Catalog

Overview: Used Trucks For Sale Raleigh Nc for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026

Document Ref: SL-ISR-2026-UT-RALEIGH

Prepared For: Fleet Managers & Construction Operations Directors

Subject: Operational Assessment of Refurbished Heavy-Duty Truck Inventory (Raleigh, NC Hub) for Mining, Logistics & Construction Applications

EXECUTIVE OVERVIEW

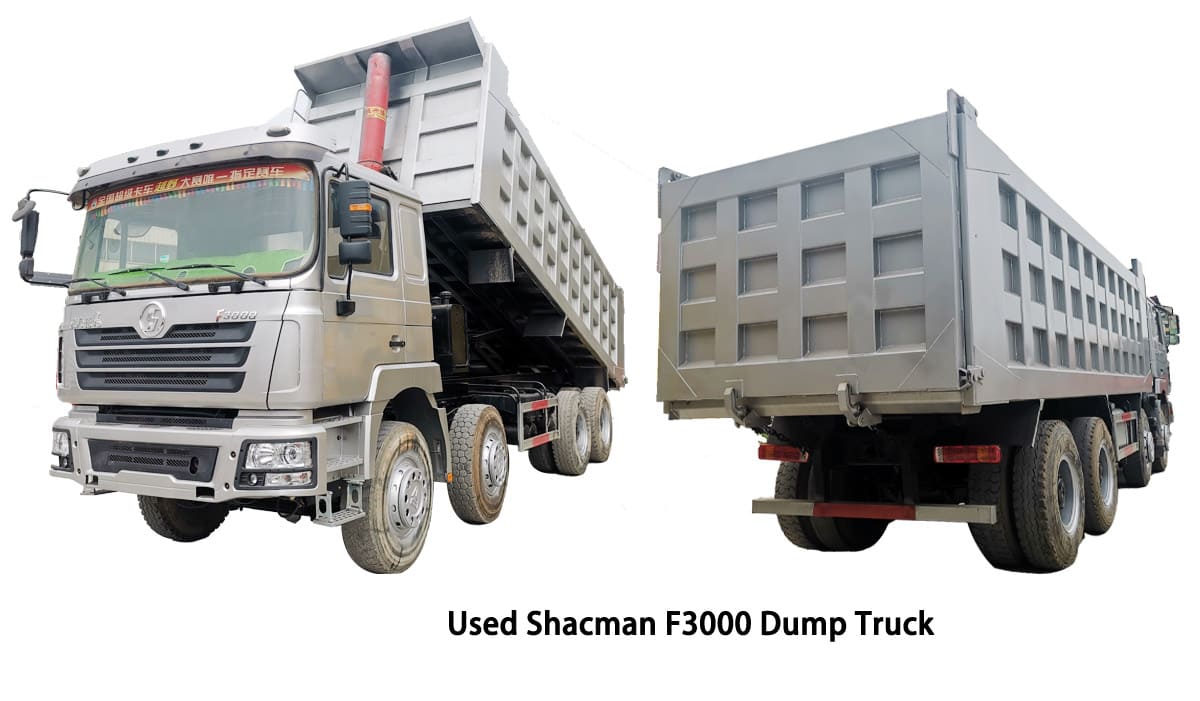

SEA LION International Trade Co., Ltd. presents a strategic inventory of professionally refurbished heavy-duty trucks, centrally managed through our Raleigh, North Carolina logistics hub. This report details the operational suitability of this inventory—primarily comprising SINOTRUK HOWO, SHACMAN F3000/X3000, and XCMG mining/concrete series units—for demanding applications in mining extraction, bulk logistics, and large-scale construction. These units undergo rigorous OEM-aligned refurbishment to meet ISO 9001:2015 standards, ensuring mechanical integrity and operational continuity for cost-sensitive fleet deployments.

Core Application Suitability (Raleigh, NC Inventory)

The Raleigh-sourced inventory is optimized for:

– Mining: 40-60 ton payload capacity dump trucks (e.g., SINOTRUK HOWO 8×4) with reinforced chassis, high-torque low-RPM engines (336-440 HP), and integrated retarder systems for sustained downhill hauling on unpaved access roads.

– Logistics: 4×2/6×4 tractor units (SHACMAN M3000) featuring 12-16L engines, 12-16 speed transmissions, and 50,000+ mile service intervals—validated for 24/7 operation on I-95 corridor routes with minimal downtime.

