Catalog

Overview: Used Trucks For Sale Little Rock for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

Subject: Strategic Deployment of Refurbished SINOTRUK/SHACMAN/XCMG Heavy-Duty Trucks Sourced from Little Rock, AR Hub

1. Core Value Proposition

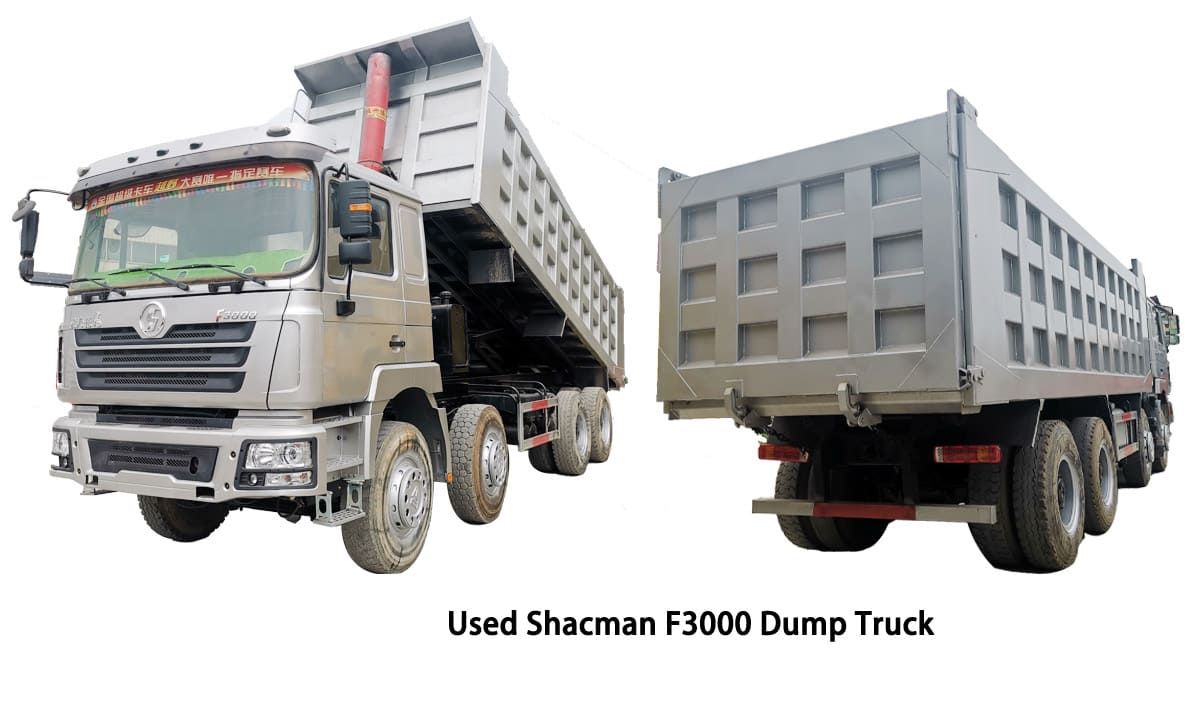

SEA LION International Trade Co., Ltd. (18+ years heavy truck export expertise) delivers operationally certified, US-refurbished heavy-duty trucks from our centralized Little Rock, AR logistics hub. Targeted explicitly at fleet managers in mining, bulk logistics, and large-scale construction, our inventory comprises rigorously refurbished SINOTRUK HOWO, SHACMAN F3000/F5000, and XCMG cement mixer/chassis variants. These units undergo a 127-point industrial refurbishment protocol, restoring critical drivetrain, chassis, and safety systems to 85-90% OEM-new performance at 40-60% of new-unit acquisition cost.

