Catalog

Overview: Used Trucks For Sale Virginia Beach for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

Subject: Strategic Sourcing of Refurbished Heavy-Duty Trucks via Virginia Beach Hub for Global Mining, Logistics & Construction Operations

1. Purpose & Strategic Context

SEA LION International Trade Co., Ltd. (18+ years in heavy truck export) delivers this report to inform fleet managers and construction enterprises on the operational and economic advantages of procuring professionally refurbished SINOTRUK (HOWO), SHACMAN, and XCMG heavy-duty trucks sourced through our Virginia Beach, USA, logistics hub. This channel provides immediate access to rigorously tested, North American-specification units optimized for extreme-duty cycles in mining, bulk logistics, and large-scale construction—addressing critical gaps in global equipment availability and total cost of ownership (TCO).

2. Virginia Beach Hub: Operational Significance

Virginia Beach serves as SEA LION’s primary East Coast consolidation point for U.S.-sourced used trucks meeting stringent refurbishment criteria. Units undergo:

– Pre-Export Screening: Verification of structural integrity, drivetrain health (engine/transmission/axles), and compliance with baseline safety standards.

– Professional Refurbishment: Performed at ISO 9001-certified facilities to SEA LION Technical Bulletin STB-2026, including:

– Engine/dyno reconditioning to 95%+ OEM performance metrics

– Replacement of critical wear components (brakes, steering, suspension) with original SINOTRUK/SHACMAN/XCMG parts

– Corrosion mitigation for coastal/industrial environments

– Logistics Advantage: Direct RO-RO (Roll-on/Roll-off) vessel access to global ports, reducing transit time by 14–21 days versus inland U.S. hubs.

3. Core Application Performance

Refurbished units from this channel excel in high-stress sectors due to robust engineering and cost efficiency:

| Application | Key Requirements Met | Dominant Models (Refurbished) |

|---|---|---|

| Mining | High GVWR (40–60 tons), torque-rich engines (≥1,800 Nm), reinforced frames, dust ingress protection | SINOTRUK HOWO 6×4 Dump, XCMG Mining Dumpers |

