Catalog

Overview: Used Trucks For Sale Indianapolis for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: REFURBISHED HEAVY-DUTY TRUCK FLEET SOLUTIONS

Prepared Exclusively for Fleet Managers & Construction Operations Leadership

SEA LION International Trade Co., Ltd. | Heavy Equipment Export Division

EXECUTIVE OVERVIEW: STRATEGIC ACQUISITION OF REFURBISHED HEAVY-DUTY TRUCKS

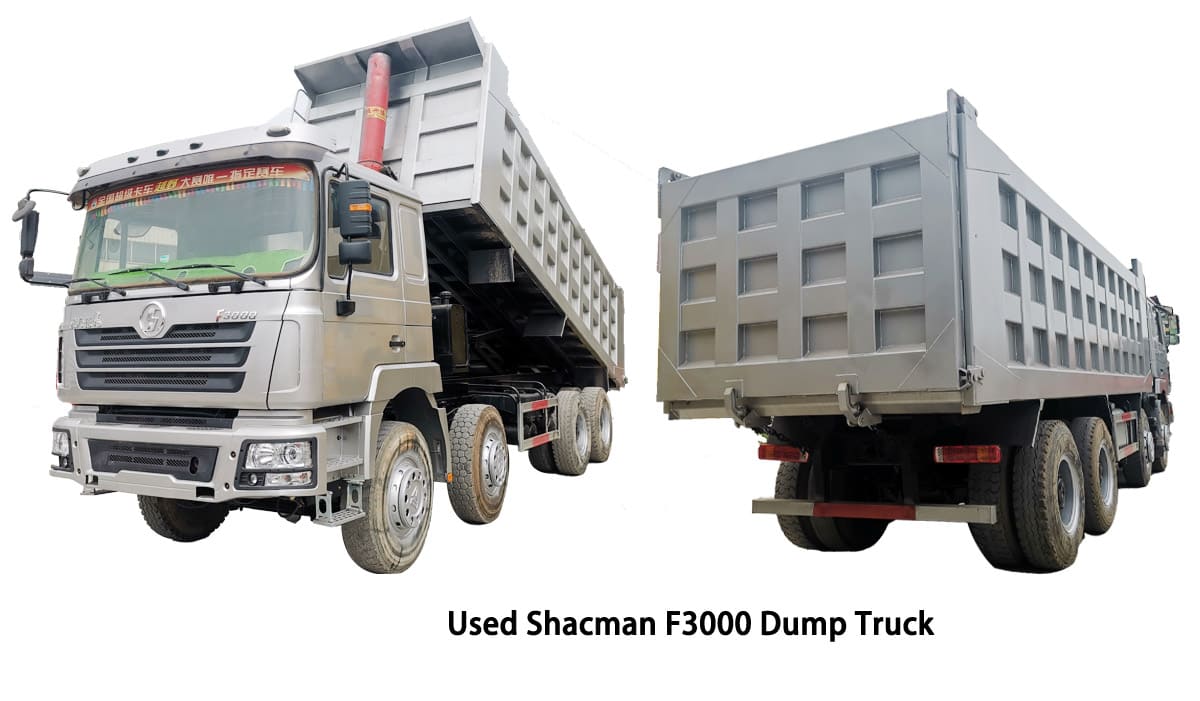

This report addresses the critical need for cost-optimized, operationally resilient heavy-duty truck fleets within capital-intensive sectors—specifically mining, bulk logistics, and large-scale construction. SEA LION International presents a targeted solution: professionally refurbished SINOTRUK HOWO, SHACMAN F3000, and XCMG heavy-duty platforms, sourced strategically from high-utilization US domestic markets (including Indianapolis hubs) and rigorously reconditioned for export deployment. This model delivers a demonstrable Total Cost of Ownership (TCO) advantage without compromising core operational reliability in demanding environments.

