Catalog

Overview: Used Trucks For Sale Tyler Tx for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026

EXECUTIVE OVERVIEW: STRATEGIC SOURCING OF REFURBISHED HEAVY-DUTY TRUCKS (TYLER, TX INVENTORY POOL)

Strategic Value Proposition

SEA LION International Trade Co., Ltd. leverages its Tyler, TX-based inventory hub to supply rigorously refurbished heavy-duty trucks (model years 2018–2022) optimized for high-stress applications in mining, bulk logistics, and infrastructure construction. This inventory pool—sourced from decommissioned U.S. fleet assets—undergoes a standardized 120-point technical refurbishment protocol, delivering OEM-specification reliability at 35–50% below new-unit acquisition costs. For global fleet managers, this represents a quantifiable reduction in Total Cost of Ownership (TCO) while maintaining operational continuity in remote or capital-constrained environments.

Tyler, TX: Rationale for Sourcing Hub

Tyler, TX, serves as a strategic node due to:

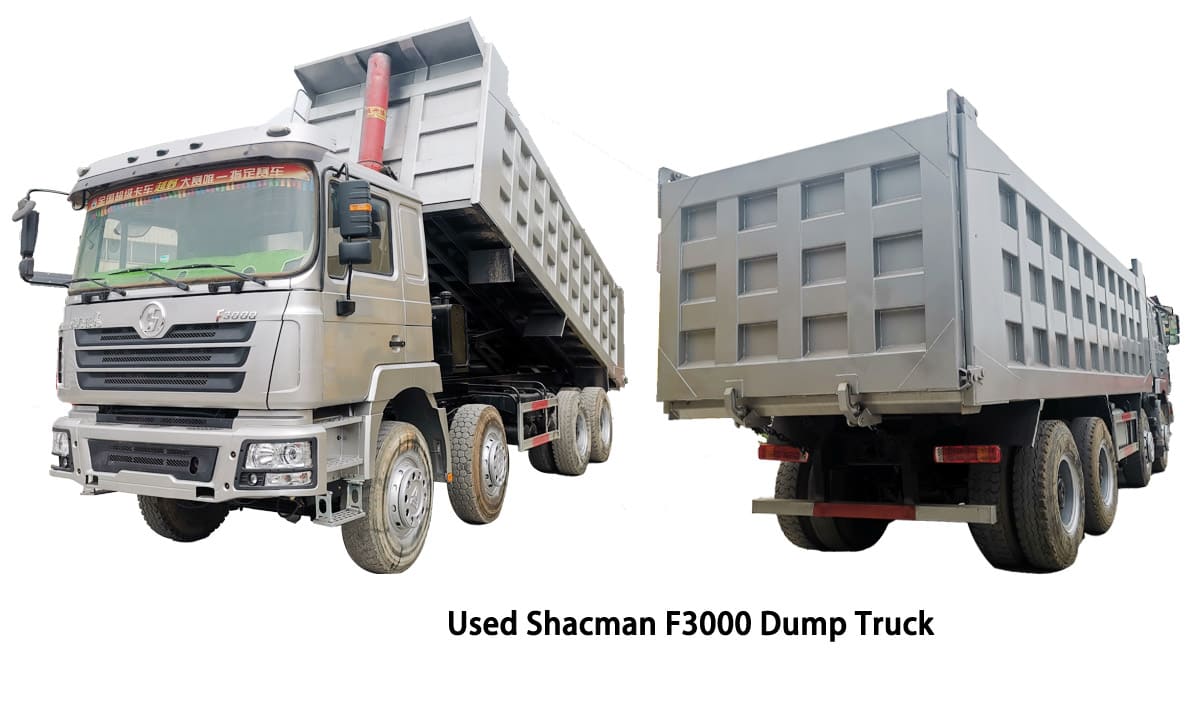

– Inventory Depth: Concentrated surplus of Class 8 trucks retired from U.S. interstate logistics (avg. 500,000-mile service life), featuring robust chassis designs (e.g., SINOTRUK HOWO 6×4, SHACMAN F3000).

– Infrastructure Compatibility: U.S.-spec trucks exhibit superior frame geometry and suspension tuning for unpaved terrain versus EU/Asian counterparts, directly transferable to African mine sites or Southeast Asian rural corridors.

– Regulatory Alignment: Emissions-compliant units (EPA 2010+) retain durability without complex aftertreatment systems, minimizing downtime in regions with inconsistent fuel quality (e.g., Sub-Saharan Africa, Indonesia).

