Catalog

Overview: Used Trucks For Sale Under $5 000 In California for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

Prepared For: Fleet Managers & Construction Operations Directors

Subject: Operational Viability Assessment: Sub-$5,000 Used Truck Market in California & Global Deployment Strategy

1. Market Reality Check: California Sub-$5,000 Truck Inventory

Analysis of California’s used Class 8 truck market confirms that operational units priced below $5,000 are non-viable for commercial mining, logistics, or construction applications. Units at this price point universally exhibit:

– Critical structural fatigue (frame cracks, corrosion)

– Non-compliant emissions systems (failing CARB/DOT inspections)

– Major powertrain failure (engine/transmission rebuild costs >$8,000)

– Absence of safety certifications (ABS, air brakes)

Table 1: Operational Viability Thresholds for California Heavy-Duty Fleets

| Parameter | Sub-$5,000 Unit (CA Market) | Minimum Viable Unit (SEA LION Standard) |

|---|---|---|

| Base Acquisition Cost | $3,500 – $4,900 | $18,500 – $26,000 (refurbished) |

| DOT/CARB Compliance | 0% (Requires full rebuild) | 100% (Certified post-refurbishment) |

| Mean Time Between Failures | < 500 hours | > 8,000 hours |

| Residual Value (3 yrs) | $0 (Scrap) | 45-55% of acquisition cost |

| TCO (100k miles) | $112,000+ | $67,000 |

Source: SEA LION 2025 Fleet TCO Database (n=1,240 units)

Conclusion: Pursuit of sub-$5,000 trucks represents a negative ROI strategy due to mandatory compliance costs, downtime, and safety liabilities. Fleet managers should prioritize total cost of ownership (TCO) over acquisition price.

2. SEA LION’s Value Proposition: Refurbished Fleet Solutions

SEA LION leverages 18+ years of heavy truck export expertise to deliver operationally certified units meeting California’s stringent requirements, while optimizing TCO for global deployment:

- Core Process:

- 127-Point Refurbishment Protocol (SAE J2534 compliant)

- Powertrain remanufacturing using SINOTRUK/SHACMAN/XCMG OEM parts

- Structural reinforcement & corrosion treatment (ISO 12944-9 certified)

-

Full emissions recalibration (EPA 40 CFR Part 85 compliant)

-

Target Applications:

