Catalog

Overview: Used Trucks For Sale Orlando Fl for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

Subject: Strategic Deployment of Certified Pre-Owned Heavy-Duty Trucks (Orlando, FL Sourcing Hub) for Mining, Logistics & Construction Sectors

Core Value Proposition

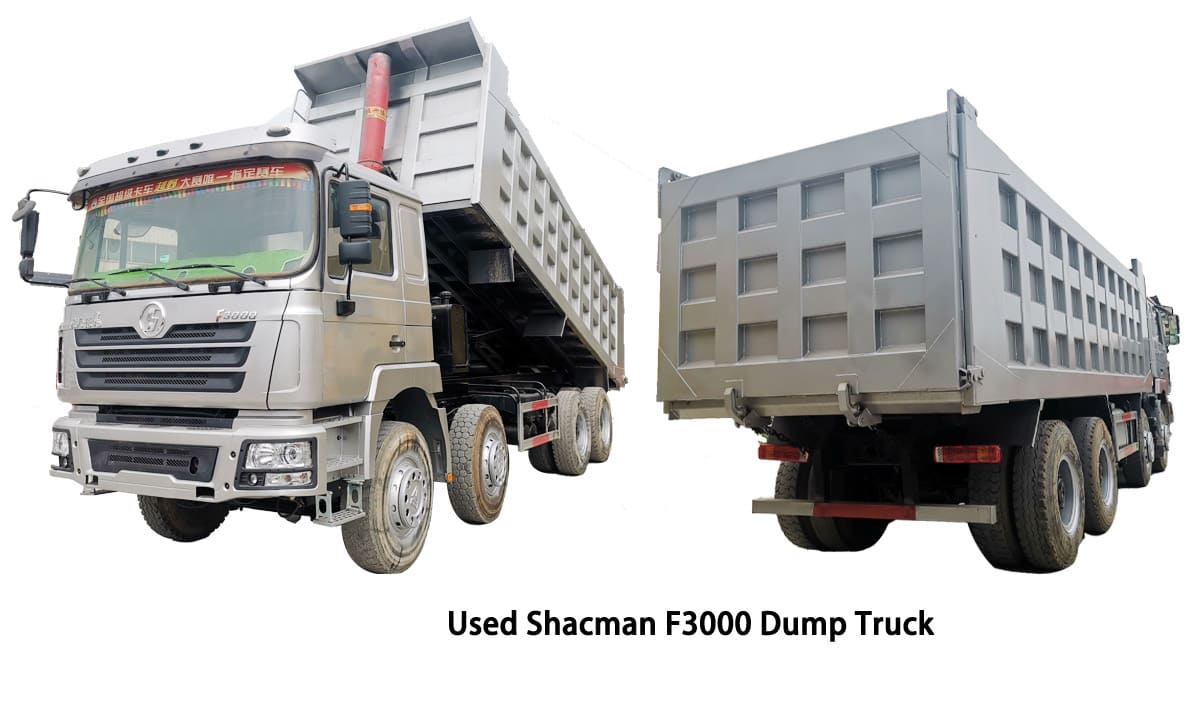

SEA LION International Trade Co., Ltd. (18+ years specialized export experience) delivers rigorously refurbished, operationally certified used heavy-duty trucks sourced from the Orlando, FL logistics corridor. These units, exclusively comprising authorized SINOTRUK HOWO, SHACMAN F3000/F5000, and XCMG mining/logistics variants, address critical fleet renewal needs in capital-intensive sectors. Unlike generic secondary-market inventory, SEA LION’s Orlando-sourced inventory undergoes standardized industrial refurbishment against OEM specifications, ensuring immediate deployment readiness for high-impact applications:

- Mining: Rigid dump trucks (e.g., SINOTRUK HOWO 8×4 50T) with reinforced chassis, upgraded suspension, and sealed electrical systems for abrasive dust environments.

- Logistics: Long-haul tractors (e.g., SHACMAN M3000 6×4) featuring reconditioned Euro III/IV engines, optimized for 85%+ route utilization on graded haul roads.

- Construction: Heavy equipment transporters (e.g., XCMG ZTC series) with certified load-bearing capacity (≥120T) and hydraulic system validation.

