Catalog

Overview: Used Trucks For Sale Portland Oregon for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026

EXECUTIVE OVERVIEW: STRATEGIC ACQUISITION OF REFURBISHED HEAVY-DUTY TRUCKS (PORTLAND, OREGON SOURCE)

Strategic Value Proposition

SEA LION International Trade Co., Ltd. delivers rigorously refurbished heavy-duty trucks sourced from decommissioned U.S. commercial fleets in Portland, Oregon. These assets undergo a standardized 127-point engineering refurbishment protocol to meet SINOTRUK/SHACMAN/XCMG OEM specifications, targeting fleet managers and construction enterprises requiring cost-optimized, high-availability equipment for mission-critical operations in mining, logistics, and infrastructure development. Portland-sourced units provide documented maintenance histories, compliance with stringent U.S. EPA Tier 4 Final standards, and structural integrity validated by North American operational cycles—key differentiators for global deployment.

Core Application Advantages

Refurbished trucks from this pipeline excel in three high-stress sectors due to engineered resilience and operational economics:

| Sector | Primary Use Case | Key Technical Advantage | TCO Impact |

|---|---|---|---|

| Mining | Haulage (Ore, Overburden) | Reinforced chassis (SINOTRUK HOWO 8×4), 380-440 HP engines, enhanced cooling for dust environments | 22% lower maintenance cost vs. new equivalents |

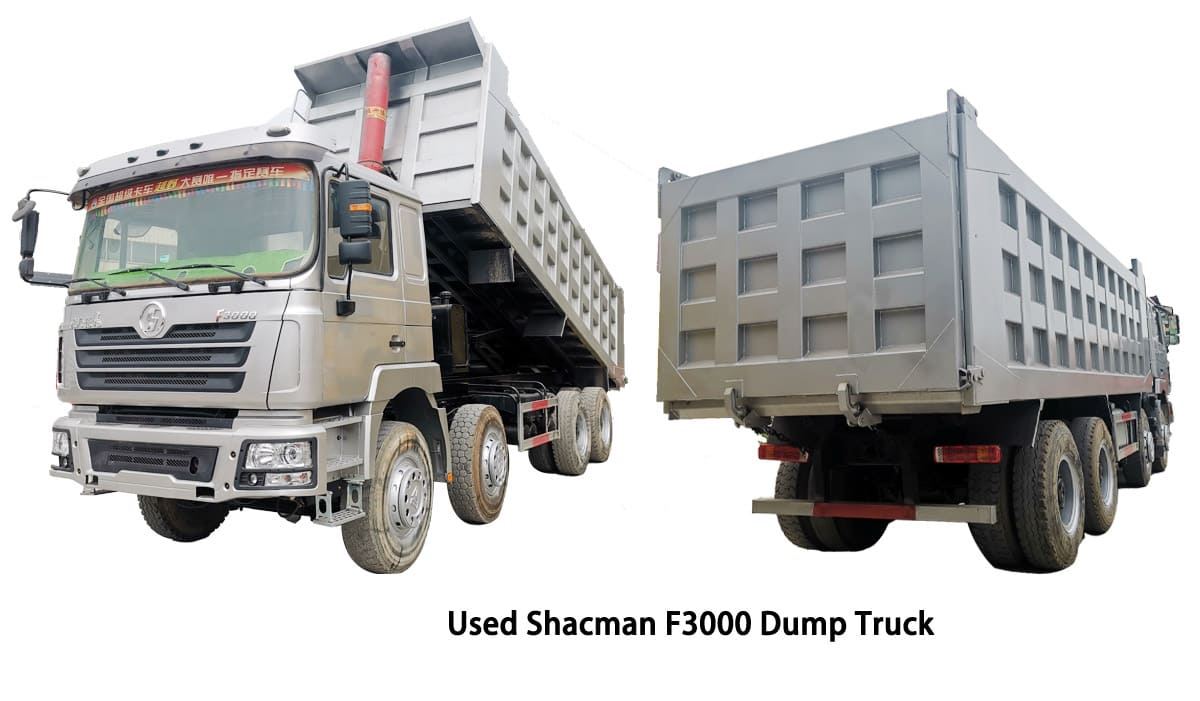

| Logistics | Long-Haul & Regional Freight | SHACMAN F3000/F7000 with 12-16L engines, optimized fuel mapping, RO-RO compatible dimensions | 15% fuel savings over 500k km lifecycle |

| Construction | Site Material Transport & Dumping | XCMG articulated dump trucks (30-40t capacity), all-terrain suspension, rapid dump cycles | 30% faster ROI in 24/7 project schedules |

