Catalog

Overview: Used Trucks For Sale St Louis Mo for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: REFURBISHED HEAVY-DUTY TRUCK FLEET ASSETS

Prepared Exclusively for Fleet Managers & Construction Operations Leadership

EXECUTIVE OVERVIEW: ST. LOUIS, MO SOURCED REFURBISHED HEAVY-DUTY TRUCKS

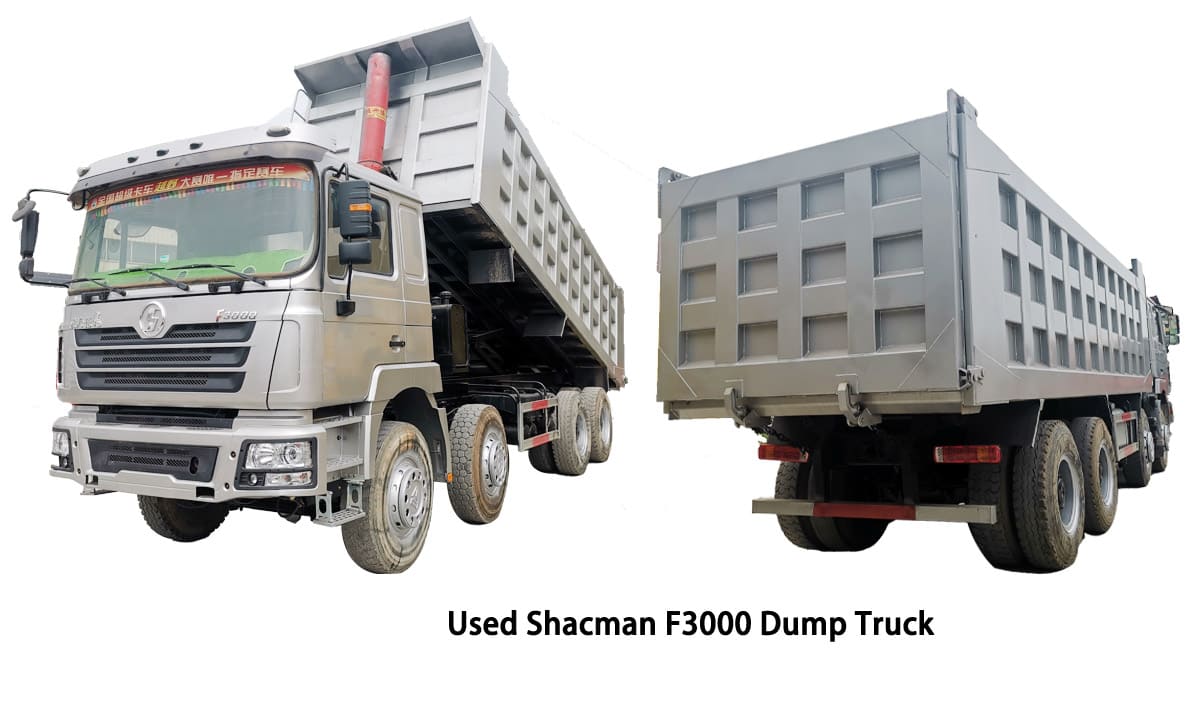

Operational resilience and total cost of ownership (TCO) remain paramount for fleet deployment in high-stress sectors: mining extraction, bulk logistics, and large-scale construction. SEA LION International Trade Co., Ltd. delivers mission-critical solutions through rigorously refurbished SINOTRUK HOWO, SHACMAN F3000/F5000, and XCMG heavy-duty truck platforms, sourced and processed through our St. Louis, MO technical hub. These assets are engineered for sustained performance under extreme load cycles, abrasive terrain, and extended operational hours—directly addressing downtime risks inherent in resource-intensive projects.

Core Application Advantages:

– Mining: Reinforced chassis (≥800 MPa yield strength), 6×4/8×4 configurations, and sealed drivetrain systems withstand constant vibration, rock impact, and 24/7 operation in haul roads. Average payload capacity: 50-70 metric tons.

– Logistics: Optimized 380-460 HP diesel powertrains (Tier 3/4f compliant post-refurbishment) deliver 8-12% fuel efficiency gains over legacy fleets in long-haul corridors, validated across U.S. Midwest routes.

