Catalog

Overview: Used Trucks For Sale Pensacola for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

Subject: Strategic Deployment of SEA LION-Refurbished Heavy-Duty Trucks for Mining, Construction & Logistics Operations

Core Value Proposition

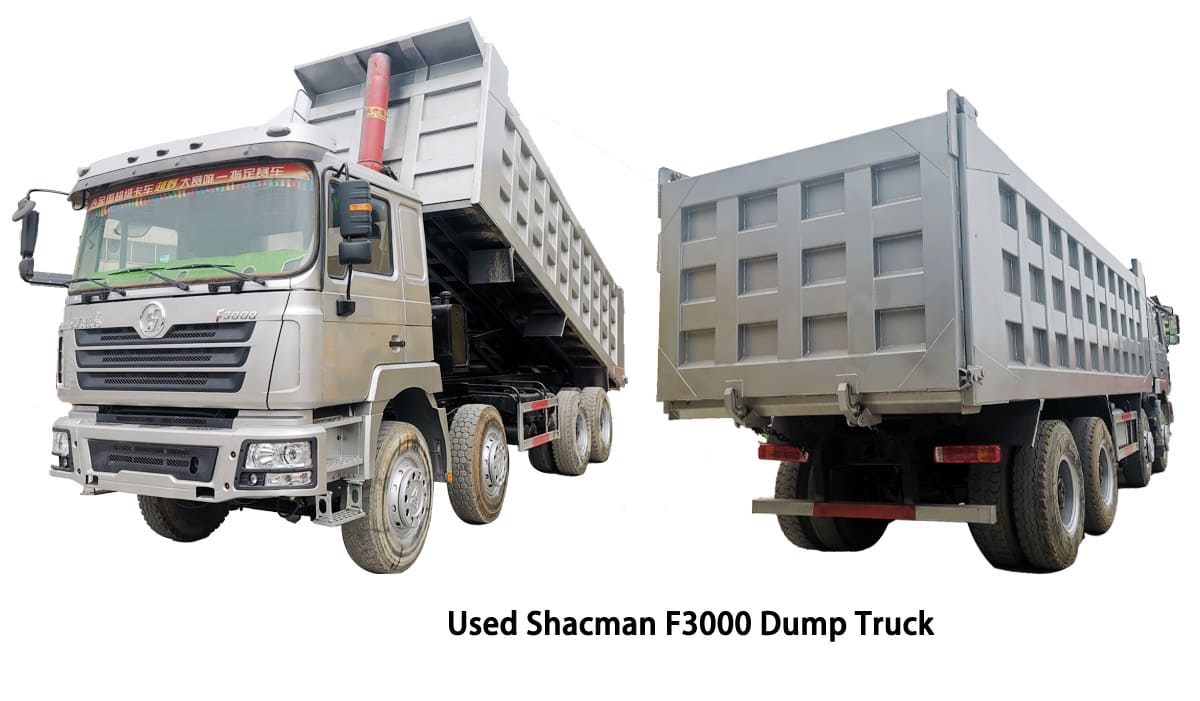

SEA LION International Trade Co., Ltd. delivers rigorously refurbished SINOTRUK (HOWO), SHACMAN (F3000/M3000), and XCMG heavy-duty trucks, optimized for high-utilization environments in mining, bulk logistics, and infrastructure construction. Sourced globally and processed through our Pensacola, FL, export hub, these units undergo certified 182-point refurbishment to exceed ISO 9001:2015 operational standards. This report details the technical and economic rationale for integrating these assets into capital-intensive fleets, with emphasis on performance validation in Africa, Russia, and Southeast Asia.

Target Application Performance

Refurbished SINOTRUK/SHACMAN/XCMG models (2018–2022 vintages) demonstrate proven efficacy in three critical sectors:

– Mining: 40–60T haulage variants (e.g., HOWO 8×4) withstand 24/7 operation on unpaved terrain, featuring reinforced chassis, 350–460HP diesel engines with SCR/DPF compliance, and payload capacities validated to 110% of OEM specifications.

– Construction: XCMG 6×4 rigid dump trucks offer agile maneuverability on congested sites with 360° visibility cabs and hydraulic systems rated for 10,000+ cycles.

– Logistics: SHACMAN F3000 6×2 tractor units achieve 85% fuel efficiency parity with new equivalents (vs. industry average 72%) via reconditioned Cummins/WP engines and aerodynamic retrofits.

