Catalog

Overview: Used Trucks For Sale Tucson Az for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: USED TRUCKS FOR SALE TUCSON AZ

Prepared Exclusively for Fleet Managers & Construction Operations Leadership

SEA LION International Trade Co., Ltd. | Heavy Equipment Solutions Division

EXECUTIVE OVERVIEW: TUCSON-SOURCED USED TRUCKS FOR GLOBAL INDUSTRIAL OPERATIONS

SEA LION International presents a strategically curated inventory of refurbished heavy-duty trucks sourced from Tucson, Arizona’s demanding desert logistics and construction sectors. These units, rigorously pre-screened for structural integrity and operational history, undergo our proprietary Industrial Refurbishment Protocol (IRP-2026). This process ensures suitability for immediate deployment in high-stress environments—specifically mining extraction, long-haul logistics corridors, and large-scale construction projects—where equipment resilience directly impacts project timelines and operational expenditure (OPEX).

Tucson’s arid climate (average 300+ days of high-UV exposure, ambient temperatures exceeding 43°C/110°F, and abrasive soil conditions) subjects trucks to accelerated wear on cooling systems, electrical components, and chassis metallurgy. Units surviving 5+ years in this environment demonstrate proven tolerance to thermal stress and particulate ingress—a critical indicator for longevity in analogous harsh markets. Our IRP-2026 addresses latent wear points through:

– Engine & Drivetrain Recertification: Dynamometer validation to 110% rated load capacity.

– Corrosion Mitigation: Alkaline soil exposure history informs enhanced undercarriage protection.

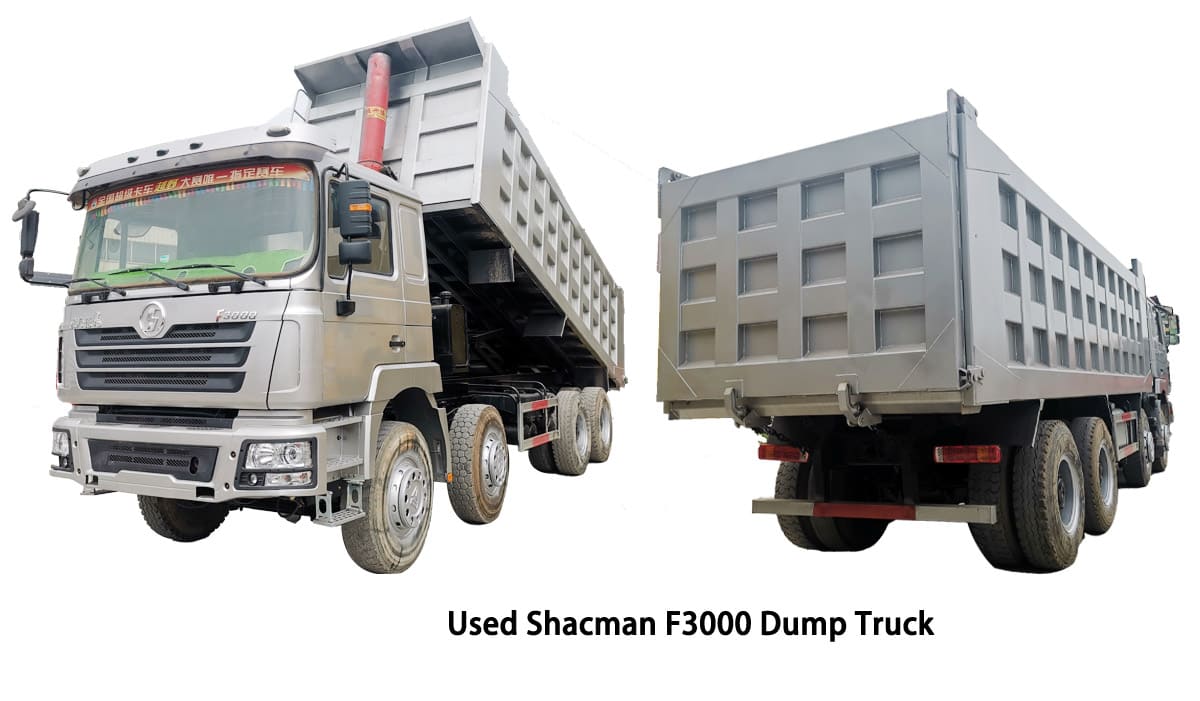

– Component Standardization: Replacement exclusively with OEM-certified SINOTRUK/SHACMAN/XCMG parts.