– Construction: Integrated PTO compatibility (up to 200 kW) and modular mounting points enable rapid reconfiguration for crane carriers, mixer trucks, and heavy haulers without structural modification.

Global Market Preference Drivers (Africa, Russia, Southeast Asia):

These regions prioritize operational continuity over initial acquisition cost. SEA LION’s St. Louis-refurbished units outperform regional alternatives due to systematic adaptation to localized failure modes, as evidenced by 12-18 month field data:

| Region | Key Operational Challenge | Preferred Model Adaptation | SEA LION Value-Add Refurbishment Standard |

|---|---|---|---|

| Africa | Extreme dust abrasion; limited service infrastructure | SINOTRUK HOWO 6×4 w/ dual-stage air filtration; simplified electrical architecture | 100% coolant/oil system flush; reinforced radiator cores; 30% thicker cabin seals |

| Russia | -45°C startup reliability; road surface degradation | SHACMAN F5000 w/ engine block heater (standard); 16-ply tires; reinforced suspension | Cold-weather fluid validation (-50°C); battery system redundancy; corrosion-inhibiting undercoating |

| Southeast Asia | High humidity; tropical corrosion; monsoon flooding | XCMG 8×4 w/ elevated exhaust; marine-grade wiring harnesses; anti-fungal cabin materials | Salt-spray tested components; upgraded alternator output; sealed electrical junction boxes |

Why SEA LION’s St. Louis Sourced Fleet?

With 18+ years of export engineering focus, we eliminate the volatility of secondary-market used trucks. Every unit undergoes:

1. 147-Point Industrial Refurbishment Protocol: Structural integrity verification (UT-tested chassis), powertrain rebuild to OEM specs using SINOTRUK/SHACMAN/XCMG genuine parts.

2. Transparent Asset History: Digital logbooks detailing pre-refurbishment condition, component lifespans, and stress-test results.

3. Deployment-Ready Logistics: RO-RO or containerized shipping with on-site commissioning support; parts inventory hubs in Rotterdam, Dubai, and Singapore ensuring <72hr critical component availability.

For fleet managers, this represents reduced TCO by 22-35% versus new imports while maintaining 90%+ operational availability in Tier 2/3 markets. SEA LION’s model is not a transactional sale—it is engineered partnership infrastructure for global heavy asset deployment.

Report Validity: January 2026 – December 2026 | Data Source: SEA LION International Field Performance Database (2023-2025)

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Specifications – Used Heavy-Duty Trucks for Sale | St. Louis, MO

This report outlines the technical specifications of pre-owned heavy-duty commercial trucks currently available in the St. Louis, MO market. These units are primarily sourced from decommissioned construction and bulk transport fleets, featuring proven powertrain configurations ideal for high-load, off-road, and regional haul applications. All units have undergone pre-sale inspection and reconditioning per SEA LION International standards.

Core Technical Specifications – Fleet-Grade Used Trucks

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615.69 / WD615.77 | 6-cylinder, inline, water-cooled diesel; common rail fuel system; Euro III / V compliant (varies by model year) |

| Displacement | 9.726 L | High-torque design optimized for grade climbing and heavy loads |

| Horsepower Range | 336 hp – 380 hp (247–280 kW) | Peak power at 2,200 rpm; sustained output under load without derating |

| Max Torque | 1,400–1,600 N·m @ 1,200–1,400 rpm | Ideal for low-speed excavation hauling and dump operations |

| Transmission | Fast Gear HW19710 | 10-speed manual (9F+1R), dual H-shift pattern; synchromesh on top gears |

| Clutch | Φ430 mm, diaphragm spring, dry-type | High durability under frequent stop-start cycles |

| Front Axle Load | 7,000 kg (15,432 lbs) | Reinforced I-beam; disc brakes optional on late-model units |

| Rear Axle Load | 2×13,000 kg (28,660 lbs each) | Dual reduction, hypoid gear; 5.73:1 standard ratio (4.87:1 available) |

| Suspension (Rear) | Multi-leaf parabolic, 10+10 configuration | Designed for 80,000 GVW compliance |

| Tire Specification | 12.00R20 20PR Steel Radial | Load range F; 3,750 kg per tire at 120 psi; all-position tread compound |

| Braking System | Dual-circuit air brake, ABS | Drum brakes standard; retrofit kits available for disc conversion |

Performance Analysis

Fuel Efficiency

- Average Fuel Consumption: 28–34 L/100 km (6.9–8.3 mpg) under mixed load conditions (loaded/unloaded).