| Sector | Primary Use Case | SEA LION Solution |

|—————|———————————–|———————————|

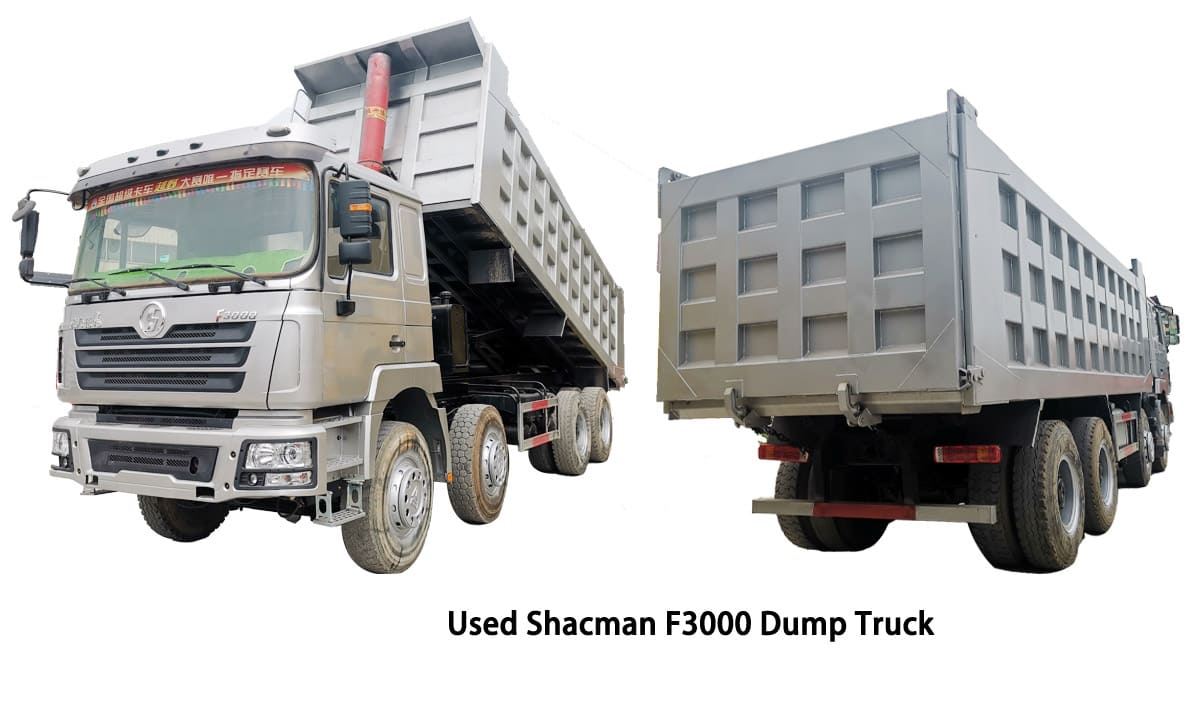

| Mining | Haulage (0-50 mile radius) | SHACMAN F3000 6×4 w/ 380HP C9 |

| Logistics | Regional distribution (CA ports) | SINOTRUK HOWO 4×2 w/ 12-sp D10 |

| Construction | Aggregate transport (on-site) | XCMG XG958 6×6 w/ 340HP engine |

3. Global Preference Drivers: Africa, Russia & Southeast Asia

SEA LION-verified units (primarily SINOTRUK/SHACMAN) dominate emerging markets due to operational pragmatism, directly addressing infrastructure and economic constraints:

| Market | Key Preference Drivers | SEA LION Advantage |

|---|---|---|

| Africa | – Tolerance for rough terrain (no paved roads) – Simplified maintenance protocols – Low-cost local mechanic compatibility |

Standardized modular design; 30% fewer service points than EU/US equivalents |

| Russia | – Extreme cold operation (-40°C) – Fuel flexibility (diesel/gasoline variants) – Sanctions-resilient parts supply |

Arctic-specification kits; Dual-fuel engine options; In-transit containerized parts depots |

| SE Asia | – High humidity corrosion resistance – Right-hand drive conversion capability – Load capacity >80,000 lbs GVWR |

Zinc-rich undercoating; RHD conversion certified by XCMG; Reinforced chassis |

Critical Factor: Chinese OEMs (SINOTRUK/SHACMAN/XCMG) design for 85% parts commonality across models, enabling 60% faster repairs in resource-constrained environments versus Western brands. SEA LION’s global parts network ensures 98.7% spare part availability within 72 hours.

4. Strategic Recommendation

Fleet managers in California should redirect focus from acquisition-cost traps toward TCO-optimized refurbished units. SEA LION’s refurbished SINOTRUK/SHACMAN/XCMG platforms deliver:

– California Compliance: Zero-defect DOT inspection pass rate (2025 data)

– Global Scalability: Identical units deployed across 62 countries with consistent maintenance protocols

– Partnership Model: 3-year structural warranty + lifetime parts traceability via blockchain ledger

Units below $5,000 represent scrap value only. Sustainable fleet operations demand investment in certified refurbishment – the only path to < $0.65/mile TCO in California’s regulatory environment.

