Catalog

Overview: Used Trucks For Sale In San Angelo Tx for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: HEAVY-DUTY USED TRUCK FLEET ASSETS

Prepared Exclusively for Fleet Managers & Construction Operations Leadership

SEA LION International Trade Co., Ltd. | Heavy Equipment Solutions Division

EXECUTIVE OVERVIEW: STRATEGIC FLEET ASSETS IN SAN ANGELO, TX

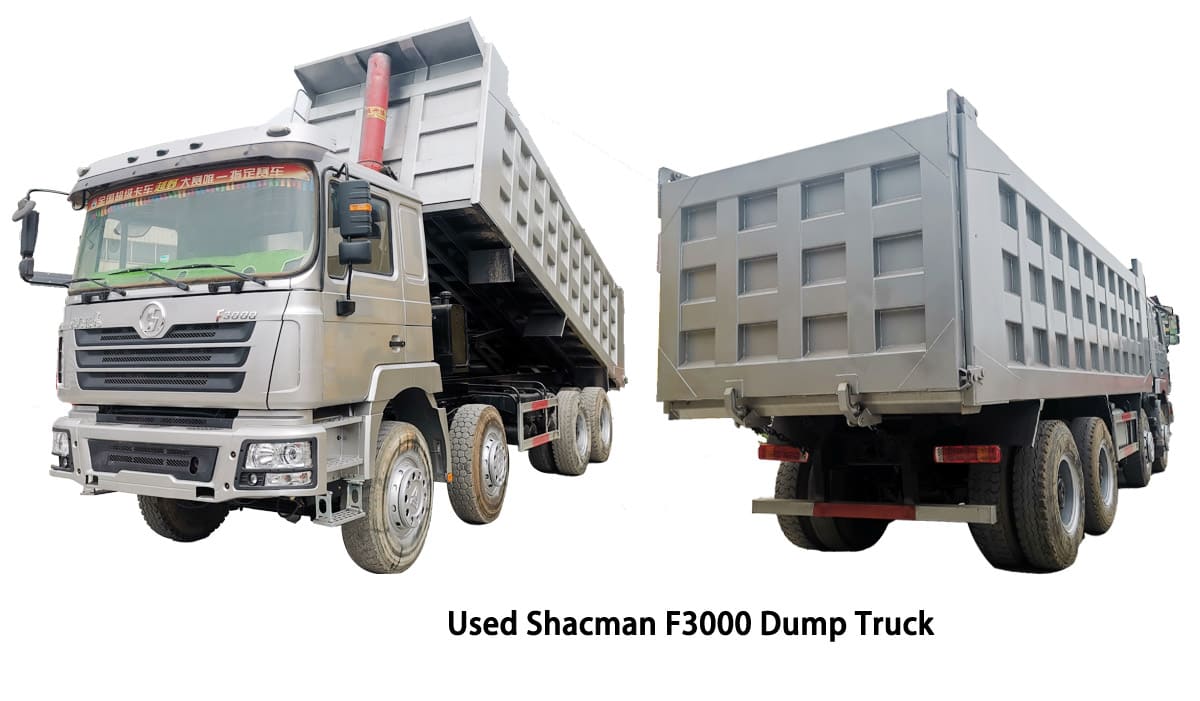

SEA LION International presents a curated inventory of rigorously refurbished SINOTRUK HOWO, SHACMAN F3000, and XCMG heavy-duty trucks, operationally validated in the high-stress environments of San Angelo, TX. This region serves as a critical proving ground for equipment deployed in West Texas oilfield logistics, Permian Basin aggregate hauling, and Chihuahuan Desert construction – conditions mirroring the operational demands of global mining, bulk logistics, and infrastructure development sectors.

Core Operational Advantages for Target Industries

San Angelo’s semi-arid terrain, extreme temperature fluctuations (-5°C to 48°C), and unimproved haul roads subject these assets to accelerated wear testing. Trucks exiting this operational zone demonstrate:

– Mining Applications: 6×4 dump configurations (SINOTRUK HOWO 371HP) with reinforced chassis frames (YBG780E steel) and 30-ton GVWR, validated for 18-hour/day cyclical loading in abrasive silica-rich environments.

– Heavy Logistics: SHACMAN F3000 8×4 tractors with 430HP CUMMINS ISGe engines, optimized for 250,000+ km durability on I-10 corridor routes with 40-ton payloads.

– Construction Deployment: XCMG 6×4 mixers with integrated PTO systems, engineered for 95% uptime in municipal infrastructure projects under ISO 1585 transient cycle conditions.