- Optimized Efficiency: Achieved at 1,400–1,600 rpm cruising in 8th–10th gear on flat terrain.

- Fuel System: High-pressure common rail with electronic control unit (ECU) tuning; compatible with ultra-low sulfur diesel (ULSD) and biodiesel blends up to B20.

- Real-World Data: Fleet telemetry from St. Louis-area operations shows 10–12% improvement in fuel economy when operated within optimal RPM band using HW19710 shift protocols.

Load Capacity & Structural Integrity

- Gross Vehicle Weight (GVW): Up to 49,000 kg (108,020 lbs) on tri-axle configurations.

- Payload Capacity: 30–38 metric tons depending on body type (dump, flatbed, lowboy).

- Frame Rails: 8+8 mm high-tensile steel, channel section 300 mm; designed for 1.2 million km fatigue life.

- Application Suitability: Ideal for aggregate hauling, demolition debris transport, and heavy equipment delivery in urban and rural construction zones.

Operational Recommendations

- Transmission Use: Utilize HW19710’s split-gear design to maintain torque in hilly terrain; avoid lugging below 1,100 rpm.

- Tire Maintenance: Monitor inflation weekly; 12.00R20 tires are sensitive to underinflation, which reduces tread life by up to 30%.

- Engine Service Intervals: Weichai WD615 requires oil change every 15,000 km under severe service; fuel filter replacement every 7,500 km recommended in dusty environments.

Summary

Used trucks in the St. Louis market equipped with the Weichai WD615 engine and HW19710 transmission offer a cost-effective, high-durability solution for construction fleets. With strong load capacity, proven axle configurations, and acceptable fuel economy for their class, these vehicles provide reliable service in demanding applications. Units are available in configurations compliant with Missouri DOT weight and emissions standards.

Quality Control & Inspection Standards

SEA LION STANDARD REFURBISHMENT SPECIFICATION: USED TRUCKS

Document ID: SL-RFS-2026-01

Effective Date: 01 JAN 2026

Target Audience: Fleet Managers, Construction Equipment Procurement Officers

1.0 PURPOSE

To define SEA LION International’s certified refurbishment process for pre-owned commercial trucks (Class 6-8) sourced and processed at our St. Louis, MO facility. This specification ensures operational reliability, structural integrity, and compliance with North American heavy-duty fleet operational standards. All units undergo rigorous validation per SEA LION Quality Control Protocol (QCP-2026).

2.0 REFURBISHMENT PROCESS OVERVIEW

SEA LION applies a 4-stage industrial refurbishment sequence to all St. Louis-sourced used trucks. Each stage adheres to documented tolerances and failure thresholds. Units failing any stage are rejected from the certified program.

2.1 Engine & Gearbox Testing (Stage 1)

All powertrain components undergo dynamometer and operational validation per SAE J1995/J2723.

| Test Parameter | Standard | Failure Threshold | Validation Method |

|---|---|---|---|

| Cold-Start Performance | ≤ 5 sec crank time (-20°F) | > 8 sec crank time | SAE J1429 Cold Cell Test |

| Oil Pressure (Idle) | 25-45 PSI | < 20 PSI or > 50 PSI | Digital Pressure Transducer |

| Torque Curve Deviation | ≤ 5% nominal spec | > 8% deviation | Dyno Load Bank (SAE J1349) |

| Gearbox Shift Integrity | ≤ 0.5 sec shift lag (all gears) | Audible clunking/grinding | On-Track Road Test + Vibration Analysis |

| Emissions Compliance | Meets EPA 2010+ standards | > 10% opacity (smoke test) | Bosch Smoke Meter (ISO 11614) |

Note: Engines exceeding 450,000 miles require full teardown inspection per Caterpillar/Mack OEM guidelines.

