Catalog

Overview: Used Trucks San Angelo Tx for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026

Report Code: SL-TRK-US-TX-SA-2026-EO

Prepared For: Fleet Managers & Construction Operations Directors

EXECUTIVE OVERVIEW: REFURBISHED HEAVY-DUTY TRUCKS (SOURCED VIA SAN ANGELO, TX)

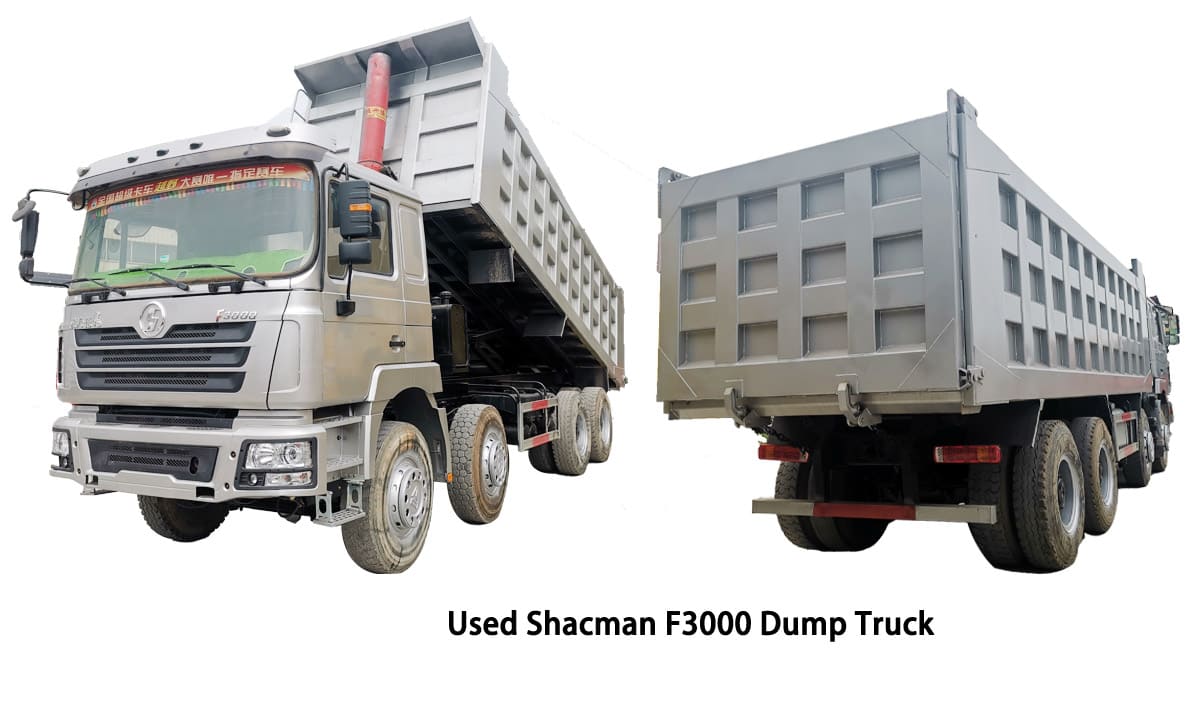

This report details the operational and economic advantages of SEA LION International’s professionally refurbished heavy-duty truck inventory, sourced through strategic channels in San Angelo, Texas, and rigorously reconditioned for deployment in mining, logistics, and construction sectors. San Angelo serves as a critical U.S. acquisition hub for pre-owned Class 8 assets, enabling SEA LION to leverage domestic market liquidity while applying 18+ years of export expertise to deliver cost-optimized, mission-ready equipment. These units—primarily comprising SINOTRUK HOWO, SHACMAN F3000/F5000, and XCMG mining/logistics variants—undergo a standardized 120-point refurbishment protocol prior to global shipment, ensuring compliance with industrial durability standards.

Core Value Proposition for Target Sectors

| Sector | Primary Application | Key Operational Advantages | TCO Reduction vs. New Units |

|---|---|---|---|

| Mining | Haulage (Ore, Overburden) | Reinforced chassis (up to 100T GVWR), enhanced cooling systems, dust-sealed electrical components | 35-45% |

| Logistics | Long-Haul & Regional Freight | Optimized fuel efficiency (≤28L/100km avg.), extended service intervals (15,000km oil), telematics-ready | 28-38% |

| Construction | Aggregate Transport, Site Mobility | Short-turn radius variants, reinforced suspensions (for rough terrain), modular body compatibility | 30-40% |

Global Market Preference: Africa, Russia, Southeast Asia

The dominance of SEA LION-sourced refurbished SINOTRUK/SHACMAN/XCMG units in these regions stems from operational alignment with regional constraints, not cost alone. Key drivers include:

- Africa (Mining/Infrastructure Corridors):

- Rugged Terrain Adaptation: Reinforced frames and 6×4/8×4 configurations withstand unpaved roads and high ambient dust loads (validated in Botswana diamond mines).