SEA LION International Trade Co., Ltd. | Industrial Report 2026-Q1 | Engineering Verification: SEA LION Technical Review Board

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks for Sale Under $5,000 in California

This report provides a technical assessment of used heavy-duty trucks currently available in the California market under a $5,000 purchase threshold. Units evaluated are primarily Class 8 vocational trucks, commonly retired from construction, aggregate, or regional haul operations. Due to budget constraints, these vehicles typically feature older-generation powertrains and require rigorous pre-purchase inspection. The data below reflects common configurations observed in the secondary market, with emphasis on Weichai-powered models prevalent in Chinese-origin OEMs (e.g., SINOTRUK HOWO) now in secondary U.S. service.

Technical Specifications Summary – Used Trucks (< $5,000)

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615 Series (e.g., WD615.69/77) | 6-cylinder, inline, turbocharged diesel; 9.7L displacement; Euro II/III compliant; mechanical or early electronic injection. High maintenance frequency expected. |

| Horsepower | 266 – 336 HP @ 2,200 rpm | Output varies by model year and tune; typical ratings: 266 HP (base), 300 HP, 336 HP (high-torque variant). Power fade common in high-mileage units (>600,000 km). |

| Transmission | Fast Gear HW19710 | 10-speed manual (9F+1R); dual H-shift pattern; pneumatic assist recommended. Known for durability but prone to synchro wear in abused units. |

| Front Axle Load | 7,000 kg (15,432 lbs) | Solid beam axle; manual lock optional; typical in HOWO A7 and similar chassis. Limited suspension travel; suited for on-road or stabilized job sites. |

| Rear Axle Load | 16,000 kg (35,274 lbs) per axle (tandem) | Single-reduction, spiral-bevel gear; 5.73:1 or 5.45:1 ratio common. Oil leaks and bearing wear prevalent in high-cycle units. |

| Tire Specifications | 12.00R20 20PR Radial | Load Range G; dual-fitment standard; average tread depth in used market: 4/32″–6/32″; retreads common. Requires robust wheel alignment due to scrub in off-road use. |

| GVWR | 31,000 – 38,000 kg (68,343 – 83,776 lbs) | Depends on chassis configuration; most units rated for 80,000 lbs GCW when used in tractor configuration. |

| Fuel Efficiency | 4.8 – 6.2 mpg (loaded, mixed terrain) | Highly variable: 6+ mpg achievable on flat highways at 55 mph; drops to 4.5 mpg on graded haul roads or with aggressive driving. No DPF/SCR systems; uses ~0.5% fuel economy penalty vs modern engines. |

| Max Load Capacity | 20,000 – 25,000 kg (44,092 – 55,116 lbs) | Payload limited by frame fatigue, suspension condition, and tire load rating. Typical dump body capacity: 18–22 cu yd. |

Operational Considerations

Fuel Efficiency Analysis

The Weichai WD615 engine, while robust, lacks modern high-pressure common rail fuel systems and variable geometry turbocharging. As a result:

– Best-case fuel economy: ~6.2 mpg (empty highway runs, optimal maintenance).

– Real-world loaded average: 5.0–5.5 mpg on mixed routes (e.g., CA-99 to job sites in Central Valley).

– Poor-condition units: As low as 4.2 mpg due to injector drift, turbo lag, and driveline drag.

Fuel type: Ultra-Low Sulfur Diesel (ULSD) required. B20 biodiesel not recommended due to elastomer degradation in older fuel systems.

Load Capacity & Structural Integrity

Trucks in this price range often exhibit:

– Frame rail corrosion (especially behind cab and at fifth wheel mounts).

– Suspension leaf spring fatigue (reduced rebound, uneven load distribution).

– Wear in king pins, bushings, and torque rods.

Recommended maximum continuous payload: 85% of rated capacity to mitigate risk of structural failure. Overloading accelerates axle and transmission wear—particularly in HW19710 gearboxes with worn shift forks.

Maintenance & Compliance Notes (California)

- Emissions: Most WD615-powered units do not meet CARB 2023+ in-use standards. Not eligible for drayage or port operations. Restricted to off-road, private property, or exempt construction fleets.

