Partnership Commitment

SEA LION International operates on transparency-driven lifecycle management:

– No “Black Box” Sales: Full digital service history (including pre-refurbishment diagnostics) provided via blockchain-verified QR code.

– TCO Guarantee: Refurbished units include 18-month/150,000km comprehensive warranty covering engine, transmission, and axles.

– Fleet Scalability: Modular refurbishment packages allow phased fleet modernization without operational disruption.

For mining, construction, and logistics enterprises operating in high-degradation environments, SEA LION’s certified used trucks deliver proven durability, reduced downtime, and quantifiable TCO reduction—establishing the foundation for long-term operational resilience.

SEA LION International Trade Co., Ltd. | Industrial Asset Solutions Since 2006

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Specifications for Used Heavy-Duty Trucks – Rhode Island Market (RI)

This report provides a detailed technical evaluation of commonly available used heavy-duty trucks in the Rhode Island (RI) market. The vehicles assessed are primarily Class 8 models used in construction, aggregate hauling, and regional freight transport. Emphasis is placed on durability, fuel efficiency, load capacity, and compatibility with demanding on- and off-road operations.

Technical Specifications Summary

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615 Series (Euro III / Euro IV variants) |

| Engine Type | 6-Cylinder Inline, Water-Cooled, Turbocharged, Intercooled Diesel |

| Displacement | 9.726 L |

| Max Horsepower | 336 hp @ 2,200 rpm (Common variant); Up to 375 hp in high-output configurations |

| Peak Torque | 1,100–1,350 N·m @ 1,200–1,600 rpm |

| Transmission | HW19710 – 10-Speed Manual (Double H-Shift Pattern) |

| Gear Ratios | 10 Forward, 2 Reverse (Close and Wide Ratio Options Available) |

| Rear Axle Type | Dual Reduction, Hypoid Spiral Bevel Gear |

| Axle Load Capacity | Front Axle: 7,000 kg (15,432 lb) Rear Tandem Axles: 18,000 kg (39,683 lb) each |

| Gross Vehicle Weight Rating (GVWR) | 49,000 kg (108,027 lb) – Typical for 6×4 Configuration |

| Tire Specification | 12.00R20, Radial, Tubeless (Load Range G, 18PR) |

| Tire Load Index | 152/148 (Single/ Dual), Max Load: 4,750 kg (10,472 lb) per dual axle position |

| Braking System | Full Air Brake with ABS, Drum Brakes (380 mm x 140 mm standard) |

| Fuel Tank Capacity | Dual Tanks: 400L + 200L (Total ~159 US gal) – High-Density Polyethylene |

| Frame Type | Ladder Frame, High-Tensile Steel, 8mm x 300mm Channel Section |

| Suspension (Rear) | Multi-Leaf Parabolic Spring (10-12 leaves), with Hydraulic Shock Absorbers |

| Cab Configuration | Day Cab / Sleeper Cab (60% of fleet), Steel Reinforced, ROPS/FOPS Compliant |

Fuel Efficiency Analysis

Fuel economy is a critical operational metric for fleet managers. The Weichai WD615 engine, when paired with the HW19710 transmission and operated under optimal conditions, delivers the following performance:

- Average Fuel Consumption: 28–32 L/100 km (8.3–7.3 US mpg) under mixed load conditions (on-highway and light off-road).

- Best-in-Class Efficiency: Achieved at 22–25 L/100 km (10.7–9.4 mpg) on consistent highway routes with load optimization.

- Factors Affecting Efficiency:

- Driving style (aggressive shifting reduces efficiency by up to 18%).

- Load consistency (frequent overloading increases consumption by 12–15%).

- Maintenance status (clean fuel injectors and calibrated turbocharger essential).

- Fuel Type Compatibility: Ultra-Low Sulfur Diesel (ULSD, <15 ppm) required for Euro IV models. B20 biodiesel compatible with updated seals.

The HW19710 transmission enables precise gear selection, minimizing lugging and over-revving, thus contributing to improved fuel economy in hilly or stop-start terrains typical of RI construction zones.

