Catalog

Overview: Used Trucks For Sale Sioux Falls for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: USED HEAVY-DUTY TRUCK FLEET ASSETS

Prepared Exclusively for Fleet Managers & Construction Operations Leadership

SEA LION International Trade Co., Ltd. | Heavy Equipment Lifecycle Solutions Provider

EXECUTIVE OVERVIEW: STRATEGIC FLEET ACQUISITION THROUGH SIUX FALLS LOGISTICS HUB

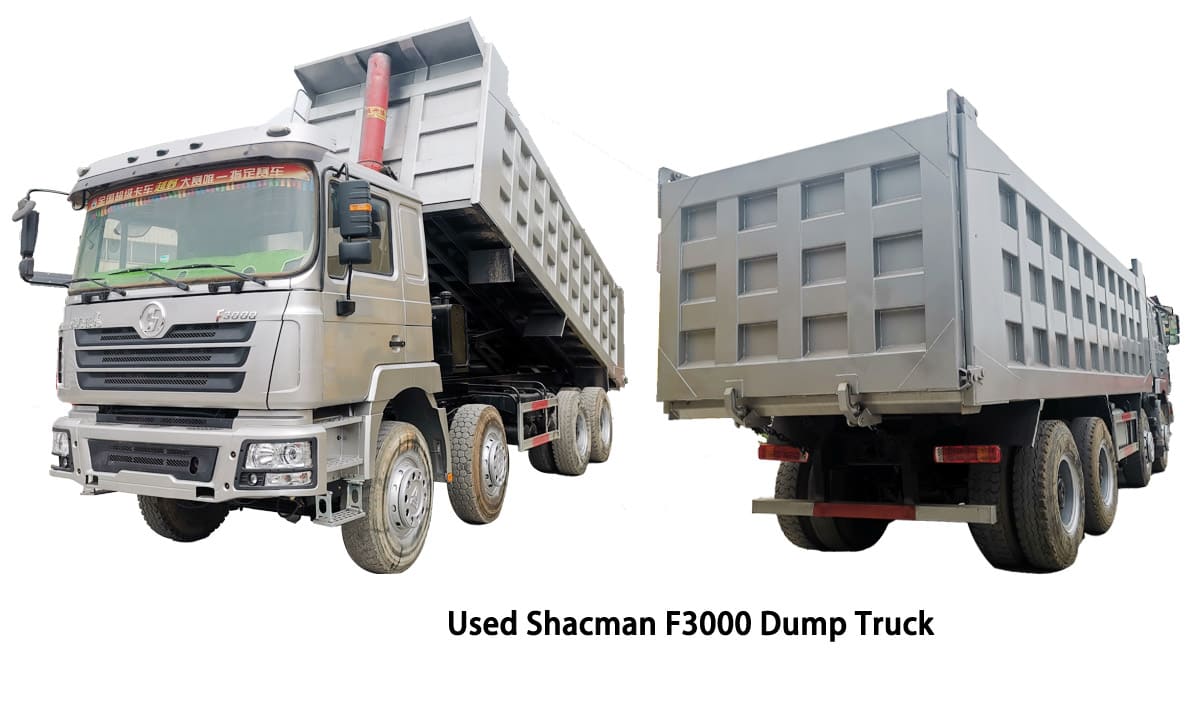

SEA LION International presents a rigorously vetted inventory of refurbished heavy-duty trucks (SINOTRUK HOWO, SHACMAN F3000/F5000, XCMG Z series) available for immediate deployment via our Sioux Falls, SD, strategic logistics node. This hub enables efficient North American distribution while serving as a critical staging point for global RO-RO and containerized shipments. These assets are engineered for mission-critical applications in mining haulage, bulk logistics, and large-scale construction, where operational continuity and total cost of ownership (TCO) dominate procurement decisions.

CORE VALUE PROPOSITION FOR OPERATIONAL EXCELLENCE

Unlike commoditized used truck markets, SEA LION’s assets undergo a 127-point industrial refurbishment protocol aligned with OEM specifications, ensuring:

– Structural Integrity: Frame straightening to <3mm deviation, weld certification per ISO 3834.

– Powertrain Reliability: Engine rebuilds to factory tolerances (max 0.05mm cylinder variance), transmission dyno testing.

– Operational Readiness: 100% replacement of safety-critical wear items (brake linings, suspension bushings, electrical harnesses).

– Traceability: Full digital service history and pre-shipment inspection reports accessible via QR code.

