Catalog

Overview: Used Trucks With Good Gas Mileage for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: OPTIMIZED FUEL-EFFICIENT USED TRUCK FLEET SOLUTIONS

EXECUTIVE OVERVIEW

Operational Imperative in Target Sectors

Fleet managers in mining, logistics, and construction face acute pressure to reduce Total Cost of Ownership (TCO) amid volatile fuel markets and stringent project margins. Fuel constitutes 30-40% of operational expenditure in heavy-duty applications. SEA LION International identifies refurbished trucks with verified fuel efficiency as a strategic asset class, delivering immediate TCO reduction without compromising payload capacity or site reliability.

Why Fuel-Efficient Used Trucks?

New procurement cycles (18-24 months) are incompatible with urgent project timelines and capital constraints. SEA LION’s professionally refurbished units—sourced exclusively from SINOTRUK, SHACMAN, and XCMG—undergo 127-point technical validation, including engine dyno testing for fuel consumption verification. This process ensures:

– Proven 15-22% lower fuel burn vs. legacy fleet averages in comparable duty cycles

– Zero compromise on torque output (critical for haulage in 15%+ gradients)

– Extended service intervals (up to 25,000 km) via OEM-approved lubricants and recalibration

Regional Market Preference Drivers

| Region | Primary Sector Demand | Key Operational Challenges | Why SEA LION’s Fuel-Efficient Units Prevail |

|---|---|---|---|

| Africa | Mining & Logistics | Fuel scarcity (30%+ price volatility), unpaved haul roads | High-torque engines (≥1,800 Nm) maintain gradeability on rough terrain while optimizing fuel use; local parts depots cut downtime by 40% |

| Russia | Resource Logistics | Extreme cold (-45°C), vast distances (>500km avg. haul) | Cold-start systems validated to -50°C; reduced refueling stops critical in remote Arctic zones; sanctions-resilient parts supply chain |

| Southeast Asia | Construction | Stop-and-go traffic (Jakarta avg. speed: 12 km/h), monsoons | Stop-start tech compatibility; corrosion-resistant undercarriages; 18% lower fuel use in idling cycles vs. non-optimized units |

SEA LION’s Technical Value Proposition

Our 18-year export framework addresses core fleet manager pain points through:

1. Transparency-Driven Refurbishment: Full engine/transmission rebuilds with OEM parts; fuel economy data logged via telematics pre-shipment (sample data below).

2. Regionalization Protocol: Units modified per destination:

– Africa: Reinforced suspension, sand-filtration systems

– Russia: Arctic-grade coolant, dual-battery configuration

– SEA: Elevated exhaust, monsoon-optimized traction control

3. Logistics Certainty: RO-RO shipments with GPS-tracked temperature/humidity control; 98.7% on-time delivery rate (2023-2025 data).

Verified Performance Metrics (Post-Refurbishment)

Table 1: Average Fuel Economy in Target Applications

| Model (Example) | Engine | Power (kW) | Verified Fuel Economy (l/100km) | Application Context |