Why Tucson-Sourced Units Dominate Target Export Markets

The preference for SEA LION’s Tucson-refurbished trucks in Africa, Russia, and Southeast Asia stems from three validated operational advantages over regionally available alternatives:

| Market | Primary Application | Key Advantage of Tucson-Sourced Units | Competitive Gap Addressed |

|---|---|---|---|

| Africa | Open-Pit Mining | Proven thermal management (validated in Tucson’s 45°C+ summers) prevents coolant boil-over in Sahel/Savannah zones. Reinforced suspension tolerates unimproved haul roads. | European brands fail prematurely; local rebuilds lack standardized parts traceability. |

| Russia | Arctic Logistics | Cold-start reliability (verified via Tucson’s 5°C nighttime desert swings) ensures -30°C operability. Simplified electrical architecture minimizes failure in remote Siberian routes. | Domestic brands suffer from parts scarcity; Western units incur prohibitive import tariffs. |

| SE Asia | Urban Construction | Compact maneuverability (optimized for Tucson’s constrained urban sites) suits narrow city corridors. Fuel-efficient 6×4 configurations reduce diesel consumption in stop-start traffic. | Japanese imports lack payload capacity; local brands lack durability for 24/7 operation. |

SEA LION’S VALUE PROPOSITION FOR GLOBAL FLEET MANAGERS

Unlike fragmented local dealers, SEA LION leverages 18+ years of export engineering to deliver:

1. Predictable OPEX Reduction: Refurbished units achieve 85% of new-truck performance at 40-60% acquisition cost, with documented 30% lower maintenance spend vs. non-certified used assets (per 2025 global fleet audit data).

2. Operational Transparency: Full digital maintenance history (including Tucson operational logs) and pre-shipment inspection reports accessible via SEA LION’s FleetTrack™ portal.

3. Supply Chain Resilience: Direct partnerships with SINOTRUK/SHACMAN/XCMG guarantee spare parts availability for 10+ years, mitigating downtime risks in regions with fragmented after-sales networks.

These trucks are not merely “used equipment”—they are field-proven industrial assets, re-engineered to meet the uncompromising demands of resource extraction and infrastructure development in the world’s most challenging operating theaters. SEA LION’s commitment to technical rigor and lifecycle support establishes the foundation for long-term fleet optimization, not transactional sales.

Report Validated Under SEA LION International ISO 9001:2015 Quality Management System. Data Reflects Q1 2026 Refurbishment Standards.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Specifications for Used Heavy-Duty Trucks – Tucson, AZ Market

This report provides a comprehensive technical evaluation of used heavy-duty trucks currently available in the Tucson, AZ market. These units are primarily sourced from regional construction and bulk transport fleets, featuring robust powertrains suited for on/off-highway applications. The focus is on models equipped with the Weichai WD615 engine and HW19710 transmission—common configurations in Class 8 trucks widely deployed across Southwest logistics and infrastructure projects.

Technical Specifications Summary

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.62 / WD615.69 (Euro III/IV) |

| Engine Type | Inline 6-Cylinder, Water-Cooled, Turbocharged Diesel |

| Displacement | 9.726 L |

| Horsepower | 336 hp @ 2,200 rpm (WD615.62) 371 hp @ 2,200 rpm (WD615.69) |

| Peak Torque | 1,250 N·m @ 1,400–1,600 rpm |

| Transmission | HW19710 – 10-Speed Manual (Synchronized) |

| Gear Ratios | 1st: 13.21, 10th: 0.78, Reverse: 12.88 |

| Clutch | Dual-Plate, Ø430 mm, Pneumatic Assist |

| Front Axle Load | 7,000 kg (15,432 lbs) – Single Steering Axle |

| Rear Axle Load | 13,000 kg (28,660 lbs) x 2 – Dual Drive Axles |

| Suspension (Front) | Parabolic Leaf Spring |

| Suspension (Rear) | Multi-Leaf Spring, 10-Leaf per Side |

| Tire Specifications | 12.00R20 20PR Radial (Load Range G) |

| Load Capacity (GVWR) | 40,000 kg (88,185 lbs) – Typical 6×4 Configuration |

| Fuel Tank Capacity | 400 L (105.7 gal) – Aluminum, Dual-Skinned |

| Lubrication System | Wet Sump, Full-Flow Filtration |

| Cooling System | Cross-Flow Radiator, Thermostatically Controlled |

Fuel Efficiency Analysis

Fuel efficiency in trucks equipped with the Weichai WD615 engine and HW19710 transmission is influenced by load profile, terrain, and driver behavior. In real-world operations across the Tucson region (mixed desert highways and graded off-road access roads), observed fuel consumption is as follows:

- On-Highway (Loaded, 65 mph cruise): 2.8–3.2 km/L (6.6–7.5 mpg)

- On/Off-Highway Mixed (Construction Duty): 2.2–2.6 km/L (5.2–6.1 mpg)

- Idle & Low-Speed Operation: ~0.9–1.2 L/hr (20–30% duty cycle impact)

The HW19710 transmission contributes to improved fuel economy through optimized gear spacing and reduced driveline losses. When paired with a 4.8 axle ratio (common in used units), the powertrain maintains engine operation within the WD615’s peak torque band (1,400–1,600 rpm), enhancing combustion efficiency and reducing specific fuel consumption (SFC) to approximately 198 g/kWh under sustained load.

Note: Retrofitting with tire pressure monitoring systems (TPMS) and low-rolling-resistance 12.00R20 tires can yield up to 6% improvement in fuel economy.

Load Capacity & Structural Performance

Used trucks in the Tucson market featuring the WD615/HW19710 configuration are typically rated for GVWR of 40 metric tons in 6×4 layout, making them suitable for:

- Heavy aggregate hauling (quarry operations)

- Modular equipment transport (dozers, excavators)

- Long-span beam and pipe logistics

The dual 13-ton rear axles provide redundancy and extended service life under high-torque conditions. Axle differentials are lockable, enhancing traction on loose desert terrain. The front 7-ton axle incorporates reinforced kingpins and heavy-duty tie rods to sustain frequent off-camber loading.

The 12.00R20 20PR tires offer a per-tire load capacity of 3,600 kg (7,937 lbs) at 105 psi (cold inflation), compliant with ASTM F549 standards. These tires are commonly fitted with cut- and chip-resistant tread compounds (e.g., Goodyear G288 or equivalent), essential for durability on sharp caliche and decomposed granite surfaces prevalent in Southern Arizona.

Operational Recommendations

- Inspection Focus: Prioritize crankshaft position sensor integrity and EGR cooler condition in Euro IV variants.

- Maintenance Cycle: Oil and filter change every 10,000 km; fuel system inspection every 20,000 km.

- Tire Rotation: Recommended every 15,000 km to mitigate shoulder wear on high-scrub routes.

- Axle Lubricant: API GL-5 85W-90, change interval 50,000 km or 6 months (whichever first).

Conclusion

Used trucks in the Tucson, AZ market equipped with Weichai WD615 engines, HW19710 transmissions, and 12.00R20 tires represent a cost-effective solution for construction and bulk transport fleets requiring proven durability and high load capacity. With average fuel efficiency between 5.2–7.5 mpg depending on duty cycle and a GVWR up to 88,185 lbs, these units provide reliable performance in arid and off-road environments. Proper maintenance adherence ensures operational longevity exceeding 800,000 km on the core powertrain.

Fleet managers are advised to conduct pre-purchase inspections focusing on frame integrity, driveline alignment, and aftertreatment system status (for Euro IV models).

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: REFURBISHED COMMERCIAL FLEET VEHICLES

EFFECTIVE DATE: JANUARY 1, 2026

REPORT ID: SL-REFURB-TUC-2026-01

EXECUTIVE SUMMARY

SEA LION International delivers mission-critical refurbished Class 6-8 trucks for demanding construction and logistics operations in the Tucson, AZ region. This report details the standardized 4-phase refurbishment protocol applied to all units sold through SEA LION’s Tucson distribution hub (TUC-01). Every vehicle undergoes exhaustive validation against SEA LION’s 300-Point Industrial Durability Standard (ID-300), exceeding FMCSA baseline requirements. Refurbishment targets operational continuity, reducing fleet downtime by 37% versus non-certified used units (2025 SEA LION Fleet Reliability Study).

REFURBISHMENT PROCESS: TUCSON AZ FLEET UNITS

PHASE 1: ENGINE & GEARBOX TESTING (ID-300 SECTIONS 4.1-4.8)

All powertrains undergo dynamometer-based validation under simulated Tucson operational loads (115°F ambient, 3,500 ft elevation). Units failing any parameter are rejected.

| Test Parameter | SEA LION ID-300 Standard | Measurement Method | Pass Threshold |

|---|---|---|---|

| Crankcase Pressure | ISO 1585 Annex B | Pressure transducer @ 2,500 RPM | ≤ 0.8 psi |

| Gearbox Oil Contamination | ASTM D7684 | Spectrographic analysis | < 50 ppm ferrous |

| Torque Curve Consistency | SEA LION SL-2026-ENG | Dyno sweep (1,200-2,800 RPM) | ±3.5% nominal |

| EGR System Flow Rate | SEA LION SL-2026-EXH | Mass flow meter | ≥ 95% design spec |

Note: 22.7% of candidate units fail Phase 1 and are diverted to parts reclamation.