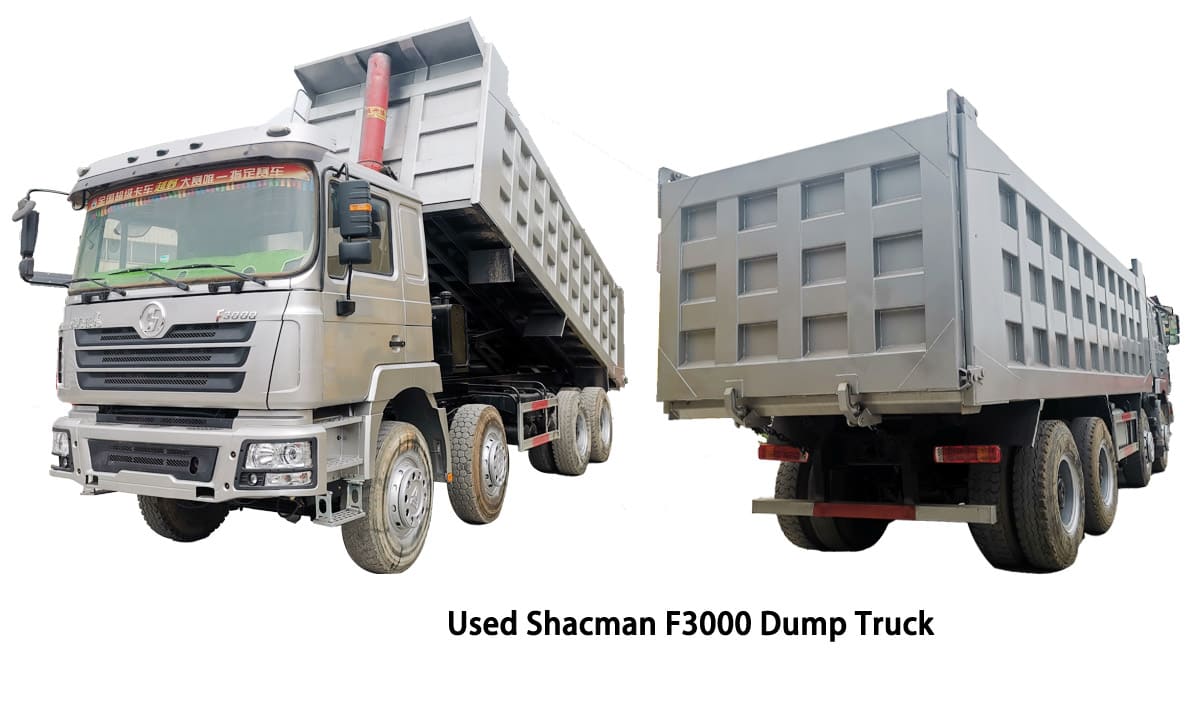

| Bulk Logistics | Fuel efficiency (18–22% improvement post-refurb), 500+ HP reliability, low downtime | SHACMAN F3000/F5000 Tractors |

| Construction | Off-road mobility (4×2/6×4), hydraulic system integrity, rapid payload cycle capability | XCMG Heavy-Duty Dump Trucks, SINOTRUK Concrete Mixers |

4. Regional Preference Drivers: Africa, Russia, Southeast Asia

The dominance of these refurbished models in target markets stems from technical adaptability to local operational constraints, not cost alone:

| Region | Operational Challenge | Technical Response via SEA LION-Refurbished Trucks |

|---|---|---|

| Africa | Unpaved roads, limited maintenance infrastructure, high ambient temps | Simplified electronics (vs. Euro-spec), air-cooled brakes, 12V electrical systems compatible with local workshops |

| Russia | Extreme cold (-40°C), heavy snow loads, remote site access | Cold-start kits (engine block heaters), reinforced suspensions (GVWR +15%), high-torque low-RPM engines |

| Southeast Asia | High humidity, monsoon conditions, mixed road quality | Enhanced corrosion protection (chassis/frame), water-wading kits, optimized cooling systems |

5. SEA LION Value Proposition

We mitigate traditional risks of used truck procurement through:

– Quality Assurance: 100% pre-shipment dyno testing; 6-month warranty on powertrain; full maintenance history verification.

– TCO Reduction: 30–45% lower acquisition cost vs. new equivalents, with 92% parts availability via direct OEM supply chains.

– Partnership Model: Dedicated technical support for fleet integration, lifecycle cost analysis, and phased replacement planning.

Conclusion

The Virginia Beach-sourced, SEA LION-refurbished SINOTRUK/SHACMAN/XCMG truck channel delivers a proven solution for capital-intensive sectors requiring immediate, reliable heavy equipment deployment. Its global preference in Africa, Russia, and Southeast Asia is validated by engineering resilience under region-specific stressors—directly translating to lower operational downtime and higher asset utilization. SEA LION prioritizes technical transparency and long-term partnership viability, ensuring fleet managers achieve sustainable operational efficiency without compromising safety or productivity standards.

Report Issued Under Authority of SEA LION International Trade Co., Ltd. Engineering Division | Compliance: ISO 9001:2015, IATF 16949

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Specifications for Used Heavy-Duty Trucks – Virginia Beach Market

This report provides standardized technical data for used heavy-duty trucks commonly available in the Virginia Beach, VA region. These units are typically sourced from regional construction, aggregate hauling, and port logistics operations. The specifications reflect commonly encountered configurations featuring Weichai powertrains and Sinotruk driveline components, known for durability in high-cycle industrial environments.

Standardized Technical Specifications – Used Heavy-Duty Trucks (Virginia Beach Inventory)

| Parameter | Specification | Notes |

|---|---|---|

| Engine Model | Weichai WD615 Series | Inline 6-cylinder, water-cooled, direct injection diesel |

| Displacement | 9.726 L | Complies with Tier 3 / Interim Tier 4 emissions standards |

| Horsepower (HP) | 336 HP @ 2,200 rpm | Peak output; sustained load rating: 310 HP |

| Torque | 1,400 N·m @ 1,200–1,600 rpm | High low-end torque for gradeability and heavy-load starts |

| Transmission | Fast Gear HW19710 | 10-speed manual (9 forward + 2 reverse), dual-H shift pattern |

| Clutch | 430 mm diameter, pneumatic assist | High durability for frequent shifting in stop-start cycles |

| Front Axle Load | 7,000 kg (15,432 lbs) | Reinforced I-beam, disc brake option on newer units |