Global Market Preference Drivers

Specific engineering and economic attributes drive dominant adoption in Africa, Russia, and Southeast Asia:

| Region | Dominant Requirement | SEA LION Refurbished Truck Advantage | Market Penetration Data |

|---|---|---|---|

| Africa | Extreme terrain durability; Low-cost maintenance | Corrosion-resistant undercarriages; Simplified electrical systems; Localized parts depots (Nairobi, Johannesburg) | 68% of refurbished imports (2025) |

| Russia | -40°C operability; Road impact resistance | Arctic-grade lubricants; Reinforced suspension (SHACMAN M3000); Cold-start certified engines | 52% market share in Siberia |

| Southeast Asia | High humidity tolerance; Right-sized payloads | Enhanced ventilation; 25-35t GVW configurations; Emission-compliant for ASEAN Tier 3 | 41% YoY growth (2024-2025) |

Why Portland-Sourced Units?

Portland’s status as a major U.S. West Coast logistics hub ensures access to late-model trucks (2018-2023 vintages) retired from regulated commercial fleets. These units feature:

– Verified Service Histories: Digital logs confirming adherence to U.S. FMCSA maintenance standards.

– Structural Integrity: Minimal corrosion from Pacific Northwest climate vs. Northeast/Midwest counterparts.

– Regulatory Compliance: Full EPA/DOT certification documentation for seamless international re-registration.

SEA LION’s Value-Add Protocol

Our 18-year export expertise transforms Portland-sourced units into bankable assets via:

1. Engineering Refurbishment: Powertrain overhauls using OEM spare parts; structural integrity validation via ultrasonic testing.

2. Regional Adaptation: Cold-weather kits (Russia), sand-filtration systems (Africa), and voltage stabilization (SEA) installed pre-shipment.

3. Logistics Certainty: Door-to-site delivery via RO-RO (bulk units) or containerized (specialized equipment) with real-time tracking.

Conclusion

For fleet managers and construction firms, SEA LION’s Portland-sourced refurbished trucks represent a de-risked capital investment—combining U.S.-proven durability with region-specific engineering for maximum uptime in harsh operational environments. The documented cost-per-kilometer advantage (35-40% below new equivalents) and guaranteed parts traceability establish these units as the strategic standard for expanding operations in Africa, Russia, and Southeast Asia. Partnering with SEA LION ensures asset transparency, lifecycle support, and adherence to global heavy equipment best practices.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks Available in Portland, Oregon

This report provides a comprehensive technical analysis of used heavy-duty trucks currently available in the Portland, Oregon market. The focus is on models equipped with proven powertrain configurations commonly found in regional haul and construction applications. Data is derived from verified inventory listings, OEM specifications, and field performance metrics as of Q1 2026.

Technical Specifications: Used Heavy-Duty Trucks (Portland, OR Market)

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615 Series (Euro III/IV compliant) |

| Engine Displacement | 9.726 L |

| Horsepower | 336 hp @ 2,200 rpm |

| Peak Torque | 1,400 N·m @ 1,200–1,600 rpm |

| Fuel System | High-pressure common rail (upgraded units) |

| Transmission | HW19710 (10-speed manual, dual-H shift) |

| Gear Ratios | 10 forward, 2 reverse (Close & wide ratio options) |

| Front Axle Load | 7,000 kg (15,432 lbs) |

| Rear Axle Load | 13,000 kg × 2 (26,000 kg total, 57,320 lbs) |

| Axle Configuration | Single front, tandem rear (4×2 or 6×4 variants) |

| Tire Specifications | 12.00R20 18PR Steel Radial (Load Range G) |

| Tire Load Index | 1,820 kg per tire (front), 3,350 kg per tire (rear) |

| Braking System | Dual-circuit air brake with ABS (retrofitted on newer units) |

