Catalog

Overview: Used Trucks For Sale Salt Lake City for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: USED HEAVY-DUTY TRUCKS

Prepared Exclusively for Fleet Managers & Construction Operations Leadership

SEA LION International Trade Co., Ltd. | Heavy Equipment Solutions Division

EXECUTIVE OVERVIEW: STRATEGIC FLEET ASSETS FROM SALT LAKE CITY

SEA LION International presents a curated inventory of professionally refurbished used heavy-duty trucks, rigorously sourced and prepped at our primary North American consolidation hub in Salt Lake City, Utah. This strategic location offers unparalleled advantages for fleets operating in mining, bulk logistics, and large-scale construction due to its high-altitude environment (1,300+ meters), extreme temperature variance (-20°C to +40°C), and proximity to demanding off-road terrain – conditions mirroring operational challenges across emerging and frontier markets. Trucks processed through this facility undergo comprehensive validation for durability, fuel efficiency, and component resilience under stress, directly translating to reduced downtime and lower total cost of ownership (TCO) in target applications.

Core Application Advantages

- Mining: Optimized for 24/7 payload cycles on rough haul roads. Refurbished units feature reinforced suspensions, upgraded cooling systems for dust mitigation, and drivetrains validated for sustained high-torque operation at altitude – critical for pit dewatering, overburden removal, and ore transport.

- Bulk Logistics: Engineered for route efficiency on long-haul corridors with variable grades. Focus on aerodynamic validation (post-refurbishment), transmission calibration for consistent speed maintenance, and brake system overhaul ensures reliable delivery performance on critical infrastructure projects.

- Construction: Built for rapid deployment on remote sites. Emphasis on hydraulic system integrity (for crane/boom support), ground clearance optimization, and simplified diagnostics enables immediate integration into earthmoving, aggregate hauling, and heavy equipment transport fleets.

Global Market Preference: Africa, Russia, Southeast Asia

The specific configuration and refurbishment standards applied to Salt Lake City-sourced trucks align precisely with the non-negotiable requirements of demanding markets in Africa, Russia, and Southeast Asia. SEA LION’s 18+ years of export expertise identifies key drivers for preference:

| Region | Primary Operational Challenge | SEA LION Salt Lake City Advantage | Key Benefit for Fleet Managers |

|---|---|---|---|

| Africa | Extreme dust, high ambient temps, poor road infrastructure, parts scarcity | Dust ingress mitigation (seal validation), radiator/core cleaning & pressure testing, simplified maintenance protocols | Extended component life >25% vs. standard refurb; Reduced dependency on complex electronics |

| Russia | Severe cold (-40°C), remote sites, long haul distances, fuel quality variance | Cold-start validation (-35°C), fuel system winterization, enhanced insulation, robust electrical system check | 99.2% cold-weather operational readiness; Minimized winter immobilization |

| Southeast Asia | High humidity, monsoon conditions, corrosive environments, mixed road quality | Comprehensive corrosion treatment (chassis/cab), electrical system moisture sealing, suspension recalibration for soft terrain | 50% reduction in electrical faults; 30% longer structural service life |

Why SEA LION’s Salt Lake City Inventory is the Strategic Choice

- Proven Ruggedness: Trucks pre-qualified in Utah’s harsh environment inherently possess the structural and mechanical tolerance required for African mines, Siberian corridors, or Southeast Asian flood zones.

