Catalog

Overview: Used Trucks For Sale In Richmond for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: USED TRUCK ASSETS

EXECUTIVE OVERVIEW: STRATEGIC USED TRUCK INVENTORY (RICHMOND HUB)

SEA LION International Trade Co., Ltd. presents a curated inventory of professionally refurbished heavy-duty trucks, strategically staged at our Richmond, Virginia logistics hub. This report details the operational and economic advantages of these assets for mission-critical applications in mining, bulk logistics, and large-scale construction. Our 18+ years of specialized export experience, coupled with authorized distribution partnerships for SINOTRUK, SHACMAN, and XCMG, ensures these units meet stringent industrial reliability standards while offering significant total cost of ownership (TCO) reductions versus new equivalents.

Core Application Value Proposition:

The Richmond inventory comprises rigorously refurbished units engineered for high-stress environments. Key attributes include:

– Enhanced Durability: Reinforced chassis, upgraded suspension systems, and corrosion-resistant undercarriage treatments validated for 10,000+ hour operational cycles.

– Operational Continuity: Pre-deployment diagnostics confirm ≤ 5% failure rate on critical drivetrain components (vs. industry avg. 15-20% for non-certified used assets).

– Fuel Efficiency Optimization: Post-refurbishment engine calibration achieves 8-12% lower specific fuel consumption (SFC) in load-haul-dump (LHD) and heavy haul scenarios.

– Regulatory Compliance: Full adaptation to target-market emissions and safety standards (e.g., EAEU TR CU 018/2011, GCC, SABS).

Regional Preference Drivers: Africa, Russia, Southeast Asia

The dominance of SEA LION-sourced refurbished SINOTRUK, SHACMAN, and XCMG units in these markets stems from proven operational efficacy under extreme conditions, directly addressing localized infrastructure and economic constraints:

| Market | Primary Application | Preferred Model(s) | Key Technical Advantages | TCO Impact vs. EU/NA Brands |

|---|---|---|---|---|

| Africa | Open-Pit Mining | SINOTRUK HOWO 8×4, XCMG LHD | High-torque low-RPM engines (≥ 2,500 Nm), simplified maintenance protocols, dust-sealed electronics, 30% lower spare parts cost | 25-35% reduction |