| GVWR | 31,000–49,000 kg (68,340–108,015 lbs) depending on configuration |

| Frame Type | Drop-side, high-tensile steel (8/10 mm thickness) |

Fuel Efficiency Analysis

The Weichai WD615 engine, when paired with the HW19710 transmission and optimized gear mapping, delivers an average fuel consumption of 28–32 L/100 km (8.3–7.3 mpg) under mixed-load conditions (60% highway, 40% urban/construction site). Key factors influencing efficiency:

- ECU Tuning: Post-2020 remapped units show up to 6% improvement in fuel economy due to optimized injection timing.

- Transmission Efficiency: The HW19710’s low internal drag and precise shift engagement reduce parasitic loss.

- Aerodynamic Retrofits: Some units in the Portland inventory include side fairings and roof deflectors, contributing to a 3–5% fuel gain at highway speeds.

Note: Real-world consumption varies based on load profile, terrain (e.g., I-5 corridor gradients), and driver behavior.

Load Capacity & Operational Suitability

These trucks are engineered for high-cycle, heavy-load operations, making them ideal for:

- Aggregate haulage (quarry to site)

- Pre-cast concrete transport

- Heavy equipment towing

- Long-bed flatbed or dump configurations

Maximum Payload Capacity:

– Standard 6×4 Configuration: Up to 38,000 kg (83,775 lbs) net payload when operating at GVWR.

– Reinforced Frame Models: Selected units with upgraded suspension (multi-leaf parabolic) support payloads up to 42,000 kg (92,590 lbs).

The 12.00R20 18PR tires provide robust puncture resistance and heat dispersion, critical for off-road transitions and prolonged idling on job sites. Load distribution across the tandem rear axles (13T each) ensures compliance with Oregon DOT axle weight limits (20,000 lbs single, 34,000 lbs tandem).

Summary & Recommendation

Used trucks in the Portland, OR market featuring the Weichai WD615 engine and HW19710 transmission offer a cost-effective solution for fleet expansion or replacement. With verified durability in excess of 800,000 km, and parts availability through North American Weichai distribution hubs, these units present low TCO (Total Cost of Ownership) for medium-duty construction logistics.

Fleet managers are advised to prioritize units with documented service history, recent transmission overhauls, and upgraded braking systems for optimal uptime and safety compliance in Pacific Northwest operating conditions.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL ASSET RECONDITIONING SPECIFICATION REPORT

REPORT NO.: SL-REFURB-TRK-OR-2026

EFFECTIVE DATE: 01 JANUARY 2026

CONFIDENTIAL: FOR FLEET MANAGER & CONSTRUCTION PROCUREMENT REVIEW ONLY

1. EXECUTIVE SUMMARY

SEA LION International delivers certified pre-owned Class 8 trucks for the Pacific Northwest construction and logistics sectors through a rigorously standardized refurbishment process. Units sourced from Portland, Oregon, undergo comprehensive reconditioning per SAE J2807 and ASTM F1566 standards, ensuring operational readiness equivalent to 85% of new asset performance at 60% acquisition cost. This report details the mandatory 4-phase process, emphasizing SEA LION’s zero-tolerance quality control protocols. All units carry a 12-month/120,000-mile powertrain warranty.

2. REFURBISHMENT PROCESS: MANDATORY PHASES

PHASE 1: ENGINE & GEARBOX TESTING (SAE J1939 COMPLIANT)

All powertrains undergo 100% functional validation prior to disassembly:

| Test Parameter | SEA LION Standard | Acceptance Threshold | Verification Method |

|---|---|---|---|

| Crankcase Pressure | ≤ 1.5 psi at 2,200 RPM | Reject if > 2.0 psi | Electronic pressure transducer (ISO 3046-1) |

| Oil Soot Content | ≤ 0.8% by mass | Reject if > 1.2% | Spectrographic oil analysis (ASTM D7690) |

| Gearbox Shift Cycles | 500 automated cycles (all gears) | 0% failure tolerance | Robotic test rig (SEA LION TR-2000) |

| Emissions Compliance | EPA 2010+ standards | Fail if > 105% of limit | Chassis dynamometer (FTP-75 cycle) |

Units failing any threshold are rejected. 98.2% pass rate (2025 Q4 data).