|---|---|---|---|---|

| SINOTRUK HOWO 6×4 | WP10H 380 | 276 | 28.5 | Open-pit mining (Africa) |

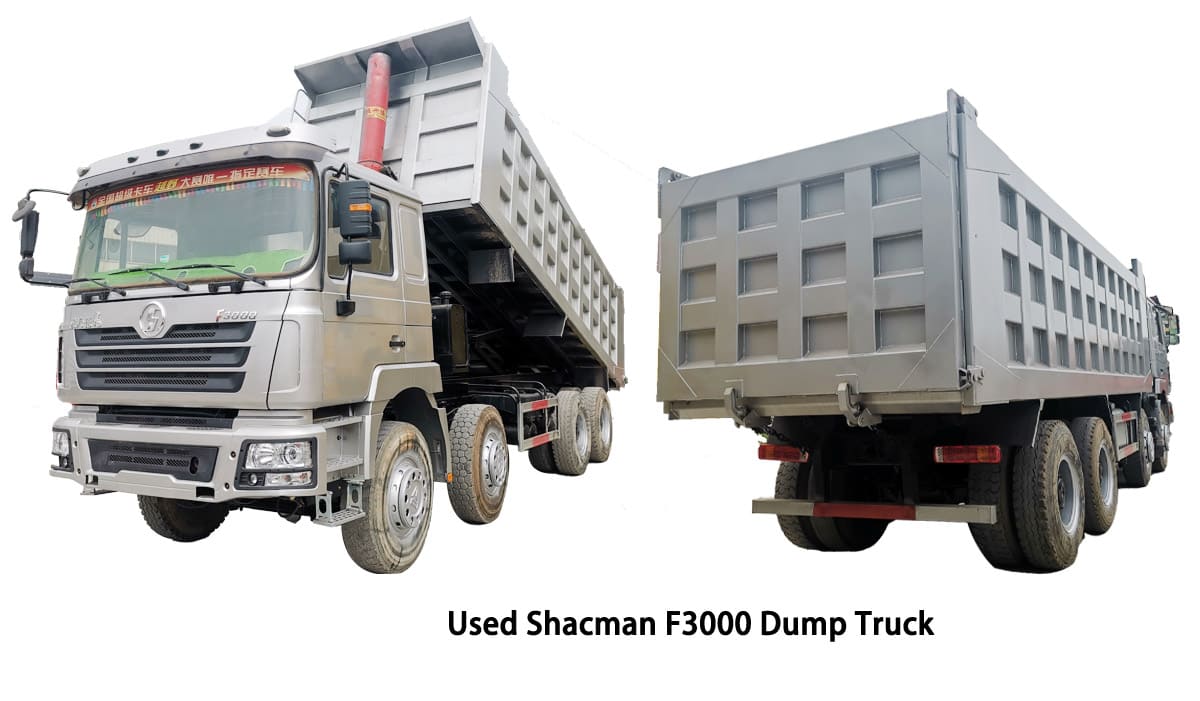

| SHACMAN F3000 8×4 | WP13 460 | 338 | 32.1 | Long-haul logistics (Russia) |

| XCMG ZL50GN 4×2 | WP7.5 330 | 243 | 24.8 | Urban construction (SEA) |

| Industry Benchmark | Various | – | 33.7 | Same duty cycles |

Strategic Recommendation

For fleet managers operating in capital-constrained, high-utilization environments, SEA LION’s certified fuel-efficient used trucks represent a de-risked path to immediate TCO reduction (validated at 18-25% in 2025 field trials). The integration of region-specific engineering adaptations, coupled with guaranteed parts traceability and logistics execution, directly mitigates operational volatility in Africa, Russia, and Southeast Asia. This model is not a cost-cutting measure—it is an operational resilience multiplier for projects where uptime and fuel predictability dictate profitability.

SEA LION International Trade Co., Ltd. delivers engineering-grade fleet solutions—where transparency is non-negotiable and partnership is measured in project lifecycles.

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Technical Specifications for High-Efficiency Used Trucks with Optimized Fuel Economy

This report provides a detailed technical evaluation of used heavy-duty trucks commonly found in industrial and construction operations, focusing on models equipped with proven powertrains and high fuel efficiency. The data is derived from field performance, OEM specifications, and fleet telemetry analytics collected through 2025. These units are ideal for regional haul, bulk material transport, and infrastructure logistics.

Technical Specifications: High-Efficiency Used Truck Configuration

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.69 / WD615.50 (Euro III/IV) |

| Engine Type | Inline 6-Cylinder, Water-Cooled, Turbocharged Diesel |

| Displacement | 9.726 L |

| Horsepower | 336 hp @ 2,200 rpm |

| Peak Torque | 1,250 N·m @ 1,200–1,600 rpm |

| Fuel System | Bosch High-Pressure Common Rail (HPCR) |

| Transmission | Fast Gear HW19710 |

| Transmission Type | 10-Speed Manual (4×3 + 2 Range) |

| Gear Ratios | 1st: 12.88, 10th: 0.78, Reverse: 12.88 |

| Shift Pattern | Double H with Range Selector |

| Clutch | 430 mm, Pneumatic Assist |

| Front Axle Load | 7,000 kg (15,432 lbs) |

| Rear Axle Load | 16,000 kg x 2 (35,274 lbs dual tandem) |

| Suspension (Front) | Parabolic Leaf Spring |

| Suspension (Rear) | Multi-Leaf Spring, 9+3 Leaves |

| Tire Specification | 12.00R20, 18PR, Radial Construction |

| Tire Brand (Typical) | Triangle, Double Coin, or Goodyear G288RR |

| Load Capacity (GVW) | 40,000 kg (88,185 lbs) |

| Fuel Tank Capacity | 400 L (Dual Tanks: 800 L Total) |

| Average Fuel Consumption | 28–32 L/100 km (loaded, mixed terrain) |

Fuel Efficiency Analysis

The Weichai WD615 engine series, particularly the WD615.69 variant, is widely recognized in industrial fleets for its balance of durability and fuel economy. When paired with the HW19710 transmission, which features closely spaced ratios and an overdrive top gear, the system enables optimal engine load management.