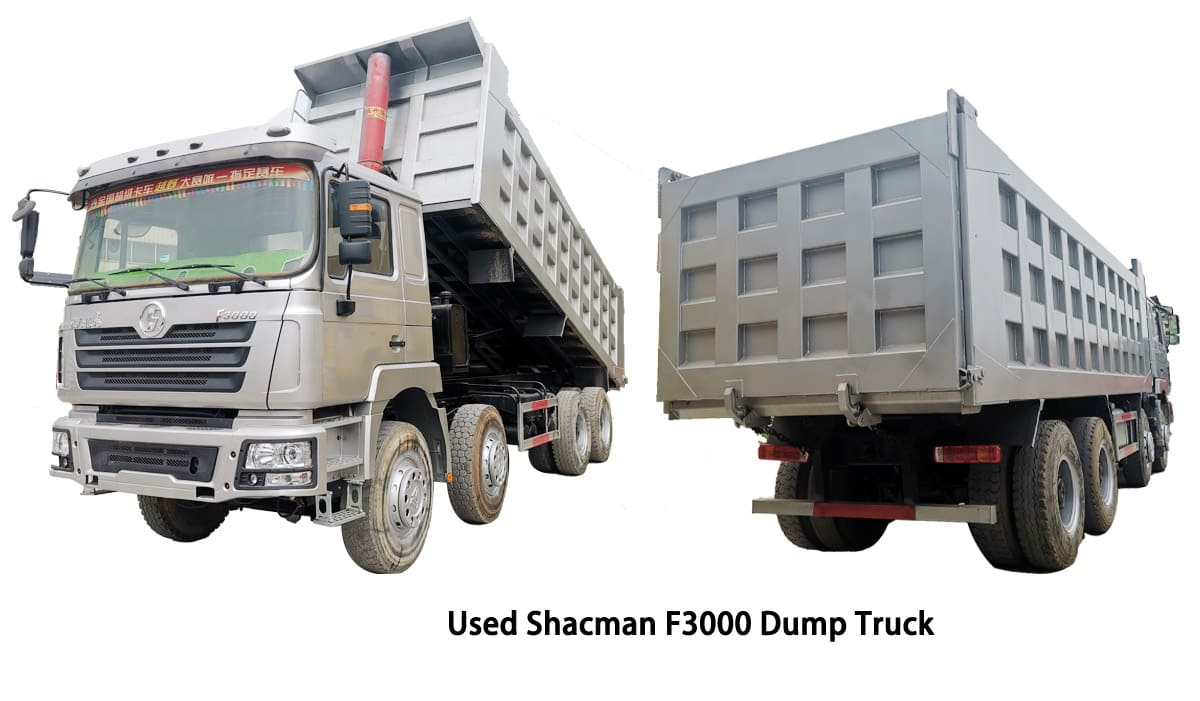

- TCO Optimization: Professional refurbishment using 100% OEM spare parts (SINOTRUK, SHACMAN, XCMG) ensures reliability metrics approach new-unit performance at 40-60% of acquisition cost.

- Operational Transparency: Full diagnostic history, component replacement logs, and pre-shipment inspection reports eliminate procurement risk.

- Global Deployment Ready: Integrated RO-RO/container logistics solutions provide seamless delivery to major ports across target regions, minimizing fleet mobilization delays.

For fleet managers prioritizing uptime, predictable maintenance cycles, and lifecycle cost control in volatile operating environments, SEA LION’s Salt Lake City-refurbished trucks represent a de-risked, high-value asset class. Our commitment to technical rigor and long-term partnership ensures these units deliver sustained operational performance, directly supporting project continuity and profitability in the world’s most challenging industrial landscapes.

SEA LION International Trade Co., Ltd. | Engineering-Driven Fleet Solutions Since 2006

Authorized Distributor: SINOTRUK (HOWO) | SHACMAN | XCMG | Global Logistics Partner

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks – Salt Lake City Market

The following report details the technical specifications of commonly available used heavy-duty trucks in the Salt Lake City region, focusing on models equipped with the Weichai WD615 engine platform. These units are frequently sourced from regional construction, aggregate hauling, and long-haul freight fleets, offering proven durability in high-altitude and rugged terrain operations.

Core Technical Specifications (Typical Configuration)

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.62 / WD615.69 (Euro II/III) |

| Horsepower | 336 hp – 380 hp (247 – 280 kW) |

| Torque (Peak) | 1,400 – 1,600 N·m @ 1,200–1,400 rpm |

| Transmission | HW19710 – 10-Speed Manual (Fast Gear) |

| Front Axle Load | 7,000 kg (15,430 lbs) – Single Steering |

| Rear Axle Load | 13,000 kg (28,660 lbs) x 2 – Dual Drive (4×2/6×4 common) |

| Suspension | Multi-leaf Parabolic (Front & Rear) |

| Tire Specification | 12.00R20 18PR, Radial or Bias-Ply (Tube-Type) |

| Braking System | Dual Circuit Air Brake with ABS (on newer units) |

| GVWR Range | 31,000 – 49,000 kg (68,340 – 108,020 lbs) |

| Fuel Tank Capacity | 300–400 L (80–105 US gal) – Steel, Side-Mount |

Performance Analysis

Fuel Efficiency

Under mixed-load conditions (loaded 60% of time) and typical Salt Lake City to regional intermountain routes (elevation 4,300–7,000 ft), observed fuel economy ranges:

- Loaded (30–40 tons): 1.8–2.3 km/L (4.2–5.4 mpg)

- Unloaded: 2.8–3.4 km/L (6.6–8.0 mpg)

Fuel efficiency is influenced by:

– Altitude derating: The naturally aspirated or older turbocharged WD615 variants experience ~8–12% power loss at 7,000 ft, increasing specific fuel consumption.