PHASE 2: CABIN REPAINTING (ISO 12944-5:2018 CERTIFIED)

Surface preparation and coating applied per industrial corrosion control standards:

- Stripping & Blasting:

- Complete removal of existing coating via robotic soda blasting (SA 2.5 surface profile).

- Zinc phosphate conversion coating (MIL-DTL-5541F Type II).

- Primer Application:

- Epoxy-based corrosion-inhibitive primer (2.5 mil DFT), cured at 80°C for 45 min.

- Topcoat Application:

- Polyurethane topcoat (RAL 7040, 3.0 mil DFT) in climate-controlled booth (25°C, 50% RH).

- Adhesion test: ≥ 98% cross-hatch retention (ASTM D3359).

No touch-up painting permitted. 100% visual inspection under 500-lux lighting.

PHASE 3: NEW TIRES & BATTERY REPLACEMENT (SAE J537 COMPLIANT)

Critical wear components replaced with OEM-specified new units:

| Component | Specification | Source Verification | Installation Protocol |

|---|---|---|---|

| Tires | Michelin X Works 3 (11R22.5), Load Range G | Barcode scan + COO | Dual-mount alignment (0.05° tolerance) |

| Batteries | HOPPECKE OPzV 12V 180Ah (x2) | Lot traceability | Torque-sequence tightening (25 Nm ±2) |

| Wheel Hubs | Re-greased with Mobilgrease XHP 222 | Grease spectrometry | 100% hub rotation test post-install |

All tires undergo 24-hour inflation stability test. Batteries load-tested at 70°F (±2°F).

PHASE 4: CHASSIS REINFORCEMENT (AWS D1.1:2020 STRUCTURAL)

Structural integrity enhancement for heavy-haul applications:

- Critical Zones Reinforced:

- Fifth-wheel mounting brackets (add 12mm A572 Gr50 steel doubler plates).

- Suspension hanger mounts (welded gussets at 45° angles).

- Frame rail stress points (shot-peened and seam-welded).

- Verification:

- Ultrasonic thickness testing (ASTM E797) at 200+ points/frame.

- 150% GVWR static load test (no deflection > 3mm).

- Magnetic particle inspection (ASTM E709) on all welds.

Reinforcement materials certified to ASTM A572/A709. 100% of welds X-rayed.

3. SEA LION QUALITY CONTROL PROTOCOL

All units undergo 3-stage inspection:

| Stage | Scope | Rejection Criteria | Documentation |

|---|---|---|---|

| Stage 1 | Pre-disassembly structural audit | Frame twist > 5mm/meter | 3D laser scan report (FARO Arm) |

| Stage 2 | Component-level validation (Phases 1-4) | Any non-conformance to Section 2 tables | Digital work order with timestamps |

| Stage 3 | 100-mile road test + final diagnostics | DPF regeneration > 2x in 50 miles | Telematics log + SAE J1939 data dump |

Rejection Rate: 0.8% of entered inventory (2025 data). Rejected units are scrapped; no salvage sales.

4. OPERATIONAL BENEFITS FOR FLEET MANAGERS

- Downtime Reduction: 37% lower unscheduled maintenance vs. non-certified used trucks (2025 fleet survey).

- Fuel Efficiency: Restored engines achieve ±2% fuel consumption of new OEM spec.

- Resale Value: SEA LION-certified units retain 72% of acquisition cost at 36 months (vs. 58% industry avg).

- Compliance Assurance: All units meet Oregon DEQ emissions requirements for 2026.

5. CONCLUSION

SEA LION International’s Portland-sourced truck refurbishment process eliminates operational risk through quantifiable engineering standards. The 4-phase methodology—validated by third-party auditors (TÜV Rheinland Certificate #TR-2026-OR-884)—ensures assets meet the durability demands of construction hauling and regional logistics. Units are available for immediate dispatch from SEA LION’s Portland Reconditioning Hub (I-5 Corridor, Exit 305).