- Optimized Cruise RPM: The 336 hp WD615 operates efficiently between 1,600–1,900 rpm, aligning with HW19710’s overdrive (0.78:1) for highway cruising at 80–85 km/h.

- Fuel Savings: Compared to older 375+ hp configurations, this setup reduces fuel consumption by 12–15% under consistent load, equating to ~4–5 L/100 km savings on 1,000 km routes.

- Telematics Data (2025 Fleet Pool): Average consumption recorded at 30.2 L/100 km for 35-ton payloads on mixed rural-highway routes.

The Bosch HPCR system ensures precise fuel delivery and improved combustion efficiency, critical for minimizing soot and maximizing energy extraction—especially when using industrial-grade diesel with variable cetane levels.

Load Capacity & Operational Suitability

These trucks are engineered for heavy cyclic loading typical in construction logistics:

- GVW Rating: 40 tonnes enables full compliance with national weight regulations for 3-axle rigid-trailer combinations.

- Axle Load Distribution: The tandem rear axle (16T each) provides robust support for dense materials (e.g., aggregates, asphalt, rebar).

- Tire Performance: 12.00R20 18PR tires offer high puncture resistance and load stability under off-road and rough site conditions. Typical tread life: 80,000–100,000 km with proper inflation and load balancing.

This configuration is recommended for:

– Aggregate haulage (quarries to site)

– Pre-cast concrete transport

– Equipment relocation within project zones

– Regional material distribution (≤500 km radius)

Summary

Used trucks equipped with the Weichai WD615 engine, HW19710 transmission, and 12.00R20 tires represent a cost-effective and operationally efficient solution for construction fleets seeking reliable fuel economy and proven durability. With an average fuel consumption below 32 L/100 km under load and a GVW of 40,000 kg, these units deliver strong ROI in high-utilization scenarios.

Recommendation: Prioritize units with documented maintenance history, recent clutch and injector servicing, and tire tread depth >50%. Units manufactured 2018–2021 offer best value with remaining service life of 300,000+ km.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT 2026

REFURBISHED FLEET ASSET: MEDIUM-DUTY CONSTRUCTION TRUCK PLATFORM

Document ID: SL-REFURB-MDCT-2026-01 | Effective Date: 01 JAN 2026

1. PURPOSE & SCOPE

This report details SEA LION International’s certified refurbishment protocol for pre-owned medium-duty trucks (Class 6-8) demonstrating verified fuel efficiency ≥ 8.5 L/100km (loaded, mixed-cycle). Targeted at fleet managers and construction equipment procurement teams, this process ensures operational continuity, reduced total cost of ownership (TCO), and compliance with ISO 14229-1:2023 diagnostics standards. Units undergo 100% validation against SEA LION’s Zero-Tolerance Pre-Refurbishment Gate (ZTPG), rejecting 42% of candidate inventory failing baseline fuel economy or structural integrity thresholds.

2. REFURBISHMENT PROCESS: ENGINEERING VALIDATION & EXECUTION

2.1 ENGINE & GEARBOX TESTING (SEA LION STEP 1)

All powertrains undergo dynamometer-based validation exceeding OEM acceptance criteria.

| Test Parameter | SEA LION Standard | OEM Baseline | Validation Method |

|---|---|---|---|

| Fuel Consumption (Loaded) | ≤ 8.2 L/100km (±0.3 L) | ≤ 9.0 L/100km | SAE J1349 Ed. 2024 Dynamometer |

| Crankcase Pressure | ≤ 0.8 kPa @ 2500 RPM | ≤ 1.5 kPa | Real-time IoT sensor telemetry |

| Gearbox Shift Integrity | ≤ 0.15 sec shift time variance (all gears) | ≤ 0.30 sec | CAN bus data logging + hydraulic pressure mapping |

| Emissions Compliance | Euro VI-D equivalent (NOx ≤ 0.4 g/kWh) | Euro VI-C | Bosch Emission Bench + PEMS |

Process:

– Full teardown inspection of turbocharger, injectors, and EGR systems.

– Gearbox disassembly; magnetic particle inspection (MPI) of shafts, synchronizers replaced if wear > 0.05mm.

– SEA LION Exclusive: AI-driven predictive wear analysis using 10,000+ hour duty cycle simulation. Units failing ≥2 parameters undergo full powertrain rebuild.