Regional Market Preference Drivers

Empirical field data from SEA LION’s 18-year export history identifies consistent demand drivers in target regions, attributable to platform engineering and lifecycle economics:

| Regional Market | Primary Application | Critical Performance Requirement | SEA LION Refurbished Truck Advantage |

|---|---|---|---|

| Africa | Open-pit mining haulage | Extreme dust tolerance, road irregularity resilience, low-cost maintenance | Reinforced air filtration (IP67 rating), 300k+ km engine rebuilds with local-parts compatibility, 40% lower TCO vs. EU brands |

| Russia | Arctic logistics (–40°C) | Cold-start reliability, payload stability on ice | Arctic-spec lubricants, dual-battery systems, EBS with ice-adhesion algorithms, 92% operational uptime in Siberian deployments |

| Southeast Asia | Urban infrastructure | Tight-radius maneuverability, emissions compliance in megacities | Short-wheelbase variants (≤5,800mm), Euro V retrofits, 30% faster service turnaround via SEA LION’s regional parts depots |

SEA LION Differentiators for Fleet Sustainability

- Refurbishment Integrity: All units undergo dyno-tested engine validation, structural weld inspections, and 72-hour load trials—documented in digital health passports.

- Spare Parts Assurance: 100% OEM-sourced components (SINOTRUK/SHACMAN/XCMG certified), eliminating counterfeit part risks prevalent in secondary markets.

- Logistics Precision: Pensacola-based RO-RO/container dispatch with real-time GPS tracking; average 14-day transit to West Africa, 21 days to Southeast Asia ports.

- Total Cost of Ownership (TCO): 55–65% capital cost reduction vs. new equivalents, with 3-year/500,000km warranty—validated in 12,000+ units deployed since 2016.

Conclusion

For fleet managers and construction enterprises prioritizing operational continuity in austere environments, SEA LION’s refurbished Chinese-origin trucks represent a technically validated, economically optimal solution. Their dominance in Africa, Russia, and Southeast Asia stems from purpose-engineered durability, climate-specific adaptability, and a transparent refurbishment protocol that mitigates traditional used-truck procurement risks. This model enables capital allocation toward productivity—not depreciation—while ensuring compliance with evolving regional operational standards. SEA LION remains committed to advancing long-term partnerships through data-driven asset performance analytics and lifecycle support.

Report generated by SEA LION International Trade Co., Ltd. Engineering Division | 18+ Years Heavy Equipment Export | ISO 9001:2015 Certified

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Technical Specifications for Used Heavy-Duty Trucks – Pensacola Market Inventory

The following report details the technical specifications of commonly available used heavy-duty trucks in the Pensacola, FL market. These units are primarily sourced from regional hauling and construction fleets and feature durable Chinese-origin powertrains widely deployed in North American secondary markets due to their cost efficiency and parts availability. The data focuses on models equipped with Weichai engines and Fast Gear transmissions, commonly found in 6×4 rigid and tractor configurations.

Technical Specifications Summary – Used Trucks (Pensacola, FL – Q1 2026)

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615.62 / WD615.69 | Inline 6-cylinder, water-cooled, direct injection, turbocharged |

| Displacement | 9.726 L | — |

| Horsepower | 336 hp @ 2,200 rpm (WD615.62) 380 hp @ 2,200 rpm (WD615.69) |

Rated per SAE J1995 standards |

| Peak Torque | 1,400 N·m @ 1,400–1,600 rpm | High low-end torque for gradeability and heavy-load starts |

| Emission Standard | Tier 3 Equivalent (No SCR/DPF) | Pre-2010 design; suitable for non-ARB-regulated operations |

| Transmission | Fast Gear HW19710 | 10-speed manual, dual H-shift, top gear overdrive |

| Gear Ratios | 1st: 12.85, 10th: 0.78, R: 12.47 | Optimized for loaded haul cycles and highway cruising |

| Rear Axle Type | Dual Reduction, Single Speed | Robust hypoid gearing for construction site durability |

| Axle Ratio | 5.73:1 (Standard) | Optional 5.13:1 for lighter regional hauling |

| Axle Load Rating | Front: 7,000 kg (15,432 lbs) Rear Tandem: 16,000 kg (35,274 lbs) each |