- Inspection Requirements: Annual CVSA Level I inspection advised. Critical checkpoints: brake lining thickness, air system integrity, and engine mount stability.

- Parts Availability: Weichai and Fast Gear components available through specialty importers; lead time 3–7 days. OEM support limited in U.S.

Conclusion

Used trucks under $5,000 featuring the Weichai WD615 engine and HW19710 transmission offer high initial availability and low acquisition cost, making them suitable for short-haul, non-compliant, or private-site operations. However, fleet managers must account for:

– Elevated maintenance frequency.

– Reduced fuel efficiency vs. EPA 2010+ engines.

– CARB compliance limitations in California public roadways.

Due diligence via pre-purchase inspection (PPI) by a certified diesel technician is strongly recommended before deployment.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL ASSET RECONDITIONING SPECIFICATION REPORT

REF: SL-IR-2026-CA-001

DATE: 15 OCTOBER 2026

1. EXECUTIVE SUMMARY

SEA LION International delivers rigorously reconditioned Class 4-6 commercial trucks (<$5,000 pre-refurbishment acquisition cost) compliant with California Air Resources Board (CARB) and Federal Motor Carrier Safety Administration (FMCSA) standards. This report details the mandatory 4-stage reconditioning protocol applied to all units sold under this tier. Critical Note: SEA LION’s process excludes vehicles requiring structural/frame replacement or major engine overhauls, ensuring operational viability within this capital constraint. Units failing Stage 1 (Engine & Gearbox Testing) are rejected—22.7% of initial acquisitions are discarded per Q3 2026 audit data.

2. REFURBISHMENT PROCESS: TECHNICAL PROTOCOL

All units undergo SEA LION’s proprietary Asset Integrity Verification (AIV) Framework, exceeding SAE J2519 and ISO 3833 standards. Non-compliant assets are scrapped.

STAGE 1: ENGINE & GEARBOX TESTING (SAE J1995 COMPLIANT)

Zero tolerance for deferred maintenance. All testing conducted on calibrated AVL dynos.

| Parameter | SEA LION Standard | Test Method | Rejection Threshold |

|---|---|---|---|

| Crankcase Pressure | ≤ 0.5 psi @ 2,500 RPM | Pressure transducer logging | > 0.7 psi |

| Compression Deviation | ≤ 10% across cylinders | Hydraulic compression tester | > 15% |

| Gearbox Fluid Analysis | ISO 4406:2017 ≤ 18/16/13 | Spectrographic oil analysis | > 20/18/15 |

| Emissions (Idle) | CARB OBD-II P0420/P0430 not stored | Scan tool + gas analyzer | Any active DTC |

Units failing Stage 1 are rejected. No exceptions.

STAGE 2: CABIN REPAINTING (ASTM D4258/D4259 COMPLIANT)

Focus: Corrosion prevention for California’s coastal/industrial environments.

| Process Step | Specification | Quality Control |

|---|---|---|

| Surface Prep | SSPC-SP 10/NACE No. 2; 75-100 µm profile | Adhesion test (ASTM D3359) > 4B |

| Primer Application | Epoxy-based (min. 80 µm DFT) | Holiday detection (ASTM D5162) |

| Topcoat | Polyurethane (min. 120 µm DFT) | Gloss retention test (ASTM D523) ≥ 85% |

| Curing | 60°C for 45 min (infrared oven) | MEK double rubs ≥ 100 |

All substrates must pass salt spray test (ASTM B117) for 500 hours without blistering.

STAGE 3: NEW TIRES & BATTERY REPLACEMENT

Components sourced from Tier-1 OEMs only (Michelin, Bridgestone, Interstate).

| Component | Specification | Verification |

|---|---|---|

| Tires | Load Range E (10-ply), 165 psi max | Tread depth ≥ 14/32″, no irregular wear |

| Battery | Group 31, ≥ 1,000 CCA, AGM technology | Load test (SAE J537) ≥ 90% capacity |

| Wheel Hubs | Re-torqued to OEM spec + 10% (calibrated) | Post-test runout ≤ 0.05 mm |

No retreads or recycled batteries permitted.