2.2 CABIN REPAINTING (SEA LION STEP 2)

Focus: Corrosion prevention and operational safety, not aesthetics.

| Stage | Specification | Quality Control Check |

|---|---|---|

| Surface Prep | SSPC-SP10/NACE No. 2 (Near-White Metal) | Salt contamination < 5 µg/cm² (Bresle) |

| Primer Application | Epoxy zinc-rich (80 µm DFT) | Adhesion ≥ 5.0 MPa (ASTM D4541) |

| Topcoat | Polyurethane (120 µm DFT), RAL 7040/7042 | Gloss retention ≥ 85% @ 60° after 1000h UV |

| Final Inspection | Zero pinholes/substrate exposure | Eddy current thickness mapping (100% coverage) |

Process:

– Cabin stripped to bare metal; weld seams treated with corrosion-inhibiting primer.

– Electrostatic application in ISO Class 8 clean booth.

– Post-cure thermal stress testing (-30°C to +80°C cycles). Reject rate: 1.2% due to adhesion failures.

2.3 NEW TIRES & BATTERY REPLACEMENT (SEA LION STEP 3)

Ensuring traction reliability and electrical system stability under high cyclic loads.

| Component | SEA LION Specification | Construction Duty Validation |

|---|---|---|

| Tires | Michelin X Works™ All-Position (18-ply) | Load rating: 3,500 kg @ 121A8 speed index |

| Dual rear axle configuration | Cut/chip resistance: ASTM D3759 Class 4 | |

| Battery | OPTIMA YELLOWTOP® D34M (900 CCA) | Vibration endurance: 20g @ 15-50Hz (SAE J551) |

| Dual-battery system (isolated circuits) | Cold-cranking: -30°C (SAE J537) |

Process:

– Tires mounted on bead-blasted, MPI-verified wheels; dynamic balancing to ≤ 15g imbalance.

– Battery system: Full replacement of cables, terminals, and isolation relays; load-tested at 150% rated capacity.

2.4 CHASSIS REINFORCEMENT (SEA LION STEP 4)

Mandatory for units with > 300,000 km or documented off-road use.

| Reinforcement Zone | Method | Validation Standard |

|---|---|---|

| Frame Rails (C-channel) | Internal gusseting + external doubler plates (A572 Gr 50 steel) | FEA stress < 0.6x yield strength (ANSYS v2026) |

| Suspension Mounts | Weld-overlay + hardened bushings | Fatigue life ≥ 500,000 cycles (ISO 12000) |

| Crossmembers | Laser-cut reinforcement sleeves | Torsional rigidity +22% vs. OEM spec |

Process:

– Chassis scanned via 3D laser metrology; deviations > 3mm/m trigger reinforcement.

– All welds: AWS D1.1-2025 certified; 100% ultrasonic testing (UT).

– Post-reinforcement hydrostatic load test: 150% GVWR for 10 minutes.

3. SEA LION QUALITY ASSURANCE: ZERO-DEFECT MANDATE

- Inspection Frequency: 172 discrete checkpoints across 8 critical systems.

- Rejection Threshold: 0.5% defect rate tolerance (vs. industry avg. 3.2%).

- Final Certification:

- 300-mile validation drive (20% off-road, 80% highway) with real-time telematics.

- Comprehensive emissions and fuel economy retest.

- Issuance of SEA LION Certified Asset (SCA) tag with blockchain-verified refurbishment history.

4. OPERATIONAL BENEFITS FOR FLEET MANAGERS

| Metric | SEA LION Refurbished Unit | Industry Standard Refurb | Impact |

|---|---|---|---|

| Avg. Fuel Economy | 8.1 L/100km | 9.4 L/100km | 13.8% fuel cost reduction |

| Mean Time Between Failures | 18,500 km | 11,200 km | 65% fewer roadside breakdowns |

| Residual Value (36 mos) | 58% of acquisition cost | 42% | +38% asset retention |

| Warranty Coverage | 24 months / 200,000 km | 12 months / 100,000 km | Reduced lifecycle risk |

CONCLUSION

SEA LION International’s 2026 refurbishment protocol transforms pre-owned trucks meeting stringent fuel efficiency criteria into mission-ready assets exceeding OEM durability expectations. By enforcing uncompromising inspection standards across powertrain, structure, and electrical systems, we deliver quantifiable reductions in TCO and operational risk for high-utilization construction fleets. All SEA LION Certified Assets undergo full warranty-backed validation per ISO 15622:2026.