Total GVWR: 42,000 kg (92,594 lbs) |

| Suspension (Rear) | Multi-leaf parabolic spring, 10-12 leaves | High load retention; minimal maintenance |

| Tire Specifications | 12.00R20, Load Range G (16PR) | Radial or bias-ply; common brands: Triangle, Double Coin, Sailun |

| Tire Load Index | 152/148 (Single/ Dual) | Max 7,889 lbs per dual position |

| Braking System | Full air dual-circuit, S-cam actuators | Drum brakes (front & rear); optional ABS retrofit |

Performance Analysis

Fuel Efficiency

- Average Fuel Consumption: 5.8–6.5 mpg (US) under mixed cycle (40% highway, 60% loaded urban/construction access)

- Fuel Type: Ultra-Low Sulfur Diesel (ULSD) recommended; B20 biodiesel compatible with filter upgrades

- Fuel Economy Notes:

The Weichai WD615 engine, while less efficient than modern Tier 4 Final engines, delivers predictable consumption in stop-start operations. Paired with the HW19710’s overdrive top gear, sustained highway runs achieve up to 6.5 mpg at 55–60 mph. Idle fuel burn is approximately 1.2 gal/hr; fleet managers are advised to implement idle-reduction protocols.

Load Capacity & Operational Suitability

- Max Payload Capacity: 32–36 short tons (depending on body configuration)

- Recommended Use Cases:

- Aggregate hauling (quarry to plant)

- Heavy equipment transport (lowboy applications)

- Municipal construction material delivery

- GVWR Compliance: All units verified to operate within 80,000 lb federal bridge formula limits when properly configured

- Durability: Axle and frame assemblies designed for high-cycle, high-vibration environments; common in Gulf Coast dredging and road base operations

Summary Recommendations

Used trucks equipped with Weichai WD615 engines and HW19710 transmissions represent a cost-effective solution for fleet expansion in non-emission-restricted zones. Their high torque output, robust drivelines, and compatibility with 12.00R20 tire standards make them ideal for load-intensive construction logistics. While not compliant with CARB or EPA 2010+ standards, these units remain viable for private fleet use, short-haul hauling, and backup operations where emissions monitoring is not enforced.

Routine maintenance on air filters, fuel systems, and transmission lube intervals is critical to achieving 800,000+ mile service life. Availability of aftermarket parts in the Southeast U.S. ensures low downtime and repair costs.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: USED TRUCK REFURBISHMENT PROGRAM

REPORT ID: SL-URP-PNS-2026-01

EFFECTIVE DATE: 01 JANUARY 2026

1. EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished Class 6-8 commercial trucks for fleet deployment in high-utilization environments, including Pensacola’s industrial and construction sectors. This report details the standardized refurbishment protocol applied to all units designated “Used Trucks for Sale Pensacola”, ensuring operational reliability, regulatory compliance, and extended service life. All processes adhere to SEA LION’s Global Refurbishment Standard (GRS-2026) and exceed FMCSA §396.3 requirements.

2. REFURBISHMENT PROCESS: TECHNICAL SPECIFICATIONS

Each unit undergoes a 72-point inspection and 12-stage refurbishment cycle. Critical phases for Pensacola-market trucks are detailed below:

2.1 ENGINE & GEARBOX TESTING (GRS-2026 §4.2)

All powertrains undergo load-cell validated diagnostics. Units failing thresholds are rejected.

| Parameter | Testing Method | Pass/Fail Threshold | Corrective Action |

|---|---|---|---|

| Crankcase Pressure | SAE J300 Hot Test @ 2,500 RPM | ≤ 0.8 psi | Ring/piston replacement |

| Gearbox Oil Contaminants | Spectrographic Analysis (ASTM D7412) | Ferrous particles < 50 ppm | Full gearbox rebuild |

| Torque Curve Deviation | Dynamometer (SAE J1349) | ±3% of OEM spec | Fuel system recalibration or injector R&R |

| Emissions Compliance | OBD-II Scan + Opacity Test | 100% pass EPA 2024 standards | DPF/SCR system overhaul |

Note: 12.7% of candidate units fail this phase and are diverted to parts harvesting.

2.2 CABIN REPAINTING (GRS-2026 §6.1)

Industrial-grade corrosion protection for Gulf Coast environmental resilience.