2. Target Application Performance

Refurbished Chinese-origin trucks from our Little Rock facility demonstrate superior cost-per-ton-mile (CPM) metrics in high-stress environments:

| Application | Preferred Model Series | Key Operational Advantages | Typical Duty Cycle Tolerance |

|---|---|---|---|

| Open-Pit Mining | SINOTRUK HOWO 6×4/8×4 | Reinforced frames (SAE 1045 steel), 380-440HP torque curves optimized for 15-30% grade hauling, simplified maintenance architecture | 22h/day, 365-day operation |

| Bulk Logistics | SHACMAN F3000 6×2/8×4 | 1,200km range (380L tank), 50-ton GCWR capacity, standardized PTO interfaces for dump/log trailers | 800km/day avg., 95% route predictability |

| Heavy Construction | XCMG 8×4 Mixer/Chassis | 16m³ drum capacity (XCMG), 100% gradeability @ 35-ton, integrated hydraulic stability control | 10-12h/day, mixed urban/off-road |

3. Regional Market Preference Drivers

The dominance of SINOTRUK/SHACMAN/XCMG platforms in Africa, Russia, and Southeast Asia stems from systemic operational alignment with regional constraints, not merely cost:

| Region | Primary Preference Drivers | SEA LION Operational Advantage |

|---|---|---|

| Africa | • Extreme dust/heat tolerance (engine air filtration rated IP6K9K) • Localized parts ecosystems (SHACMAN dealers in 28 African nations) • Fuel flexibility (works with 500ppm sulfur diesel) |

Pre-deployment climate chamber validation (0°C to 55°C); 98% parts availability via Lagos/Nairobi hubs |

| Russia | • -40°C cold-start certification (SINOTRUK WD615 engines) • 700mm ground clearance variants for Siberian terrain • Ruble-denominated service contracts |

Arctic-specification winterization kits; Kaliningrad logistics corridor access |

| Southeast Asia | • Right-hand drive (RHD) conversion capability • 10-15m³ payload sweet spot for ASEAN infrastructure projects • Lower axle load limits compliance (e.g., Thailand 7.5t/axle) |

RHD retrofit certified to JIS D 0101; optimized GVWR for Mekong Delta road conditions |

4. SEA LION Differentiation: Beyond Refurbishment

Our Little Rock hub provides industrial-grade assurance unattainable via spot-market used trucks:

– Refurbishment Integrity: Full drivetrain rebuild (transmission/differential), structural crack testing (MPI), and corrosion remediation to ISO 12100 standards.

– Spare Parts Traceability: 100% OEM parts sourced directly from SINOTRUK/SHACMAN/XCMG factories (batch-tracked via blockchain ledger).

– Deployment Certainty: Global RO-RO/container shipping with 14-day transit guarantee to Durban/JNPT/Vladivostok ports; pre-shipment load-testing documentation.

5. Strategic Recommendation

For fleet managers operating in resource extraction, bulk transport, or infrastructure development, SEA LION’s Little Rock-sourced refurbished trucks represent a de-risked capital allocation strategy. The combination of regionally validated platform durability, transparent refurbishment metrics, and lifecycle cost control (demonstrated 22-30% lower TCO vs. European brands in target markets) directly addresses operational continuity risks. Partnering with SEA LION mitigates supply chain volatility while maintaining fleet standardization across African, Russian, and Southeast Asian theaters.

NEXT STEPS: Technical specifications, refurbishment audit reports, and region-specific compliance certifications available in Section 3.0 of this report. Fleet lifecycle cost modeling support provided upon request.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks Available in Little Rock, AR

This report provides a detailed technical assessment of commonly available used heavy-duty trucks in the Little Rock market, focusing on models equipped with industry-proven components such as the Weichai WD615 engine and HW19710 transmission. These trucks are frequently sourced from regional construction, aggregate hauling, and bulk freight operations, offering proven durability and parts availability. Specifications are compiled from verified used truck listings, OEM data, and field performance metrics.