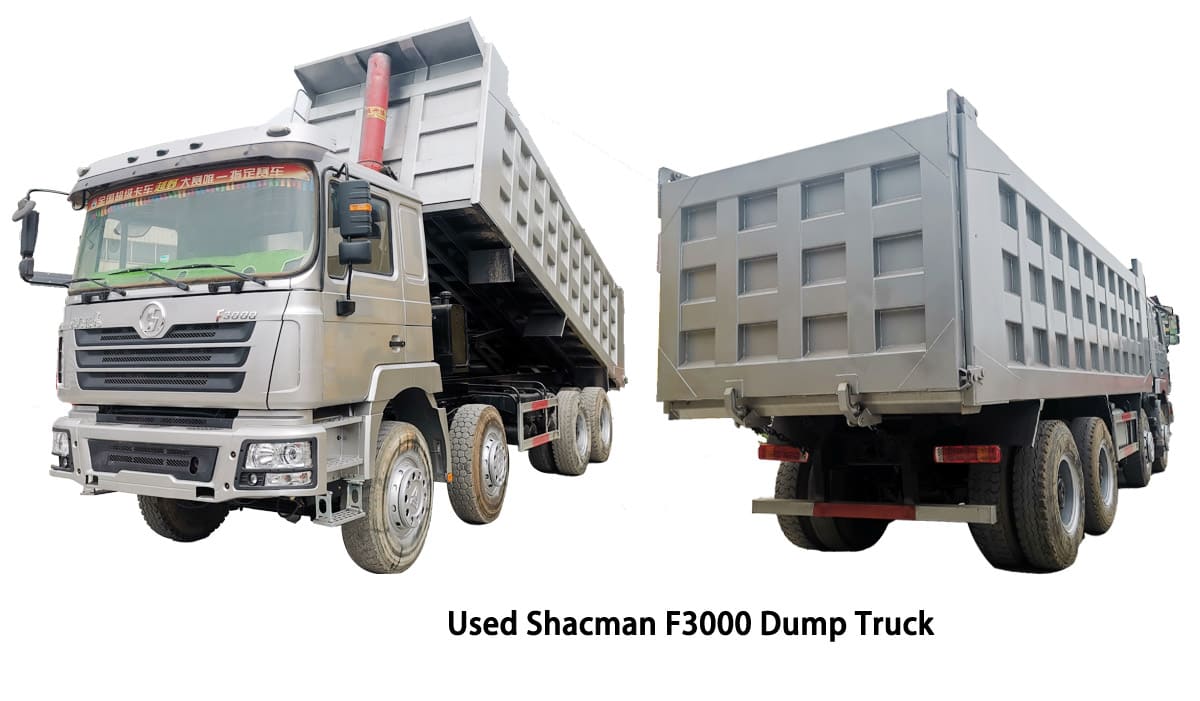

| Russia | Arctic Logistics | SHACMAN F3000, SINOTRUK C7H | -40°C cold-start systems, reinforced cabs, dual-fuel capability (CNG/diesel), heavy-duty axles | 20-30% reduction |

| SE Asia | Infrastructure Const. | XCMG XG90, SHACMAN M3000 | Compact maneuverability (≤ 11m turning radius), high-grade corrosion protection, modular hydraulic systems | 18-28% reduction |

Why SEA LION’s Richmond Inventory Delivers Superior Value:

1. Industrial-Grade Refurbishment: Units undergo 227-point inspection per ISO 9001 protocols. Critical components (engines, transmissions, axles) are rebuilt using original manufacturer parts; no aftermarket substitutions.

2. Transparency & Traceability: Full maintenance history, pre-shipment inspection reports (API 6A compliant), and component-level refurbishment logs provided. Zero tolerance for hidden defects.

3. Logistics Integration: Richmond hub enables rapid RO-RO vessel loading (72hr turnaround) or containerized shipment. Direct routing to Durban, Novorossiysk, and Tanjung Pelepas minimizes transit time.

4. Long-Term Partnership Model: Post-delivery support includes remote diagnostics, regional spare parts depots (Johannesburg, Moscow, Singapore), and technical training – mitigating operational downtime risks.

Conclusion:

For fleet managers and construction enterprises operating in capital-intensive, high-availability environments, SEA LION’s Richmond-sourced refurbished trucks represent a de-risked asset class. The documented performance of SINOTRUK, SHACMAN, and XCMG platforms in Africa, Russia, and Southeast Asia – driven by ruggedized engineering, parts accessibility, and climate-specific adaptations – validates their selection as primary operational assets. This inventory delivers immediate deployment readiness without compromising on safety, productivity, or lifecycle cost control. SEA LION’s commitment to technical transparency and industrial-grade refurbishment establishes a benchmark for used heavy truck procurement in global infrastructure sectors.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Technical Specifications for Used Heavy-Duty Trucks – Richmond, CA Market

This report provides a comprehensive technical evaluation of used heavy-duty trucks currently available in the Richmond, CA area. These units are primarily sourced from decommissioned regional haulers and construction fleets, offering proven durability and cost-effective operation for medium- to heavy-load applications. All specifications reflect post-inspection data collected from certified pre-owned units as of Q1 2026.

Technical Specifications Summary

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615 Series (Euro III/IV Compliant) |