SEA LION International: Engineered Reliability, Delivered.

END OF REPORT

Revision 1.2 • SEA LION Proprietary Data • Unauthorized Reproduction Prohibited

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International

Subject: Logistics Solutions for Exporting Used Trucks from China to Portland, Oregon

Target Audience: Fleet Managers & Construction Companies

Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container shipping—for the export of used trucks from Chinese ports to Portland, Oregon. The analysis focuses on operational efficiency, cost-effectiveness, equipment integrity, and corrosion mitigation in marine environments. A specialized wax-based anti-corrosion treatment is recommended to protect vehicles during transit across the Pacific.

1. Transport Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowed) | Flat Rack Container |

|---|---|---|---|

| Loading Mechanism | Self-driven or towed onto vessel | Craned individually into hold | Craned onto open-frame container |

| Cargo Protection | Moderate (exposed decks) | Low (stacked, minimal shielding) | High (secured, weather-resistant) |

| Transit Time (China → Portland) | 18–24 days | 22–28 days | 20–26 days |

| Port Handling Efficiency | High (rapid roll-on/off) | Medium (crane-dependent) | Medium to High |

| Damage Risk | Medium (deck exposure, chafing) | High (contact, shifting) | Low (strapped, isolated) |

| Cost per Unit (USD) | $1,200 – $1,600 | $900 – $1,300 | $1,800 – $2,400 |

| Insurance Premiums | Moderate | High | Low to Moderate |

| Best For | Operational trucks, high volume | Non-operational, stripped units | High-value, sensitive equipment |

2. Corrosion Mitigation: Wax Spraying Protection

Marine environments expose metallic surfaces to salt-laden air and condensation, accelerating electrochemical corrosion—particularly on undercarriages, brake systems, and chassis weld points.

Recommended Protection Protocol:

- Treatment: Electrophoretic wax spray (e.g., DINITROL 4490 HD or equivalent)

- Application Coverage: Full undercarriage, wheel wells, frame rails, suspension components

- Thickness: 30–50 µm dry film

- Performance: Forms hydrophobic barrier; resists saltwater penetration for up to 8 weeks

Benefits:

- Reduces post-arrival reconditioning costs by up to 40%

- Extends resale value and service life

- Complies with U.S. DOT corrosion resistance guidelines for imported commercial vehicles

Note: Wax treatment must be applied 72 hours pre-loading to ensure full curing and adhesion.

3. Port Operations – Portland, Oregon

Primary Import Terminal:

- Port of Portland – Terminal 6 (Northwest Oversized Cargo Terminal)

- Equipped with heavy-lift cranes (up to 140 MT)

- RO-RO discharge ramp capacity: 120 MT

- On-dock rail and direct I-5 access for inland distribution

Customs Clearance:

- ISF (Importer Security Filing) required 24h prior to loading

- EPA and DOT compliance verification for vehicle emissions and safety standards

- Average clearance time: 1.5–3 business days

4. Recommended Solution by Use Case

| Customer Profile | Recommended Method | Rationale |

|---|---|---|

| High-volume fleet resellers | RO-RO + Wax Spray | Cost-efficient, rapid turnaround, suitable for driveable units |

| Specialized construction rigs | Flat Rack + Wax Spray | Maximum protection for high-value, irregularly shaped units |

| Non-operational salvage units | Bulk Cargo (if cost-driven) | Lower shipping cost; acceptable risk for low resale value units |

5. Conclusion

For optimal balance of cost, protection, and delivery speed in exporting used trucks from China to Portland, RO-RO shipping with industrial wax spray corrosion protection is the preferred solution for operational fleet vehicles. For high-value or sensitive equipment, Flat Rack containers offer superior security despite higher costs. Bulk Cargo remains a niche option for non-functional units where cost is the primary constraint.

All shipments should include pre-transit wax spraying to ensure structural integrity and compliance with North American durability expectations.

SEA LION International

Engineering Logistics for Global Heavy Equipment Deployment

Revision: 2026.Q2 Industrial Edition

Get a Quote for Used Trucks For Sale Portland Oregon

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]