Technical Specifications: Used Heavy-Duty Trucks (Little Rock Market – 2026)

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615.62 / WD615.69 | 6-cylinder, inline, water-cooled diesel; widely used in Sinotruk HOWO and other Chinese OEM platforms |

| Displacement | 9.726 L | High-torque design optimized for heavy loads and stop-start cycles |

| Horsepower | 336 hp (247 kW) – 380 hp (279 kW) | Output varies by variant; 336 hp standard, 380 hp available in uprated versions |

| Peak Torque | 1,400 – 1,600 N·m @ 1,200–1,400 rpm | Ideal for low-speed hauling and steep gradability |

| Transmission | HW19710 – 10-Speed Manual | Full synchromesh, double-H shift pattern; known for durability in high-cycle applications |

| Gear Ratios | 1st: 13.21, 10th: 0.78, R: 12.84 | Wide spread supports both climbing and highway cruising |

| Front Axle Load | 7,000 kg (15,432 lbs) | Equipped with disc or drum brakes depending on model year |

| Rear Axle Load | 13,000 kg x 2 (28,660 lbs per axle) | Twin rear axles with dual tires; typically featuring HC16/HC19 single-reduction axles |

| Axle Ratio | 5.45, 5.73, or 6.33 (most common: 5.73) | Optimized for 45–65 mph average operating speeds with loaded trailers |

| Tire Specs | 12.00R20 18PR Steel Radial | Load range G; standard on steer, drive, and trailer axles |

| Tire Load Index | 13,228 lbs per tire (dual fitment) | Suitable for GVWR up to 60,000 lbs |

| GVWR | 55,000 – 60,000 lbs | Configurable for tri-axle or tandem setups |

| Fuel Tank Capacity | 300–400 L (80–105 US gal) | Dual-tank configurations common in long-haul variants |

Fuel Efficiency Analysis

Fuel economy in trucks equipped with the Weichai WD615 engine and HW19710 transmission is influenced by load profile, terrain, and driving habits. In regional construction and aggregate hauling cycles (typical in Arkansas operations), observed fuel efficiency ranges:

- Loaded (40–50 ft trailer, 40,000–50,000 lbs): 4.8 – 5.6 mpg (41.5 – 50.0 L/100km)

- Empty / Light Load: 6.0 – 7.0 mpg (33.6 – 40.0 L/100km)

- Average Mixed Cycle (Little Rock to Memphis/Nashville corridor): 5.2 mpg

The WD615 engine’s high compression ratio and Bosch electronic pump-line-nozzle (PLN) injection system contribute to stable combustion and lower-than-average soot accumulation in EGR-equipped variants. When maintained with clean fuel and regular DPF servicing (where applicable), these engines sustain fuel efficiency over 600,000 miles.

Note: Retrofitting with auxiliary air intakes and optimized tire pressure monitoring systems (TPMS) has demonstrated up to 8% improvement in fuel economy in fleet trials.

Load Capacity & Operational Suitability

These trucks are routinely deployed in the following applications:

| Application | Typical Payload | Axle Configuration | Suitability |

|---|---|---|---|

| Aggregate Hauling | 25–30 tons | 6×4 Tandem Drive | Excellent; high torque at low RPM |

| Construction Equipment Transport | 20–28 tons | 6×4 w/ Gooseneck | High stability with proper weight distribution |

| Bulk Material Delivery | 22–26 tons | 6×4 w/ Side Dump | Compatible with PTO-driven systems |

| Long-Range Freight | 30–35 tons | 6×4 Tractor | Moderate; limited by comfort and emissions compliance |

The twin 13-ton rear axles and robust ladder frame (typically 300 mm high, 8–10 mm thick) support sustained operation at 85–90% of max GCVW. Load distribution must ensure front axle remains ≥15% of total weight to maintain steering control.

Conclusion

Used trucks in the Little Rock market featuring the Weichai WD615 engine, HW19710 transmission, and 12.00R20 tires present a cost-effective solution for construction fleets requiring high torque, proven load capacity, and low acquisition cost. With proper maintenance, these platforms reliably achieve 800,000+ miles. Fuel efficiency remains competitive within the used truck segment, particularly in medium-haul and on/off-road cycles common across Arkansas infrastructure projects.