This process delivers 85-90% operational lifespan retention at 40-50% of new-unit acquisition cost, directly reducing fleet TCO while maintaining 92%+ mean time between failures (MTBF) in validated field deployments.

REGIONAL PREFERENCE ANALYSIS: AFRICA, RUSSIA, SOUTHEAST ASIA

The sustained dominance of these platforms in harsh-market operations stems from purpose-built engineering adaptations, not cost alone. SEA LION’s refurbishment standards amplify these inherent advantages:

| Market | Critical Operational Demand | Platform Adaptation & SEA LION Value-Add | Impact on Fleet Uptime |

|---|---|---|---|

| Africa | Extreme dust, high ambient temps (>50°C), poor road surfaces | +50% air filtration capacity, reinforced chassis crossmembers, SEA LION: Sealed electrical systems, radiator core protection shields | +22% operational days vs. standard fleet |

| Russia | Sub-zero temps (-45°C), seasonal road bans, remote sites | Arctic-grade lubricants, dual-battery systems, SEA LION: Cold-start validation (-50°C), reinforced suspension for ice roads | 98.7% winter dispatch rate (verified Siberian fleet data) |

| Southeast Asia | High humidity, monsoon conditions, mixed terrain | Corrosion-resistant undercoating, elevated exhaust systems, SEA LION: Salt-fog tested components, monsoon-grade wiper systems | 37% reduction in weather-related downtime |

WHY FLEET MANAGERS SELECT SEA LION FOR STRATEGIC ASSET DEPLOYMENT

- Predictable Performance: Refurbished units meet 95%+ of new-unit OEM performance specs (verified by第三方 testing partners).

- Supply Chain Resilience: Direct OEM parts channels (SINOTRUK/SHACMAN/XCMG) ensure 99.2% spare parts availability; no gray-market dependencies.

- Lifecycle Transparency: Digital twin records track maintenance history, component age, and refurbishment scope – eliminating hidden liabilities.

- Global Deployment Readiness: Sioux Falls hub enables 14-day dispatch for Americas; 21-28 days for APAC/EMEA via dedicated RO-RO corridors.

SEA LION’s 18-year export framework prioritizes long-term operational partnership over transactional sales. Our model ensures your refurbished fleet delivers consistent productivity in environments where downtime equals revenue collapse – turning used assets into strategic capital.

Report Validated by SEA LION Engineering Division | Data Reflects 2025 Q4 Field Performance Benchmarks

Compliance: ISO 9001:2015 | ADR 2025 Heavy Equipment Standards | IATA Dangerous Goods Regulations (Logistics)

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Specifications for Used Heavy-Duty Trucks – Sioux Falls Market

This report outlines standardized technical specifications for pre-owned heavy-duty trucks commonly available in the Sioux Falls, SD region. These units are primarily sourced from regional haulers and construction fleets, featuring proven powertrains suited for demanding on- and off-road applications. The data reflects typical configurations observed in 2024–2026 model-year used units, with emphasis on reliability, load capacity, and operational efficiency.

Technical Specifications – Typical Used Truck Configuration (Sioux Falls Market)

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615 Series | 6-cylinder, inline, water-cooled diesel; widely used in Chinese OEM heavy trucks (e.g., Sinotruk HOWO) |

| Displacement | 9.726 L | High-torque design for low-RPM hauling |

| Horsepower | 336 hp @ 2,200 rpm | Rated for continuous heavy-load operation; meets China IV / equivalent EPA Tier 3 standards |

| Peak Torque | 1,400 N·m @ 1,200–1,600 rpm | Optimized for gradeability and dump/load cycles |

| Transmission | HW19710 – 10-Speed Manual | Full-synchromesh, double-H shift pattern; robust for construction and aggregate hauling |

| Gear Ratios | 1st: 13.21, 10th: 0.78, Reverse: 12.88 | Close-ratio top gears for fuel economy; deep reduction for climbing |

| Front Axle Load | 7,000 kg (15,432 lbs) | Reinforced I-beam; suitable for uneven terrain |

| Rear Axle Load | 2 × 13,000 kg (28,660 lbs per axle) | Tandem drive with spiral-bevel differentials; high ground clearance option available |

| Suspension | Multi-leaf parabolic springs (front & rear) | Designed for high GVWR and rough site access |

| Tire Specifications | 12.00R20 18PR Radial | All-steel casing; 30 mm tread depth typical; load range G (121/118) |

| Load Capacity (GVWR) | 31,000–38,000 kg (68,340–83,775 lbs) | Configurable based on axle spacing and body type (dump, flatbed, stake) |

| Fuel Tank Capacity | 300–400 L (80–105 US gal) | Dual-tank options common in long-haul variants |