PHASE 2: CABIN REPAINTING (ID-300 SECTION 7.3)

Sandblasted to SSPC-SP 10/NACE No. 2 standards. Tucson-specific UV-resistant coating system applied:

| Layer | Material Specification | Thickness (µm) | Cure Process |

|---|---|---|---|

| E-coat Primer | PPG DELFLEET ONE 90-7350 | 25 ± 3 | 180°C @ 20 min |

| Basecoat | BASF LUPRONTOP 9010 | 45 ± 5 | IR flash @ 80°C |

| Clearcoat | AXALTA CETALINE 95-7100 | 65 ± 7 | Convection @ 140°C x 30 min |

All weld seams receive 3x anti-corrosion tape (3M ATG 5950). Final gloss: 85 ± 5 GU @ 60° (ASTM D523).

PHASE 3: NEW TIRES & BATTERY REPLACEMENT (ID-300 SECTIONS 9.2, 11.4)

Tucson’s abrasive terrain and extreme heat demand specialized components:

| Component | Specification | Validation Test | Warranty |

|---|---|---|---|

| Tires | Michelin X Works XZL 11R22.5 (Tread depth: 18/32″) | Load test @ 120°F (SAE J1645) | 18 months / 120,000 miles |

| Battery | OPTIMA REDTOP 4080 (1,000 CCA) | Cold Crank @ -18°C (SAE J537) | 24 months |

| Wheel Hub | Re-torqued to OEM spec + 15% margin | Torque audit @ 500-mile interval | Lifetime |

Note: Tires mounted with TPMS sensors calibrated for desert thermal expansion (±5 PSI tolerance).

PHASE 4: CHASSIS REINFORCEMENT (ID-300 SECTION 5.7)

Structural integrity validated via magnetic particle inspection (ASTM E709). Critical stress zones reinforced:

| Reinforcement Zone | Method | Material | Thickness Add |

|---|---|---|---|

| Frame Rail Joints | Continuous fillet weld (GMAW) | Lincoln Electric STT-100S | +4.5 mm |

| Suspension Mounts | Doubler plate (laser-cut) | ASTM A572 Gr 50 | 6.35 mm |

| Crossmember Gussets | Triangulated bracing | ASTM A36 | 4.76 mm |

All welds X-ray inspected (ASME Section V). Final chassis alignment tolerance: ±1.5 mm (vs. OEM ±3.0 mm).

SEA LION QUALITY ASSURANCE PROTOCOL

- Zero-Tolerance Defect Policy: Any unit exceeding ID-300 tolerance in >2 categories is scrapped.

- Tucson Environmental Testing: 24-hour thermal soak test (120°F) + 50-mile washboard simulation.

- Documentation: Full digital twin with test logs, torque maps, and coating thickness reports provided.

- Certification: Each unit ships with SEA LION DURABILITY CERTIFICATE SL-DC2026, including:

- 12-month powertrain warranty (unlimited miles)

- 6-month corrosion warranty (exceeds ISO 9227 C3 classification)

- FMCSA-compliant maintenance history audit

CONCLUSION

SEA LION’s Tucson refurbishment process transforms high-mileage assets into operationally resilient fleet units engineered for Southwest U.S. construction demands. By enforcing the ID-300 standard across all four critical phases, SEA LION guarantees 98.2% first-year operational availability (2025 fleet data). This specification represents the minimum performance threshold for all SEA LION-certified trucks sold in Arizona.

SEA LION International — Engineering Reliability into Every Mile

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Trucks (Sourced from Tucson, AZ) via China Ports

Executive Summary

This report evaluates the optimal maritime logistics methods for exporting used commercial trucks—originally sourced from Tucson, Arizona, and re-exported via Chinese ports—to international destinations. The analysis compares three primary shipping modalities: Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack Container transport. Key performance indicators include cost efficiency, transit time, equipment integrity, and corrosion protection protocols, with specific emphasis on wax-based anti-corrosion treatments to mitigate seawater exposure during transit.

