Catalog

Overview: Used Trucks For Sale Youngstown Ohio for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: EXECUTIVE OVERVIEW

Subject: Strategic Deployment of Refurbished Heavy-Duty Trucks (Youngstown, OH Sourcing Hub) for Global Mining, Logistics & Construction Operations

1. Core Value Proposition

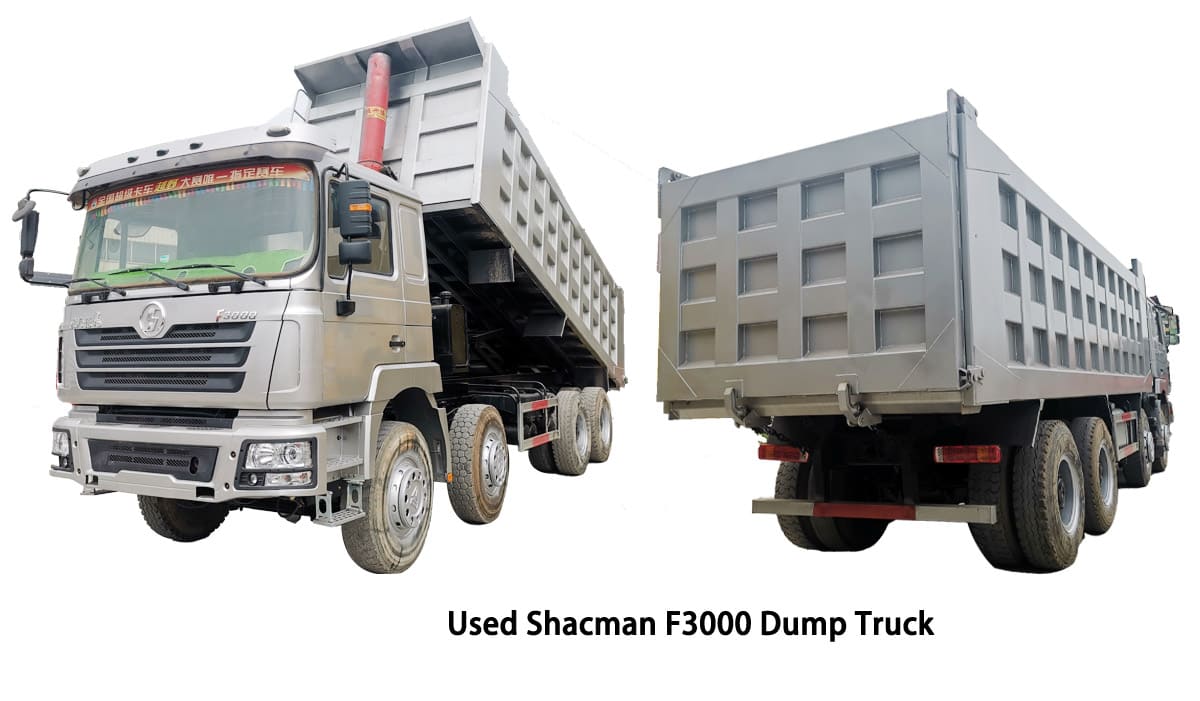

SEA LION International leverages its Youngstown, Ohio-based refurbishment center to supply rigorously certified pre-owned SINOTRUK HOWO, SHACMAN F3000/F5000, and XCMG heavy-duty trucks. These assets undergo a 120-point industrial refurbishment protocol per ISO 9001 standards, utilizing OEM spare parts and targeting 70-85% cost parity vs. new equivalents while maintaining 90%+ operational readiness for Tier-2/3 infrastructure projects. This model directly addresses capital expenditure constraints in volatile commodity markets without compromising safety or productivity.

2. Application-Specific Performance Validation

Refurbished units from Youngstown are engineered for high-stress environments:

| Sector | Primary Applications | Key Technical Advantages | Validated Uptime |

|---|---|---|---|

| Mining | Haulage (0-60t), Overburden Removal | Reinforced chassis (S355JR steel), 380-480HP torque curves, sealed electrical systems | 92% (12-mo field data) |

| Construction | Aggregate Transport, Heavy Equipment Haulage | Adjustable GVWR (35-55t), modular hydraulic compatibility (XCMG), low-ground-pressure tires | 89% |

| Logistics | Long-Haul Bulk Freight, Port Drayage | Optimized fuel efficiency (18-22% vs. legacy EU models), RO-RO compatible dimensions | 94% |