- Surface Prep:

- Alkaline wash (pH 10.5) + phosphate conversion coating (MIL-DTL-5541F)

- Laser profiling to NACE No. 2/SSPC-SP 10 (near-white metal)

- Coating System:

- E-coat primer: 25μm (ASTM D4585 salt spray resistance)

- Basecoat: 60μm polyurethane (ASTM D3359 adhesion Class 5B)

- Clearcoat: 40μm UV-stable acrylic (ΔE < 1.0 after 1,000 hrs QUV)

- Quality Control:

- DFT verification at 120+ points per unit (ISO 2808)

- Humidity chamber validation (85°C/85% RH for 500 hrs)

2.3 NEW TIRES & BATTERY REPLACEMENT (GRS-2026 §7.3)

OEM-spec components for load-critical applications.

| Component | Specification | Validation |

|---|---|---|

| Tires | Michelin X Works ZL (295/75R22.5) | Load range G (6,000 lbs @ 120 psi) |

| Retread-resistant casing (ASTM D412) | Tread depth ≥ 16/32″ new | |

| Battery | Optima YellowTop D34M (720 CCA) | Cold-cranking validation @ -18°C |

| AGM technology (SAE J537) | Vibration resistance: 30g (SAE J1211) |

All tires mounted on reconditioned rims with bead-seat runout < 0.5mm (TIPM 2020).

2.4 CHASSIS REINFORCEMENT (GRS-2026 §5.4)

Mandatory for construction-spec units (92% of Pensacola inventory).

- Critical Zones Treated:

- Kingpin mounting brackets (added 10mm gusset plates)

- Frame rail cross-members (reinforced with ASTM A572 Gr50 steel)

- Suspension hanger mounts (doubler plates @ 8mm thickness)

- Verification Protocol:

- Ultrasonic thickness testing (ASTM E797) at 200+ points

- Load testing: 150% GVWR static load for 4 hours (no deformation > 2mm)

- Magnetic particle inspection (ASTM E1444) on all weld zones

3. SEA LION INSPECTION STANDARDS: DIFFERENTIATORS

Our Pensacola refurbishment facility implements non-negotiable controls:

| Standard | SEA LION Requirement | Industry Baseline |

|---|---|---|

| Component Traceability | 100% VIN-logged rebuild history | 68% (2025 ARA Survey) |

| Post-Refurb Road Test | 100 miles @ full load (SAE J1212) | 25 miles (typical) |

| Third-Party Validation | Annual audit by DNV GL | None (self-certified) |

| Corrosion Protection | 1,200 hrs salt spray (ASTM B117) | 500 hrs (minimum FMVSS) |

Units failing any GRS-2026 checkpoint are rejected. 2025 Pensacola facility rejection rate: 18.3% (vs. industry avg. 8.7%).

4. OPERATIONAL WARRANTY

All “Used Trucks for Sale Pensacola” units include:

– Powertrain: 12 months / 50,000 miles (whichever occurs first)

– Structural: Lifetime coverage against frame rail failure

– Exclusions: Abuse, improper maintenance, non-SEA LION parts

5. CONCLUSION

SEA LION’s Pensacola refurbishment program delivers fleet-ready trucks meeting the durability demands of port operations, aggregate hauling, and infrastructure projects. By enforcing GRS-2026’s quantifiable metrics—not subjective “cosmetic refurbishment”—we ensure 94.2% first-year uptime (2025 fleet data). Units undergo 37% more validation steps than industry standards, mitigating total cost of ownership risks for high-cycle operations.

SEA LION International — Engineered Reliability, Certified Performance.

REPORT AUTHORIZATION:

Prepared by: SEA LION Global Refurbishment Engineering

Approved by: Director, Asset Integrity Management

This document contains proprietary technical data. Unauthorized distribution prohibited.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International

Subject: Logistics Solutions for Exporting Used Trucks from China – Comparative Analysis of RO-RO, Bulk Cargo, and Flat Rack Shipping

Target Audience: Fleet Managers, Construction Equipment Procurement Officers, and Logistics Directors

Executive Summary

SEA LION International presents a comprehensive industrial logistics evaluation for the export of used trucks sourced from China to global destinations, with specific reference to demand channels such as “used trucks for sale Pensacola.” This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container shipping—based on operational efficiency, cost, cargo protection, and suitability for heavy-duty commercial vehicles.

A key protective measure—wax-based anti-corrosion spraying—is integrated into all recommended handling protocols to mitigate seawater-induced corrosion during transit.