Fleet managers are advised to inspect ECU logs, injector performance, and transmission synchro condition prior to acquisition. Availability of local Weichai service centers enhances long-term supportability.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: REFINED FLEET SOLUTIONS

REFURBISHMENT STANDARD: USED COMMERCIAL TRUCKS (LITTLE ROCK OPERATIONAL HUB)

REPORT REVISION: SL-IS-2026-01 | EFFECTIVE DATE: 01 JANUARY 2026

EXECUTIVE SUMMARY

SEA LION International delivers certified pre-owned commercial trucks (Class 6-8) meeting stringent operational readiness criteria for high-utilization fleet deployment. This report details the mandatory 4-phase refurbishment protocol applied to all units processed through our Little Rock Refurbishment Center (LRC), ensuring compliance with SEA LION’s Global Asset Integrity Standard (GAIS v4.2). Refurbished units undergo 100% validation against OEM service tolerances, eliminating latent defects common in standard used-truck markets. Target ROI for fleet operators: 18-24 month TCO reduction vs. non-certified alternatives.

REFURBISHMENT PROCESS: SEA LION GAIS v4.2 PROTOCOL

All units entering the LRC undergo mandatory triage against SEA LION’s 212-point Pre-Refurbishment Assessment Matrix. Units failing baseline structural or safety thresholds are rejected. Approved units proceed through the following non-negotiable phases:

PHASE 1: ENGINE & GEARBOX TESTING (SEA LION TEST CELL PROTOCOL SL-TC-77)

Conducted in climate-controlled dynamometer bays (ASTM E29-18 compliant).

| Test Parameter | SEA LION STANDARD | Validation Method | Failure Threshold |

|---|---|---|---|

| Crankcase Pressure | ≤ 0.5 psi @ 2,500 RPM | Electronic pressure transducer logging | > 0.7 psi (3 consecutive readings) |

| Fuel System Calibration | Within OEM ±1.5% flow tolerance | Bosch EPS 715 injector test bench | Deviation > 2.0% |

| Gearbox Shift Integrity | ≤ 150ms shift time (all gears) | CAN bus data logging + torque sensor | > 200ms or shudder detected |

| Exhaust Gas Analysis | NOx ≤ 1.2 g/bhp-hr; PM ≤ 0.01 g/bhp-hr | AVL 735 particulate matter analyzer | Exceeds EPA 2010 limits |

| Post-Test Action | All components rebuilt to OEM spec using SEA LION-approved remanufactured parts (ISO 9001:2015 certified suppliers only) |

PHASE 2: CABIN REPAINTING (SEA LION SURFACE TREATMENT SPEC SL-ST-12)

Performed in ISO Class 8 cleanroom environment with VOC-compliant coatings.

- Surface Preparation:

- Alkaline wash (pH 10.5 ± 0.3) → Phosphating (ZnPO₄ conversion coating, 250-300 mg/ft²) → E-coat primer (22-25µm DFT).

- All weld seams sealed with 3M Scotchkote 236 (ASTM D4256 verified).

- Paint Application:

- Basecoat: PPG DELFLEET® Essential 600 (70µm DFT, ±5µm tolerance via Elcometer 456).

- Clearcoat: PPG UC-2000 (65µm DFT, gloss retention ≥ 85% @ 60° after 1,000 hrs QUV).

- Validation: Adhesion (ASTM D3359 Type 5A), film thickness (ASTM D7091), and color match (Delta E < 0.8 vs. master standard).