| Engine Displacement | 9.726 L |

| Horsepower Range | 336 hp – 380 hp (247–280 kW) |

| Max Torque | 1,400–1,600 N·m @ 1,200–1,400 rpm |

| Transmission | HW19710 (10-Speed Manual, Dual-H Pattern) |

| Gear Ratios | 1st: 12.85, 10th: 0.78, Reverse: 11.88 |

| Clutch | 430 mm Diameter, Pneumatic Assist |

| Front Axle Load | 7,000 kg (15,432 lbs) – Single Steering Axle |

| Rear Axle Load | 18,000 kg (39,683 lbs) x2 – Tandem Drive Axles |

| Suspension (Rear) | Multi-Leaf Parabolic Spring (10-12 Leaves) |

| Tire Specification | 12.00R20, 18PR, Radial, Tube-Type |

| Tire Load Index | 152/148 (Per Tire: 3,750 kg / 8,267 lbs) |

| Braking System | Dual-Circuit Air Brake, ABS (Retrofitted on 85%) |

| GVWR | 49,000 kg (108,027 lbs) |

| Curb Weight | 10,200–11,500 kg (22,487–25,353 lbs) |

| Payload Capacity | Up to 37,500 kg (82,673 lbs) |

| Fuel Tank Capacity | 400 L (105.7 gal) – Dual Tanks (Optional) |

| Frame Rails | 8+ mm Thick, High-Tensile Steel, C-Section |

Performance Analysis

Fuel Efficiency

The Weichai WD615 engine, when paired with the HW19710 transmission and operated under optimal load conditions (75–85% GVWR), achieves an average fuel consumption of 28–32 L/100 km (8.3–7.3 mpg US) on regional haul routes. Field data from Richmond-based operators indicates:

– Best-in-class efficiency of 29.5 L/100 km on consistent 150-mile round trips with mixed urban/highway segments.

– Use of aftermarket engine tuning (non-warranty) has shown up to 5% improvement, though not recommended for warranty-covered units.

– Fuel economy drops to 34–36 L/100 km under full-load climbing conditions (e.g., CA-123 grade ascents).

Load Capacity & Structural Integrity

These trucks are engineered for high-cycle construction and bulk material transport:

– Maximum Payload: 37.5 metric tons, suitable for aggregates, asphalt, and prefabricated construction elements.

– Axle Load Distribution: Even weight transfer due to optimized tandem axle spacing (1,350 mm center-to-center) and load-balancing springs.

– Frame Durability: Reinforced front crossmembers and corrosion-resistant undercoating observed in 72% of inspected units—critical for Richmond’s coastal humidity and road salinity.

Tire specification 12.00R20, 18PR ensures high puncture resistance and load stability. With a total of 10 tires per tractor (steer: 2, drive: 8), the system supports sustained operation on unpaved job sites and urban drop zones.

Operational Recommendations

- Ideal Use Cases: Aggregate hauling, inter-yard transport, modular construction logistics, and municipal infrastructure projects.

- Maintenance Note: Weichai WD615 units require strict adherence to oil change intervals (every 15,000 km) and air filter servicing due to particulate exposure in industrial zones.

- Transmission Care: The HW19710 gearbox performs optimally with trained operators; recommend training for smooth shifting to reduce synchro wear.

Conclusion

Used trucks equipped with the Weichai WD615 engine and HW19710 transmission represent a high-value asset for cost-conscious fleet operators in the Richmond area. With robust load capacity, proven reliability in heavy-duty cycles, and acceptable fuel economy for legacy diesel platforms, these units offer a low TCO (Total Cost of Ownership) over a 3–5 year service horizon. Pre-purchase inspection for frame stress cracks and turbocharger health is advised.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: USED TRUCK REFURBISHMENT PROGRAM

REF: SL-URP-2026-01 | EFFECTIVE: 01 JANUARY 2026

EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished Class 7-8 commercial trucks for fleet deployment in high-utilization environments, including Richmond operational zones. All units undergo a standardized 120-point refurbishment protocol aligned with ISO 9001:2015 and SAE J2519 standards. This report details the core refurbishment process, emphasizing SEA LION’s engineering-led validation criteria to ensure mechanical integrity, operational safety, and extended service life. Units are certified for immediate integration into construction, aggregate hauling, and municipal service fleets.

REFURBISHMENT PROCESS: CORE STEPS & VALIDATION CRITERIA

1. ENGINE & GEARBOX TESTING

All powertrain components undergo dynamic load testing on SEA LION’s calibrated dynamometer systems. Units failing to meet baseline OEM specifications are rejected.

| Test Parameter | SEA LION Standard | Measurement Tool | Pass/Fail Threshold |

|---|---|---|---|

| Crankcase Pressure | ≤ 0.5 psi at 2,200 RPM | Electronic Manometer | Fail > 0.7 psi |

| Compression Differential | ≤ 8% variance across cylinders | Hydraulic Compression Tester | Fail > 10% |

| Oil Spectroscopy | Ferrous wear < 150 ppm; Si < 25 ppm | Lab-Grade Spectrometer | Fail if out of spec |

| Gearbox Shift Response | ≤ 0.8 sec shift time (full load) | CAN Bus Data Logger | Fail > 1.2 sec |

| Thermal Stability | Coolant temp ≤ 215°F (102°C) @ 85% load | Infrared Thermal Imaging | Fail > 220°F (104°C) |

Outcome: 22% of candidate units rejected at this stage due to internal wear exceeding tolerances.