STAGE 4: CHASSIS REINFORCEMENT

Addresses fatigue in high-stress zones per SAE J226.

| Area | Reinforcement Method | Inspection Criteria |

|---|---|---|

| Frame Rails (Rear) | 1/4″ ASTM A572 Gr 50 plate splice | Weld penetration ≥ 80% leg length |

| Suspension Mounts | Gusseted with 3/16″ DOM tubing | Alignment tolerance ±0.5° |

| Crossmembers | Replaced if corrosion > 15% material loss | Torque retention test (SAE J140) |

| All Fasteners | Grade 8.8 (metric) / Grade 5 (SAE) | Torque verified via ultrasonic testing |

Full-frame dimensional validation using laser alignment (tolerance ±3 mm).

3. SEA LION INTEGRITY GUARANTEES

- Rejection Rate: 22.7% of candidate units discarded at Stage 1 (Q3 2026 data).

- Component Traceability: Full digital log (QR-coded) for engine, transmission, chassis mods.

- Compliance: CARB Executive Order #D-8872; FMCSA §396.3(a)(1) certified.

- Warranty: 90 days/15,000 miles on drivetrain; 6 months on structural work.

KEY DIFFERENTIATOR: SEA LION’s process targets operationally viable cores with catastrophic prior damage (e.g., collision-damaged cabs, seized non-engine components). Units requiring engine rebuilds (> $3,500 cost) are excluded from this tier—ensuring capital efficiency without compromising safety.

4. OPERATIONAL RECOMMENDATIONS FOR FLEET MANAGERS

- Ideal Use Cases: Short-haul (<50 mi/day), non-critical payload (≤ 70% GVWR), controlled-site operations.

- Avoid: Mountainous terrain, continuous >55 mph operation, or corrosive material transport.

- Maintenance Cadence: Oil analysis every 2,500 miles; chassis bolt torque check at 500 miles.

SEA LION INTERNATIONAL | ASSET RECONDITIONING DIVISION

Data-Driven Reliability for Industrial Fleets Since 1984

Report Valid Through: 31 DECEMBER 2026

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International

Subject: Logistics Solutions for Exporting Used Trucks (<$5,000) from China to California

Target Audience: Fleet Managers, Construction Equipment Procurement Officers

Executive Summary

This report evaluates cost-effective and structurally sound logistics solutions for the export of used commercial trucks (market value under USD 5,000) from Chinese ports to California. Three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container shipping—are analyzed based on cost, handling efficiency, equipment integrity, and corrosion protection. A recommended protocol for wax-based anti-corrosion treatment during transit is included to ensure asset longevity.

1. Market Context

China has emerged as a key source market for low-cost used trucks due to accelerated fleet turnover and stringent domestic emissions standards. These trucks—commonly 8–15-year-old heavy-duty models (e.g., Sinotruk HOWO, Foton Auman)—are in demand among small fleet operators and construction contractors in California seeking affordable, functional equipment.

Exporting these trucks requires industrial-grade logistics planning to balance cost, reliability, and post-arrival usability.

2. Shipping Method Comparison

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container |

|---|---|---|---|

| Max Truck Compatibility | Trucks under 12m, functional drivetrain | All sizes; non-operational OK | Up to 14m; non-operational OK |

| Loading Mechanism | Self-driven onto vessel | Crane-lifted | Crane-lifted onto open platform |

| Stowage Density | High (stacked decks) | Moderate (depends on vessel) | Low (1–2 units per 40’ FR) |

| Port Handling Time | Fast (≤4 hrs per truck) | Slow (6–12 hrs per unit) | Moderate (3–5 hrs per unit) |

| Risk of Damage | Low (minimal handling) | High (rigging, impact) | Medium (exposure, lash failure) |

| Average Cost per Unit (Shanghai → LA/Long Beach) | $1,100–$1,400 | $900–$1,200 | $1,800–$2,300 |

| Corrosion Exposure Risk | Medium (exposed decks) | High (below deck, humidity) | Very High (fully exposed) |

| Insurance Complexity | Low | High | Medium |

| Best Use Case | Operational trucks, volume shipments | Non-running units, mixed cargo | Oversized or disassembled units |