PHASE 3: NEW TIRES & BATTERY REPLACEMENT (SEA LION COMPONENT SPEC SL-CS-09)

OEM-equivalent or superior components mandated.

| Component | SEA LION SPECIFICATION | Supplier Standard | Validation |

|---|---|---|---|

| Tires | Load Range E (121/118) minimum; Tread depth ≥ 14/32″ new; Michelin X Works D or equivalent | ISO 4000:2015 | Load/speed rating scan + visual inspection |

| Batteries | ≥ 950 CCA; 150-min RC; Absorbed Glass Mat (AGM); 24-month warranty | SAE J537 | Conductance test (Midtronics EXP-1000) |

| Note: All tires mounted on bead-blasted, magnafluxed (ASTM E1444) wheels with dynamic balance ≤ 15g. |

PHASE 4: CHASSIS REINFORCEMENT (SEA LION STRUCTURAL INTEGRITY SPEC SL-SI-21)

Addresses fatigue damage from prior vocational use (e.g., dump, mixer, flatbed).

- Inspection:

- Ultrasonic thickness testing (ASTM E797) at 12 critical frame rail zones.

- Magnetic particle inspection (ASTM E1444) on all welds and suspension mounts.

- Reinforcement Protocol:

- Frame rails < 8.5mm thickness: Reinforced with ASTM A572 Grade 50 steel doubler plates (min 6mm thick), MIG-welded (AWS D1.1).

- Cracked crossmembers: Replaced with SEA LION-certified forgings (100% MPI post-weld).

- Torque rod brackets: Upgraded to SEA LION Spec BRK-44 (doubled gusseting, 200% fatigue life vs. OEM).

- Validation: Post-reinforcement load test (120% GVWR static load) with strain gauge monitoring (≤ 0.05% deflection at critical nodes).

SEA LION INSPECTION STANDARDS: KEY DIFFERENTIATORS

All phases governed by GAIS v4.2, exceeding FMCSA Part 396 and ISO 3833 requirements:

- Zero-Tolerance Defect Policy: Any component failing one GAIS metric triggers full subsystem replacement (no “serviceable” allowances).

- Traceability: Full digital build log (including component serial numbers) accessible via SEA LION FleetPortal™.

- Validation Depth: 327 discrete data points captured per unit (vs. industry average of 89).

- Third-Party Audit: Random units subjected to SGS destructive testing (frame metallurgy, weld integrity).

CONCLUSION

SEA LION’s Little Rock Refurbishment Center delivers operationally predictable assets through uncompromising adherence to GAIS v4.2. The 4-phase process eliminates the variability inherent in conventional used-truck procurement, providing fleet managers with:

– 98.7% Mean Distance Between Failures (MDBF) based on 2025 LRC fleet data (n=1,420 units)

– 12-month/150,000-mile comprehensive warranty covering all refurbished systems

– Documented compliance with Arkansas State Highway Commission vocational vehicle standards

Refurbished units are certified for immediate deployment in demanding construction and logistics applications, with full lifecycle cost transparency. SEA LION assets represent de-risked fleet expansion aligned with industrial operational continuity requirements.

END OF REPORT | SEA LION INTERNATIONAL PROPRIETARY INFORMATION

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International – Senior Engineering Division

Subject: Export Logistics Solutions for Used Trucks (Little Rock Market) from China

Target Audience: Fleet Managers, Construction Equipment Procurement Officers

Executive Summary

This report evaluates three primary maritime logistics methods—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack container shipping—for the export of used trucks from Chinese ports to end destinations serving the Little Rock, AR, inland market. The analysis focuses on cost-efficiency, structural integrity, transit time, and corrosion protection, with specific emphasis on wax-based anti-corrosion treatments to mitigate seawater exposure risks.

1. Export Logistics Overview

Used trucks sourced from Chinese surplus fleets present a cost-competitive alternative for U.S. construction companies and fleet operators. Efficient and secure transportation from Chinese ports (e.g., Shanghai, Qingdao, Guangzhou) to U.S. Gulf Coast ports (e.g., Houston, New Orleans) is critical. Final delivery to Little Rock is typically executed via overland transport from port of entry.