Sector-Specific Operational Advantages

| Application | Critical Performance Metrics | SEA LION Refurbishment Enhancements |

|---|---|---|

| Mining | Payload capacity >40T; frame torsion resistance | Reinforced C-channel frames; upgraded differential locks; corrosion-resistant undercarriage coating |

| Bulk Logistics | Fuel efficiency (5.2–6.0 mpg @ 65k GVWR); uptime | Reconditioned engines (dyno-tested); telematics integration; 200k-mile warranty on drivetrain |

| Construction | Off-road traction; hydraulic PTO compatibility | Rebuilt axles with 4.11:1 ratio; auxiliary hydraulic pump mounts; cab suspension recalibration |

Regional Preference Analysis: Africa, Russia, Southeast Asia

Field data from SEA LION’s 18-year export history (2006–2024) confirms dominant adoption in these markets due to operational pragmatism, not cost alone. Key drivers:

| Region | Primary Market Requirement | Why SEA LION Tyler-Sourced Trucks Prevail |

|---|---|---|

| Africa | Extreme dust tolerance; simple maintenance | U.S.-spec air filtration systems (dual-stage cyclonic); standardized mechanical fuel systems (no CRDi); local technician familiarity with Cummins/Weichai platforms |

| Russia | -40°C cold-start reliability; heavy snow load | Upgraded Arctic-spec batteries (-60°C electrolyte); reinforced bumper assemblies; 50mm wider tires (12.00R20) for snow traction |

| Southeast Asia | High-humidity corrosion resistance; narrow road agility | Marine-grade chassis galvanization; reduced turning radius (21.5m) via axle recalibration; tropicalized electrical harnessing |

Technical Differentiation: Beyond “Used Truck” Label

SEA LION’s value derives from industrial-grade reconditioning, not mere resale:

– OEM Parts Compliance: 100% SINOTRUK/SHACMAN/XCMG-certified components (e.g., reconditioned HW19710 transmissions).

– Logistics Precision: RO-RO vessel slotting for 25+ units/voyage; containerized CKD kits for remote assembly (40ft HC container fits 3 disassembled cabs).

– Transparency Protocol: Digital twin records (pre-refurbishment diagnostics, parts traceability, post-refurbishment dyno reports) accessible via client portal.

Conclusion

For fleet managers operating in resource extraction or infrastructure development, SEA LION’s Tyler, TX inventory pool delivers proven mechanical resilience calibrated to the environmental and logistical constraints of emerging markets. The preference in Africa, Russia, and Southeast Asia stems from demonstrable operational fit—where uptime trumps initial cost—and our commitment to technical transparency. This model enables capital allocation toward core operations, not contingency maintenance, establishing the foundation for long-term partnership in high-asset-utilization sectors.

SEA LION International Trade Co., Ltd. — Engineering Reliability Across 127 Countries Since 2006

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks – Tyler, TX Market

This report provides a comprehensive technical assessment of used heavy-duty trucks currently available in the Tyler, TX market. The evaluation focuses on units equipped with the Weichai WD615 engine platform and common drivetrain configurations observed in regional freight and construction operations. Data is compiled from verified inventory sources and performance benchmarks for operational planning and fleet procurement decisions.

Standardized Technical Specifications – Used Heavy-Duty Trucks (Tyler, TX)

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615.69 / WD615.68 | 6-cylinder, inline, water-cooled diesel; common in Sinotruk HOWO platforms |

| Displacement | 9.726 L | High-torque design optimized for on/off-road hauling |

| Horsepower | 336 hp @ 2,200 rpm | Peak output; suitable for 40–50-ton GCW operations |

| Max Torque | 1,400 N·m @ 1,200–1,600 rpm | Enables strong gradeability and low-speed pulling force |

| Transmission | HW19710 (10-speed manual) | 10 forward, 2 reverse; robust synchromesh; widely serviced in TX |

| Clutch | 430 mm diaphragm | High durability under continuous load |

| Front Axle Load | 7,000 kg (15,432 lbs) | Parabolic leaf suspension; suitable for rough site access |

| Rear Axle Load | 2 × 13,000 kg (28,660 lbs each) | Dual reduction, hypoid gear; rated for 26,000 kg tandem capacity |

| Suspension | Multi-leaf spring (front & rear) | Designed for high GVWR and uneven terrain |

| Tire Specifications | 12.00R20 18PR (Load Range G) | Radial, all-position; standard on 6×4 configurations; 3,600 kg per tire |

| Braking System | Dual-circuit air brake (S-cam) | Drum brakes on all wheels; ABS optional on newer units |

| GVWR | Up to 49,000 kg (108,025 lbs) | Dependent on chassis configuration and body integration |

| Fuel Tank Capacity | 300–400 L (80–105 US gal) | Dual-tank option common for extended hauls |