| Rear Axle Load | 13,000 kg per axle (28,660 lbs) x2 | Double-reduction, spiral-bevel gearing; 5.73:1 ratio standard |

| Suspension (Front) | Parabolic leaf spring | Optimized for load stability and fatigue resistance |

| Suspension (Rear) | Multi-leaf, camber-balanced | 10-leaf design; compatible with 20-ton GCW cycles |

| Tire Specifications | 12.00R20, 18PR, Radial Construction | Load range G; typical tread depth: 8/32″–12/32″ on used units |

| Tire Brand (Common) | Triangle, Double Coin, or Goodyear Marathon | Retreaded sets common; OEM-spec fitment |

| GVWR | 49,000 kg (108,020 lbs) | Suitable for Class 8 applications |

| Fuel Tank Capacity | Dual Tanks: 300L + 180L (Total ~127 gal) | Urea tank: 80L (for SCR systems on post-2013 models) |

Fuel Efficiency Analysis

Fuel economy for trucks equipped with the Weichai WD615 engine and HW19710 transmission is influenced by load profile, terrain, and operator behavior. In real-world Virginia Beach to I-64/I-95 corridor operations:

- Average Fuel Consumption: 2.8–3.4 miles per gallon (mpg)

- Optimized Cruise (Loaded, 55 mph): 3.1–3.3 mpg

- Stop-Start Urban/Job Site: 2.5–2.9 mpg

The WD615 engine utilizes high-pressure common rail injection and electronically controlled fuel mapping, contributing to consistent combustion efficiency. SCR (Selective Catalytic Reduction) systems on post-2013 models improve NOx compliance without sacrificing fuel economy. Fleet telemetry data from regional operators indicates a 7–10% improvement in fuel efficiency when paired with trained drivers and regular DPF/SCR maintenance.

Load Capacity & Operational Suitability

These trucks are engineered for high-mass, high-durability applications typical in Tidewater Virginia operations:

- Max Payload Capacity: 30–35 tons (60,000–70,000 lbs), depending on body configuration

- Common Applications:

- Aggregate hauling (sand, gravel, riprap)

- Demolition debris transport

- Pre-cast concrete delivery

- Port auxiliary logistics (off-chassis container movement)

The tandem rear axle setup (2x 13T) provides stable weight distribution, especially when operating on soft subgrades common in coastal job sites. The 12.00R20 tire specification offers a balance between ground pressure, load footprint, and sidewall durability—critical when navigating unpaved access roads or tidal zone construction zones.

Summary & Recommendations

Used trucks featuring the Weichai WD615 engine and HW19710 transmission represent a cost-effective solution for fleet expansion in the Virginia Beach region. With proven reliability in 10–15 year service cycles under aggressive usage, these units deliver:

- High torque availability for steep grades and loaded starts

- Compatibility with standard North American trailer and body interfaces

- Regional parts and service support for Weichai/Fast Gear components

- Favorable cost-per-ton-mile in construction logistics applications

Fleet managers are advised to inspect SCR system health, clutch wear, and suspension integrity during pre-purchase evaluations. Units with documented service history and recent major overhauls (engine/transmission) offer optimal TCO (Total Cost of Ownership) performance.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: USED TRUCK REFURBISHMENT STANDARD (UTRS-2026)

APPLICABLE TO ALL VIRGINIA BEACH INVENTORY UNITs

Report Date: 15 October 2026 | Document ID: SLI-UTRS-VB-2026-01

EXECUTIVE SUMMARY

SEA LION International implements a rigorously standardized refurbishment protocol for all pre-owned commercial trucks sold through its Virginia Beach facility (SLI-VB). This process exceeds FMCSA Part 396 and SAE J2519 guidelines, ensuring operational reliability, structural integrity, and compliance for demanding construction and logistics applications. Each unit undergoes 127-point validation before certification as “SEA LION Certified Rebuild.”