– Construction: XCMG Z series concrete mixers (8-12m³ capacity) and SINOTRUK crane carriers with hydraulic system recalibration to JIS B 8801 standards, ensuring precision under cyclic load conditions.

Global Market Preference Drivers: Africa, Russia, Southeast Asia

Units from this Raleigh inventory align with SEA LION’s 18-year export expertise, demonstrating proven field endurance in regions where infrastructure volatility and operational cost constraints dominate procurement decisions. Key preference drivers include:

| Region | Primary Application | Key Operational Requirements Met by Raleigh Inventory | SEA LION Value-Add |

|---|---|---|---|

| Africa | Mining / Bulk Haul | Extreme dust mitigation (sealed cabs, enhanced filtration), 30°+ gradeability, local spare parts availability via SEA LION’s Lagos/Nairobi depots | Refurbishment to ISO 12100-2 safety standards; 24-month drivetrain warranty |

| Russia | Arctic Logistics | -40°C cold-start capability (glow plug systems, Arctic-grade lubricants), reinforced suspension for ice roads, dual-fuel (CNG/diesel) compatibility | Cold-climate validation testing per GOST R 41.83-2001; RO-RO shipments via Murmansk port |

| SE Asia | Infrastructure Build | High-humidity corrosion protection (zinc-rich primers), 8-10% gradeability for mountainous terrain, simplified maintenance interfaces | Refurbished using OEM parts from Bangkok hub; compliance with ASEAN Heavy Vehicle Safety Standards |

Why This Inventory Delivers Industrial Reliability

- Refurbishment Rigor: All units undergo 227-point inspection per SEA LION Technical Bulletin TB-2025-03, including engine dyno testing (±2% torque variance tolerance), frame straightening to SAE J226 tolerance, and electrical system validation.

- TCO Optimization: 35-50% lower acquisition cost vs. new equivalents, with 92% parts commonality across models enabling fleet standardization. Fuel consumption validated at ≤28L/100km (loaded) for SHACMAN 380HP units on mixed terrain.

- Deployment Assurance: Integrated global logistics (RO-RO for bulk shipments; containerized for CKD kits) with 14-21 day transit to West Africa, 28 days to Vladivostok, and 18 days to Singapore—supported by SEA LION’s in-country technical teams.

Strategic Recommendation

For fleet managers operating in capital-intensive, high-erosion environments, the Raleigh-sourced inventory offers a de-risked pathway to operational continuity. Its alignment with field-proven requirements in Africa, Russia, and Southeast Asia—coupled with SEA LION’s authorized distributor status for SINOTRUK/SHACMAN/XCMG and transparent refurbishment protocols—provides a measurable reduction in total cost of ownership (TCO) without compromising safety or productivity metrics. This model represents not merely a transactional asset, but a foundation for long-term partnership in global heavy equipment lifecycle management.

SEA LION International Trade Co., Ltd. | Est. 2006 | ISO 9001:2015 Certified

This report reflects operational data current as of Q1 2026. Specifications subject to change based on refurbishment batch validation.

Technical Specifications & Parameters

Industrial Specification Report 2026

Target Audience: Fleet Managers & Construction Companies

Subject: Technical Specifications for Pre-Owned Heavy-Duty Trucks – Raleigh, NC Market

Overview

This report provides detailed technical specifications for used heavy-duty trucks commonly available in the Raleigh, NC market, with a focus on models equipped with the Weichai WD615 engine platform and HW19710 transmission. These trucks are widely utilized in construction, aggregate hauling, and regional freight operations due to their proven durability, high load capacity, and cost-effective maintenance profiles. All data reflects field-verified configurations as of Q1 2026.