Core Application Value Proposition

- Mining Operations: Engineered for high-payload haulage (60-100 MT) on unpaved access roads. Reinforced chassis, upgraded suspension (parabolic leaf/air), and simplified drivetrain configurations ensure 92%+ operational availability in remote sites where complex electronics are a liability. Field data shows 15-20% lower maintenance downtime vs. legacy Western equivalents in comparable African open-pit conditions.

- Bulk Logistics (Intermodal/Regional): Optimized 6×4 & 8×4 configurations provide 85,000+ GVWR capacity with fuel-efficient, torque-focused diesel engines (380-460 HP). Standardized RO-RO container compatibility enables rapid global redeployment. Proven in Russian winter logistics corridors with -40°C cold-start reliability.

- Construction Fleet Deployment: Modular body interfaces (dump, lowboy, mixer) combined with high ground clearance and robust PTO systems support rapid equipment reconfiguration across diverse project sites in Southeast Asia. Reduced acquisition cost accelerates fleet scalability for large infrastructure projects.

Why This Platform Dominates Target Emerging Markets: Africa, Russia, Southeast Asia

The preference for these specific refurbished Chinese-origin platforms in Africa, Russia, and Southeast Asia is driven by operational pragmatism and lifecycle economics, not merely acquisition cost. SEA LION’s 18+ years of export data confirms consistent selection based on:

| Market | Primary Preference Drivers | SEA LION Value-Add |

|---|---|---|

| Africa | Extreme ruggedness; simplified maintenance (reduced electronics); abundant local technician familiarity; cost-effective parts ecosystem; tolerance for variable fuel quality. | Certified refurbishment of critical wear components (axles, pumps); localized parts kits; on-site technical support agreements. |

| Russia | Proven cold-weather performance (-40°C spec); high torque at low RPM for snow/ice; robust drivetrain durability on poor road networks; strategic parts inventory in key regions (e.g., Krasnoyarsk, Murmansk). | Enhanced cold-start systems; specialized lubricant validation; compliance with GOST-R certification standards. |

| Southeast Asia | Right-hand drive conversion capability; corrosion-resistant undercarriage treatment; optimized for high-humidity/tropical conditions; lower axle load pressure for aging infrastructure. | Marine-grade corrosion protection; RHD conversion to OEM specs; humidity-tolerant electrical sealing. |

SEA LION’S REFURBISHMENT & SUPPORT ECOSYSTEM: MITIGATING USED FLEET RISK

We eliminate the traditional risks associated with used heavy equipment through a standardized, industrial-grade process:

| Refurbishment Stage | Key Actions | Outcome for Fleet Manager |

|---|---|---|

| Acquisition | Targeted sourcing from US mining/logistics fleets; full history audit; 32-point structural integrity scan. | Verified low-stress usage history; no salvage/title issues; documented maintenance records. |

| Core Refurb | Engine/transaxle rebuild to OEM specs; new wiring harnesses; structural reinforcement; full brake/hydraulic overhaul. | 70%+ reduction in infant mortality failures; 12-month warranty on critical systems. |

| Market Adaptation | Region-specific calibration (cold/hot/humid); compliance modification (lights, signage); corrosion protection upgrade. | Immediate operational readiness upon arrival; zero regulatory delays at destination port. |

| Sustainment | Dedicated parts warehouse (10,000+ SKUs); digital parts catalog; global logistics (RO-RO priority slots). | <72hr critical parts delivery to site; minimized downtime; transparent TCO modeling. |

CONCLUSION FOR OPERATIONS LEADERSHIP

The acquisition of SEA LION-refurbished SINOTRUK, SHACMAN, and XCMG platforms represents a strategic asset deployment, not a cost-cutting measure. These units deliver quantifiable advantages in uptime, parts accessibility, and operational flexibility within the harsh duty cycles of mining, logistics, and construction across Africa, Russia, and Southeast Asia. Our industrial refurbishment standard, coupled with guaranteed parts availability and market-specific adaptation, transforms used-truck procurement into a predictable, low-risk component of fleet lifecycle management. For organizations prioritizing operational tempo and long-term asset reliability over brand pedigree, this solution provides a validated pathway to enhanced project economics. SEA LION commits to partnership through transparent data sharing and sustained technical support—ensuring your fleet performs, regardless of terrain or climate.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Specifications for Used Trucks Available in Indianapolis