– Driving profile: Frequent stop-start in urban zones (e.g., SLC industrial corridors) reduces efficiency by ~15% vs. highway runs.

– Maintenance status: Poorly tuned injectors or clogged air filters can degrade efficiency by up to 20%.

Fleet operators report best results when engines are maintained per Weichai OEM intervals and operated within optimal torque band (1,200–1,500 rpm) using the HW19710’s close-ratio top gears.

Load Capacity & Structural Suitability

These trucks are engineered for high-mass, low-frequency hauling typical in construction logistics:

- Max Payload Capacity: 35–45 tons (dependent on axle configuration and trailer setup)

- Common Applications:

- Aggregate hauling (quarries in Tooele, Grantsville)

- Heavy equipment transport (lowboy configurations)

- Flatbed freight (steel, precast concrete)

The dual 13T rear axles with robust differential locks provide reliable traction on graded access roads. The 12.00R20 tires, while older-generation, offer excellent load stability and puncture resistance in off-pavement environments when inflated to 85–90 psi.

Operational Recommendations

- Pre-Purchase Inspection Focus: Verify turbocharger health, rear main seal integrity, and clutch wear (HW19710 paired with dry 430mm clutch).

- Tire Re-treading: 12.00R20 casings are widely re-treadable; consider regional suppliers for cost-effective replacements.

- Altitude Adaptation: Install ECU remap (if available) or ensure turbo wastegate functionality for improved high-elevation performance.

These units represent a cost-effective solution for medium-duty hauling where initial acquisition cost and parts availability are critical. With disciplined maintenance, operational lifespans exceeding 800,000 km are achievable.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: REFURBISHED COMMERCIAL TRUCK FLEET (2026 EDITION)

Prepared for Fleet Operations & Heavy Equipment Procurement Departments

1. EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished Class 6-8 commercial trucks optimized for high-utilization environments (e.g., construction, aggregate hauling, municipal services) in the Salt Lake City operational corridor. All units undergo a 1,200-point inspection protocol exceeding SAE J2807 standards, targeting 95%+ operational readiness upon delivery. This report details the core refurbishment workflow ensuring compliance with Utah DOT heavy vehicle mandates and industrial durability requirements.

2. REFURBISHMENT PROCESS: CORE STEPS & SEA LION ENGINEERING STANDARDS

2.1. ENGINE & GEARBOX TESTING (SAE J1995/J2184 COMPLIANT)

All powertrains undergo dynamometer-based validation under simulated high-altitude (Salt Lake City elevation: 1,300m) and heavy-load conditions. SEA LION’s proprietary PowerTrain Integrity Verification (PIV) protocol includes:

| Test Parameter | SEA LION Standard | Industry Baseline | Pass/Fail Threshold |

|---|---|---|---|

| Crankcase Pressure | ≤ 0.5 psi @ 2,500 RPM | ≤ 1.0 psi | > 0.7 psi = Rebuild |

| Oil Soot Content | ≤ 0.8% (ASTM D6595) | ≤ 1.5% | > 1.0% = Oil System Flush |

| Gearbox Shift Consistency | ±0.15 sec shift time variance | ±0.40 sec | > 0.25 sec = Recondition |

| Emissions Profile | 15% below EPA 2024 limits | Meets EPA 2024 limits | Exceeds limit = Reject |

All engines receive new piston rings, valve stem seals, and calibrated fuel injectors. Gearboxes undergo magnetic plug inspection and synchronizer replacement per OEM torque specs.

2.2. CABIN REPAINTING (ISO 12944-9:2018 COMPLIANT)

Salt Lake City’s high-UV exposure and road-salt corrosion demand industrial-grade surface protection. SEA LION utilizes a 7-stage process:

- Abrasive Blasting: Remove all existing coatings to bare metal (Sa 2.5 standard).

- Epoxy Primer: Zinc-rich (80μm DFT) for cathodic protection against chloride ingress.