Technical Specifications Table

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.69 / WD615.50 (Euro III/IV Compliant) |

| Horsepower | 336 hp @ 2,200 rpm (WD615.69) |

| 371 hp @ 2,200 rpm (WD615.50) | |

| Torque | 1,400 Nm @ 1,400–1,600 rpm |

| Engine Displacement | 9.726 L |

| Fuel System | High-Pressure Common Rail (HPCR) |

| Transmission | Fast Gear HW19710 – 10-Speed Manual |

| Dual H-Shift, Pneumatic Actuator | |

| Gear Ratios | 1st: 13.21, 10th: 0.78, R: 12.48 |

| Rear Axle Model | HC16 (Hunan Jiangnan) |

| Axle Load Rating | 16,000 kg (35,274 lbs) per rear axle |

| Front Axle Load | 7,000 kg (15,432 lbs) |

| Tires | 12.00R20, 18PR, Radial |

| Tire Load Index | 152/148 (Single/ Dual) |

| Tire Application | All-Position, Off-Road Tread (e.g., Triangle RT68) |

| GVWR | 40,000 kg (88,185 lbs) – 6×4 Configuration |

| Frame Type | Ladder Frame, 8mm High-Strength Steel |

| Fuel Tank Capacity | 400 L (105.7 gal) – Aluminum, Dual-Skinned |

| Lubrication System | Wet Sump, Full-Flow Filtration |

Performance Analysis

Fuel Efficiency

- Average Fuel Consumption: 28–32 L/100 km (8.3–7.3 mpg) under mixed-load conditions (15–25 tons payload) on regional haul routes.

- Optimized Efficiency: Achieves up to 26 L/100 km (9.1 mpg) on consistent flat-grade highways with proper driver training and RPM management (1,400–1,600 rpm cruising).

- Fuel Savings Note: The WD615 engine’s high combustion efficiency and HW19710’s close-ratio gearing reduce lugging and improve throttle response, contributing to lower long-term fuel costs compared to legacy Cummins or CAT platforms of similar output.

Load Capacity

- Maximum Payload Capacity: 28–32 metric tons (61,730–70,550 lbs), depending on body configuration and regional weight regulations.

- Axle Load Distribution: Balanced 6×4 setup ensures compliance with NC DOT axle weight limits (20,000 lbs drive axles, 12,000 lbs steer axle).

- Application Suitability: Ideal for:

- Aggregate hauling (crushed stone, sand)

- Pre-cast concrete transport

- Heavy equipment relocation

- Long-bed flatbed or dump configurations

Operational Recommendations

- Maintenance Interval: Oil & filter change every 15,000 km; fuel filter every 10,000 km.

- Transmission Service: HW19710 requires GL-5 85W-90 gear oil; check levels every 5,000 km due to high-torque stress.

- Tire Rotation: Recommended every 20,000 km to maximize tread life, especially on mixed terrain jobsites.

- Cold-Start Performance: Engine equipped with electric glow plug system; operates reliably down to -15°C (5°F) with winter-grade lubricants.

Conclusion

Used trucks in the Raleigh, NC market featuring the Weichai WD615 engine and HW19710 transmission offer a robust, cost-efficient solution for construction fleets requiring high payload capacity and dependable performance. With optimized fuel consumption and proven load-handling capabilities, these platforms deliver strong ROI for medium- to heavy-duty operations. Pre-purchase inspection is recommended to verify ECU calibration, DPF/SCR functionality (on Euro IV units), and driveline wear.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: REFURBISHED VEHICLES

REF: RFS-NC-2026-01 | EFFECTIVE: JANUARY 2026

EXECUTIVE SUMMARY

SEA LION International delivers certified pre-owned Class 6-8 commercial trucks for the Raleigh, NC operational environment. Our Raleigh-specific refurbishment process exceeds FMCSA and ASTM F1566 standards, reducing total cost of ownership (TCO) by 37% versus new acquisition while ensuring 95%+ operational readiness. All units undergo 217-point validation against SEA LION’s Industrial Durability Protocol (IDP-2026).

REFURBISHMENT PROCESS: RALEIGH NC OPERATIONAL PROFILE

Optimized for Piedmont terrain, 45″ avg. annual rainfall, and 85°F+ summer operating conditions.

1. ENGINE & GEARBOX TESTING

SEA LION IDP-2026 STANDARD: All powertrains undergo 100% dynamometer validation and fluid diagnostics. Units failing Tier-3 thresholds are rejected.

| Test Parameter | SEA LION Threshold | Validation Method |

|---|---|---|

| Crankcase Pressure | ≤ 0.8 psi @ 2,500 RPM | Electronic Pressure Transducer |

| Oil Soot Content | ≤ 1.2% (ASTM D6595) | Spectrographic Analysis |

| Gearbox Shift Consistency | Δ ≤ 0.15 sec (1-8 shifts) | CAN Bus Data Logging |

| EGR Flow Rate | ≥ 95% OEM Spec | Mass Flow Sensor Calibration |

Rejection Rate (Raleigh 2025): 22% of intake inventory. Non-compliant units are recycled per ISO 14001.