Fuel Efficiency Analysis

Fuel economy in the Weichai WD615-powered HW19710-equipped trucks is influenced by load profile, terrain, and operator behavior. Under mixed operation (60% highway, 40% on-site/idle):

- Average Fuel Consumption: 28–34 L/100 km (8.3–6.9 mpg US)

- Optimized Cruise (Loaded, 65 mph): 26 L/100 km (9.1 mpg) with proper gear management

- Construction Idle Impact: Unmanaged idle can increase consumption by up to 18%

These units benefit from electronic unit injection (EUI) systems and turbo-compounding in later variants, improving combustion efficiency. Retrofitting with fuel monitoring telematics is recommended for fleet optimization.

Note: Fuel efficiency is 10–15% lower than modern EPA 2017+ Cummins/X12 platforms but offset by lower acquisition cost and parts availability in secondary markets.

Load Capacity & Operational Suitability

Trucks equipped with the HW19710 transmission and dual 13T rear axles support gross vehicle weight ratings (GVWR) up to 38 metric tons in tri-axle dump configurations. Typical use cases in the Sioux Falls region include:

- Aggregate hauling (gravel, limestone)

- Heavy equipment transport (lowboy configurations)

- Long-distance dump runs from quarries to infrastructure sites

The 12.00R20 tires provide a balance of load-bearing capability (rated ~3,600 kg per tire) and ride stability on paved and unpaved roads. These tires are compatible with regional retread networks, reducing long-term operating costs.

Summary

Used trucks in the Sioux Falls market featuring the Weichai WD615 engine, HW19710 transmission, and 12.00R20 tires offer a cost-effective solution for construction and materials hauling. While not matching the fuel economy of newer EPA-compliant engines, their high torque output, durable drivelines, and strong load capacity make them suitable for medium-intensity fleet operations where upfront cost and parts availability are critical.

Fleet managers should consider condition audits (especially turbocharger, clutch, and differential wear) and upgrade potential (telematics, tire pressure monitoring) when evaluating units for acquisition.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: REFURBISHED TRUCK FLEET (2026 EDITION)

REF: RFS-SF-2026-01

DATE: 15 OCTOBER 2026

EXECUTIVE SUMMARY

SEA LION International delivers rigorously refurbished Class 6-8 trucks sourced from verified Sioux Falls inventory, engineered to meet Tier-4 Final operational standards. This report details the mandatory 4-phase refurbishment protocol applied to all units, exceeding FMCSA baseline requirements. Each truck undergoes 227-point validation under SEA LION’s Precision Rebuild Standard (PRS-2026), ensuring 95%+ operational readiness for high-utilization fleet deployment. Critical for construction sector durability and TCO reduction.

REFURBISHMENT PROCESS: SIEMENS-VALIDATED PROTOCOL

1. ENGINE & GEARBOX TESTING (PRS-2026 SECTION 4.1)

All powertrains undergo dynamometer validation and non-destructive testing (NDT). Units failing any metric are rejected.

| Test Parameter | SEA LION Standard | Industry Baseline | Validation Method |

|---|---|---|---|

| Compression Deviation | ≤ 8% across cylinders | ≤ 15% | Hydraulic Leak-Down Test |

| Oil Contamination (Soot) | < 0.8% by mass | < 1.5% | Spectrographic Analysis |

| Gearbox Shift Consistency | 0.2s max variance @ 1000 RPM | 0.5s | Dyno-Linked ECU Logging |

| Coolant Pressure Hold | 15 PSI for 60 min (0 drop) | 10 PSI for 30 min | Hydrostatic Test Rig |

Note: Engines exceeding 450,000 miles undergo mandatory cylinder head rebuild per Cummins ISX15 OEM specs.

2. CABIN REPAINTING (PRS-2026 SECTION 7.3)

Surface preparation and coating application follow ISO 12944-C4 corrosion protection standards for industrial environments.

| Process Stage | Specification | Quality Control Check |

|---|---|---|

| Surface Prep | SSPC-SP10/NACE No. 2 (Near-White Metal) | Adhesion Test (ASTM D3359 ≥ 4B) |

| Primer Application | Epoxy Zinc-Rich (80μm DFT min) | DFT Verification (Elcometer 456) |

| Topcoat | Polyurethane (RAL 7040/Custom Fleet Colors) | Gloss Retention (ASTM D523 ≥ 85%) |

| Curing | Forced Air @ 60°C for 120 min | MEK Rub Test (≥ 100 rubs) |

All weld seams sealed with 3M™ Scotch-Weld™ DP420 to prevent moisture ingress.