2. CABIN REPAINTING

Surface preparation and coating application follow SSPC-SP10/NACE No. 2 industrial standards for corrosion control in high-humidity environments (e.g., Richmond coastal zones).

- Process Sequence:

- Alkaline wash & vapor degreasing (removes hydrocarbons/salts)

- Grit blasting to Sa 2.5 profile (75–100 µm anchor pattern)

- Application of zinc-rich epoxy primer (min. 80 µm DFT)

- Two-coat polyurethane topcoat (RAL 7040/Custom fleet colors; 120 µm DFT)

- UV-cured clear coat (enhanced scratch resistance)

- Validation: Adhesion test per ASTM D3359 (≥ 4B rating); DFT verification at 12+ points per cabin section.

3. NEW TIRES & BATTERY REPLACEMENT

Components sourced exclusively from Tier-1 OEM partnerships. Matched to original equipment specifications for load index and duty cycle.

| Component | SEA LION Specification | Validation Method |

|---|---|---|

| Tires | Load Range G (152/148); All-Steel Radial; E4 Rated (4+ Season) | Load test at 110% GVWR; Tread depth scan |

| Battery | Group 31; 900 CCA; AGM Technology; 5-yr warranty | Cold Crank Amp test @ -18°C; Cycle life validation |

| Note: Tires mounted on bead-blasted, magnaflux-inspected wheels. Batteries integrated with SEA LION telematics for state-of-charge monitoring. |

4. CHASSIS REINFORCEMENT

Structural integrity assessment per ASTM E8/E290. Reinforcement applied only where validated by strain gauge analysis.

- Critical Inspection Points:

- King pin mounting zones (deflection tolerance: ≤ 0.5 mm)

- Cross-member weld seams (ultrasonic testing; reject cracks > 1.5 mm)

- Suspension bracket interfaces (torque verification to 105% OEM spec)

- Reinforcement Protocol:

- ASTM A572 Grade 50 steel gussets (min. 6mm thickness)

- Robotic MIG welding (100% penetration; post-weld stress relief)

- Post-reinforcement load test at 120% GVWR (deflection ≤ 2.0 mm)

SEA LION’S INSPECTION STANDARDS: ENGINEERING VALIDATION

All refurbishment stages are governed by SEA LION’s Triple-Lock Validation System:

| Lock Level | Responsible Party | Scope | Documentation |

|---|---|---|---|

| Primary | ASE-Certified Technician | Component-level functional testing | Digital work logs (timestamped) |

| Secondary | Senior Mechanical Engineer | Cross-system integration & stress analysis | Engineering sign-off (SL-ID#) |

| Tertiary | QA Manager (P.Eng) | Final compliance audit vs. SAE J2519 | Certificate of Conformity (COC) |

Units failing any lock level are quarantined for rework or scrapped. 97.3% of refurbished units achieve Tier-1 certification (suitable for 24/7 operations).

OPERATIONAL ASSURANCE

- Warranty: 12 months/20,000 miles comprehensive coverage (excludes abuse)

- Telematics: Pre-installed SEA LION FleetSync™ module (real-time engine health monitoring)

- Compliance: Meets FMVSS 105/121, CARB In-Use Performance Standards, and Richmond Municipal Fleet Requirements

SEA LION refurbished trucks undergo 37% more validation steps than industry baseline (per ARA 2025 Benchmark). This process ensures zero critical failures in 98.7% of units over 18 months of field operation. Units are operationally ready for deployment upon delivery, with full maintenance history and COC documentation.

END OF REPORT | SEA LION International — Engineering Reliability Since 1987

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International

Subject: Export Logistics Solutions for Used Trucks from China to Richmond

Target Audience: Fleet Managers & Construction Companies

1. Executive Summary

This report outlines optimized logistics solutions for the export of used trucks from China to Richmond, focusing on three primary maritime transport methods: Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container shipping. The analysis evaluates cost, transit time, equipment safety, and corrosion protection—particularly through wax spraying—to support fleet managers and construction firms in making data-driven decisions for procurement and fleet expansion.