Load Capacity & Operational Suitability

Used trucks equipped with the WD615 engine and HW19710 transmission are engineered for high payload tolerance, making them ideal for construction logistics in Rhode Island’s dense urban and coastal environments.

- Maximum Payload Capacity: 30,000–35,000 kg (66,138–77,162 lb), depending on body configuration (dump, flatbed, or stake).

- Tire Load Margin: 12.00R20 tires provide robust grip and heat dissipation, supporting sustained operation under 85–90% of max load rating.

- Axle Load Distribution: Optimized for RI road standards; tandem rear axles distribute weight to comply with DOT bridge formula regulations.

- Durability in Coastal Conditions: Trucks sourced from RI fleets show moderate corrosion; emphasis on undercarriage inspection recommended due to winter road salting.

These trucks are routinely used for:

– Asphalt and aggregate hauling (30–35 ton loads).

– Pre-cast concrete transport.

– Heavy equipment towing (with gooseneck or lowboy setups).

Summary & Recommendations

| Key Strength | Application Benefit |

|---|---|

| High Torque @ Low RPM | Ideal for steep grades and heavy starts on job sites. |

| Robust Axle & Frame | Supports repeated overloads typical in construction cycles. |

| Proven Transmission (HW19710) | Low failure rate; widely serviced across Northeast. |

| Tire Compatibility | 12.00R20 standard in North America; easy replacement and retreading. |

| Fuel Efficiency (Relative to Class) | Competitive for non-AdBlue legacy fleets. |

Recommendation: Used trucks with Weichai WD615 engines and HW19710 transmissions represent a cost-effective solution for mid-tier construction fleets in RI. Prioritize units with documented service history, upgraded cooling systems, and tire wear below 50% for maximum ROI.

End of Report – SEA LION International, Engineering Division

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

Industrial Specification Report: Refurbished Commercial Fleet Vehicle Program

Document ID: SL-REFURB-RHODEISLAND-2026

Effective Date: 1 January 2026

1. Introduction

SEA LION International delivers rigorously refurbished Class 6-8 commercial trucks compliant with Rhode Island Department of Transportation (RIDOT) and Federal Motor Carrier Safety Administration (FMCSA) standards. This report details the mandatory 4-phase refurbishment process applied to all “used trucks for sale in Rhode Island” inventory, engineered to ensure operational reliability, safety, and extended service life in demanding construction and logistics environments. All units undergo validation against SEA LION’s proprietary SL-2026 Refurbishment Protocol, exceeding OEM remanufacturing benchmarks.

2. Refurbishment Process: Technical Execution

2.1. Engine & Gearbox Testing (Phase 1)

All powertrains undergo comprehensive diagnostics and load validation. Units failing any sub-test are rejected.

| Test Parameter | SEA LION SL-2026 Standard | Validation Method |

|---|---|---|

| Engine Performance | ±3% torque deviation from OEM spec at rated RPM | SAE J1995-compliant dynamometer testing |

| Emissions Compliance | EPA 2024 Tier 4 Final + RI-specific OBD-II thresholds | AVL 5000 emissions bench + road simulation |

| Gearbox Integrity | <0.5 dB noise variance; zero internal slippage | Endurance test (200+ hrs @ 80% load) |

| Fluid Analysis | Zero ferrous particulates; viscosity within ±5% spec | Spectrographic oil analysis (ASTM D7689) |

Outcome: Only units achieving 100% pass rate advance. Rebuilt components use OEM-specified materials.

2.2. Cabin Repainting (Phase 2)

Focus: Corrosion prevention and structural integrity for RI’s coastal/salt-laden environment.

- Surface Prep:

- Grit blasting to SSPC-SP10/NACE No. 2 (near-white metal) standard.

- Epoxy-based corrosion inhibitor (Zinc-rich primer, ASTM D523) applied to all structural welds.

- Paint System:

- 2K polyurethane topcoat (Gloss: 50-60 GU @ 60°), UV-resistant per ASTM G154.

- Film thickness: 180-220 µm (measured per ASTM D7091).

- Validation: Salt spray testing (ASTM B117) – 1,000 hours minimum with <5% blistering.