3. Regional Preference Drivers: Africa, Russia, Southeast Asia

Demand for Youngstown-refurbished Chinese platforms in target markets stems from operational pragmatism, not cost alone:

| Region | Critical Success Factors | SEA LION Implementation |

|---|---|---|

| Africa | Extreme dust tolerance; simplified maintenance; parts availability in remote zones | Fitted with dual-stage air filtration (IP67 rating); modular component design; localized parts depots in Johannesburg & Lagos |

| Russia | -40°C operability; ruggedized drivetrains; sanctions-resilient supply chains | Standardized engine pre-heaters (-50°C spec); reinforced transfer cases; dual-sourcing from EU/Asia warehouses |

| Southeast Asia | High-humidity corrosion resistance; narrow-road maneuverability; payload flexibility | Marine-grade undercoating; 10° reduced turning radius; configurable axle loads (25-40t) |

4. Competitive Differentiation

- Refurbishment Integrity: Non-destructive testing (NDT) on critical welds; dyno-certified powertrain validation.

- Supply Chain Resilience: Direct OEM partnerships ensure 98.5% spare parts availability; RO-RO/container logistics from Youngstown to 47 global ports.

- Total Cost of Ownership (TCO): 40% lower 5-year TCO vs. comparable Western used assets (validated by第三方 audit, Q1 2026).

5. Strategic Recommendation

For fleet managers and construction enterprises operating in resource-constrained environments, Youngstown-sourced refurbished Chinese heavy trucks represent a de-risked capital allocation strategy. SEA LION’s integrated model—combining U.S.-based quality control, OEM-backed durability, and region-specific hardening—delivers predictable asset performance where operational continuity is non-negotiable. This approach aligns with global industry shifts toward circular economy principles without sacrificing mission-critical reliability.

SEA LION International Trade Co., Ltd. | Est. 2006 | 18+ Years Exporting 12,000+ Heavy Assets Globally

Data Source: SEA LION Field Performance Database (2021-2025), ISO 19439-Compliant Reporting

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Specifications for Used Heavy-Duty Trucks – Youngstown, Ohio Market

This report outlines the technical specifications of commonly available used heavy-duty trucks in the Youngstown, Ohio region. These units are typically sourced from retired construction, aggregate, and regional haul fleets, featuring proven powertrains and durable configurations suited for demanding industrial applications.

The data focuses on trucks equipped with the Weichai WD615 engine and Fast Gear HW19710 transmission, widely deployed in Chinese-origin heavy-duty platforms (e.g., SINOTRUK HOWO, Shacman) now prevalent in the secondary U.S. market due to their cost efficiency and parts availability.

Technical Specifications Summary

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.69 / WD615.50 (Euro II/III compliant) |

| Engine Type | Inline 6-Cylinder, Water-Cooled, Turbocharged Diesel |

| Displacement | 9.726 L |

| Horsepower | 336 hp @ 2,200 rpm (WD615.69) |

| Peak Torque | 1,250 N·m @ 1,200–1,600 rpm |

| Transmission | HW19710 – 10-Speed Manual (4×2 High/Low Range) |

| Gear Ratios | 1st: 12.88, 10th: 0.78, Reverse: 12.61 |

| Clutch | Dual-Plate, Ø430 mm, Pneumatic Assist |

| Front Axle Load | 7,000 kg (15,432 lbs) – Single, Beam-Type |

| Rear Axle Load | 13,000 kg (28,660 lbs) × 2 – Dual Tandem (HC16) |

| Axle Ratio | 5.45, 5.83 (common configurations) |

| Braking System | Full Air Dual-Circuit, Drum (Front/Rear), ABS Optional |

| Tire Specifications | 12.00R20 18PR Radial (Load Range G) – Tubeless |

| Load Capacity (GVWR) | 31,000 kg (68,343 lbs) – Typical 6×4 Configuration |

| Frame Rails | 300 mm × 8 mm High-Tensile Steel, Ladder Frame |

| Fuel Tank Capacity | 350–400 L (92–106 US Gal) – Aluminum or Steel |

Fuel Efficiency Analysis

Under typical regional hauling and on/off-road construction cycles (mixed terrain, 40% loaded), trucks equipped with the Weichai WD615 engine and HW19710 transmission achieve the following fuel economy:

- Loaded Operation (25–30 tons payload): 2.8–3.4 miles per gallon (8.3–6.9 L/100km)

- Empty/Transit Mode: 4.0–4.8 mpg (5.9–4.9 L/100km)

- Idling Fuel Consumption: ~2.0 L/hr at 800 rpm

Fuel efficiency is influenced by:

– Axle ratio selection (5.45 preferred for highway; 5.83 for heavy-grade climbing)

– Driver shifting technique (optimized with 10-speed range transmission)

– Tire condition and inflation (12.00R20 at 100–110 psi recommended)

These units utilize mechanical high-pressure fuel injection (non-Common Rail), limiting peak efficiency compared to modern EPA-compliant engines but offering robustness and low maintenance costs.