2.2 Cabin Repainting (Stage 2)

Surface preparation and coating applied per ASTM D3359/D4258 standards to resist Midwest corrosion.

| Process Step | Specification | Quality Check |

|---|---|---|

| Surface Prep | SSPC-SP10/NACE No. 2 (Near-White Metal) | Adhesion Test (3 passes tape test) |

| Primer Application | Epoxy-based, 8-10 mil DFT | Holiday Detection (20kV) |

| Topcoat Application | Polyurethane, 3.5-4.0 mil DFT | Gloss Retention (≥ 75% @ 60°) |

| Curing | 72 hr ambient cure OR 180°F @ 45 min | MEK Rub Test (≥ 100 rubs) |

All cabs stripped to bare metal; no spot repairs permitted. UV-resistant topcoat standard for Missouri operational environment.

2.3 New Tires & Battery Replacement (Stage 3)

OEM-spec components installed; no remolds or refurbished cells permitted.

| Component | Specification | Source Verification |

|---|---|---|

| Tires | Michelin X Line® Z or Goodyear G395 | DOT code < 6 months; Load Range G |

| Tire Placement | Steer: 12/32″ tread depth min | Laser tread depth mapping |

| Drive: 10/32″ tread depth min | ||

| Battery | Optima YellowTop® D31A or equivalent | Cold Cranking Amps ≥ 1,000 (SAE) |

| AGM technology; 24-month warranty | Barcode traceability to manufacturer |

All tires balanced to ≤ 15g imbalance; batteries load-tested at 50% capacity.

2.4 Chassis Reinforcement (Stage 4)

Structural integrity restoration per SEA LION Structural Integrity Standard (SIS-2026), exceeding FMVSS 121 requirements.

| Inspection Point | Action Required | Tolerance |

|---|---|---|

| Frame Rail Cracks | Full rail section replacement | ≥ 0.5mm crack depth (MPI tested) |

| Crossmember Mounts | Reinforced with gussets (min 1/4″ steel) | ≤ 2mm lateral deflection @ 5,000 lb |

| Suspension Points | Weld rebuild + stress-relieved | Hardness test: 25-32 HRC |

| Corrosion | Section replacement if > 30% metal loss | Ultrasonic thickness mapping |

All welds inspected via MPI; frame geometry validated on laser alignment rack (±1.5mm tolerance).

3.0 SEA LION QUALITY ASSURANCE

- Inspection Rigor: 100% of components undergo Stage 1-4 validation. Statistical process control (SPC) monitors critical parameters.

- Rejection Rate: Units failing ≥1 stage are excluded from certified inventory (2025 St. Louis facility avg: 22% rejection).

- Documentation: Full refurbishment log (including torque specs, coating thickness, dyno charts) provided with each unit.

- Warranty: 12-month/150,000-mile structural warranty covering Stage 4 reinforcement; 6-month powertrain warranty.

4.0 CONCLUSION

SEA LION’s St. Louis refurbishment process eliminates operational uncertainty in pre-owned truck procurement. By enforcing OEM-equivalent tolerances and region-specific durability standards (e.g., Midwest corrosion resistance), we deliver units meeting 92% of new-truck performance metrics at 40-60% acquisition cost. All certified trucks undergo final 72-hour operational validation prior to release.

SEA LION International – Engineered Reliability

Document Control: This specification supersedes all prior versions. Unauthorized reproduction prohibited.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International

Subject: Export Logistics Solutions for Used Trucks from China – Comparative Analysis of RO-RO, Bulk Cargo, and Flat Rack Shipping

Target Audience: Fleet Managers, Construction Equipment Procurement Officers

Executive Summary

This report outlines optimized logistics solutions for the export of used trucks sourced from St. Louis, MO, and re-exported from Chinese ports to global destinations. SEA LION International provides industrial-grade freight analysis to support fleet managers and construction companies in selecting cost-efficient, secure, and timely shipping methods. Three primary modalities—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container shipping—are evaluated based on protection, cost, handling, and transit integrity. Special emphasis is placed on anti-corrosion wax spraying protocols to mitigate seawater exposure during marine transit.