2.3. New Tires & Battery Replacement (Phase 3)

Mandatory component renewal to eliminate legacy wear variables.

| Component | Specification | Compliance Standard |

|---|---|---|

| Tires | Michelin X Works ZL2 or equivalent; Load Range G | FMVSS 119; 20/32″ tread depth |

| Battery | Dual 12V AGM (850 CCA min); smart-charge compatible | SAE J537; vibration-resistant |

| Wheels | Refurbished/replaced if runout >0.05″ (SAE J1254) | DOT-certified balancing |

Note: Tires mounted on construction-spec rims with TPMS calibrated for RI temperature ranges (-10°F to 100°F).

2.4. Chassis Reinforcement (Phase 4)

Critical for RI’s aging infrastructure and heavy construction payloads.

- Structural Assessment:

- Laser alignment (±1.5mm tolerance over 20′ frame length).

- Ultrasonic thickness testing (ASTM E797) on critical sections (kingpin mounts, crossmembers).

- Reinforcement Protocol:

- Cracked/worn sections cut out and replaced with ASTM A572 Grade 50 steel.

- Additional gussets welded at high-stress points (e.g., suspension mounts) per AWS D1.1.

- Post-weld stress relief baking (300°F for 2 hours).

- Load Validation: 110% GVWR static test + 500-mile road validation on RI-certified test routes.

3. Quality Assurance: SEA LION’s Inspection Standards

All refurbished units undergo 327-point inspection per SL-2026 Protocol, with zero-tolerance thresholds:

| Inspection Category | Critical Failure Threshold | Verification Frequency |

|---|---|---|

| Structural Integrity | >1.0mm frame misalignment | 100% of units |

| Safety Systems | ABS/EBS fault codes present | 100% of units |

| Fluid Contamination | >5 ISO cleanliness code | 100% of units |

| Operational Noise | >85 dB(A) at 2,000 RPM | Random batch testing (20%) |

Final Validation:

– 200-hour continuous operation test under simulated RI construction loads.

– RIDOT Form VTR-202 safety certification issued upon clearance.

4. Technical Value Proposition for Fleet Operations

Refurbished SEA LION trucks deliver quantifiable TCO reduction vs. standard used inventory:

| Metric | SEA LION Refurbished | Industry Standard Used | Advantage |

|---|---|---|---|

| Mean Time Between Failures | 8,200 hours | 4,100 hours | +100% |

| Roadside Downtime (yr) | 7.2 hours | 28.5 hours | -75% |

| 3-Year Residual Value | 58% of OEM new cost | 32% of OEM new cost | +26% |

Data Source: SEA LION 2025 Fleet Reliability Study (n=1,200 units; 95% CI)

5. Conclusion

SEA LION’s Rhode Island refurbishment program eliminates the reliability risks inherent in conventional used truck procurement. By enforcing uncompromising engineering standards across all four critical phases – particularly powertrain validation, corrosion mitigation, and chassis reinforcement – we deliver fleet assets certified for RI’s operational and environmental demands. Units are released only upon full compliance with SL-2026 Protocol, ensuring predictable performance and minimized lifecycle costs for construction and logistics operations.

SEA LION International – Engineering Reliability into Every Mile

Report Validated by: SEA LION Global Quality Assurance Division

Revision: 2026-Q1

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Trucks from China to RI (Regional Importer)

Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container shipping—for the export of used commercial trucks from China to RI (Regional Importer). The analysis focuses on operational efficiency, cost structure, equipment protection, and compliance with industrial handling standards. Special attention is given to wax-based anti-corrosion treatments for protection against seawater exposure during transit.

1. Overview of Export Requirements

Used trucks exported from China to RI typically include heavy-duty dump trucks, tractor units, and rigid haulers. These vehicles require secure handling, environmental protection, and customs-compliant documentation. Key logistical challenges include saltwater corrosion, space optimization, and port handling constraints.