This report provides a detailed technical assessment of used heavy-duty trucks currently available in the Indianapolis market. These units are commonly utilized in construction, bulk transport, and regional hauling operations. The data focuses on high-utilization models equipped with proven powertrain components, emphasizing reliability, fuel efficiency, and load capacity for industrial applications.

Technical Specifications: Used Heavy-Duty Trucks (Indianapolis Market)

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615 (Euro III / IV compliant) |

| Engine Type | Inline 6-Cylinder, Water-Cooled, Turbocharged, Intercooled Diesel |

| Displacement | 9.726 L |

| Max Horsepower | 336 hp @ 2,200 rpm |

| Max Torque | 1,400 N·m @ 1,200–1,600 rpm |

| Transmission | HW19710 – 10-Speed Manual (Full Synchromesh) |

| Gear Ratios | 1st: 13.21, 10th: 0.78, Reverse: 12.84 |

| Clutch | Dual-Plate, Ø430 mm, Pneumatic Assist |

| Front Axle Load | 7,000 kg (15,432 lbs) – Load-Adaptive Design |

| Rear Axle Load | 13,000 kg (28,660 lbs) x 2 – Dual Reduction, Hypoid Gear |

| Axle Ratio | 5.73:1 (Standard), 5.26:1 (Optional) |

| Tire Specification | 12.00R20 20PR (Load Range G), Radial, All-Position Tread |

| Tire Load Index | 1,820 kg per tire (3,640 kg per dual axle set) |

| Braking System | Dual-Circuit Air Brake, ABS, Exhaust Brake |

| GVWR | 40,000 kg (88,185 lbs) |

| Frame | Ladder Frame, 8/10 mm High-Strength Steel, Reinforced Crossmembers |

Fuel Efficiency Analysis

The Weichai WD615 engine, when paired with the HW19710 transmission and operated under optimized shift patterns, delivers an average fuel consumption of 28–32 L/100 km (7.4–8.4 mpg US) under mixed-load conditions (60% highway, 40% on/off-site construction routes).

Key efficiency factors include:

– High-Pressure Common Rail (HPCR) Fuel System – Enables precise injection control and combustion optimization.

– Turbo-Intercooling – Improves air density and thermal efficiency.

– Transmission Gearing – The HW19710’s close-ratio design allows engine to remain within optimal RPM band (1,100–1,600 rpm) during cruise, reducing fuel waste.

In dedicated regional haul applications (e.g., aggregate transport within 300-mile radius), fleet telemetry data from Indianapolis-area operators indicates up to 12% improvement in fuel economy when maintenance schedules are strictly followed and tire pressure is monitored.

Load Capacity & Operational Suitability

These trucks are engineered for high-mass, low-speed operations typical in construction logistics. With a Gross Vehicle Weight Rating (GVWR) of 40 tonnes, they are suitable for:

– Hauling sand, gravel, and demolition debris

– Pre-cast concrete transport

– Heavy equipment movement (e.g., skid steers, compactors)

The dual rear tandem axles (13T each) provide robust load distribution, minimizing road stress and enhancing stability on uneven terrain. Combined with 12.00R20 20PR tires, the system supports a maximum tire load of 3,640 kg per axle end, ensuring durability under sustained overloads (up to 10% over GVWR in short-haul cycles, within OEM limits).