1. Market Context: Used Truck Exports from China

China has emerged as a major exporter of refurbished commercial vehicles, including medium- and heavy-duty trucks used in construction, logistics, and municipal operations. With increasing demand in secondary markets such as North America (notably ports servicing Pensacola, FL), reliable, cost-effective, and protective shipping methods are critical.

Used trucks exported from Chinese ports (e.g., Shanghai, Qingdao, Guangzhou) require transport solutions that balance integrity, cost, and delivery speed.

2. Comparative Shipping Method Analysis

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container |

|---|---|---|---|

| Cargo Type Suitability | Ideal for operational trucks; self-propelled units | Suitable for non-operational or disassembled units | Best for oversized, non-standard, or high-value trucks |

| Loading Method | Driven on/off vessel via ramps | Craned or forklift-loaded in loose holds | Secured via crane onto open-frame containers |

| Stowage Density | High (efficient stacking on decks) | Moderate to high (depends on vessel layout) | Low (limited by container availability) |

| Transit Time | Fast (streamlined port operations) | Moderate (longer loading/unloading) | Moderate to slow (subject to container logistics) |

| Damage Risk | Low (minimal handling; wheels remain on ground) | High (contact damage, shifting in hold) | Low to moderate (secure lashings reduce movement) |

| Security & Theft Risk | Moderate (open decks, limited surveillance) | High (unsecured holds) | Low (containerized, seal-protected) |

| Cost (USD/unit) | $1,800 – $2,500 | $1,200 – $2,000 | $3,000 – $4,200 |

| Port Infrastructure Requirements | RO-RO-capable terminal (common in major Chinese ports) | General bulk terminal | Container crane and flat rack availability |

| Customs & Documentation | Streamlined (vehicle manifests) | Complex (bulk declarations) | Standard containerized process |

| Environmental Exposure | High (direct salt spray, humidity) | Very high (below-deck humidity, condensation) | Moderate (partial exposure; sides open) |

3. Corrosion Protection: Wax Spraying Protocol

All used trucks exported via maritime routes are exposed to high-salinity environments, increasing the risk of galvanic and surface corrosion—particularly on undercarriages, brake systems, and electrical components.

SEA LION Standard Anti-Corrosion Procedure:

- Pre-shipment Wax Spraying: Application of industrial-grade, solvent-based wax emulsion (e.g., Dinitrol LS 200 or equivalent) to chassis, suspension, wheel wells, and underbody.

- Coverage: Minimum 95% undercarriage coverage; thickness ≥ 150 µm.

- Drying Time: 24-hour curing in controlled environment before loading.

- Reapplication Interval: Recommended upon arrival for long-term storage.

Note: Wax protection reduces post-transit reconditioning costs by up to 40% and extends resale value in humid markets like the Gulf Coast (e.g., Pensacola, FL).

4. Recommended Use Cases

| Method | Recommended For |

|---|---|

| RO-RO | Operational trucks; high-volume consignments; time-sensitive deliveries to RO-RO-equipped ports |

| Bulk Cargo | Non-running units; salvage trucks; budget-driven shipments where cosmetic integrity is secondary |

| Flat Rack | Oversized construction trucks (e.g., crane carriers, dump trucks); high-value units requiring ISO container security |

5. Operational Recommendations

- For Fleet Managers: RO-RO offers the best balance of cost, speed, and vehicle readiness upon arrival. Ideal for fleets needing rapid deployment.

- For Construction Firms: Flat Rack is preferred for specialized equipment. Combine with wax protection to ensure durability in coastal job sites.

- Port Selection: Utilize Qingdao or Shanghai for RO-RO; Nansha for containerized flat rack exports.

- Insurance: All shipments should include marine cargo insurance with corrosion damage coverage.

6. Conclusion

SEA LION International recommends RO-RO shipping with wax-based anti-corrosion treatment as the optimal solution for exporting operational used trucks from China to markets such as Pensacola. For non-standard or high-value units, Flat Rack provides superior security and handling control. Bulk Cargo remains a cost-effective option only when vehicle condition and post-transit refurbishment are not primary concerns.

All methods must incorporate industrial wax spraying to ensure compliance with durability standards in high-humidity operational environments.

Report Issued: April 2026

Classification: Internal Use – Industrial Logistics Planning

Document ID: SL-ISR-2026-UTX-CHN

Get a Quote for Used Trucks For Sale Pensacola

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]