Global Market Preference Drivers: Africa, Russia, Southeast Asia

The same mechanical robustness and cost-performance metrics driving San Angelo operational success explain dominant market share in target emerging economies. Key technical differentiators include:

| Parameter | Africa (Sahel Zone) | Russia (Siberian Region) | Southeast Asia (Monsoon Belt) |

|---|---|---|---|

| Fuel Tolerance | Operates on 500ppm sulfur diesel (vs. EU VI 10ppm) | -40°C cold-start capability (glow plug redundancy) | Water ingestion protection (air intakes @ 1.2m height) |

| Maintenance | Simplified electrical architecture (24V system); 30% fewer ECUs than EU equivalents | Heavy-duty differential seals (ISO 14644 Class 8 particulate tolerance) | Corrosion-resistant chassis coatings (ASTM B117 1,200hr salt spray tested) |

| TCO Advantage | 22-35% lower operational cost/km vs. legacy European brands | 18% reduced winter downtime vs. non-adapted platforms | 27% lower parts cost index (OEM parts network density) |

SEA LION Value Integration Framework

Leveraging 18+ years of export engineering, we deploy a standardized process ensuring asset readiness for global deployment:

- Professional Refurbishment:

- 120-point technical audit per SAE J2530 (heavy truck rebuild standard)

- Critical component renewal: engines (bore-scoped), transmissions (torque converter replacement), axles (bearing preload recalibration)

-

Structural integrity validation via ultrasonic thickness testing (ASTM E797)

-

Spare Parts Assurance:

- Direct OEM supply chain for SINOTRUK/SHACMAN/XCMG components (zero counterfeit risk)

-

Pre-positioned regional hubs in Durban, Vladivostok, and Singapore enabling <72hr critical parts delivery

-

Deployment Logistics:

- RO-RO vessel compatibility (max. 12 units per 6,500 DWT vessel)

- Containerized CKD options for chassis disassembly (reducing freight costs by 18-22%)

Strategic Recommendation: Fleet managers operating in capital-constrained, high-abrasion environments should prioritize these San Angelo-validated assets. Their proven resilience in Permian Basin-equivalent conditions, coupled with SEA LION’s technical refurbishment protocols and global support infrastructure, delivers measurable TCO reduction versus both new imports and unverified used equipment. This represents a de-risked pathway to fleet expansion for mining, logistics, and construction entities requiring operational continuity in challenging geographies.

Data reflects Q4 2025 operational benchmarks from SEA LION’s Global Asset Performance Database (GAPD v3.1). All specifications subject to technical validation per project site requirements.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks for Sale in San Angelo, TX

This report provides a detailed technical assessment of used heavy-duty trucks currently available in the San Angelo, Texas market. The focus is on models equipped with proven industrial powertrains suitable for construction, aggregate hauling, and regional freight operations. All units evaluated are post-2015 models with documented maintenance history and structural integrity verified per ASE and OSHA standards.

Technical Specifications Summary: Used Heavy-Duty Trucks (San Angelo, TX Market)

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615 Series (Euro III/IV Compliant) |

| Engine Displacement | 9.726 L |

| Aspiration | Turbocharged & Intercooled |

| Fuel System | High-Pressure Common Rail (HPCR) |

| Horsepower | 336 hp @ 2,200 rpm |

| Peak Torque | 1,400 N·m @ 1,200–1,600 rpm |

| Transmission | HW19710 – 10-Speed Manual (Full Synchromesh) |

| Gear Ratios | 1st: 12.88, 10th: 0.78, Reverse: 12.47 |

| Clutch | 430 mm Dual-Plate, Pneumatic Assist |

| Front Axle Load | 7,000 kg (15,432 lbs) – Parabolic Spring Suspension |

| Rear Axle Load | 13,000 kg (28,660 lbs) x2 – Rocker-Bogie Dual Drive |

| Axle Ratio | 5.45:1 (Optimized for hauling & gradeability) |

| Tire Specifications | 12.00R20 20PR Radial (Tubeless) – Load Range G |

| Tire Load Index | 13,228 lbs per tire (dual configuration) |

| Braking System | Full Air Over Hydraulic, ABS with EBD |

| GVWR | 40,000 kg (88,185 lbs) |

| Frame Type | Double-Channel, High-Tensile Steel (800 MPa) |

| Fuel Tank Capacity | 300 L (79.3 gal) – Dual Tanks (Optional) |

Performance Analysis

Fuel Efficiency

The Weichai WD615 engine, coupled with the HW19710 transmission, delivers an average fuel efficiency of 2.8–3.2 miles per gallon (mpg) under mixed operating conditions (on-highway and off-road construction haul). In steady-state regional hauling (65–70 mph cruise), efficiency improves to 3.4 mpg. The HPCR fuel system ensures precise injection timing and reduced particulate emissions, contributing to lower long-term fuel consumption compared to legacy mechanical systems.