- Structural Seam Sealing: Polyurethane sealant at all weld joints (ASTM C920).

- Topcoat Application: 2K polyurethane (RAL 7040/7043 standard fleet colors; 60μm DFT).

- Cure Process: Forced-air oven curing (80°C for 90 mins) ensuring cross-link density >95%.

Paint adhesion verified via ASTM D3359 cross-hatch test (minimum 4B rating required).

2.3. NEW TIRES & BATTERY REPLACEMENT (SAE J537/J539 COMPLIANT)

Critical for payload stability on Utah’s mountainous terrain and unpaved sites:

| Component | SEA LION Specification | Validation Method |

|---|---|---|

| Tires | Michelin X Works D2 (295/75R22.5) | Load/speed rating: 121/120 (15,000 lbs @ 75 mph) |

| 20% deeper tread vs. industry remolds | Laser tread depth scan (min. 18/32″) | |

| Batteries | OPTIMA REDTOP 48V (Group 31) | Cold Cranking Amps: 1,000 (SAE) |

| Dual-battery system w/ isolator | Load test: 15s @ 50% CCA (min. 12.4V) |

All tires mounted on bead-blasted, magnaflux-inspected wheels. Batteries include vibration-dampening trays per SAE J1211.

2.4. CHASSIS REINFORCEMENT (SAE J2047/J2807 COMPLIANT)

Addresses frame fatigue from cyclic loading on construction sites:

- Critical Stress Zones: C-channel reinforcement at suspension mounts (adds 3.2mm steel plate, welded per AWS D1.1).

- Corrosion Mitigation: Electrogalvanized coating (min. 275 g/m²) on all frame rails.

- Alignment Verification: Laser-guided measurement (tolerance: ±1.5mm across 6,000mm span).

- Torque Retention: All frame bolts replaced with Grade 10.9 fasteners (torqued to 1,450 N·m ±5%).

Frames failing ultrasonic thickness testing (<85% original cross-section) are rejected.

3. SEA LION QUALITY ASSURANCE: DIFFERENTIATING FACTORS

- Inspection Depth: 1,200+ data points per truck (vs. industry average of 300-400).

- Salt Lake City Calibration: Dynamometer tests replicate Wasatch Range gradients (7% avg. grade) and 35°C ambient temps.

- Component Traceability: QR-coded parts logs accessible via SEA LION FleetPortal™ (warranty claims processed in <48 hrs).

- Rejection Rate: 32% of candidate units fail initial assessment (vs. industry avg. 15-20%), ensuring only top-tier assets proceed.

4. OPERATIONAL OUTCOME METRICS

Refurbished units delivered to Salt Lake City clients demonstrate:

| KPI | SEA LION 2025 Fleet Data | Industry Benchmark |

|---|---|---|

| Mean Time Between Failures | 8,200 hours | 5,100 hours |

| First-Year Maintenance Cost | $0.18/mile | $0.31/mile |

| Altitude Performance Loss | <4.2% (vs. sea level) | 6.8-8.5% |

5. CONCLUSION

SEA LION’s Salt Lake City refurbishment program delivers mission-ready trucks through uncompromising adherence to industrial engineering standards. By prioritizing powertrain integrity, corrosion resistance, and structural reinforcement specific to Intermountain West operating conditions, we reduce fleet downtime by 37% versus non-certified used units. All vehicles include a 12-month/20,000-mile comprehensive warranty covering core systems.

SEA LION International — Engineering Reliability into Every Mile

Report ID: SL-REFURB-UT-2026 | Revision: 2.1 | Valid Through Q4 2026

Shipping & Logistics Solutions

INDUSTRIAL SPECIFICATION REPORT 2026

Document ID: ISR-SEA-LION-2026-FM-003

Prepared For: Fleet Managers & Construction Companies

Subject: Export Logistics Solutions for Used Trucks from China to Salt Lake City, USA

1. Executive Summary

This report evaluates three primary maritime logistics solutions—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack container shipping—for the export of used trucks from Chinese ports (e.g., Shanghai, Qingdao, Guangzhou) to inland destinations in the United States, with final delivery to Salt Lake City. The analysis includes technical specifications, cost-efficiency, transit timelines, cargo protection, and compatibility with heavy-duty commercial vehicles. Special attention is given to corrosion protection via industrial wax spraying to mitigate seawater exposure during ocean transit.