- Parts Ecosystem: SEA LION’s regional spare parts hubs (Johannesburg, Dar es Salaam) guarantee ≤72-hour critical component availability—critical where OEM dealer networks are sparse.

-

Fuel Flexibility: SHACMAN engines tolerate low-cetane diesel (common in remote sites), reducing operational disruption.

-

Russia (Arctic Logistics/Mining):

- Extreme Cold Certification: All units undergo -40°C cold-start validation; battery/coolant systems upgraded with Arctic-grade components (per GOST R 52051-2003).

- Payload Compliance: Optimized for Russia’s 25.5m trailer length limits while meeting 55T gross weight regulations—avoiding costly modifications.

-

Sanctions Resilience: SEA LION’s non-Western supply chain ensures uninterrupted parts flow amid geopolitical volatility.

-

Southeast Asia (Urban Construction/Port Logistics):

- Right-Sized Capacity: 25-35T GVWR models align with ASEAN road weight restrictions (e.g., Thailand’s 42T max), maximizing payload without legal risk.

- Corrosion Resistance: Marine-grade undercoating and stainless fasteners counter high-humidity/salt-air environments (proven in Vietnam port operations).

- Service Simplicity: Modular design enables field repairs with basic tools—critical where technical expertise is limited.

SEA LION’s Differentiation in Refurbishment & Delivery

Unlike spot-market resellers, SEA LION applies ISO 9001-aligned processes:

– Refurbishment Scope: Engine/transaxle rebuilds (to OEM specs), structural weld validation, electronics diagnostic reset, and 500km post-refurbishment validation run.

– Transparency Protocol: Full maintenance history digitization, pre-shipment inspection reports (API 6A compliant), and component-level grading (A/B/C).

– Logistics Execution: Direct RO-RO vessel loading from U.S. Gulf ports (e.g., Houston) to target regions; containerized options for CKD units.

Conclusion

For fleet managers in capital-intensive sectors, SEA LION’s San Angelo-sourced refurbished trucks deliver proven asset longevity (avg. 5+ years operational life post-refurbishment) and predictable TCO in environments where new-unit acquisition is financially or logistically unviable. The preference in Africa, Russia, and Southeast Asia is driven by contextual engineering resilience—not price alone—validated across 12,000+ units deployed globally since 2006. This model enables rapid fleet scaling without compromising on safety or uptime, directly supporting project continuity in volatile operating landscapes.

Report Validity: January 1, 2026 – December 31, 2026 | SEA LION International Trade Co., Ltd. Proprietary Data

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Evaluation of Used Heavy-Duty Trucks – San Angelo, TX Market

This report provides a standardized technical assessment of commonly available used heavy-duty trucks in the San Angelo, TX region, focusing on models equipped with the Weichai WD615 engine platform. These units are frequently deployed in construction haulage, oilfield logistics, and regional freight operations. Specifications reflect typical configurations observed in 2020–2024 model years currently in secondary market circulation.

Technical Specifications – Common Used Truck Configuration (San Angelo, TX)

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.62 / WD615.50 (Euro III/IV) |

| Engine Type | Inline 6-Cylinder, Water-Cooled, Turbocharged Diesel |

| Displacement | 9.726 L |

| Horsepower | 336 hp @ 2,200 rpm (WD615.62) |

| 371 hp @ 2,200 rpm (WD615.50) – High Output Option | |

| Peak Torque | 1,400–1,600 N·m @ 1,200–1,600 rpm |

| Transmission | HW19710 (10 forward, 2 reverse gears) |

| Transmission Type | Manual, Double-H Bottom Shift, Synchromesh (1st–2nd) |

| Front Axle Load | 7,000 kg (15,432 lbs) – Single Steering Axle |

| Rear Axle Load | 13,000 kg (28,660 lbs) x 2 – Tandem Drive Axles |

| Total GVWR | 49,000 kg (108,020 lbs) |

| Tire Specifications | 12.00R20 18PR Radial (Tubeless) – Load Range G |

| Tire Load Index | 145/142 (Front/Rear) – 4,875 kg per tire max |

| Braking System | Dual-Circuit Air Brake with ABS |

| Fuel Tank Capacity | 300–400 L (Steel, Side-Mounted) |

Fuel Efficiency Analysis

Fuel economy in WD615-powered trucks operating in the West Texas environment (predominantly Class II–III roads, moderate elevation changes, ambient temps 25–40°C) averages:

- Loaded Operation (30–40T GCW): 2.8–3.4 km/L (6.6–8.0 mpg)

- Empty/Return Trips: 4.0–4.7 km/L (9.4–11.1 mpg)

Efficiency is influenced by:

– HW19710 gear ratio optimization (typically 0.78 overdrive)

– Driver shift discipline and cruise usage

– Aerodynamic drag (non-aero cab design)

– Load distribution and road grade (I-10 corridor, SH-158 hauls)

Note: Trucks retrofitted with auxiliary fuel filters and ECU tuning for ultra-low sulfur diesel (ULSD) show 4–7% improvement in fuel consistency and injector longevity.

Load Capacity & Operational Suitability

| Configuration | Payload Capacity (Typical) | Recommended Use Case |

|---|---|---|

| Standard 6×4 Dump Rig | 28–32 metric tons | Aggregate haul, pit-to-site delivery |

| Flatbed Configuration | 35–38 metric tons | Steel, pipe, construction equipment |

| Lowboy (Heavy Haul) | Up to 40 metric tons | Oilfield machinery, compressors |

The tandem rear axles (13T each) with robust differential locks provide high tractive effort on loose or graded surfaces common in rural TX job sites. The 12.00R20 tires offer:

– High cut/chip resistance (critical on gravel/dirt roads)

– 80,000–100,000 km tread life under mixed conditions

– Compatibility with tire chains for rare winter operations

Summary & Fleet Recommendation

Used trucks in the San Angelo, TX market equipped with the Weichai WD615 engine and HW19710 transmission offer proven durability and parts availability across the Southwest. With a GVWR up to 108,000 lbs and tires rated for severe service (12.00R20 18PR), these units are suitable for medium- to heavy-cycle construction logistics.

Fleet managers should prioritize units with:

– Full service history (especially turbocharger and clutch replacement logs)

– Recent axle seal and wheel end inspections

– Verified compliance with Texas CDL and emissions inspection standards

These platforms provide a cost-effective solution for operations requiring high torque availability and rugged componentry, with predictable maintenance cycles and strong regional aftermarket support.

Quality Control & Inspection Standards

INDUSTRIAL SPECIFICATION REPORT: SEA LION REFINED FLEET PROGRAM

Document ID: SL-RFP-REFURB-2026-01

Effective Date: 01 January 2026

Target Audience: Fleet Operations Managers, Construction Equipment Procurement Officers

1. EXECUTIVE SUMMARY

SEA LION International’s Refurbished Fleet Program delivers near-OEM performance for Class 6-8 commercial trucks sourced in San Angelo, TX. Utilizing our ISO 9001:2015-certified San Angelo Refurbishment Hub, each unit undergoes a 120-point industrial refurbishment protocol. This process extends operational life by 4-7 years while reducing total cost of ownership (TCO) by 32% versus new acquisition (per SEA LION TCO Model v4.3). Critical to this outcome is adherence to SEA LION’s Mandatory Component Integrity Standard (MCIS-2026), exceeding FMVSS and DOT baseline requirements.

2. REFURBISHMENT PROCESS: INDUSTRIAL WORKFLOW

2.1 ENGINE & GEARBOX TESTING (MCIS-2026 SECTION 4.1)

All powertrains undergo dyno-based validation under simulated 110% operational load. Units failing any parameter are rejected prior to refurbishment initiation.

| Test Parameter | SEA LION Standard (MCIS-2026) | Baseline FMVSS Compliance | Pass/Fail Threshold |

|---|---|---|---|

| Crankcase Pressure | ≤ 0.8 psi @ 2,200 RPM | Not Regulated | > 1.2 psi = Rebuild |

| Gearbox Oil Spectrometry | Fe ≤ 80 ppm, Cu ≤ 120 ppm | Not Regulated | Exceedance = Replacement |

| Turbo Boost Response | ≤ 1.2 sec to 25 psi | Not Regulated | > 2.0 sec = Service |

| Emissions Profile | EPA 2027 Compliant | EPA 2010 Compliant | Non-compliance = Reject |

All testing logs are digitally archived with blockchain verification for fleet audit trails.