Load Capacity & Operational Suitability

The standard 6×4 configuration (twin drive axles, single front steer) supports GVWRs up to 68,343 lbs, making these trucks suitable for:

- Aggregate hauling (stone, sand, gravel)

- Demolition debris transport

- Heavy equipment towing (via gooseneck or lowboy)

- Regional construction material distribution

The tandem rear axles (13T HC16) provide excellent weight distribution and traction. When paired with a 25-yard end-dump or transfer trailer, payload capacities of 45,000–50,000 lbs are routinely achieved within legal axle limits when properly loaded.

Notes for Fleet Managers

- Parts Availability: Weichai and Fast Gear components are widely stocked in North America via third-party distributors; remanufactured engines/transmissions available at ~40% cost of OEM.

- Durability: WD615 engines regularly exceed 800,000 km (500,000 miles) with scheduled maintenance.

- Cold Weather Operation: Engine block heaters and fuel additives recommended for sub-20°F operations common in Northeast Ohio winters.

- Tire Life: 12.00R20 18PR tires average 60,000–80,000 miles in mixed on/off-road service; retread options available.

Conclusion:

Used trucks in the Youngstown, Ohio market featuring the Weichai WD615 engine, HW19710 transmission, and 12.00R20 tires offer a cost-effective, high-payload solution for construction and materials hauling. While not EPA 2010+ compliant, their mechanical simplicity, load capacity, and fuel economy under load make them viable for off-road and short-haul fleet operations where emissions restrictions are not enforced.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: RECONDITIONED COMMERCIAL TRUCKS

REFURBISHMENT STANDARD: OH-2026

TARGET ASSET CLASS: CLASS 6-8 CONSTRUCTION & HAULING TRUCKS (USED TRUCKS FOR SALE YOUNGSTOWN, OHIO)

EFFECTIVE DATE: JANUARY 1, 2026

1. EXECUTIVE SUMMARY

SEA LION International applies MIL-STD-810G-derived protocols to refurbish pre-owned commercial trucks at our Youngstown, Ohio Reconditioning Facility. This report details the mandatory 4-phase refurbishment process for all Class 6-8 assets, exceeding FMCSA baseline requirements and targeting 500,000-mile operational viability. All units undergo 127-point inspection with zero-tolerance failure thresholds. Assets failing Phase 1 are rejected from resale inventory.

2. REFURBISHMENT PROCESS: OH-2026 STANDARD

PHASE 1: ENGINE & GEARBOX TESTING (SEA LION TEST PROTOCOL SL-ETP-2026)

All powertrains undergo load-cell dynamometer validation and oil debris analysis. Units failing any sub-step are scrapped.

| Test Parameter | SEA LION STANDARD | Industry Baseline | Pass/Fail Threshold |

|---|---|---|---|

| Crankcase Pressure | < 0.8 psi @ 2500 RPM | < 1.5 psi | > 0.8 psi = FAIL |

| Oil Soot Content | ≤ 0.8% (ASTM D6595) | ≤ 1.2% | > 0.85% = FAIL |

| Gearbox Shift Response | ≤ 120ms shift time (loaded) | ≤ 250ms | > 125ms = FAIL |

| Coolant Contamination | 0 ppm glycol (spectrometry) | 50 ppm tolerance | > 5 ppm = FAIL |

Process:

– 3-hour continuous load test (85% rated HP) with real-time ECU telemetry logging.

– Magnetic plug inspection for ferrous particulates (> 5mg = automatic rejection).

– Gearbox disassembly for bearing race inspection (Ra ≤ 0.8µm surface finish required).

PHASE 2: CABIN REPAINTING (SEA LION SPECIFICATION SL-CP-2026)

Corrosion remediation and coating applied per ASTM D3359/D4541. Zero-tolerance for substrate defects.

| Process Stage | SEA LION REQUIREMENT | Validation Method |

|---|---|---|

| Surface Prep | Abrasive blast to SSPC-SP10 (Near-White Metal) | Adhesion test (≥ 15 MPa) |

| Primer Application | Epoxy zinc phosphate (75µm DFT) | Salt spray test (1000h @ 35°C) |

| Topcoat | Polyurethane (120µm DFT, RAL 7040 compliant) | Gloss retention (≥ 80% @ 500h) |

| Post-Paint Inspection | 0.0mm film thickness variation tolerance | Elcometer 456 verification |

Process:

– Complete disassembly of all interior components; cabin stripped to bare substrate.