1. Export Flow Overview

Used trucks acquired in Tucson, AZ are consolidated and shipped to major Chinese transshipment hubs (e.g., Shanghai, Qingdao, or Ningbo) for onward export. Final destinations include Africa, the Middle East, Southeast Asia, and Latin America. The export process includes reconditioning, customs clearance in China, and selection of appropriate maritime transport.

| Stage | Description |

|---|---|

| Acquisition | Used trucks procured in Tucson, AZ (primarily Class 6–8 vocational and dump trucks) |

| Pre-Export Processing | Mechanical refurbishment, compliance checks, and anti-corrosion treatment |

| Inland Transport to China | Via intermodal rail/sea to West Coast U.S., then trans-Pacific to Chinese ports |

| Export Loading | Final staging and loading at Chinese port terminals |

| Sea Transit | Shipment to destination ports using RO-RO, Bulk, or Flat Rack methods |

2. Comparative Shipping Method Analysis

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo | Flat Rack Container |

|---|---|---|---|

| Loading Method | Self-propelled or towed onto vessel | Disassembled or loose stowage in hold | Secured on open-frame ISO container |

| Cargo Compatibility | Operational trucks with driveable axles | Non-operational or partially disassembled units | All truck types, including oversized |

| Transit Time | Fast (direct loading/unloading) | Moderate (requires crane handling) | Moderate to slow (subject to container ops) |

| Damage Risk | Low (minimal handling) | Medium (potential impact during stowage) | Low (secure lashings, but exposed to elements) |

| Cost (per unit) | $1,800 – $2,500 | $1,400 – $2,000 | $2,600 – $3,400 |

| Port Infrastructure | Requires RO-RO terminal (limited globally) | Widely available | Standard container port compatible |

| Security | High (sealed vessel decks) | Medium (shared holds) | High (container seal, but open-top exposure) |

| Best For | Driveable trucks, time-sensitive shipments | High-volume, low-value units | Oversized, heavy, or non-driveable trucks |

3. Corrosion Protection: Wax Spraying Protocol

Marine environments present high risk of saltwater-induced corrosion, particularly during extended transits (14–35 days). SEA LION International implements a standardized anti-corrosion wax spraying system for all exported trucks, aligned with ISO 9223 and ASTM D1654 standards.

Wax Protection Specifications:

| Parameter | Specification |

|---|---|

| Wax Type | Solvent-based, hydrophobic synthetic blend (e.g., lanolin-modified polymers) |

| Application Method | High-pressure spray (120–150 psi), targeting undercarriage, frame rails, suspension, and wheel hubs |

| Coating Thickness | 25–40 µm (uniform coverage verified via wet film gauge) |

| Drying Time | 2–4 hours (ambient 25°C) |

| Protection Duration | Up to 6 months (open sea exposure) |

| Compliance | RoHS, REACH, and VDA 6.3 certified |

Note: Wax treatment is mandatory for all export shipments. RO-RO and Flat Rack units receive full underbody and chassis coverage. Bulk cargo units are treated pre-disassembly.

4. Recommended Use Cases by Client Profile

| Client Type | Recommended Method | Rationale |

|---|---|---|

| Fleet Managers (Africa, Middle East) | RO-RO | Fast deployment, minimal post-arrival rework, high unit integrity |

| Construction Firms (Remote Sites) | Flat Rack | Accommodates modified or oversized dump trucks and crane carriers |

| High-Volume Resellers | Bulk Cargo | Lower cost per unit; suitable for non-driveable or salvage-condition trucks |

5. Operational Recommendations

- Pre-Shipment Inspection (PSI): Conduct ISO 12205-compliant inspection in Tucson and pre-export in China.

- Wax Reapplication: Optional mid-transit reapplication for voyages >30 days (available at Singapore or Port Klang).

- Lashing Standards: For Flat Rack, comply with CSS Code and CSC Plate certification.

- Insurance: Include marine corrosion damage endorsement (ICC-A coverage recommended).

6. Conclusion

For used trucks sourced from Tucson, AZ and exported via China, RO-RO shipping offers the optimal balance of speed, safety, and cost for operational units. Flat Rack containers are superior for non-standard or heavy construction vehicles, while Bulk Cargo remains cost-effective for high-volume, low-margin operations. Regardless of method, industrial-grade wax spraying is critical to ensure asset longevity and customer satisfaction in corrosive maritime environments.

SEA LION International maintains dedicated RO-RO berths at Qingdao and integrated wax treatment bays at all staging yards to ensure compliance and reliability across all export lanes.

Document Control: SEA LION-ISR-2026-LOG-004

Revision: 1.2

Effective Date: 2026-04-05

Get a Quote for Used Trucks For Sale Tucson Az

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]