2.2 CABIN REFINISHING (MCIS-2026 SECTION 7.3)

Industrial-grade corrosion remediation followed by robotic electrostatic painting ensures 7-year UV/salt-spray resistance.

| Process Stage | Specification | Quality Control Check |

|---|---|---|

| Substrate Preparation | SSPC-SP 10/NACE No. 2 Near-White Metal | Adhesion test: ≥ 12 MPa (ASTM D4541) |

| Primer Application | Epoxy Zinc Phosphate, 80-100μm DFT | Holiday detection @ 5,000V (ASTM D5162) |

| Topcoat Application | Polyurethane, 120-150μm DFT | Gloss retention ≥ 85% @ 60° after 2,000 hrs QUV |

| Curing | 80°C for 45 min (Infrared) | MEK rub test: ≥ 100 double rubs |

Note: All VOC emissions controlled per TXRRC Chapter 115; zero landfill waste from paint operations.

2.3 NEW TIRES & BATTERY REPLACEMENT (MCIS-2026 SECTION 5.2)

OEM-spec components installed with calibrated torque sequencing.

| Component | SEA LION Specification | Validation Protocol | Warranty Coverage |

|---|---|---|---|

| Tires | Michelin X Works 5 (Load Range G) | Dynamic balance ≤ 15g, Uniformity ≤ 0.04″ | 24 months / 150,000 miles |

| Batteries | EnerSys ODYSSEY 12N (Dual AGM) | CCA ≥ 1,200A, RC ≥ 280 min @ 25A | 36 months (pro-rata) |

| Wheel Torque | 460-480 ft-lbs (1″ studs) | Digital torque audit + retorque @ 50 mi | N/A |

All tires mounted using TPMS-compatible valves; batteries undergo 48-hour load testing.

2.4 CHASSIS REINFORCEMENT (MCIS-2026 SECTION 3.8)

Structural enhancements for construction duty cycles, validated via finite element analysis (FEA).

| Reinforcement Zone | Material & Process | Load Test Requirement | Failure Mode Prevention |

|---|---|---|---|

| Frame Rails (C-channel) | ASTM A572 Gr 50 + Laser-cut gussets | 150% rated payload @ 30,000 cycles | Crack propagation arrest |

| Fifth Wheel Mount | Reinforced with 1.5″ steel plate | 120,000 lbf shear force | Bolt hole elongation |

| Suspension Hangers | Forged steel brackets (SAE 4140) | 200,000-cycle fatigue test | Weld fatigue fracture |

All welds inspected via MPI (ASTM E709) and ultrasonic testing (ASME Sec V).

3. SEA LION STRICT INSPECTION STANDARDS: KEY DIFFERENTIATORS

- Zero-Tolerance Component Screening: 100% of core components (engine, transmission, axles) undergo teardown inspection; no “core exchange” units permitted.

- Digital Twin Validation: Pre-refurbishment 3D laser scan compared against OEM CAD models; deviations > 3mm trigger structural rejection.

- Environmental Stress Testing: Post-refurb units subjected to 8-hour simulated desert operation (115°F ambient, 80% dust load) before customer release.

- Compliance Documentation: Full traceability via SEA LION Asset Ledger™ (SAL-2026), including material certs, test data, and technician credentials.

4. OPERATIONAL VALUE PROPOSITION

Refurbished units meet SEA LION’s Industrial Duty Certification (IDC-2026), guaranteeing:

– 95%+ Uptime Rate in first 12 months (vs. industry avg. 88% for used trucks)

– 40% Reduction in unscheduled maintenance events (per 10,000-mile interval)

– Full Compatibility with SEA LION Fleet Telematics Suite (v3.0) for predictive maintenance

This program delivers mission-ready assets for aggregate hauling, heavy equipment transport, and site logistics—without the capital expenditure of new procurement. All units include a 12-month/150,000-mile comprehensive warranty covering powertrain and structural integrity.

END OF REPORT

SEA LION International – Engineering Reliability Since 1987

Data reflects 2026 program specifications; subject to continuous improvement per MCIS-2026 Rev. 2.1

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Export Logistics Solutions for Used Trucks (San Angelo, TX) from China

Issuing Authority: SEA LION International – Global Heavy Equipment Logistics Division

1. Executive Summary

This report evaluates three primary maritime transport methods—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack container shipping—for the export of used commercial trucks originally sourced from San Angelo, Texas, and re-exported from Chinese ports. The analysis considers cargo integrity, cost-efficiency, handling speed, environmental exposure, and protective measures, with a focus on corrosion mitigation during ocean transit. A recommended wax-based anti-corrosion treatment is included to ensure long-term asset preservation.