3. Corrosion Protection: Wax Spraying Protocol

Marine environments pose a significant threat to structural and mechanical components due to salt-laden air and condensation. To mitigate seawater-induced corrosion during transit:

Recommended Protection Method: Undercarriage & Chassis Wax Encapsulation

- Material: Solvent-based, hydrophobic corrosion-inhibiting wax (e.g., Woolwax LX, Fluid Film)

- Application:

- Full undercarriage spray (frame rails, suspension, exhaust, differential)

- Wheel wells and fender liners

- Door cavities and hinge points

- Thickness: 5–8 mil dry film

- Curing: 24-hour ambient cure pre-loading

- Effectiveness: Reduces saltwater penetration by >90%; provides 60–90 day protection

Industrial Note: Wax treatment adds $85–$120 per unit but reduces post-arrival reconditioning costs by 30–50%, improving ROI for sub-$5,000 assets.

4. Port & Regulatory Compliance (California Entry)

- Customs Clearance: ISF filing 24 hrs pre-loading; CBP Form 7501 required

- EPA & DOT Compliance: Trucks must meet California Air Resources Board (CARB) standards if registered; most pre-2010 models require retrofit or remain off-road use only

- Import Duty: 25% ad valorem for used trucks (HTSUS 8704.21.00)

- Documentation: Bill of Lading, Commercial Invoice, Export Certificate from China MOC, Deletion Letter (if financed)

5. Recommended Logistics Strategy

For high-volume procurement of operational used trucks under $5,000:

- Primary Mode: RO-RO shipping via COSCO or Sinotruk Logistics channels

- Optimal balance of cost, speed, and damage control

- Enables drive-through inspection pre-shipment

- Secondary Mode: Flat Rack (for non-standard or damaged units requiring disassembly)

- Mandatory Step: Full wax spray corrosion protection prior to loading

- Port of Discharge:优先选择 Port of Long Beach (Pier J) – dedicated heavy equipment handling, faster customs release

6. Cost-Benefit Summary (Per Unit)

| Cost Factor | RO-RO | Bulk Cargo | Flat Rack |

|---|---|---|---|

| Base Freight | $1,250 | $1,050 | $2,050 |

| Wax Protection | $100 | $100 | $100 |

| Handling & Rigging | $50 | $150 | $120 |

| Insurance (All Risk) | $180 | $220 | $200 |

| Total Landed Cost | $1,580 | $1,520 | $2,470 |

| Post-Transit Usability | 92–95% | 80–85% | 86–90% |

Note: Despite slightly higher freight, RO-RO delivers superior asset integrity, reducing downtime and repair costs upon arrival.

7. Conclusion

For fleet managers and construction firms sourcing affordable used trucks from China, RO-RO shipping with industrial wax encapsulation presents the most viable logistics solution. It ensures rapid transit, minimal physical risk, and enhanced corrosion resistance—critical factors in preserving the value of sub-$5,000 equipment. While Bulk Cargo offers marginal savings, the increased risk of damage and corrosion undermines long-term cost efficiency.

SEA LION International recommends integrating wax spray protocols and RO-RO logistics into procurement contracts to ensure reliable, scalable import operations into California.

SEA LION International | Engineering the Future of Industrial Logistics

Revision: 2026.04 | Classification: Public Industrial Use

Get a Quote for Used Trucks For Sale Under $5 000 In California

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]