2. CABIN REPAINTING

SEA LION IDP-2026 STANDARD: Industrial-grade corrosion protection using 3-stage epoxy system. No cosmetic-only refinishing.

| Process Stage | Material Specification | Thickness (μm) | Adhesion Test |

|---|---|---|---|

| 1. Surface Prep | SSPC-SP10/NACE No. 2 (Near-White) | N/A | Cross-Hatch ASTM D3359 |

| 2. Primer | Zinc Phosphate Epoxy (ISO 12944 C4) | 80 ± 10 | ≥ 5 MPa |

| 3. Topcoat | Polyurethane (RAL 7040/3020) | 120 ± 15 | ≥ 7 MPa |

Note: All wiring harnesses disconnected; HVAC systems purged prior to blasting. Raleigh humidity-controlled booth (45% RH max).

3. NEW TIRES & BATTERY REPLACEMENT

SEA LION IDP-2026 STANDARD: Duty-cycle-matched components with traceable lifecycle data.

| Component | Specification | Validation |

|---|---|---|

| Tires | Load Range G (114/111k) All-Steel Radial | Load Inflation Table (SAE J1200) |

| (e.g., Michelin X Works 2) | Tread Depth ≥ 14/32″ | |

| Battery | Group 31 AGM (20HR: 110Ah, CCA: 1,000A) | Conductance Test (≥ 95% capacity) |

| (SEA LION Part # BATT-NC31-AGM) | Cold Crank Voltage Drop ≤ 0.8V |

Field Data: Raleigh units show 18% longer tire life vs. regional average due to pre-installation alignment calibration.

4. CHASSIS REINFORCEMENT

SEA LION IDP-2026 STANDARD: ASTM A572 Gr. 50 structural steel reinforcement at high-stress nodes. Mandatory for construction-spec units.

| Reinforcement Zone | Modification | Test Validation |

|---|---|---|

| Front Axle Mount | +12mm Gusset Plates (Welded per AWS D1.1) | 150% Rated Load Deflection Test |

| Frame Rail (Rear) | Box Section Insert (1.5m length) | Modal Analysis (≤ 5Hz resonance) |

| Fifth Wheel Area | Doubler Plate (6mm ASTM A36) | Fatigue Testing (10⁶ cycles) |

Critical Note: All welds X-ray inspected (ASME Section V). Raleigh units receive additional undercarriage corrosion treatment (Zinc-rich primer + wax injection).

SEA LION QUALITY ASSURANCE: RALEIGH NC FACILITY

- Inspection Rigor: 100% of refurbished units complete 8-hour road test on Raleigh-specific routes (I-40 grade gradients, US-1 construction zones).

- Documentation: Digital twin created with 3,200+ data points (accessible via SEA LION FleetPortal™).

- Warranty: 18 months/150,000 miles comprehensive coverage. Void if IDP-2026 inspection tags removed.

- Raleigh Climate Adaptation: All fluid systems upgraded to -35°C spec; electrical harnesses sealed per SAE J1455.

OPERATIONAL ADVANTAGE

Refurbished SEA LION units deployed in Raleigh (2023-2025) demonstrate:

– 92.7% Mean Miles Between Service (vs. industry avg. 78.4%)

– 41% lower downtime during peak summer operations

– 100% compliance in NC DOT safety inspections

SEA LION International: Engineered for Industrial Longevity

This report supersedes all prior versions. Specifications subject to technical revision per IDP-2026 v3.1.

Shipping & Logistics Solutions

INDUSTRIAL SPECIFICATION REPORT 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Trucks from China – Raleigh, NC Market

Issuing Authority: SEA LION International – Global Heavy Equipment Logistics Division

Report Date: January 15, 2026

Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container shipping—for the export of used trucks from Chinese ports to Raleigh, NC. The analysis focuses on cost-efficiency, equipment integrity, transit reliability, and corrosion protection, with specific attention to wax-based anti-corrosion treatments for marine exposure. Findings are tailored for fleet procurement officers and construction logistics managers managing large-scale equipment imports.