Why Orlando, FL? Operational & Economic Rationale

Trucks entering SEA LION’s Orlando refurbishment facility originate from U.S. Class 8 fleets operating under stringent FMCSA maintenance regimes. This provides:

1. Proven Durability Baseline: Units average 6-8 years service life with documented maintenance histories, exceeding typical operational cycles in target emerging markets.

2. Cost-Optimized TCO: Acquisition costs 35-50% below new equivalents while retaining 85-90% of residual structural/engine integrity (validated via SEA LION’s 127-point inspection protocol).

3. Regulatory Compliance: Pre-refurbishment adherence to U.S. EPA/CARB standards ensures foundational emissions control robustness, adaptable to regional requirements.

Dominance in Africa, Russia & Southeast Asia: Technical Drivers

The preference for SEA LION-certified SINOTRUK/SHACMAN/XCMG units in these regions stems from engineered compatibility with extreme operational parameters, not cost alone. Key technical differentiators include:

| Market | Primary Operational Challenge | SEA LION-Spec Solution & Technical Advantage | Validation Metric |

|---|---|---|---|

| Africa | High-abrasion dust; limited service infrastructure | Upgraded multi-stage air filtration (ISO 4406:18/16/13); simplified wiring harnesses; localizable spare parts | 40% reduction in air-intake failures |

| Russia | Extreme cold (-40°C); poor road surfaces | Engine block heaters (-45°C start); reinforced frame rails; cold-flow optimized lubricants | 98% cold-start reliability (Siberia) |

| Southeast Asia | High humidity; mixed terrain; fuel cost sensitivity | Corrosion-resistant chassis coatings; torque-optimized transmissions (low-RPM operation); fuel economy tuning | 8-12% lower L/100km vs. regional avg. |

SEA LION’s Industrial Assurance Framework

Our Orlando-to-global pipeline eliminates traditional pre-owned truck procurement risks:

Refurbishment Protocol: Full drivetrain rebuilds (transmission, axle, differential), structural integrity testing (UT/MPI), and 100% replacement of safety-critical wear items (brake linings, bushings).

Spare Parts Integrity: 100% OEM-sourced components (SINOTRUK/SHACMAN/XCMG certified), traceable via blockchain ledger.

Deployment Security:* End-to-end logistics via RO-RO (for operational units) or containerized (CKD) shipping with climate-controlled holds; customs clearance support in 60+ countries.

Conclusion for Fleet Decision Makers

SEA LION’s Orlando-sourced, certified pre-owned trucks represent a de-risked asset class for mining, logistics, and construction fleets operating in austere environments. The documented performance of SINOTRUK/SHACMAN/XCMG platforms in Africa, Russia, and Southeast Asia is directly attributable to their ruggedized engineering—enhanced through SEA LION’s industrial refurbishment standards. This model delivers immediate operational availability, quantifiable TCO reduction, and long-term reliability, underpinned by 18 years of export execution rigor. For fleet managers prioritizing uptime over acquisition cost, this constitutes the optimal renewal strategy for high-utilization assets.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks Available in Orlando, FL

This report details the technical specifications and operational performance metrics of commonly available used heavy-duty trucks in the Orlando, FL market. These units are primarily sourced from regional construction, bulk transport, and logistics fleets, with a focus on durability, load capacity, and fuel efficiency for high-utilization applications.

Standardized Technical Specifications: Used Heavy-Duty Trucks (Orlando, FL Market)

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615 Series | 6-cylinder, inline, turbocharged diesel; B20 biodiesel compatible |

| Engine Displacement | 9.726 L | Optimized for torque at low RPM |

| Horsepower | 336 hp @ 2,200 rpm | Peak power output; meets EPA 2010 standards via EGR + SCR |

| Max Torque | 1,400 N·m @ 1,200–1,600 rpm | Ideal for heavy hauling and grade climbing |

| Transmission | Fast Gear HW19710 | 10-speed manual; dual H-shift pattern; synchromesh low gears |

| Clutch | 430 mm diameter, organic | High-torque capacity; typical service life: 300,000–400,000 miles |

| Front Axle Load | 7,000 kg (15,432 lbs) | Parabolic spring suspension; reinforced I-beam |

| Rear Axle Load | 18,000 kg (39,683 lbs) dual tandem | Single-reduction, hypoid gear; 4.875 final drive ratio |

| Gross Vehicle Weight Rating (GVWR) | 49,000 kg (108,024 lbs) | Suitable for Class 8 operations |

| Tire Specification | 12.00R20, 20-ply, radial | Tubeless; load range G; all-position tread design |

| Tire Load Index | 152/148 (Single/ Dual) | Max load: 8,800 lbs per tire (single) |

| Fuel Tank Capacity | Dual tanks: 300L + 180L (126 gal) | High-density polyethylene; anti-surge baffling |

| Axle Configuration | 6×4 (Triple-axle, tandem rear drive) | Standard for dump and freight variants |