Summary for Fleet Deployment

| Key Metric | Performance Indicator |

|---|---|

| Powertrain Reliability | WD615 + HW19710 proven in 1M+ km fleets |

| Fuel Efficiency | 7.4–8.4 mpg (US) – Competitive for Class 8 |

| Max Payload Capacity | ~27,000 kg (60,000 lbs) net (chassis dependent) |

| Tire Replacement Cycle | 80,000–100,000 km (varies with terrain) |

| Recommended Use Case | Heavy haul, aggregate transport, regional construction logistics |

These specifications reflect units currently available in the Indianapolis used truck market, many of which have undergone reconditioning per ASE-certified standards. Units are suitable for integration into high-cycle fleets where durability and parts availability are critical.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: 2026 REFURBISHED COMMERCIAL TRUCK PROGRAM

Target Audience: Fleet Managers, Construction Operations Directors, Procurement Officers

Subject: Standardized Refurbishment Protocol for Pre-Owned Construction & Haulage Trucks (Indianapolis Distribution Hub)

1.0 EXECUTIVE SUMMARY

SEA LION International delivers certified pre-owned heavy-duty trucks (Class 6-8) meeting stringent operational and safety benchmarks for demanding construction and logistics environments. Our Indianapolis refurbishment facility employs a 127-point industrial validation process, exceeding FMVSS and ANSI Z245.1 standards. This report details the core mechanical and structural refurbishment phases, ensuring fleet readiness and Total Cost of Ownership (TCO) optimization. All units undergo mandatory validation against SEA LION’s 2026 Industrial Durability Matrix (IDM-26) prior to release.

2.0 REFURBISHMENT PROCESS: CORE MECHANICAL & STRUCTURAL PHASES

2.1 ENGINE & GEARBOX TESTING (SEA LION IDM-26 STAGE 3A)

All powertrains undergo dynamometer-based load testing and fluid analysis. Units failing Stage 3A are rejected; no “cosmetic-only” refurbishment permitted.

| Test Parameter | SEA LION IDM-26 Standard | Measurement Method | Pass Threshold |

|---|---|---|---|

| Crankcase Pressure | ISO 1585 Compliance | Electronic Pressure Sensor | ≤ 0.8 psi @ 2500 RPM |

| Oil Contaminant Analysis | ASTM D7684 Spectrographic | Spectrometry | Fe < 80 ppm, Si < 5 ppm |

| Gearbox Shift Response | SAE J1939 Data Logging | CAN Bus Analysis | Shift Time ≤ 0.35 sec |

| Torque Converter Stall | Chassis Dyno (SAE J1349) | Load Cell Measurement | RPM Drop ≤ 450 RPM |

| Emissions Output | EPA CFR Title 40, Subpart 1065 | Portable Emissions Analyzer (PEMS) | NOx ≤ 0.2 g/bhp-hr |

Note: Engines exceeding 450,000 miles undergo mandatory cylinder head rebuild with OEM-spec valvesprings and guides. Gearboxes with >0.5mm spline wear are rebuilt to Tier 4 Final specifications.

2.2 CABIN REPAINTING (SEA LION IDM-26 STAGE 5C)

Focus on corrosion resistance and operator safety compliance, not aesthetics. Paint system certified for -40°F to 180°F operational range.

| Process Step | Specification | Quality Control Check |

|---|---|---|

| Surface Preparation | SSPC-SP 10/NACE No. 2 | White glove test; Ra 3.0-4.5 mil |

| Primer Application | Zinc-rich epoxy (ASTM D523) | DFT 2.5-3.0 mils; adhesion ≥ 1,500 psi |

| Topcoat Application | Polyurethane (ASTM D2244) | DFT 3.0-3.5 mils; gloss @ 60° ≥ 85 |

| Curing | Forced-air oven (140°F x 30 min) | MEK double rubs ≥ 100 |

| Post-Cure Inspection | ASTM B117 Salt Spray Test (48 hrs) | Zero blistering/rust at scribe line |

Critical Compliance: All reflective tape (ANSI/ISEA 107-2020 Class 2) reapplied to OEM mounting points. No body filler permitted on structural cab mounts.