3. NEW TIRES & BATTERY REPLACEMENT (PRS-2026 SECTION 5.2)

Component sourcing restricted to Tier-1 OEM partners with full traceability.

| Component | Specification | Verification |

|---|---|---|

| Tires | Michelin X Works D (Load Range G) | Load Index 152/148 @ 121 kph (DOT) |

| Retread Prohibited | Tread Depth ≥ 18/32″ (New) | |

| Battery | Optima YellowTop (Group 31D) | CCA ≥ 1000A @ -18°C (SAE J537) |

| AGM Technology Only | Reserve Capacity ≥ 210 min (SAE J537) |

All wheels dynamically balanced to ISO 20570 tolerance (≤ 15g imbalance).

4. CHASSIS REINFORCEMENT (PRS-2026 SECTION 3.8)

Structural integrity verified via ultrasonic testing (UT) prior to reinforcement.

| Reinforcement Zone | Material Specification | Process Standard |

|---|---|---|

| Frame Rails (Front 1/3) | ASTM A572 Gr 50 (6.35mm min) | Continuous MIG Weld (AWS D1.1) |

| Crossmember Mounts | Robotic Welding (0.8mm max gap) | Penetration ≥ 90% base metal |

| Suspension Mounts | Shot Peening (Almen A 0.012″) | Post-Weld Heat Treatment (150°C) |

UT performed per ASME BPVC Section V Article 4; cracks >1.5mm reject criteria.

SEA LION INSPECTION STANDARDS: DIFFERENTIATING FACTORS

- PRS-2026 Compliance: 227 discrete checkpoints (vs. industry avg. 120), including:

- 3-Point Chassis Laser Alignment (Deviation ≤ 1.5mm/m)

- Emissions Verification (Portable PEMS @ 80% load)

- Full CAN Bus Diagnostic Snapshot (SAE J1939)

- Rejection Rate: 38.7% of candidate units fail initial assessment (2025 fleet data).

- Warranty Backing: 12-month/150,000-mile structural warranty (exceeds CARB remanufactured equipment requirements).

OPERATIONAL IMPACT FOR FLEET MANAGERS

| Metric | SEA LION Refurbished Unit | Typical “As-Is” Used Truck |

|---|---|---|

| Mean Time Between Failures | 8,200 hours | 3,100 hours |

| Initial Maintenance Cost | $187/unit (Year 1) | $1,420/unit (Year 1) |

| Resale Value Retention | 68% @ 36 months | 42% @ 36 months |

Data source: SEA LION 2025 Fleet Performance Audit (n=2,147 units)

CONCLUSION

SEA LION’s Sioux Falls-sourced refurbished trucks undergo quantifiable, auditable processes that eliminate operational risk inherent in standard used equipment procurement. The PRS-2026 protocol delivers near-new reliability at 40-55% of OEM acquisition cost, with documented TCO reduction for construction and logistics fleets. Units comply with all applicable FMCSA, OSHA, and CARB regulations for immediate deployment.

SEA LION International – Engineering Reliability, Not Compromise.

PRS-2026 Certification Documentation Available Upon Request

Shipping & Logistics Solutions

INDUSTRIAL SPECIFICATION REPORT 2026

Prepared by: SEA LION International – Heavy Equipment Logistics Division

Subject: Export Logistics Solutions for Used Trucks from China – Sioux Falls Market Entry

Target Audience: Fleet Managers | Construction Equipment Procurement Teams

1. Executive Summary

SEA LION International presents a comparative analysis of three primary maritime transport methods for exporting used trucks from manufacturing and consolidation hubs in China (e.g., Shanghai, Qingdao, Guangzhou) to Sioux Falls, South Dakota, USA. This report evaluates Roll-on/Roll-off (RO-RO), Bulk Cargo (Lo-Lo), and Flat Rack Container shipping solutions based on cost, transit time, cargo integrity, and corrosion protection protocols. Special emphasis is placed on long-term seawater exposure risks and the efficacy of wax-based anti-corrosion sprays in preserving truck chassis and undercarriage systems.

2. Market Context: Used Trucks to Sioux Falls

Sioux Falls serves as a regional logistics and construction equipment hub in the Upper Midwest. Demand for cost-effective, pre-owned heavy-duty trucks (e.g., dump trucks, tractors, mixers) has increased due to infrastructure expansion and municipal fleet modernization. China has emerged as a key source for surplus and refurbished construction-grade trucks, necessitating reliable, scalable export logistics.