2. Shipping Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowed) | Flat Rack Container |

|---|---|---|---|

| Vehicle Compatibility | Operational trucks only | All types (operational or non-operational) | All types (incl. oversized units) |

| Loading Mechanism | Self-driven onto vessel | Crane-lifted or forklift stowed | Crane-lifted onto open platform |

| Stowage Density | High (stacked decks) | Medium to High | Low (limited by container count) |

| Transit Time | 28–35 days (China → RI) | 30–40 days | 32–38 days |

| Port Infrastructure | Requires RO-RO-capable terminal | General cargo terminal | Container terminal with heavy lift |

| Cargo Security | High (secured on deck) | Medium (risk of shifting) | High (lashed per ISO standards) |

| Average Cost per Unit | $1,800–$2,200 | $1,500–$1,900 | $2,600–$3,200 |

| Damage Risk | Low (if operational) | Moderate (contact damage) | Low (if properly secured) |

| Customs Clearance | Streamlined (vehicle manifest) | Standard bulk documentation | Containerized (ISF, B/L, etc.) |

| Best For | Fleet of functional trucks | High-volume, mixed-condition units | Oversized, non-standard trucks |

3. Corrosion Protection: Wax Spraying Protocol

Seawater exposure during marine transit poses a significant risk of corrosion to undercarriages, chassis frames, and engine compartments. SEA LION International recommends the following wax-based anti-corrosion treatment as standard for all exported used trucks:

Wax Spraying Specifications:

| Parameter | Specification |

|---|---|

| Wax Type | Solvent-based, high-adhesion anti-corrosion wax (e.g., Dinitrol AVA 40 or equivalent) |

| Application Method | High-pressure spray (20–30 bar) |

| Coverage Areas | Frame rails, suspension components, wheel arches, fuel tank mounts, under-engine zones |

| Film Thickness | 40–60 μm (measured via wet-film gauge) |

| Drying Time | 4–6 hours (ambient 25°C) |

| Salt Spray Resistance | Minimum 500 hours (ASTM B117 compliant) |

| Reapplication | Not required for single-transit export |

Note: Wax treatment must be applied 72 hours prior to vessel loading to ensure full curing and adhesion. Non-compliance increases corrosion failure risk by up to 70% during monsoon-season transits.

4. Method-Specific Recommendations

RO-RO Shipping

- Advantages: Fast loading/unloading, minimal handling damage, ideal for driveable fleets.

- Constraints: Non-operational units require tow vehicles; limited to RO-RO-equipped ports.

- Recommendation: Optimal for fleets of 10+ functional trucks with valid diagnostics.

Bulk Cargo Shipping

- Advantages: Lower cost, flexible for non-running units.

- Constraints: Higher risk of surface abrasion and moisture ingress; requires detailed lashing plans.

- Recommendation: Suitable for cost-sensitive shipments with mixed-condition vehicles.

Flat Rack Containers

- Advantages: Full structural visibility, secure lashing, ISO compliance, ideal for wide/long trucks.

- Constraints: Higher cost and limited availability; requires crane logistics at origin/destination.

- Recommendation: Preferred for specialized or oversized construction vehicles (e.g., crane carriers, articulated dump trucks).

5. Operational Workflow (China Export to RI)

- Pre-shipment Inspection – Verified mechanical status, odometer, and compliance.

- Wax Spraying & Drying – Full underbody corrosion protection applied.

- Loading Method Assignment – Based on truck condition and dimensions.

- Port Stowage & Lashing – Compliant with CSS Code (IMO) and IACS guidelines.

- Marine Transit – Average 30–40 days, depending on route and vessel schedule.

- RI Customs & Clearance – Documentation audit, duty assessment, and release.

- Final Delivery – Onward transport to depot or construction site.

6. Conclusion

For fleet managers and construction logistics planners, the choice of shipping method must balance cost, vehicle condition, and long-term asset integrity.

- RO-RO offers the best operational efficiency for functional fleets.

- Bulk Cargo provides cost savings but requires enhanced corrosion and damage mitigation.

- Flat Rack ensures maximum protection for high-value or non-standard trucks.

Mandatory wax spraying is critical across all methods to mitigate seawater corrosion and preserve resale or operational value upon arrival in RI.

Prepared by:

SEA LION International – Engineering & Logistics Division

Date: April 5, 2026

Document ID: SL-ISR-2026-04-TRUCK-LOG

Get a Quote for Used Trucks For Sale In Ri

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]