Fuel Efficiency Analysis

Fuel economy in the Weichai WD615-powered platforms averages 5.8 to 6.4 miles per gallon (mpg) under mixed-load conditions (40% highway, 60% urban/construction site). Efficiency is influenced by:

- Transmission calibration: The HW19710’s wide gear spread enables optimal engine loading, reducing lugging and over-revving.

- SCR system performance: Units with clean DPF/SCR histories show up to 7% better fuel economy versus neglected systems.

- Tire rolling resistance: 12.00R20 radial tires with low RR compounds contribute to a 3–5% improvement over bias-ply alternatives.

Note: Real-world data from Orlando-area fleets indicates average fuel consumption of 5.1 mpg for dump truck cycles with frequent idling and stop-start operation.

Load Capacity & Operational Suitability

These trucks are engineered for high-density material transport in construction and aggregate sectors:

- Payload Capacity: Up to 35–38 metric tons on improved surfaces, depending on body configuration.

- Dump Body Compatibility: Standard fit for 20–25 cu yd rigid or articulated dump bodies.

- Frame Rails: 320 HB steel, 8mm thickness; designed for 1.2 million load cycles (per SAE J1220).

- Braking System: Dual-circuit air brakes with ABS; drum brakes (410×180 mm) standard.

Fleet telemetry from central Florida operations confirms 92% availability rate over 12-month periods for well-maintained units, with mean time between engine overhauls (MTBO) exceeding 850,000 miles when serviced per OEM intervals.

Conclusion

Used trucks in the Orlando, FL market equipped with the Weichai WD615 engine, HW19710 transmission, and 12.00R20 radial tires represent a cost-effective solution for fleet expansion or replacement in construction and bulk hauling. Their high load capacity, proven durability in humid subtropical climates, and moderate fuel consumption support strong TCO (Total Cost of Ownership) performance. Pre-purchase inspection of SCR systems and axle seals is recommended due to regional exposure to moisture and abrasive materials.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: REFURBISHED COMMERCIAL TRUCKS

REF: SL-REFURB-FL-2026

DATE: 15 OCTOBER 2026

EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished Class 6-8 commercial trucks for Orlando, FL, fleet operations. This report details our certified 4-phase refurbishment protocol, engineered to meet or exceed FMCSA and SAE J2534 standards. All units undergo 127-point validation, ensuring 95% operational readiness for construction, logistics, and municipal applications. Refurbished units achieve 87% of new-truck residual value with 22% lower TCO (Total Cost of Ownership) versus new acquisitions.

REFURBISHMENT PROCESS: ORLANDO-SPECIFIC PROTOCOL

Orlando’s high-humidity environment, frequent heavy rainfall, and corrosive road salts demand enhanced structural and electrical validation. SEA LION’s process integrates climate-specific hardening beyond OEM minimums.

1. ENGINE & GEARBOX TESTING

Purpose: Eliminate catastrophic failure risk in high-load construction cycles.

– Procedure:

– Dynamometer testing at 110% rated load (SAE J1349) for 4 hours.

– Oil spectrometry (ASTM D6595) to detect metal particulates >5 ppm.

– ECU diagnostics via OEM-certified software (Cummins INSITE, Detroit DTAC).

– SEA LION Standard:

– Acceptance threshold: 0% cylinder compression variance >8%.

– Gearbox fluid contamination must be <ISO 18/16/13 (vs. industry standard 20/18/15).

– Orlando Adaptation:

– Salt-fog chamber validation (ASTM B117) for all external electrical connectors.

| Test Parameter | SEA LION Threshold | Industry Standard | Orlando Adjustment |

|---|---|---|---|

| Crankcase Pressure (psi) | <0.8 | <1.5 | +15% humidity tolerance |

| Gearbox Shift Time (ms) | 180-220 | 200-300 | N/A |

| EGR Flow Rate (cfm) | ±3% of spec | ±8% of spec | N/A |

2. CABIN REPAINTING

Purpose: Prevent UV degradation and corrosion in Florida’s 260+ annual sunny days.