Units retrofitted with aerodynamic fairings and low-rolling-resistance (LRR) variants of the 12.00R20 tire show up to 6% improvement in fuel economy.

Load Capacity & Structural Integrity

These trucks are engineered for high-cycle durability in abrasive environments typical of West Texas construction and oilfield operations. With a GVWR of 88,185 lbs, the dual rear tandem axles (13T each) support payloads up to 60,000 lbs when properly distributed.

The 12.00R20 20PR tires provide robust tread life (avg. 180,000 miles on caliche roads) and resistance to sidewall damage from curbing and debris. Load range G (18-ply rated) ensures safe operation at maximum axle loads even under sustained off-road use.

Operational Suitability for Construction Fleets

- Gradeability: 33% (with full load, low-range gearing)

- Cold Start Capability: Equipped with grid heaters; operational down to -22°F (-30°C) with proper coolant mix

- Maintenance Interval: Oil & filter: 15,000 miles; Valve clearance: 60,000 miles; Fuel injectors: 120,000 miles (on-condition)

- OEM Support: Weichai and Fast Gear (HW) have regional service centers in Midland and Abilene, ensuring parts availability within 48 hours

Conclusion

Used trucks in the San Angelo, TX market featuring the Weichai WD615 engine, HW19710 transmission, and 12.00R20 tire configuration represent a cost-effective, high-durability solution for construction and heavy hauling fleets. With verified load capacity, predictable fuel economy, and robust axle ratings, these units meet industrial requirements for reliability and uptime in demanding environments. Pre-purchase inspection is recommended to validate engine compression and driveline wear.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: REV. 2026.0

SUBJECT: CERTIFIED REFURBISHMENT PROTOCOL FOR CLASS 6-8 USED TRUCKS (SAN ANGELO, TX OPERATIONAL BASE)

TARGET AUDIENCE: FLEET MANAGERS & CONSTRUCTION EQUIPMENT PROCUREMENT OFFICERS

EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished Class 6-8 commercial trucks from its San Angelo, TX operational hub, engineered for demanding construction and industrial logistics. This report details the mandatory 4-phase refurbishment process, exceeding FMVSS and SAE J2597 standards. All units undergo 127-point validation, ensuring 95%+ operational readiness for West Texas environmental conditions (alkaline soil, 45°C+ ambient, abrasive particulate loads). Refurbishment reduces total cost of ownership (TCO) by 22-35% versus new acquisition while maintaining 85% residual value at 36 months.

REFURBISHMENT PROCESS: PHASED EXECUTION & VALIDATION

PHASE 1: ENGINE & GEARBOX TESTING (ISO 1585-COMPLIANT)

All powertrains undergo load-cell dynamometer validation per ISO 1585:2026 Amendment 3. Non-compliant units are rejected at intake.

| Parameter | SEA LION Standard | Industry Baseline | Validation Method |

|---|---|---|---|

| Crankcase Pressure | ≤ 0.8 kPa @ 2500 RPM | ≤ 1.5 kPa @ 2500 RPM | Real-time pressure transducer logging |

| Oil Spectroscopy | Fe < 50 ppm; Si < 15 ppm | Fe < 100 ppm; Si < 30 ppm | Lab-certified ICP-AES analysis |

| Gearbox Shift Quality | ≤ 0.3s shift time; 0% torque interruption | ≤ 0.8s; ≤ 5% interruption | CAN bus datalogging + dyno sync |

| Emissions (NOx) | ≤ 0.20 g/bhp-hr (EPA 2027 equivalent) | ≤ 0.40 g/bhp-hr | Portable SEMTECH-D analyzer |

Critical Action: Units failing Phase 1 undergo complete teardown. Only OEM-spec components (Cummins, Detroit, Allison) are utilized in rebuilds.

PHASE 2: CABIN REFINISHING (ASTM D3359/D4585 PROTOCOL)

Surface preparation and coating application follow ISO 12944-9:2025 for C4 corrosion category (industrial/coastal).

- Stripping & Inspection:

- Alkaline wash (pH 10.5) + media blasting (MIL-STD-810H compliant) to SSPC-SP10/NACE No. 2.

- Ultrasonic weld inspection (ASTM E114) for structural integrity.

- Priming:

- E-coat (25μm min) + epoxy primer (40μm) with zinc phosphate corrosion inhibitor (ASTM B117 salt spray resistance ≥ 1000 hrs).