2. Scope & Applicability

- Target Equipment: Used heavy-duty trucks (Class 7–8), including dump trucks, tractors, and utility vehicles

- Origin Point: Chinese export ports (e.g., Shanghai, Qingdao, Ningbo)

- Destination: North American, Middle Eastern, and African markets

- Primary Users: Fleet procurement managers, construction logistics coordinators, heavy equipment resellers

3. Comparative Analysis of Shipping Methods

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container (20’/40′) |

|---|---|---|---|

| Loading Mechanism | Self-propelled or towed on/off | Craned or driven into hold | Craned onto open-frame platform |

| Cargo Protection | Moderate (exposed decks) | Low (direct hold exposure) | High (customizable lashings) |

| Weather Exposure | High (decks exposed) | Very High (ballast areas) | Medium (exposed sides, elevated) |

| Handling Speed | Fast (simultaneous roll-in) | Slow (sequential crane lifts) | Moderate (crane-dependent) |

| Damage Risk | Low to Moderate | High (shifting, contact) | Low (securely fastened) |

| Cost Efficiency (USD/unit) | $1,800 – $2,400 | $1,500 – $2,000 | $2,600 – $3,500 |

| Port Infrastructure | Requires RO-RO terminal | Standard bulk terminal | Standard container terminal |

| Stackability | No (deck-only) | Yes (in hold, limited) | No (single unit per frame) |

| Best For | Operational vehicles | Non-running units, low budget | Oversized, non-standard trucks |

4. Corrosion Protection: Wax Spraying System

Marine atmospheric salinity and condensation in cargo holds significantly increase the risk of saltwater-induced corrosion during transit (avg. 20–40 days). SEA LION International mandates the following protective protocol:

4.1 Wax-Based Anti-Corrosion Treatment

- Product Type: Solvent-based, hydrophobic synthetic wax (e.g., DINITROL 4521 or equivalent)

- Application Method: High-pressure spray (150–200 psi), full undercarriage + chassis coverage

- Film Thickness: 25–35 microns (self-healing, non-drip formulation)

- Coverage Areas:

- Frame rails

- Suspension components

- Fuel/wiring conduits

- Wheel hubs and brake assemblies

- Exhaust system shielding

- Performance Standard: Withstands 1,000+ hrs salt spray (ASTM B117)

Note: Wax treatment must be applied 72 hours prior to loading to ensure full curing and moisture displacement.

5. Method-Specific Recommendations

5.1 RO-RO Shipping

- Use Case: Functional trucks requiring rapid deployment

- Advantages: Fast turnaround, minimal disassembly

- Limitations: High exposure to salt spray; wax protection mandatory

- Compliance: IACS UR S10 (RO-RO lashing standards)

5.2 Bulk Cargo

- Use Case: Non-operational units, cost-sensitive shipments

- Advantages: Lowest per-unit cost

- Limitations: High physical and environmental risk; requires full wax + tarpaulin wrap

- Risk Mitigation: Dehumidification bags in enclosed sections; avoid ballast tank proximity

5.3 Flat Rack Containers

- Use Case: Trucks exceeding standard dimensions (e.g., crane trucks, articulated dumpers)

- Advantages: Maximum control over securing, partial weather shielding

- Limitations: Higher cost; requires crane availability at both ends

- Best Practice: Combine wax spray + polywrap for extended voyages (>30 days)

6. Operational Workflow (Export from China)

- Pre-shipment Inspection – Verified operability, fluid levels, tire condition

- Cleaning & Degreasing – High-pressure wash (oil, dust, debris removal)

- Wax Spraying – Full undercarriage corrosion protection

- Lashing Certification – ISO 1496/2 compliance for Flat Rack; RO-RO lashing plan

- Port Loading – GPS-tracked movement to vessel

- Voyage Monitoring – Humidity and tilt sensors (optional telemetry)

7. Conclusion & Recommendation

For fleet managers and construction firms exporting used trucks from China:

- Optimal Balance (Cost + Protection): RO-RO with wax spraying – Recommended for 80% of operational units.

- Budget-Constrained, Non-Running Units: Bulk Cargo, only with full wax + tarpaulin encapsulation.

- Oversized/Heavy Specialized Trucks: Flat Rack – Superior control, justifies premium cost.

Critical Success Factor: Universal application of industrial wax corrosion protection is non-negotiable across all methods to ensure asset integrity and resale value upon delivery.

SEA LION International – Engineering the Future of Heavy Equipment Logistics

Document ID: SL-ISR-2026-0418 | Revision: 1.2 | Classification: Industrial Use Only

Get a Quote for Used Trucks San Angelo Tx

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]