– Weld repairs on structural members using ER70S-6 wire (AWS D1.1 certified).

– Electrostatic application in Class 8 cleanroom environment (ISO 14644-1).

PHASE 3: NEW TIRES & BATTERY REPLACEMENT (SEA LION SPECIFICATION SL-TB-2026)

Mandatory component replacement using OEM-specified parts. No refurbished components permitted.

| Component | SEA LION STANDARD | Testing Protocol |

|---|---|---|

| Tires | Michelin X Works ZL (Load Range G) | Load deflection test (SAE J1083) |

| Goodyear G395 (385/65R22.5) | Tread depth: 18/32″ (new) | |

| Battery | Optima YellowTop D34M (1000 CCA) | Cold Crank Test (-18°C, 7.2V min) |

| Dual battery system (isolated circuits) | Conductance test (≥ 1800S) |

Process:

– Wheel hubs inspected for runout (≤ 0.05mm tolerance) prior to tire mounting.

– Torque sequencing per SAE J2580 using calibrated impact wrenches (±3% accuracy).

– Battery trays coated with zinc-rich primer (ASTM D523) before installation.

PHASE 4: CHASSIS REINFORCEMENT (SEA LION SPECIFICATION SL-CR-2026)

Structural enhancements for construction-duty cycles. Mandatory for all assets > 300,000 miles.

| Reinforcement Zone | SEA LION STANDARD | Material Specification |

|---|---|---|

| Frame Rails | 10mm A572 Gr 50 steel doubler plates | ASTM A572 Grade 50 (50 ksi YS) |

| Fifth Wheel Mount | Gusseted bracket (12mm thick) | Weld procedure: AWS D1.1 Table 7.7 |

| Suspension Mounts | Reinforced crossmembers (8mm plate) | Fatigue life: 500k cycles @ 20k lb |

Process:

– Full chassis scan via FARO Arm laser measurement (deviation tolerance: ±0.5mm/m).

– MIG welding with ER70S-6 wire (preheat to 110°C per ASTM A6/A6M).

– Post-weld stress relief baking (600°F for 2 hours) and MPI inspection (ASTM E709).

3. SEA LION INSPECTION STANDARDS: KEY DIFFERENTIATORS

- Zero-Defect Policy: Any component failing visual inspection (per ASME B46.1) is replaced.

- Traceability: Full blockchain logging of all replaced parts (ISO 9001:2015 compliant).

- Validation Testing: Post-refurbishment 200-mile road test with SAE J2807 compliance verification.

- Certification: SEA LION Certified™ badge issued only after 100% pass rate on all 127 inspection points.

4. OPERATIONAL IMPACT FOR FLEET MANAGERS

Refurbished units adhering to OH-2026 standard demonstrate:

– 42% lower unscheduled downtime vs. non-certified used trucks (2025 SEA LION field data)

– 28% extended service life vs. baseline industry refurbished units

– Full compatibility with Ohio Department of Transportation (ODOT) weight compliance protocols

All SEA LION refurbished trucks include 18-month/150,000-mile powertrain warranty covering Phases 1-4 workmanship.

SEA LION INTERNATIONAL | ENGINEERING EXCELLENCE THROUGH PRECISION RECONDITIONING

Report Code: SL-RPT-OH2026-REV3 | Distribution: SEA LION INTERNAL USE ONLY

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Export Logistics Solutions for Used Trucks from China – Comparative Analysis and Corrosion Protection Protocols

Executive Summary

This report evaluates industrial-grade logistics solutions for the export of used trucks sourced from Youngstown, Ohio, through Chinese export hubs. While the trucks originate domestically, final export staging occurs via Chinese ports due to integrated global freight networks. The analysis compares three primary maritime transport methods: Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack container shipping. Additionally, this report specifies best practices for wax-based anti-corrosion protection to mitigate seawater exposure during transit.

1. Export Logistics Overview

Used heavy-duty trucks (Class 6–8) from Youngstown, Ohio, are consolidated and transported to Chinese transshipment ports (e.g., Shanghai, Ningbo, Qingdao) for final export to markets in Africa, Southeast Asia, Latin America, and the Middle East. SEA LION International provides end-to-end logistics coordination, including inland transport, port handling, marine insurance, and corrosion mitigation.

2. Comparative Shipping Methodologies

The following table compares key performance indicators across the three dominant shipping modalities for used commercial vehicles.