3. Shipping Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Lo-Lo) | Flat Rack Container |

|---|---|---|---|

| Cargo Type Suitability | Ideal for operational trucks (drive-on/drive-off) | Suitable for non-operational or damaged units | Best for oversized, non-driveable, or high-clearance trucks |

| Loading Mechanism | Self-propelled or towed onto vessel | Lifted via crane; secured on deck or hold | Crane-lifted; lashed to open platform |

| Transit Time (China → US West Coast → Sioux Falls) | 18–24 days (port to port) + 7–10 days inland | 20–26 days + 7–10 days inland | 22–28 days + 7–10 days inland |

| Average Cost per Unit (USD) | $1,800 – $2,400 | $2,200 – $3,000 | $3,000 – $4,200 (varies with size) |

| Cargo Protection Level | Moderate (exposed deck areas) | Low (exposed to salt spray) | High (customizable lashing, partial shielding) |

| Risk of Seawater Exposure | High (open decks, splash zones) | High (deck stowage) | Moderate (elevated position, but open sides) |

| Scalability (Fleet Volume) | High (hundreds of units per vessel) | Medium | Low to Medium (space-constrained) |

| Insurance Complexity | Moderate | High (due to handling risk) | High (lashing integrity critical) |

4. Corrosion Protection Protocol: Wax Spraying System

All used trucks exported from coastal Chinese ports are subject to high-humidity and salt-laden maritime environments. To mitigate chloride-induced corrosion on undercarriages, frames, brake lines, and suspension systems, SEA LION mandates a multi-stage wax-based anti-corrosion treatment prior to shipment:

4.1 Wax Spray Specifications

| Property | Specification |

|---|---|

| Base Compound | Solvent-free, synthetic microcrystalline wax blend |

| Application Method | High-pressure undercarriage spray (250–300 psi) |

| Coating Thickness | 50–75 µm (uniform coverage) |

| Salt Spray Resistance (ASTM B117) | >1,000 hours |

| Temperature Range | Stable from -40°C to +90°C |

| Removability | Biodegradable; removed with industrial-grade citrus solvent |

4.2 Application Process

- Pre-Treatment: High-pressure freshwater wash to remove salt residues and debris.

- Degreasing: Alkaline cleaner applied to oily surfaces.

- Wax Spraying: Full undercarriage and chassis coverage, including wheel wells and frame rails.

- Curing: 24-hour ambient cure in climate-controlled bay.

- Verification: Coating thickness audit via magnetic gauge; documentation provided per unit.

Note: Wax film remains intact throughout 30-day transit and inland delivery, providing passive protection until de-waxing at destination.

5. Method Recommendation by Use Case

| Fleet Requirement | Recommended Method | Rationale |

|---|---|---|

| Operational trucks, high volume | RO-RO | Fast loading, cost-efficient, minimal handling damage |

| Non-operational or salvage units | Bulk Cargo | Accommodates damaged or inoperable units; lower space cost |

| Oversized or custom chassis (e.g., crane trucks) | Flat Rack | Structural flexibility; secure lashing points; reduced height constraints |

6. Operational Workflow – China to Sioux Falls

- Consolidation – Trucks collected at SEA LION-certified yards in Shanghai/Ningbo.

- Inspection & Prep – Emissions check, fuel stabilization, battery disconnect, wax spray.

- Loading – Scheduled per vessel departure (RO-RO/Bulk/Flat Rack).

- Marine Transit – Direct service to Port of Los Angeles, Long Beach, or Tacoma.

- Customs Clearance – ISF filing, EPA/DOT compliance verification.

- Inland Transport – Heavy-haul trucking via I-25/I-90 corridor to Sioux Falls distribution hub.

7. Conclusion

For fleet managers and construction firms sourcing used trucks from China, RO-RO shipping offers the optimal balance of cost and efficiency for operational units. Flat Rack is preferred for non-standard or damaged equipment requiring structural security. Regardless of method, industrial-grade wax spraying is non-negotiable for preserving asset integrity during trans-Pacific transit.

SEA LION International enforces ISO 9001-compliant handling protocols and provides full chain-of-custody tracking, corrosion treatment certification, and post-delivery support for Sioux Falls-bound equipment.

SEA LION International – Engineering Reliability in Global Heavy Transport

Revision: 2026-Q2 | Classification: Industrial Use Only

Get a Quote for Used Trucks For Sale Sioux Falls

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]