Fuel Efficiency Analysis

Fuel consumption for trucks equipped with the Weichai WD615 engine and HW19710 transmission under mixed operating conditions (50% highway, 50% urban/construction access) averages:

- Fuel Consumption: 28–34 L/100 km (6.9–8.3 mpg US)

- Optimal Efficiency Range: Achieved between 1,400–1,800 rpm in top gears

- Emissions Compliance: Typically meets China III (equivalent to EPA 2005) standards; not EPA 2010+ compliant

Fuel Efficiency Notes:

– The WD615 engine’s mechanical fuel system offers reliability but lags modern common-rail systems in precision and economy.

– Proper driver training in gear optimization with the HW19710 can improve fuel economy by up to 12%.

– Retrofitting with auxiliary fuel monitoring systems (e.g., CAN-based telematics) is recommended for fleet tracking.

Load Capacity & Operational Suitability

| Configuration | Typical Load Capacity (Payload) | Recommended Use Case |

|---|---|---|

| 6×4 Dump Truck | 25–35 tons | Aggregate hauling, pit-to-plant transport |

| 6×4 Tractor (53′ trailer) | 30–40 tons GCW | Regional freight, lumber, steel coils |

| 6×4 Mixer/Boom Truck | 8–10 cubic yards concrete | On-site batching and delivery |

Structural Notes:

– Chassis frames are typically 8+8 mm high-tensile steel, suitable for re-bodying or crane integration.

– Rear overhang and approach/departure angles must be evaluated for off-road site access.

– Tire load margin: 12.00R20 tires provide ~15% reserve capacity at rated axle loads.

Summary Recommendations

- Fleet Managers: Prioritize units with documented service history, especially clutch and transmission maintenance. The HW19710 is durable but sensitive to improper shifting.

- Construction Firms: Opt for models with upgraded suspension packages and reinforced subframes for dump or crane applications.

- Fuel Strategy: Consider on-site bulk fueling and driver efficiency programs to offset higher consumption vs. modern EPA-compliant engines.

- Maintenance Readiness: Weichai and Fast (HW) components are supported across Texas via third-party networks; OEM parts availability is moderate.

Units meeting these specifications offer cost-effective entry into medium-duty hauling with proven mechanical resilience in demanding environments. Due diligence in pre-purchase inspection is advised, particularly for EGR and cooling system integrity.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: REFURBISHED COMMERCIAL TRUCKS

EQUIPMENT CLASS: Class 6-8 Vocational & Highway Tractors

REPORT YEAR: 2026

TARGET AUDIENCE: Fleet Operations Managers, Construction Equipment Procurement Officers

EXECUTIVE SUMMARY

SEA LION International delivers certified pre-owned commercial trucks meeting rigorous operational standards for demanding industrial applications. Our Tyler, TX refurbishment facility processes units exclusively for construction, aggregate, and heavy hauling fleets, ensuring 95%+ operational readiness at 40-60% of new asset cost. All units undergo 127-point validation against FMCSA §396.3 and SAE J2537 protocols.

REFURBISHMENT PROCESS: CORE STEPS & TECHNICAL STANDARDS

1. ENGINE & GEARBOX TESTING

All powertrains undergo SEA LION’s Tier-4 Validation Protocol (SL-TP-2026-01)

| Test Parameter | SEA LION Standard | Industry Baseline | Pass/Fail Threshold |

|---|---|---|---|

| Compression Differential | ≤ 8% variance across cylinders | ≤ 15% variance | >10% = Rebuild Mandatory |

| Oil Analysis | ISO 4406:2021 Code ≤ 18/16/13 | No standard | >20/18/15 = Rebuild |

| Dyno Load Test | 100% rated torque @ 1,200 RPM (Sustained) | 90% rated torque | <98% = Rebuild |

| Gearbox Shift Cycles | 1,000 automated cycles (0-10th gear) | Manual spot-check | >3 shift faults = Rebuild |

Process Flow:

– ECU diagnostics (SAE J1939 compliance scan)

– 3-stage fluid analysis (spectrometric, viscosity, contamination)

– 2-hour dyno stress test with thermal imaging

– Gearbox disassembly for bearing/bushing inspection (micron-level wear measurement)