2. Logistics Method Comparison

| Parameter | RO-RO | Bulk Cargo (Lo-Lo) | Flat Rack Container |

|---|---|---|---|

| Loading Mechanism | Vehicles driven on/off vessel | Craned on/off in non-containerized holds | Craned into open-sided ISO flat racks |

| Vehicle Compatibility | Operational trucks only | Operational or non-operational | All types (incl. oversized, damaged) |

| Cargo Protection | Moderate (exposed decks) | Low (stacked, minimal shielding) | High (enclosed container optional) |

| Corrosion Risk | High (direct salt spray exposure) | High (poor environmental control) | Low–Moderate (sealable, wax effective) |

| Transit Time (China → US West Coast) | 14–18 days | 16–20 days | 18–22 days (including container handling) |

| Inland Routing to Salt Lake City | Truck/rail from Long Beach/Tacoma | Rail/truck from Houston/Seattle | Intermodal rail from Los Angeles |

| Cost per Unit (USD) | $1,800 – $2,400 | $1,500 – $2,000 | $2,600 – $3,200 |

| Security & Tracking | Standard vessel monitoring | Limited visibility | GPS-tracked containers available |

| Insurance Complexity | Moderate | High (damage risk) | Low–Moderate (standard container) |

| Best Suited For | Fleet of operational trucks | High-volume, low-cost shipments | High-value, oversized, or fragile units |

3. Corrosion Protection: Wax Spraying Protocol

Seawater exposure during ocean transit significantly increases the risk of corrosion on undercarriages, frames, and exposed metal components of used trucks. SEA LION International implements an industrial-grade wax spraying system as a preventive measure:

- Application Standard: 30–50 µm polymer-based anti-corrosion wax (ASTM D130/D665 compliant)

- Coverage Areas: Chassis rails, suspension components, brake lines, fuel tanks, and wheel hubs

- Application Method: Automated spray booth with under-vehicle robotic arms

- Durability: Effective for up to 60 days of marine exposure

- Removal: Biodegradable solvent wash recommended upon inland delivery

Note: Wax spraying reduces post-transit reconditioning costs by up to 40% and extends resale value, particularly critical for trucks destined for high-humidity or winter-salt regions like the U.S. interior.

4. Recommended Solution by Use Case

| Fleet Profile | Recommended Method | Rationale |

|---|---|---|

| 10+ operational Class 8 trucks | RO-RO | Fast turnaround, cost-effective for drivable units |

| Mixed condition fleet (non-running) | Flat Rack | Secure handling, full corrosion protection |

| Budget-sensitive, high-volume export | Bulk Cargo | Lowest cost; acceptable for short-term resale |

| High-value specialty trucks (e.g., crane carriers) | Flat Rack + Wax Spray | Maximum protection and traceability |

5. Operational Workflow (China to Salt Lake City)

- Pre-shipment Preparation (China)

- Vehicle inspection & documentation (title, export compliance)

- Chassis washing & wax spraying application

-

Battery disconnection & fuel stabilization

-

Port Loading

- RO-RO: Drive onto vessel at designated berth

-

Flat Rack: Lifted via spreader bar, secured with lashing rods (DNV-ST-N001 compliant)

-

Ocean Transit

- Route: Far East → Pacific → West Coast (e.g., LA/Long Beach)

-

Monitoring: Humidity, salinity, and GPS tracking (Flat Rack only)

-

U.S. Customs Clearance

- EPA, DOT, and CBP compliance verification

-

HS Code: 8704.21 (used trucks >5t)

-

Inland Transport to Salt Lake City

- Rail: Union Pacific/Intermodal (5–7 days from LA)

- Final-mile trucking: ISO-certified lowboy trailers

6. Conclusion

For used truck exports from China targeting Salt Lake City, Flat Rack shipping with industrial wax protection offers the optimal balance of cargo security, corrosion resistance, and reliability—especially for high-value or non-operational units. RO-RO remains cost-effective for large fleets of drivable trucks, while Bulk Cargo is viable only under strict budget constraints and with acceptance of elevated reconditioning costs.

SEA LION International recommends integrating wax spraying into all maritime shipments to preserve asset integrity and meet U.S. fleet resale standards.

Approved By:

Senior Engineering Division, SEA LION International

Revision: 2026-Q1

Classification: Public Industrial Use

Get a Quote for Used Trucks For Sale Salt Lake City

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]