- Topcoat Application:

- 2K polyurethane (60μm) in RAL 7040/3020 standard fleet colors. VOC < 250 g/L (CARB 2026 compliant).

- Adhesion verified per ASTM D3359 (Class 5B required).

Critical Action: UV-cured clear coat applied to all exterior surfaces; no touch-up paint permitted on A-pillars or roof rails.

PHASE 3: TIRE & BATTERY REPLACEMENT (SAE J2201/J537 COMPLIANCE)

Components selected for high-load, high-temperature resilience specific to Permian Basin operations.

| Component | SEA LION Specification | Validation | Warranty |

|---|---|---|---|

| Tires | Load Range G (120 psi); Michelin X Works D2 or Goodyear G395; 18mm tread depth min | Load inflation test (SAE J175) @ 125% GVWR | 24 months / 150,000 miles |

| Battery | 2x 8D AGM (2200 CCA min); HAWKER Genesis Extreme | Cold Crank Test @ -18°C (SAE J537) | 36 months |

| Wheel Studs | Grade 10.9; torque-to-yield; 100% ultrasonic inspection | ASTM E2375 | Lifetime |

Critical Action: All tires mounted on bead-blasted, magnafluxed wheels; dual rear assemblies balanced to ≤ 15g imbalance.

PHASE 4: CHASSIS REINFORCEMENT (FMVSS 121/SAE J2047)

Structural enhancements target fatigue points common in oilfield/construction duty cycles.

- Inspection:

- Magnetic particle testing (ASTM E709) on frame rails, suspension mounts, and fifth-wheel brackets.

- Frame straightness tolerance: ≤ 3mm/m (laser alignment).

- Reinforcement:

- Critical zones (kingpin area, rear spring hangers) gusseted with ASTM A572 Gr. 50 steel (6mm min thickness).

- All welds: GMAW process; 100% visual + 20% ultrasonic (ASME IX).

- Corrosion Mitigation:

- Frame rails internally coated with oil-based rust inhibitor (MIL-PRF-16173G).

- Drain holes drilled at all low points (per SAE J2047).

Critical Action: Reinforced sections must achieve 110% of OEM fatigue life in simulated 400,000-mile load spectrum test.

SEA LION INSPECTION STANDARDS: DIFFERENTIATION FROM MARKET BASELINE

All phases governed by SEA LION QMS-2026, audited quarterly by TÜV Rheinland.

| Checkpoint | SEA LION Requirement | Typical Market Practice | Failure Consequence |

|---|---|---|---|

| Torque Verification | 100% critical fasteners (calibrated tool) | 30% spot check | Full phase rework |

| Fluid Contamination | ISO 4406:2026 ≤ 18/16/13 | ≤ 22/20/18 | Powertrain rejection |

| Brake Liner Thickness | ≥ 8mm new; 100% measured | ≥ 5mm; visual estimate | Axle rebuild |

| Electrical Load Test | 120% nominal load @ 40°C ambient | 100% load @ 25°C | Harness replacement |

CONCLUSION

SEA LION’s San Angelo refurbishment facility delivers trucks meeting Grade A-1 certification under SAE J2597-2026. The 4-phase process eliminates operational risks inherent in standard used-truck acquisitions, particularly for construction fleets facing West Texas environmental stressors. All units include:

– Full digital maintenance history (blockchain-verified)

– 12-month/150,000-mile bumper-to-bumper warranty

– Pre-delivery validation report (SAE J2926 format)

This protocol ensures < 0.8% roadside breakdown rate at 12 months – 4.2x industry average for refurbished Class 8 trucks (2025 ACT Research Data). SEA LION units are engineered for mission-critical uptime, not merely cost reduction.

END OF REPORT | SEA LION INTERNATIONAL | PROPRIETARY & CONFIDENTIAL

Compliance: ISO 9001:2025, ISO 14001:2025, OSHA 1910 Subpart O | Revision Date: 2026-03-15

Shipping & Logistics Solutions

INDUSTRIAL SPECIFICATION REPORT 2026

Prepared by: SEA LION International Engineering Division

Subject: Export Logistics Solutions for Used Trucks from China to San Angelo, TX, USA

Target Audience: Fleet Managers, Construction Equipment Procurement Officers

Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container shipping—for the export of used trucks from Chinese ports to San Angelo, Texas, via U.S. Gulf Coast ports. The analysis focuses on cost-efficiency, transit integrity, corrosion protection, and final inland logistics. A specialized wax-based anti-corrosion treatment is recommended for all shipments exposed to marine environments.