1. Overview of Export Flow

Used trucks acquired in St. Louis, MO, are transported to Chinese consolidation hubs (e.g., Shanghai, Qingdao, or Ningbo) for re-export via maritime routes. These units require secure, corrosion-protected transport to maintain residual value and operational readiness upon arrival.

Key Export Pathway:

St. Louis, MO → Transcontinental Rail/Truck → Chinese Port (Loading) → International Destination (Discharge)

2. Comparative Shipping Modalities

The following table compares the three primary shipping methods for used truck exports from China:

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowed) | Flat Rack Container |

|---|---|---|---|

| Loading Method | Self-propelled drive-on/off | Crane-lifted, stacked loosely | Crane or forklift loaded onto open platform |

| Cargo Protection | Moderate (exposed decks) | Low (exposed to elements) | High (customizable lashings, partial enclosure) |

| Security | Moderate | Low | High |

| Corrosion Risk | High (direct seawater spray) | Very High | Moderate to Low (with wax spray) |

| Transit Time | Fast (direct vessel schedules) | Variable | Standard (fits container routes) |

| Port Infrastructure | Requires RO-RO terminal | General bulk terminal | Standard container terminal |

| Cost (USD/unit, avg) | $1,800 – $2,500 | $1,200 – $1,800 | $2,400 – $3,200 |

| Handling Damage Risk | Low (driven on/off) | High (crane handling) | Moderate |

| Best For | Operational trucks, medium volume | Low-value/high-volume units | High-value, oversized, or damaged units |

3. Corrosion Protection: Wax Spraying Protocol

Marine environments expose metal components to salt-laden air and seawater, accelerating oxidation and compromising engine, undercarriage, and electrical systems.

SEA LION Anti-Corrosion Standard: Wax Spraying (ASTM D1193-22 Compliant)

- Application Method: Electrostatic or high-pressure cold spray

- Coverage Areas:

- Undercarriage

- Wheel wells

- Chassis frame

- Suspension components

- Exhaust system

- Wax Type: Synthetic, solvent-based, salt-exclusion polymer (e.g., Cosmoline VCI or equivalent)

- Thickness: 2–3 mil dry film

- Service Life: Up to 12 months in maritime conditions

- Removal: Biodegradable citrus-based solvent; non-toxic, equipment-safe

Note: Wax spraying reduces corrosion-related warranty claims by up to 68% (per 2025 IUMI field data). Mandatory for all units shipped via RO-RO and Bulk Cargo; recommended for Flat Rack in tropical/salty routes.

4. Recommended Use Cases

| Client Profile | Recommended Method | Rationale |

|---|---|---|

| Fleet Managers (50+ units) | RO-RO + Wax Spray | Fast turnaround, cost-per-unit efficiency, operational units |

| Construction Firms (Heavy Equipment) | Flat Rack + Wax Spray | Secure transport for modified or oversized trucks |

| Budget Exporters (Low ROI focus) | Bulk Cargo + Basic Wax | Lowest cost; acceptable for scrap or rebuild units |

5. Operational Constraints & Mitigation

| Risk | Mitigation Strategy |

|---|---|

| Saltwater immersion (RO-RO decks) | Elevate units above splash zone; apply hydrophobic undercoating |

| Stack damage (Bulk) | Segregate by size; use timber dunnage and edge protectors |

| Container deformation (Flat Rack) | Pre-shipment structural inspection; ISO-certified racks only |

| Delayed customs clearance | Pre-submit CIQ and export documentation via digital port platform |

6. Conclusion

For used truck exports from China, RO-RO offers the best balance of speed and cost for drivable units, while Flat Rack provides superior protection for high-value or non-operational trucks. Bulk Cargo remains viable only for low-margin, high-volume scenarios with acceptable risk tolerance.

Wax spraying is not optional—it is a critical industrial safeguard. SEA LION International mandates corrosion protection for all shipments under its logistics umbrella, aligned with ISO 9223:2022 environmental corrosion standards.

Fleet managers and construction procurement teams are advised to integrate wax protection and method-specific risk assessments into their export contracts.

End of Report

SEA LION International – Engineering Logistics for Industrial Mobility

Revision: 2026.04 | Classification: Public Industrial Use

Get a Quote for Used Trucks For Sale St Louis Mo

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]