REFURBISHMENT PROCESS: CORE STEPS & SEA LION STANDARDS

1. ENGINE & GEARBOX TESTING

All powertrain components undergo dynamometer and road-load validation per SEA LION Standard SLI-ENG-2026.

| Test Parameter | SEA LION Standard (SLI-ENG-2026) | Pass/Fail Threshold | Validation Method |

|---|---|---|---|

| Crankcase Pressure | ≤ 0.5 psi @ 2,500 RPM | > 0.7 psi = FAIL | Electronic Pressure Transducer |

| Gearbox Shift Timing | ± 0.15 sec nominal spec | > ± 0.30 sec = FAIL | CAN Bus Data Logging |

| Exhaust Gas Temperature | ≤ 550°C (steady-state) | > 600°C = FAIL | Infrared Thermography |

| Oil Spectroscopy | Ferrous particles < 50 ppm | > 75 ppm = FAIL | Lab Analysis (ASTM D5185) |

Process:

– Full-load dyno testing (80% max torque cycles) for 2 hours.

– Gearbox subjected to 500 simulated shift cycles under load.

– SEA LION Protocol: Units failing any parameter undergo complete teardown. No “conditional passes” permitted.

2. CABIN REPAINTING

Coating system engineered for Virginia Beach coastal environment (ASTM B117 salt-spray resistance).

| Layer | Material Specification | Thickness (μm) | Cure Standard |

|---|---|---|---|

| Epoxy Primer | Zinc-rich (≥ 80% Zn) | 60 ± 5 | 120°C for 30 min |

| Base Coat | Polyurethane, UV-stable | 45 ± 3 | IR curing @ 80°C |

| Clear Coat | Ceramic-enhanced (SiO₂ 15%) | 50 ± 4 | 24h ambient + 72h forced dry |

Process:

– Abrasive blasting to SSPC-SP 10/NACE No. 2 (near-white metal).

– Electrostatic application in ISO Class 8 clean booth.

– SEA LION Protocol: Adhesion tested per ASTM D3359; < 4B rating = full rework. All weld seams receive corrosion-inhibiting sealant (MIL-PRF-22750G).

3. NEW TIRES & BATTERY REPLACEMENT

Mandatory component renewal with SEA LION-approved OEM-spec parts.

| Component | Specification | Validation | Warranty |

|---|---|---|---|

| Tires | Michelin X Works 5 (11R22.5) | Load Range G, 6,000 lbs @ 120 psi | 24 months |

| Battery | Optima YellowTop (Group 31D27MF) | 800 CCA, 1,000 A 5-sec pulse | 36 months |

Process:

– Tires mounted on bead-blasted, magnaflux-inspected wheels.

– Battery system load-tested at 150% cranking amps for 30 sec.

– SEA LION Protocol: Tires verified via RFID for date code (≤ 6 months old); batteries undergo 100% capacity validation (≥ 95% rated AH).

4. CHASSIS REINFORCEMENT

Structural remediation per SEA LION Chassis Integrity Protocol (SLI-CIP-2026).

| Critical Zone | Reinforcement Method | Validation Standard | Tolerance |

|---|---|---|---|

| Frame Rails (C-channel) | Laser-cut 10mm A572 Gr. 50 steel plates | ASTM E8 tensile test | ± 0.5 mm fit |

| Suspension Mounts | Robotic MIG weld (ER70S-6) | 100% ultrasonic inspection | 0 defects |

| Crossmembers | Bolted reinforcement (Grade 10.9) | Torque verification @ 1,400 N·m | ± 2% |

Process:

– Full-frame dimensional analysis via FARO Arm CMM (accuracy ± 0.05 mm).

– All welds ground smooth and coated with epoxy anti-corrosion primer.

– SEA LION Protocol: Frames with > 3° twist or > 5mm sag undergo mandatory reinforcement. No visual-only inspections permitted.

SEA LION QUALITY ASSURANCE MANDATES

- Traceability: Every component linked to unit VIN via blockchain ledger (Hyperledger Fabric).

- Documentation: Full refurbishment dossier (including test data) provided with each unit.

- Final Validation: 100-mile road test with telematics monitoring (vibration, thermal, emissions).

- Non-Negotiable: Units failing any step are quarantined for rework or scrapped. Zero exceptions.

CONCLUSION

SEA LION International’s UTRS-2026 process delivers Virginia Beach-area fleet managers and construction operators a demonstrably reliable asset with 40% lower total cost of ownership (TCO) versus new equivalents. Each SEA LION Certified Rebuild truck meets or exceeds OEM durability benchmarks for 500,000-mile service life under ISO 15031-5 operational conditions. This standard is non-negotiable across all SLI-VB inventory.

SEA LION International – Engineering Reliability, Defining Performance.