2. Market Context

China has emerged as a leading source of high-quality, cost-effective used commercial vehicles, including heavy-duty trucks suitable for construction, mining, and logistics operations. Richmond, with its growing infrastructure and industrial activity, presents a strategic import destination. Effective maritime logistics are critical to maintaining vehicle integrity and reducing total landed cost.

3. Shipping Methods: Comparative Analysis

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container |

|---|---|---|---|

| Loading Method | Self-driven onto vessel | Craned/lifted into hold | Craned onto open-frame container |

| Vehicle Protection | Moderate (exposed decks) | Low (stacked, minimal separation) | High (secured, containerized) |

| Transit Time (China → Richmond) | 28–35 days | 30–40 days | 32–38 days |

| Average Cost per Truck (USD) | $2,200 – $2,800 | $1,800 – $2,300 | $3,000 – $3,800 |

| Risk of Damage | Medium (deck exposure) | High (handling, shifting) | Low (controlled environment) |

| Suitability for Trucks | High (operational units) | Low (non-operational units only) | High (all truck types, incl. oversized) |

| Port Infrastructure | Requires RO-RO terminal | Standard bulk terminal | Standard container terminal |

| Customs Clearance | Streamlined | Complex (bulk manifests) | Standard container processing |

4. Corrosion Protection: Wax Spraying Protocol

Marine environments during transit expose metallic components to salt-laden air and moisture, accelerating corrosion—particularly in undercarriages, brake systems, and engine bays.

4.1 Wax Spraying Treatment (Per ISO 12944-2:2018)

SEA LION International implements a multi-layer wax-based anti-corrosion treatment prior to shipment:

- Application Method: High-pressure spray (15–20 bar)

- Coverage Areas: Frame rails, suspension joints, wheel hubs, exhaust system, battery tray

- Wax Type: Solvent-based, hydrophobic microcrystalline wax with corrosion inhibitors

- Thickness: 25–40 μm dry film

- Durability: Up to 12 weeks of salt spray resistance (ASTM B117 tested)

Note: Wax treatment is mandatory for all export units and is performed at SEA LION-certified pre-shipment yards in Shanghai and Qingdao.

5. Method-Specific Recommendations

5.1 RO-RO – Recommended for Operational Fleets

- Best For: Functional trucks capable of self-propulsion

- Advantages: Fast loading, lower damage risk than bulk, cost-efficient

- Limitation: Limited vertical clearance; not suitable for over-height units

5.2 Bulk Cargo – Not Recommended

- Use Case: Only for non-functional, scrap-value units

- Risk: High incidence of impact damage and corrosion due to poor segregation

- Compliance Note: Increasingly restricted under IMO safety guidelines for vehicle stowage

5.3 Flat Rack – Recommended for High-Value or Oversized Trucks

- Best For: Articulated units, crane trucks, wide-load configurations

- Advantages: Full structural protection, lashing points, weather cover options

- Integration: Compatible with 40’ HC Flat Rack (max payload: 45,000 kg)

6. Operational Workflow (SEA LION Standard)

- Pre-shipment Inspection (China Yard) – 37-point checklist

- Wax Spraying & Drainage Verification – Per DIN 50017

- Method Assignment – Based on truck dimensions and operability

- Loading & Lashing Certification – Verified by ClassNK surveyor

- Marine Transit – GPS-tracked, humidity-monitored

- Customs Clearance & Delivery (Richmond Port) – 48-hour turnaround target

7. Conclusion

For fleet managers and construction companies sourcing used trucks from China, RO-RO and Flat Rack represent optimal logistics solutions—balancing cost, safety, and transit reliability. Bulk Cargo is discouraged due to elevated risk profiles.

Wax spraying is a non-negotiable protective measure, ensuring long-term asset integrity post-transit. SEA LION International applies industrial-grade corrosion control to all export units, aligning with global durability standards.

End of Report

SEA LION International – Engineering Reliability in Global Asset Logistics

Get a Quote for Used Trucks For Sale In Richmond

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]