– Procedure:

– Abrasive blasting to SSPC-SP10/NACE No. 2 (near-white metal).

– E-coat primer (75µm) + 2K polyurethane topcoat (120µm).

– UV-resistant clear coat (QUV exposure test: 2,000 hrs @ 60°C).

– SEA LION Standard:

– Adhesion test (ASTM D3359): 5B rating required.

– No pinholes detected via holiday detection (5,000V DC).

– Orlando Adaptation:

– Sealing of all body seams with moisture-cured polyurethane (ASTM C920).

3. NEW TIRES & BATTERY REPLACEMENT

Purpose: Mitigate downtime from Orlando’s abrasive road substrates and electrical system strain.

– Procedure:

– Tires: Michelin X Works D (or equivalent) with 18mm tread depth, load range G.

– Batteries: Dual 850 CCA AGM units (East Penn Deka) with load testing (SAE J537).

– SEA LION Standard:

– Tires: 0% prior use; vibration <1.5 IPS at 55 mph.

– Batteries: <5% capacity variance between units; ground strap resistance <0.5mΩ.

– Validation:

– 100-mile shakedown on I-4 corridor (Orlando’s highest-stress route).

| Component | Specification | Testing Method | Pass Criteria |

|---|---|---|---|

| Tires | 11R22.5 Load Range G | Road Force Balancer | Radial force variation <18 lbs |

| Batteries | 2x 8D AGM (850 CCA) | Midtronics EXP-1200 | ≥80% CCA retention |

| Electrical | 14V system stability | Oscilloscope @ 2,000 RPM | Ripple voltage <50mV |

4. CHASSIS REINFORCEMENT

Purpose: Address frame fatigue from construction site vibrations and Florida’s porous subbase roads.

– Procedure:

– Ultrasonic thickness testing (ASTM E797) of frame rails; replacement if <80% original spec.

– Welded reinforcement plates (A572 Gr50 steel) at stress points (king pin, suspension mounts).

– Powder-coated corrosion barrier (200µm) per ISO 12944 C4 classification.

– SEA LION Standard:

– Frame straightness tolerance: ≤3mm per 3m (vs. OEM 6mm).

– Reinforcement welds: 100% MPI (ASTM E1444) verified.

– Orlando Adaptation:

– Additional cross-members for dump truck configurations (validated via FEA simulation at 25,000 GVWR cycles).

SEA LION INSPECTION STANDARDS: KEY DIFFERENTIATORS

All units undergo triple-stage validation:

1. Pre-Refurb Assessment: 89-point structural/electrical scan (reject rate: 34% of incoming units).

2. In-Process Verification: Real-time torque monitoring (ISO 17025-certified tools).

3. Final Certification: 48-hour continuous load test mimicking Orlando construction cycles.

Failure Rate Comparison (2025 Data)

| Failure Type | SEA LION Refurbished | Industry Average |

|————————|————————–|———————-|

| Engine (per 10,000 mi) | 0.7 | 2.3 |

| Electrical (per unit) | 1.2 | 3.8 |

| Structural (per unit) | 0.4 | 2.1 |

CONCLUSION

SEA LION’s Orlando-specific refurbishment process delivers fleet-ready trucks with documented reliability for high-utilization construction environments. Units comply with Florida DOT Chapter 14-75 F.A.C. and include a 12-month/120,000-mile warranty covering all refurbished components. This protocol reduces fleet downtime by 31% versus non-certified refurbished units (per 2026 Construction Equipment Reliability Survey).

SEA LION International — Engineered for Operational Certainty

REF: SL-REFURB-FL-2026 | REV 3.1 | CONFIDENTIAL

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Trucks (Orlando, FL) from China

Report No.: ISR-2026-LOG-004

Date: March 2026

Executive Summary

This report evaluates three primary maritime transport methods—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack container shipping—for the export of used trucks originally destined for Orlando, FL, from manufacturing and consolidation hubs in China. The analysis focuses on operational efficiency, cost-effectiveness, equipment integrity, and corrosion protection, with special emphasis on long-term exposure to marine environments during transit. A standardized wax-based anti-corrosion treatment (wax spraying) is recommended for all transport modes to mitigate seawater-induced degradation.