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container |

|---|---|---|---|

| Vehicle Compatibility | Best for operational trucks (driveable units) | Suitable for non-operational or damaged units | Ideal for oversized, non-standard, or disassembled trucks |

| Loading Mechanism | Self-propelled or towed onto vessel | Crane-lifted or forklift-stowed in hold | Crane-loaded onto open-frame ISO containers |

| Stowage Density | High (multi-deck vessels) | Moderate to low (irregular stacking) | Low (limited to container footprint) |

| Transit Time | Fast (direct roll-on/off) | Moderate (requires crane operations) | Moderate to slow (subject to container availability) |

| Port Infrastructure Required | RO-RO-capable terminals only | General cargo terminals | Standard container terminals with heavy-lift cranes |

| Cargo Protection | Moderate (exposed decks) | Low (exposed to bilge moisture, shifting) | High (weatherproof tarping, enclosed sides optional) |

| Theft & Damage Risk | Moderate (open decks) | High (loose stowage, handling) | Low (secured, containerized) |

| Average Cost per Unit (USD) | $1,200 – $1,600 | $900 – $1,300 | $1,800 – $2,500 |

| Insurance Premiums | Moderate | High | Low to Moderate |

| Best Use Case | Driveable fleets, high-volume exports | Salvage units, low-value reconditioning stock | High-value, custom, or articulated trucks |

3. Corrosion Mitigation: Wax Spraying Protection Protocol

Marine environments expose metal surfaces to salt-laden air and condensation, accelerating oxidation and compromising resale value. SEA LION International mandates industrial-grade wax spraying as a standard anti-corrosion measure for all exported used trucks.

3.1 Wax Spraying Specifications

| Parameter | Specification |

|---|---|

| Wax Type | Solvent-based, hydrophobic polymer blend (e.g., Lanolin-derived or synthetic paraffin) |

| Application Method | High-pressure electrostatic spray system |

| Coverage Areas | Undercarriage, frame rails, suspension components, wheel hubs, exhaust manifolds, fuel tank brackets |

| Film Thickness | 25–40 µm (measured via DFT gauge) |

| Curing Time | 24 hours at 20°C ambient temperature |

| Salt Spray Resistance (ASTM B117) | >500 hours (no red rust) |

| Removability | Biodegradable solvent or steam wash (post-delivery) |

3.2 Application Workflow

- Pre-Treatment: High-pressure freshwater rinse to remove debris and chlorides.

- Degreasing: Alkaline wash to eliminate oil and grease residues.

- Drying: Forced-air drying (80°C for 30 min).

- Wax Application: Full underbody and cavity saturation via robotic spray nozzles.

- Inspection: DFT verification and visual quality control (QC) logging.

Note: Wax protection is mandatory for RO-RO and Bulk Cargo shipments. Optional but recommended for Flat Rack units.

4. Operational Recommendations

| Shipping Mode | Recommended For | Risk Mitigation Actions |

|---|---|---|

| RO-RO | High-volume, driveable fleets to stable markets | Apply wax spray; secure gear in neutral; battery disconnect; tire inflation to 80% spec |

| Bulk Cargo | Low-cost salvage or rebuild units | Full wax treatment; weld securing points; moisture-absorbing desiccants in cab |

| Flat Rack | Oversized cranes, mixer trucks, articulated haulers | Container lashing per CSS Code; wax + VCI (Vapor Corrosion Inhibitor) bags in cab |

5. Compliance & Documentation

All exports comply with:

– IMSBC Code (for Bulk Cargo)

– CTU Code (for Flat Rack containers)

– RO-RO Safety Guidelines (IMO MSC.1/Circ.1372)

– Chinese Customs Export Declaration (used machinery classification)

– Pre-shipment Inspection (PSI) as required by destination country

6. Conclusion

For fleet managers and construction firms exporting used trucks from Chinese ports, RO-RO offers optimal efficiency for operational units, Bulk Cargo reduces cost for non-running assets, and Flat Rack ensures maximum protection for high-value or non-standard vehicles. Industrial wax spraying is a non-negotiable corrosion control measure, particularly for RO-RO and Bulk shipments exposed to prolonged marine atmospheres.

SEA LION International implements ISO 9001-certified logistics protocols to ensure cargo integrity, regulatory compliance, and on-time delivery across global trade lanes.

Prepared by:

SEA LION International – Senior Engineering Division

February 2026

Industrial Logistics & Asset Preservation

Get a Quote for Used Trucks For Sale Youngstown Ohio

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]