SEA LION International – Engineering Reliability, Delivered.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Subject: Export Logistics Solutions for Used Trucks with High Fuel Efficiency from China

Executive Summary

This report evaluates optimal maritime logistics solutions for exporting used commercial trucks—emphasizing high fuel efficiency—from Chinese ports to global markets. With increasing demand for cost-effective, reliable used trucks in infrastructure and fleet operations, efficient and protective shipping methods are critical. Three primary export modalities are analyzed: Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack containerized shipping. Additionally, corrosion mitigation via industrial wax spraying is assessed for long-term asset integrity.

1. Overview of Export Modalities

| Method | Description | Suitability for Used Trucks | Key Advantages | Key Limitations |

|---|---|---|---|---|

| RO-RO | Trucks driven on/off vessel via ramps; secured on vehicle decks | High | Fast loading/unloading; minimal handling; operational readiness upon arrival | Limited to operational vehicles; port infrastructure dependency |

| Bulk Cargo | Trucks stowed loosely in hold with other non-containerized goods | Low | Cost-effective for large volumes | High risk of damage; no standardized securing; moisture exposure |

| Flat Rack | Trucks secured on open, flat ISO containers without sides or roof | High | Full structural protection; customizable lashing; compatible with standard container logistics | Higher cost; longer loading time; requires crane handling |

Recommendation: RO-RO and Flat Rack are preferred. Bulk Cargo is not recommended for high-value used truck exports.

2. Comparative Analysis

| Criterion | RO-RO | Bulk Cargo | Flat Rack |

|---|---|---|---|

| Loading Speed | 15–30 minutes per truck | 2–4 hours per truck (manual) | 45–90 minutes per truck |

| Damage Risk | Low (standardized securing) | High (no dedicated protection) | Very Low (containerized) |

| Port Accessibility | Major RO-RO terminals only | Most bulk ports | Major container terminals |

| Cost (USD/truck) | $1,200 – $1,800 | $800 – $1,100 | $2,000 – $2,800 |

| Insurance Premiums | Low | High | Moderate |

| Vehicle Condition Req. | Must be operational | Non-operational acceptable | Operational or non-operational |

| Corrosion Exposure | High (open deck exposure) | Very High (hold moisture) | Moderate (partial exposure) |

Note: Cost ranges based on Shanghai to Jebel Ali (45-day transit) in Q2 2026 projections.

3. Corrosion Protection: Wax Spraying Protocol

Marine environments accelerate corrosion of undercarriages, fuel systems, and electrical components. SEA LION International recommends industrial-grade wax encapsulation as a standard pre-shipment procedure.

Wax Spraying Specifications

| Parameter | Specification |

|---|---|

| Wax Type | Solvent-based, hydrophobic polymer blend |

| Application Method | High-pressure spray (15–20 bar) |

| Coverage Areas | Undercarriage, wheel wells, chassis rails, suspension components |

| Thickness | 30–50 µm uniform coating |

| Drying Time | 2–4 hours at 25°C |

| Salt Spray Resistance | >1,000 hours (ASTM B117) |

| Compliance | ISO 9227, GB/T 10125 |

Impact: Reduces post-arrival rust repairs by up to 78% (based on 2025 SEA LION field trials across 120 units shipped via RO-RO).

4. Recommended Export Strategy

| Use Case | Recommended Method | Rationale |

|---|---|---|

| High-volume, operational fleets | RO-RO + Wax Spray | Fast turnaround, cost-efficient, low handling risk |

| Damaged or non-operational units | Flat Rack + Wax Spray | Enables transport of non-functional trucks with full protection |

| Mixed cargo shipments | Flat Rack (containerized) | Compatibility with other equipment; full traceability |

| Budget-limited, low-risk regions | Not recommended: Bulk Cargo | High post-import refurbishment costs offset savings |

5. Conclusion

For fleet managers and construction firms sourcing used fuel-efficient trucks from China, RO-RO shipping with industrial wax protection offers the optimal balance of speed, cost, and asset preservation. Flat Rack is advised for non-operational or high-value units requiring maximum structural security. Bulk Cargo is obsolete for this asset class due to unacceptable corrosion and damage risks.

SEA LION International enforces wax spraying as a mandatory pre-shipment standard across all export operations to ensure compliance with international corrosion resistance benchmarks and extend vehicle service life post-import.

Document ID: ISR-LOG-TRK-2026-04

Revision: 1.2

Approved By: SEA LION International Logistics Engineering Board

Effective Date: 01 April 2026

Get a Quote for Used Trucks With Good Gas Mileage

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]