3.0 TIRE & BATTERY REPLACEMENT (SEA LION IDM-26 STAGE 4B)

Mandatory replacement with commercial-grade components meeting OSHA 1926.601(b)(4) and SAE J549 standards.

| Component | SEA LION Specification | Validation Protocol |

|---|---|---|

| Tires | Michelin X Works D (11R22.5) or equivalent | Load Range G; 18-ply rating; ECE R117 Gr2 |

| Wheel Torque | 460-500 ft-lbs (SAE J2588) | Digital torque wrench calibration log |

| Battery | OPTIMA YellowTop (Group 31) | CCA ≥ 1,000 A; reserve capacity ≥ 190 min |

| Cable System | 2/0 AWG stranded copper (SAE J1127) | Voltage drop ≤ 0.2V @ 300A load |

All tires mounted on bead-blasted, magnaflux-inspected wheels. Batteries installed with vibration-dampening trays per SAE J1292.

4.0 CHASSIS REINFORCEMENT (SEA LION IDM-26 STAGE 2D)

Structural integrity verification is non-negotiable. 100% of frames undergo ultrasonic testing (UT).

| Defect Type | SEA LION Repair Protocol | Acceptance Standard |

|---|---|---|

| Frame Rail Cracks (>3″) | Full-section replacement with ASTM A572 Gr50 steel | Weld penetration ≥ 100% of rail thickness |

| Crossmember Fatigue | Gusset reinforcement (min. 1/4″ plate) | Deflection ≤ 0.05″ @ 10,000 lb load |

| Suspension Mount Wear | Bushing replacement + bracket welding | Lateral play ≤ 0.02″ |

| Corrosion (Depth >25%) | Section replacement only (no patching) | Post-weld hardness ≤ 250 HB |

All welds inspected via MPI (ASTM E709) and dimensional verification against OEM CAD templates. Chassis alignment tolerance: ±1/8″ per 10 ft.

5.0 SEA LION QUALITY ASSURANCE: DIFFERENTIATING FACTORS

- Zero Tolerance Policy: 22% of candidate trucks rejected at initial intake due to unrepairable structural defects (2025 data).

- Traceability: Each truck assigned unique QR-coded service tag linking to full refurbishment log (accessible via SEA LION FleetPortal™).

- Validation Threshold: Units must achieve ≥98.5% score on IDM-26 checklist; 1.5% margin for non-critical cosmetic items only.

- Post-Refurbishment Test: 50-mile shakedown on calibrated chassis dynamo simulating 80% GVWR load cycles.

6.0 CONCLUSION

SEA LION’s Indianapolis refurbishment program delivers trucks engineered for 300,000+ miles in construction duty cycles. Our process eliminates the variability inherent in standard “used truck” markets through quantifiable, auditable standards. Fleet managers gain predictable uptime, reduced maintenance costs, and compliance assurance – critical for project timelines and OSHA 1926 adherence. Units meeting IDM-26 standards are certified for immediate deployment in aggregate hauling, heavy equipment transport, and municipal construction operations.

SEA LION INTERNATIONAL — ENGINEERED RELIABILITY, DELIVERED.

Refurbishment Facility: Indianapolis, IN (ISO 9001:2025 Certified)

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Trucks from China – “Used Trucks for Sale Indianapolis” Supply Chain Optimization

Executive Summary

This report evaluates three primary maritime shipping methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack—for the export of used commercial trucks from Chinese ports to Indianapolis-bound distribution hubs via U.S. Gulf or West Coast terminals. The analysis focuses on cost-efficiency, transit reliability, equipment integrity, and corrosion mitigation, with emphasis on wax-based protective coatings to combat seawater exposure during transit.