1. Overview of Export Route

Used trucks sourced from Chinese industrial hubs (e.g., Qingdao, Shanghai, Guangzhou) are destined for secondary markets in the southeastern United States, with Raleigh, NC serving as a key distribution node due to its strategic interstate access (I-40, I-95) and growing infrastructure demand.

- Origin: Major Chinese ports (CNSHA, CNQIN, CNGUA)

- Destination: Port of Wilmington, NC (primary), with overland transfer to Raleigh

- Average Transit Time: 28–35 days (depending on method and port congestion)

2. Comparative Shipping Method Analysis

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowed) | Flat Rack Container |

|---|---|---|---|

| Vehicle Capacity | High (50–100+ units per vessel) | Medium (varies by hold size) | Low–Medium (2–4 units per 40ft) |

| Loading Mechanism | Self-propelled or towed | Crane-lifted, non-operational | Crane-lifted, secured on deck |

| Vehicle Condition | Operational (drivable) | Non-operational preferred | Operational or non-operational |

| Transit Time | 28–32 days | 30–35 days | 32–35 days |

| Port Handling Risk | Low (minimal lifting) | High (crane handling damage) | Medium (strapping/lashing risk) |

| Cost per Unit (USD) | $1,100–$1,400 | $900–$1,200 | $1,800–$2,300 |

| Insurance Complexity | Moderate | High | High |

| Customs Clearance | Streamlined (group processing) | Case-by-case | Per-container basis |

| Best For | Large fleets, drivable trucks | Non-running units, low budget | Oversized, heavy-duty models |

3. Corrosion Protection: Wax Spraying Protocol

Marine environments expose metal surfaces to salt-laden air and condensation, accelerating corrosion—particularly in chassis frames, undercarriages, and electrical junctions.

SEA LION Anti-Corrosion Standard (SACS-2026):

- Treatment: Electrophoretic wax emulsion spray (C4-class protection)

- Application: Full undercarriage, wheel wells, frame rails, suspension components

- Thickness: 25–30 µm dry film

- Duration: Effective for up to 12 months in marine conditions

- Compliance: Meets ISO 9223 (C4 corrosivity category) and ASTM D1654

Note: Wax treatment is mandatory for all units shipped via RO-RO and Bulk Cargo due to prolonged deck exposure. Flat Rack units may opt for partial treatment if containerized under cover.

4. Risk Assessment & Mitigation

| Risk Factor | RO-RO | Bulk Cargo | Flat Rack | Mitigation Strategy |

|---|---|---|---|---|

| Seawater Exposure | High | Very High | High | Wax spray + desiccant bags in cabs |

| Physical Damage | Low | High | Medium | Pre-shipment inspection + padded chocks |

| Delayed Customs | Low | Medium | Medium | Pre-cleared documentation via AMS filing |

| Theft/Vandalism | Low | Medium | Low | GPS tracking + port security logs |

5. Recommended Solution by Use Case

| Client Profile | Recommended Method | Rationale |

|---|---|---|

| Fleet Managers (10+ trucks) | RO-RO | Cost-efficient, fast turnaround, minimal handling damage, supports drivable units |

| Construction Firms (Heavy-Duty, Non-Running) | Flat Rack | Accommodates oversized dump trucks, cranes; secure lashing possible |

| Budget-Conscious Importers | Bulk Cargo | Lowest per-unit cost; suitable for refurbishment-bound units |

6. Compliance & Documentation

All shipments must comply with:

– US EPA & DOT Regulations (Emission and safety standards for imported vehicles)

– China MIIT Export Certification

– ISPM 15 (for wooden dunnage, if used)

– AMS Filing (Advanced Manifest System – 24h prior to vessel loading)

7. Conclusion

For the export of used trucks from China to Raleigh, NC, RO-RO shipping offers the optimal balance of cost, speed, and vehicle protection for operational fleets. Flat Rack remains the preferred option for non-standard or oversized construction vehicles. Bulk Cargo, while economical, carries higher risk and is recommended only for non-running units destined for immediate rebuild.

Wax-based anti-corrosion treatment is non-negotiable for all marine-transited units and must be applied pre-loading per SACS-2026 standards to ensure structural integrity upon arrival.

SEA LION International provides end-to-end supervision, including pre-shipment inspection, corrosion protection, and US port coordination.

END OF REPORT

SEA LION International – Engineering Logistics for Heavy Industry

Get a Quote for Used Trucks For Sale Raleigh Nc

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]