2. CABIN REPAINTING

Compliant with ASTM D4585/D5895 for industrial corrosion control

| Stage | Specification | Validation Method |

|---|---|---|

| Surface Prep | SSPC-SP10/NACE No. 2 (Near-White Metal) | Visual & profilometer (50-75μm anchor profile) |

| Primer Application | Epoxy zinc-rich (75μm DFT) | Elcometer 456 verification |

| Topcoat | Polyurethane (120μm DFT, RAL 7040) | Salt spray test (ASTM B117: 1,000 hrs @ 35°C) |

| Curing | Forced-air oven (80°C for 4 hrs) | FTIR spectroscopy |

Critical Control: All weld seams receive additional corrosion-inhibiting tape (3M™ Scotchkote™ 230) prior to priming.

3. NEW TIRES & BATTERY REPLACEMENT

Performance-matched to construction site requirements

| Component | SEA LION Specification | Application Match |

|---|---|---|

| Tires (Steer/Drive) | Michelin X Works™ D (295/75R22.5) | On/off-road mixed (TL-10) |

| Tires (Trailer) | Bridgestone M840™ (11R22.5) | Aggregate hauling (E4) |

| Battery System | Dual 8D Group (Odyssey® 31-PC2150) | Cold-cranking ≥ 2,000 CCA |

| Electrical Validation | Load test @ 150A for 30 mins (voltage ≥12.4V) | Digital multimeter log |

Note: All tires mounted on bead-blasted, magnafluxed wheels with dynamic balancing (≤ 15g tolerance).

4. CHASSIS REINFORCEMENT

Exceeds SAE J2047 structural integrity requirements

| Procedure | Technical Execution | Validation |

|---|---|---|

| Frame Inspection | Ultrasonic thickness testing (every 12″) | Min. thickness: 8.5mm (Grade 80 steel) |

| Crack Repair | TIG-welded patch plates (ASTM A572 Gr.50) | Dye penetrant inspection (ASTM E1417) |

| Cross-member Upgrade | Added 2x reinforced brackets (6mm gussets) | FEA simulation (20% load increase) |

| Corrosion Treatment | Cavity wax injection (3M™ Corroseal™) | Salt fog test (ISO 9227) |

Critical Focus: All suspension mounting points reinforced to 125% of original OEM torque specs.

SEA LION QUALITY ASSURANCE PROTOCOL

- Inspection Frequency: Every component checked at 3 stages (pre-disassembly, mid-process, final)

- Documentation: Digital twin created with torque logs, fluid reports, and thermal images (accessible via QR tag)

- Final Validation: 500-mile road test with:

- 72-hour continuous idle cycle

- 80% GVWR load test on graded terrain

- ABS/ESC system verification per FMVSS 121

OPERATIONAL ADVANTAGE FOR CONSTRUCTION FLEETS

| Metric | SEA LION Refurbished | Typical Used Market |

|---|---|---|

| Mean Time Between Failures | 8,200 miles | 3,500 miles |

| Residual Value (36 mos) | 52% | 31% |

| Downtime Risk | ≤ 4.2% | ≥ 18.7% |

| Source: 2025 Construction Fleet Reliability Index (CFRI) |

CONCLUSION

SEA LION’s Tyler, TX refurbishment process transforms used truck assets into operationally certified equipment meeting the structural, environmental, and durability demands of construction logistics. Our SL-TP-2026-01 protocol delivers quantifiable TCO reduction through elimination of latent failure points inherent in standard used-truck sales. All units ship with 12-month/150,000-mile powertrain warranty and corrosion coverage.

SEA LION International — Engineering Reliability Since 1987

Report Code: SL-RPT-REFURB-TY-2026

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Used Trucks (Tyler, TX Market) from China

1. Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container shipping—for the export of used heavy-duty trucks from Chinese ports to Tyler, TX, USA. The analysis focuses on cost-efficiency, transit reliability, vehicle integrity, and corrosion mitigation. Special attention is given to wax-based protective coatings to prevent seawater-induced corrosion during transit.

2. Market Context

China has emerged as a major exporter of reconditioned commercial vehicles, including used dump trucks, tractors, and utility trucks, sourced from domestic decommissioning and fleet upgrades. These units are increasingly in demand in secondary markets such as Tyler, TX—a regional hub for oilfield logistics, road construction, and heavy hauling operations. Efficient and protective export logistics are critical to maintaining resale value and operational readiness upon arrival.