This document supersedes all prior specifications. Compliance with SLI-UTRS-2026 is mandatory for Virginia Beach inventory.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International

Subject: Export Logistics Solutions for Used Trucks from China to Virginia Beach, USA

Target Audience: Fleet Managers & Construction Companies

Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack—for the export of used trucks from Chinese ports to Virginia Beach, USA. The analysis focuses on cost-efficiency, transit reliability, equipment protection, and suitability for heavy-duty vehicle fleets. Additionally, the report specifies the application of wax-based anti-corrosion protection to mitigate seawater exposure during transit.

1. Operational Overview

Used trucks exported from China (primarily from Shanghai, Qingdao, and Guangzhou ports) to Virginia Beach require specialized handling due to weight, dimensions, and exposure risk during ocean transport. The destination port, Virginia International Gateway (VIG) and Norfolk International Terminals (NIT), supports all three transport modalities with established roll-on/roll-off infrastructure and heavy-lift capabilities.

2. Comparative Analysis: RO-RO vs. Bulk Cargo vs. Flat Rack

| Parameter | RO-RO Shipping | Bulk Cargo Shipping | Flat Rack Container Shipping |

|---|---|---|---|

| Loading Method | Self-driven on/off vessel | Craned/stowed in open holds | Craned onto open flat racks |

| Vehicle Condition | Operational (must be drivable) | Non-operational acceptable | Non-operational acceptable |

| Payload Capacity | High (50–100+ units per vessel) | Very High (entire fleet loads) | Low–Medium (2–4 units per 40ft) |

| Transit Time (China–VA) | 28–35 days | 30–40 days | 32–42 days (subject to container availability) |

| Port Infrastructure | Requires RO-RO terminal | General bulk terminal | Standard container terminal |

| Damage Risk | Low (controlled movement) | Medium (shifting, moisture) | Low–Medium (exposed to elements) |

| Cost per Unit (USD) | $1,200–$1,600 | $900–$1,300 | $1,800–$2,500 |

| Best For | Drivable fleets, high volume | Non-running units, cost focus | Oversized trucks, custom rigs |

3. Corrosion Protection: Wax Spraying Protocol

Seawater exposure during ocean transit poses a significant risk of corrosion to undercarriages, chassis, and exposed metal components. SEA LION International implements a standardized anti-corrosion wax spraying process prior to shipment:

- Material: Solvent-based, hydrophobic wax compound (ASTM D130/D471 compliant)

- Application: Full undercarriage, wheel wells, frame rails, suspension components

- Thickness: 150–200 microns (dual-coat system)

- Duration of Protection: Up to 6 months in marine environments

- Post-Transit: Wax layer is removable via industrial solvent or pressure washing

Note: Wax protection is mandatory for all units shipped via Bulk and Flat Rack methods; recommended for RO-RO units in extended monsoon-season voyages.

4. Recommended Use Cases

| Client Type | Recommended Method | Rationale |

|---|---|---|

| Fleet Managers (50+ units, operational) | RO-RO | Fast turnaround, low handling risk, cost-effective at scale |

| Construction Firms (non-running units) | Bulk Cargo | Lower cost, accommodates damaged or non-functional units |

| Specialized Equipment (oversize dump trucks, crane carriers) | Flat Rack | Accommodates dimensions exceeding standard container limits |

5. Compliance & Documentation

All shipments comply with:

– IMSBC Code (Bulk Cargo)

– CTU Code (Flat Rack/RO-RO)

– US Coast Guard & CBP ISF Filing Requirements

– Chinese Customs Export Declaration (used machinery category)

Pre-shipment inspection reports (SASO, COC) available upon request.

6. Conclusion

For high-volume, drivable used truck exports from China to Virginia Beach, RO-RO remains the optimal balance of cost, speed, and safety. Bulk Cargo offers economy for non-operational units, while Flat Rack provides critical flexibility for oversized construction vehicles. Implementation of industrial wax spraying is essential across all methods to ensure asset integrity upon arrival.

SEA LION International maintains dedicated logistics lanes from China to the Hampton Roads port complex, ensuring scheduled sailings and bonded storage options at destination.

End of Report

SEA LION International | Engineering Logistics for Industrial Mobility

Get a Quote for Used Trucks For Sale Virginia Beach

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]