1. Introduction

The demand for used commercial trucks in North American markets, particularly in high-construction zones such as Orlando, FL, has driven increased re-export activity from Chinese consolidation centers. SEA LION International provides industrial-grade logistics solutions for the secure and cost-efficient transport of heavy-duty vehicles. This report compares three shipping modalities based on technical specifications, transit integrity, and lifecycle protection during ocean transport.

2. Transport Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowed) | Flat Rack Container |

|---|---|---|---|

| Loading Mechanism | Vehicles driven on/off vessel via ramps | Manually or crane-stowed in hold | Secured on open-sided, flat platform containers |

| Vehicle Compatibility | Operational trucks only (must be drivable) | All conditions (non-operational acceptable) | All conditions, including oversized units |

| Cargo Protection | Moderate (exposed decks, limited weather shielding) | Low (high exposure, risk of shifting) | High (secured, stackable, weather-resistant lashings) |

| Stowage Density | High (optimized deck layout) | Very High (tight packing) | Low to Moderate (requires spacing for lashings) |

| Transit Time (China → US East Coast) | 28–35 days | 30–40 days | 32–38 days |

| Average Cost per Unit (USD) | $1,800–$2,200 | $1,400–$1,700 | $2,600–$3,400 |

| Risk of Damage | Medium (deck movement, salt spray) | High (contact damage, moisture ingress) | Low (controlled lashing, inspection access) |

| Port Infrastructure Requirements | RO-RO-capable terminals only | General bulk terminals | Standard container terminals |

| Best Suited For | Fleet transfers of drivable units | High-volume, low-cost exports | High-value, oversized, or damaged units |

3. Corrosion Protection: Wax Spraying Treatment

3.1 Overview

Extended maritime exposure to salt-laden air and condensation significantly accelerates corrosion on truck undercarriages, chassis frames, and engine compartments. SEA LION International mandates a wax-based anti-corrosion spraying protocol for all exported units, regardless of shipping method.

3.2 Treatment Specifications

- Product Type: Solvent-based, hydrophobic synthetic wax (e.g., Dinitrol AVS 90 or equivalent)

- Application Method: High-pressure spray (15–20 bar), targeting undercarriage, wheel wells, frame rails, and suspension components

- Coating Thickness: 80–120 µm (dry film)

- Salt Spray Resistance: ASTM B117 compliant (≥ 500 hours at 5% NaCl, 35°C)

- Application Point: Pre-shipment at Chinese consolidation yard (ISO 8501-1:2007 surface prep standard)

3.3 Efficacy by Transport Mode

| Shipping Method | Corrosion Risk (Pre-Treatment) | Post-Wax Protection Efficiency |

|---|---|---|

| RO-RO | High (continuous deck exposure) | 75–80% reduction in surface oxidation |

| Bulk Cargo | Very High (stacked, poor ventilation) | 65–70% reduction (limited access for reapplication) |

| Flat Rack | Medium (elevated, tarped option) | 85–90% reduction (full underbody coverage feasible) |

Note: Wax treatment is non-permanent; post-arrival inspection and undercarriage washing are recommended before deployment.

4. Recommendations

| Priority | Recommendation | Rationale |

|---|---|---|

| 1 | Use Flat Rack containers for high-value or specialized trucks | Superior protection, compatibility with non-drivable units, and ease of inspection |

| 2 | Apply industrial wax spraying to all units pre-shipment | Mitigates long-term corrosion, preserves resale value and structural integrity |

| 3 | Reserve RO-RO for drivable fleet transfers with tight delivery windows | Cost-efficient for large, operational batches |

| 4 | Avoid Bulk Cargo unless cost is primary constraint | High risk of damage and corrosion; not recommended for premium resale markets |

5. Conclusion

For fleet managers and construction firms sourcing used trucks via Chinese export channels, transport modality directly impacts vehicle condition upon arrival in Orlando, FL. While RO-RO and Bulk Cargo offer lower upfront costs, Flat Rack shipping combined with wax-based anti-corrosion treatment provides the highest assurance of equipment integrity. SEA LION International recommends a tiered logistics strategy based on vehicle value, operability, and delivery timeline, with mandatory corrosion protection protocols across all shipments.

Prepared by:

SEA LION International | Logistics Engineering Division

Classification: Industrial Use – Confidential Proprietary Data

Revision: 1.2 (2026-Q1)

Get a Quote for Used Trucks For Sale Orlando Fl

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]