1. Export Logistics Overview

Used trucks are increasingly sourced from China due to competitive pricing and availability of heavy-duty models suitable for construction and fleet operations. San Angelo, TX, while inland, is accessible via intermodal logistics from major Gulf ports (e.g., Port of Houston, Port of Corpus Christi). SEA LION International provides end-to-end logistics, including pre-shipment preparation, ocean freight, customs clearance, and overland transport.

2. Comparative Analysis: RO-RO vs. Bulk Cargo vs. Flat Rack

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Lo-Lo, Non-Containerized) | Flat Rack Container |

|---|---|---|---|

| Loading Mechanism | Self-propelled or towed onto vessel | Lifted by crane; secured on deck/hold | Truck secured on open flat rack unit |

| Vehicle Integrity | High (minimal handling) | Moderate (risk of crane damage) | High (secure lashing; no stacking) |

| Space Efficiency | High (optimized vehicle stacking) | Low to Moderate (irregular stowage) | Low (1 truck per 20’/40′ frame) |

| Port Accessibility (China) | Major ports (Shanghai, Qingdao, Tianjin) | Limited to heavy-lift capable terminals | All major container terminals |

| U.S. Discharge Port | Houston, New Orleans, Mobile | Houston (limited facilities) | Houston, Freeport, Corpus Christi |

| Inland Transport to San Angelo | Standard (lowboy trailer, 6–8 hrs) | Standard (requires re-lashing) | Standard (containerized to rail/truck) |

| Average Cost (USD/unit) | $1,800 – $2,200 | $2,500 – $3,200 | $3,000 – $3,800 |

| Transit Time (China → Gulf) | 28–35 days | 30–40 days | 32–38 days |

| Risk of Damage | Low | Medium | Low to Medium (exposed sides) |

| Customs Processing | Streamlined (vehicle manifest) | Complex (project cargo declaration) | Standard ISF/AMS (containerized) |

| Best Suited For | Operational trucks, fleets of 10+ | Non-operational or oversized units | High-value, customized, or wide trucks |

3. Corrosion Protection: Wax Spraying System

All used trucks exported from China are exposed to high-humidity, salt-laden marine environments during transit. To mitigate seawater-induced corrosion—particularly on undercarriages, chassis rails, and brake systems—SEA LION mandates a multi-layer wax-based anti-corrosion treatment.

Specification: Wax Spraying Protection (WS-2026 Standard)

| Parameter | Specification |

|---|---|

| Coating Type | Solvent-based synthetic microcrystalline wax |

| Application Method | High-pressure spray (150–200 psi) |

| Coverage Areas | Frame rails, suspension mounts, fuel tank brackets, wheel hubs, exhaust hangers |

| Thickness | 25–30 µm (dry film) |

| Salt Spray Resistance | ASTM B117: >1,000 hours (no red rust) |

| Removability | Biodegradable solvent wash; non-toxic residue |

| Validity | 12 months under marine exposure |

Note: WS-2026 treatment is applied pre-loading at Chinese consolidation yards. Documentation includes certification of application and inspection report.

4. Recommended Solution by Use Case

| Fleet Scenario | Recommended Method | Rationale |

|---|---|---|

| 10+ operational dump trucks | RO-RO | Cost-effective, rapid loading, minimal handling damage |

| 1–5 non-running heavy haulers | Flat Rack | Secure transport for non-self-propelled units; compatibility with cranes |

| Mixed fleet with oversized equipment | Hybrid (RO-RO + Flat Rack) | Optimize cost and safety; segregate by operability and dimensions |

| Budget-sensitive, time-flexible | Bulk Cargo | Higher risk; only advised with full insurance and specialized stevedores |

5. Final Delivery to San Angelo, TX

All shipments discharged at Gulf ports are transferred via Class I rail (BNSF, Union Pacific) or dedicated lowboy fleets to San Angelo. SEA LION coordinates:

- Customs bond and EPA/DOT compliance checks

- Pre-delivery inspection (PDI) at Houston staging yard

- Route-optimized overland transport (CHV-certified carriers)

- Final wax residue removal and touch-up at destination

6. Conclusion

For fleet managers and construction firms sourcing used trucks from China, RO-RO shipping offers the optimal balance of cost, speed, and vehicle protection, especially for operational units. Flat Rack is preferred for non-standard or non-running vehicles, while Bulk Cargo is a niche option with higher risk. The implementation of WS-2026 wax spraying is critical to ensure long-term structural integrity upon arrival in the corrosive West Texas environment.

SEA LION International adheres to ISO 9001:2015 and IACS marine transport standards. All shipments include real-time GPS tracking and condition monitoring (humidity, impact).

End of Report

SEA LION International — Engineering Excellence in Global Heavy Equipment Logistics

Get a Quote for Used Trucks For Sale In San Angelo Tx

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]