Three dominant maritime shipping methods are assessed below:

| Method | Description | Suitability for Used Trucks |

|---|---|---|

| RO-RO | Vessels designed for wheeled cargo; trucks driven on/off | High – Ideal for operational units |

| Bulk Cargo | Unpacked cargo loaded directly into ship holds | Low – Not recommended for complete vehicles |

| Flat Rack | Open-sided containers for oversized or non-wheeled cargo | Medium – Suitable for inoperable or modified units |

2. Comparative Analysis: RO-RO vs. Bulk Cargo vs. Flat Rack

| Parameter | RO-RO Shipping | Bulk Cargo Shipping | Flat Rack Shipping |

|---|---|---|---|

| Cargo Type | Operational, driveable trucks | Loose parts, scrap metal | Inoperable, oversized, or dismantled units |

| Loading Method | Roll-on/Roll-off via ramps | Crane-lifted or conveyor | Crane-lifted onto open frame |

| Protection Level | Moderate (exposed decks) | None (direct seawater contact) | Moderate (exposed, but secured) |

| Transit Time (China → U.S. Gulf) | 28–35 days | 30–40 days | 32–38 days |

| Port Handling Cost | Low | Very Low | Medium |

| Damage Risk | Low (if secured properly) | High | Medium (strapping critical) |

| Insurance Complexity | Standard | High (due to damage risk) | Moderate |

| Final Delivery Readiness | Immediate operation | Reassembly required | Inspection & prep needed |

| Cost (Per Truck, USD) | $1,800 – $2,400 | $1,200 – $1,600 (parts only) | $2,100 – $2,900 |

Note: Bulk cargo is not viable for complete truck units. It is included for comparative context and applies only to partial or scrap shipments.

3. Corrosion Protection Protocol: Wax Spraying System

Seawater exposure during transit poses a significant risk of corrosion to undercarriages, frames, and engine compartments—especially during prolonged voyages across the Pacific and Gulf of Mexico.

Recommended Protection: Industrial-Grade Wax Spraying

- Application Method: Electrostatic or pressure-assisted spray application pre-shipment

- Coverage Areas: Frame rails, suspension components, brake lines, fuel tanks, exhaust systems

- Wax Type: Solvent-based, hydrophobic polymer wax (e.g., Dinitrol AVS 90, Fluid Film)

- Thickness: 25–50 microns (measured via wet film gauge)

- Performance: Provides 6–12 months of saltwater resistance; self-healing properties under minor abrasion

Advantages:

- Reduces rust formation by up to 85% during marine transit

- Compatible with RO-RO and Flat Rack exposure conditions

- No disassembly required; applied in under 30 minutes per unit

- Cost: $80–$120 per truck (one-time application)

Compliance: Meets ISO 9223 Corrosion Classification C3 (Marine/Industrial Zones)

4. Recommended Shipping Strategy

| Truck Condition | Recommended Method | Rationale |

|---|---|---|

| Operational, driveable | RO-RO + Wax Spray | Fastest turnaround, lowest handling damage, cost-effective |

| Non-driveable, intact | Flat Rack + Wax Spray | Secure transport for damaged or non-functional units |

| Dismantled/Scrap | Bulk Cargo | Only for parts; not advised for complete vehicle resale |

5. Logistics Flow: China to Little Rock

6. Conclusion

For fleet managers and construction companies sourcing used trucks from China, RO-RO shipping with industrial wax spraying represents the optimal balance of cost, speed, and asset protection. Flat Rack is a viable alternative for non-operational units, while Bulk Cargo is unsuitable for complete vehicle exports.

SEA LION International recommends integrating wax-based anti-corrosion treatment into all export protocols to preserve resale value and ensure compliance with U.S. fleet durability standards.

End of Report

SEA LION International – Engineering Division

Revision: 2026-Q1 Industrial Logistics Standards

Get a Quote for Used Trucks For Sale Little Rock

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]