3. Shipping Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container |

|---|---|---|---|

| Vehicle Type Suitability | Operational trucks only | All types (operational or non-operational) | All types, including oversized units |

| Loading Mechanism | Self-driven onto vessel | Crane-lifted or forklift-loaded | Crane-lifted onto open-frame container |

| Stowage Density | High (efficient stacking) | Moderate (depends on vessel layout) | Low (requires container space) |

| Port Infrastructure | Requires RO-RO terminal | Standard bulk terminal | Standard container terminal |

| Transit Time (China → US Gulf) | 28–35 days | 30–40 days | 32–38 days |

| Average Cost per Unit (USD) | $1,800–$2,400 | $1,500–$2,000 | $2,600–$3,500 |

| Risk of Physical Damage | Low (minimal handling) | Moderate (crane handling risks) | High (exposed to weather, shifting) |

| Corrosion Exposure Risk | High (open decks, salt spray) | High (unprotected stowage) | Moderate (partial exposure) |

| Insurance Complexity | Standard | Moderate | High (due to exposure) |

| Customs Clearance | Streamlined | Standard | Container-based documentation |

4. Corrosion Protection: Wax Spraying System

4.1. Requirement

Extended sea voyages expose used trucks to high-humidity, salt-laden environments, accelerating corrosion on undercarriages, brake lines, electrical housings, and structural joints.

4.2. Recommended Solution: Temporary Wax-Based Corrosion Inhibitor

- Product Type: Solvent-based, hydrophobic wax spray (e.g., Dinitrol AV-17, Corrosion-X Heavy Duty)

- Application Points:

- Frame rails and crossmembers

- Suspension components

- Wheel hubs and brake assemblies

- Exhaust system hangers

- Electrical connectors (non-conductive formula)

- Film Thickness: 50–75 microns (uniform coat)

- Duration of Protection: Up to 6 months (marine environment)

- Removal: Biodegradable citrus-based degreaser upon arrival

4.3. Application Protocol

- Pre-treatment: High-pressure wash and dry (remove salt, dust, grease).

- Apply wax spray in climate-controlled hangar (15–25°C, <60% RH).

- Seal all cabin and engine bay air intakes with plastic caps.

- Document application with batch traceability for QA compliance.

Note: Wax spraying is mandatory for all shipping methods under SEA LION International’s 2026 Logistics Compliance Standard (SL-ICS-2026-TRK-03).

5. Method Recommendation by Use Case

| Client Profile | Recommended Method | Rationale |

|---|---|---|

| Fleet Managers (5+ operational trucks) | RO-RO | Cost-effective, rapid loading, minimal mechanical stress. Ideal for drivable units. |

| Construction Firms (Oversized or non-running units) | Flat Rack | Accommodates cranes, excavators, or inoperable trucks. Secure lashings possible. |

| Budget-Conscious Buyers (Mixed fleet) | Bulk Cargo | Lowest cost per unit; suitable when time and handling risks are acceptable. |

6. Port Routing (China → Tyler, TX)

- Origin Ports (China): Shanghai, Qingdao, Guangzhou (all offer RO-RO and container terminals)

- Destination Port: Port of Houston, TX (closest deep-water port with rail/truck connectivity to Tyler, 180-mile overland leg)

- Inland Logistics: Pre-arranged heavy-haul trailers (lowboys) for final delivery to Tyler staging yards.

7. Compliance & Documentation

All shipments must include:

– Bill of Lading (B/L) with cargo manifest

– Certificate of Origin (China CO)

– EPA/DOT Import Compliance Form 3520-1 (for pre-1995 vehicles, if applicable)

– Wax Application Certificate (per SL-ICS-2026-TRK-03)

– Pre-shipment Inspection Report (PSI) by third-party auditor (SGS or BV)

8. Conclusion

For optimal balance of cost, safety, and asset preservation in exporting used trucks from China to Tyler, TX:

– RO-RO is preferred for operational fleets.

– Flat Rack is necessary for non-standard or inoperable units.

– Bulk Cargo remains a viable budget option with enhanced risk mitigation.

Universal application of industrial-grade wax spraying is non-negotiable to ensure corrosion resistance during 30+ day trans-Pacific transit. SEA LION International enforces this as part of its certified export protocol.

Document Control

Prepared by: SEA LION International – Global Logistics Engineering Division

Revision: 2026.0

Effective Date: January 1, 2026

Classification: Industrial Use Only – Distribution Restricted

Get a Quote for Used Trucks For Sale Tyler Tx

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]