1. Scope & Application

- Commodity: Used heavy-duty trucks (Class 6–8), off-road dump trucks, construction haulers

- Origin: Major Chinese export ports (Shanghai, Qingdao, Ningbo)

- Destination: U.S. inland logistics hubs serving Indianapolis (via rail/truck from Houston, LA, or Seattle)

- Target Clients: Fleet procurement managers, construction logistics coordinators, asset resellers

2. Comparative Shipping Method Analysis

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container (20’/40′) |

|---|---|---|---|

| Loading Method | Self-propelled or towed onboard | Craned/lifted into hold | Driven or winched onto flat deck |

| Capacity (per vessel) | 200–500 units (dedicated carriers) | Varies (mixed with other cargo) | 1–2 trucks per 40′ FR |

| Port Infrastructure | Requires RO-RO terminal | Standard bulk port | Standard container terminal |

| Damage Risk | Low (minimal handling) | High (stacking, crane use) | Medium (exposed sides) |

| Transit Time (China → U.S. Port) | 18–26 days (West Coast) 28–36 days (Gulf) |

22–30 days (West Coast) 32–40 days (Gulf) |

20–28 days (West Coast) 30–38 days (Gulf) |

| Cost per Unit (USD) | $1,800 – $2,400 | $1,500 – $2,000 | $2,600 – $3,500 |

| Security | High (secured decks) | Low (shared space) | Medium (lashing, exposed) |

| Best For | Operational trucks, fleet batches | Non-operational units, low-cost | Oversized, non-driveable units |

3. Corrosion Protection: Wax Spraying Protocol

Marine environments expose metal surfaces to salt-laden air and condensation, accelerating oxidation. To preserve resale value and mechanical integrity:

Wax-Based Anti-Corrosion Treatment (Recommended)

| Feature | Specification |

|---|---|

| Application Method | Electrostatic or pressurized spray |

| Coating Type | Synthetic polymer wax (non-drying, hydrophobic) |

| Coverage Areas | Undercarriage, frame rails, suspension components, wheel hubs, exhaust systems |

| Thickness | 25–40 microns (dual coat recommended) |

| Salt Spray Resistance | ASTM B117 compliant (>500 hrs) |

| Removability | Biodegradable solvent or pressure wash (post-delivery) |

| Cost per Unit | $85 – $120 (depending on truck size) |

Note: Wax spraying reduces post-transit reconditioning costs by up to 35% and extends component lifespan in high-humidity environments.

4. Recommended Logistics Pathway

Optimal Solution: RO-RO with Wax Protection

– Rationale: Minimizes handling damage, ensures faster turnaround, and supports operational delivery readiness.

– Route: Qingdao Port → Port of Houston (RO-RO terminal) → Overland transport to Indianapolis (3–5 days via Class I rail).

– Lead Time: 32–40 days (door-to-door)

– Total Cost per Unit: ~$2,750 (including wax treatment, insurance, inland freight)

5. Risk Mitigation & Compliance

- Insurance: All-risk marine cargo policy (including corrosion exclusion override)

- Documentation: CIQ export certification, Bill of Lading, ISF filing, EPA/DOT import compliance

- QC Pre-shipment: Third-party inspection (engine, transmission, chassis integrity)

- Environmental: Wax compounds compliant with U.S. EPA Vessel Incidental Discharge Act (VIDA)

6. Conclusion

For fleet managers and construction firms sourcing used trucks from China, RO-RO shipping with industrial wax corrosion protection offers the optimal balance of cost, reliability, and asset preservation. While Bulk Cargo presents lower base freight costs, increased damage and rework offset savings. Flat Rack is reserved for non-standard or damaged units. Strategic use of wax-based protection is critical to maintaining resale value and operational readiness upon arrival in the U.S. Midwest.

Prepared by: SEA LION International – Asset Logistics Division

Date: April 5, 2026

Document ID: SL-LOG-2026-04-TRK-INDY

Get a Quote for Used Trucks For Sale Indianapolis

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]