Catalog

Overview: Vacuum Excavator for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: VACUUM EXCAVATOR SYSTEMS

Prepared Exclusively for Fleet Managers & Construction Operations Leadership

SEA LION International Trade Co., Ltd. | Heavy Equipment Solutions Division

EXECUTIVE OVERVIEW: VACUUM EXCAVATOR SYSTEMS

Vacuum excavators represent a critical non-destructive excavation (NDE) solution for high-risk subsurface operations across mining, construction, and logistics infrastructure development. Unlike conventional mechanical excavation, these systems utilize high-velocity air or water coupled with industrial-strength vacuum suction to safely expose underground utilities, pipelines, and ore veins with zero ground disturbance. This capability directly mitigates project delays, utility strikes (reducing incident rates by up to 90%), and environmental remediation costs—key pain points in capital-intensive projects.

Core Applications Driving Adoption:

– Mining: Precision overburden removal and pit dewatering in sensitive ore zones; minimizes equipment downtime during exploration.

– Construction: Safe utility potholing for foundation work, trenching, and pipeline installation in congested urban sites.

– Logistics: Rapid spill containment (e.g., chemical, oil) and trench restoration along transport corridors without road closures.

Regional Preference in Africa, Russia & Southeast Asia:

Market dominance in these regions stems from the vacuum excavator’s resilience to extreme operational variables where conventional equipment fails. SEA LION’s distributed models (primarily XCMG-mounted systems) integrate ruggedized components validated for local conditions:

| Region | Primary Operational Challenge | SEA LION Vacuum Excavator Advantage |

|---|---|---|

| Africa | Unstable laterite soils; 45°C+ ambient temps; limited utility maps | Air excavation mode prevents slurry collapse; reinforced filtration handles abrasive dust; rapid deployment in unmapped zones |

| Russia | -40°C permafrost; short seasonal work windows | Hydraulic pre-heaters; cold-rated vacuum pumps; 30% faster cycle times vs. excavators in frozen ground |

| Southeast Asia | Monsoon saturation; dense urban infrastructure | Submersible pumps for 1m flood conditions; compact chassis (SHACMAN/XCMG) for narrow streets; non-vibratory operation near structures |

Why SEA LION Delivers Unmatched Value:

As an authorized distributor for SINOTRUK, SHACMAN, and XCMG with 18+ years in heavy equipment export, SEA LION addresses the total cost of ownership (TCO) critical to fleet managers:

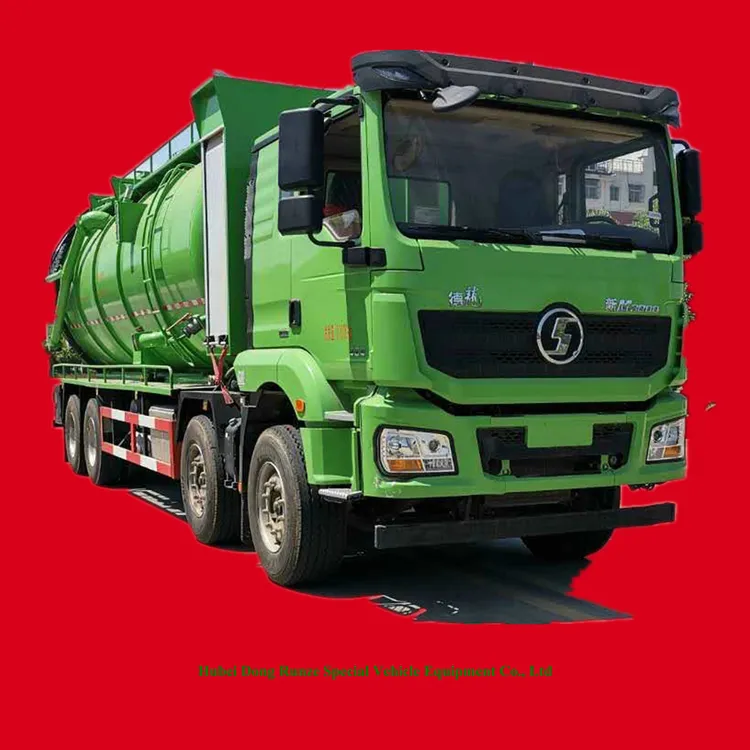

1. Proven Chassis Integration: Vacuum systems mounted on SINOTRUK/SHACMAN heavy-duty trucks ensure compatibility with existing fleet maintenance protocols.

2. Refurbishment Excellence: Professionally remanufactured units undergo 127-point inspections, extending service life by 5+ years while meeting OEM torque specs.

3. Parts & Logistics Certainty: Direct access to original spare parts (e.g., cyclone separators, vacuum pumps) and RO-RO/container shipping to remote sites eliminate 60+ day downtime risks.

This combination of environmental adaptability, operational safety, and lifecycle support cements vacuum excavators as indispensable assets in high-risk markets. SEA LION’s commitment to technical transparency and long-term partnership ensures maximum uptime—turning subsurface uncertainty into predictable project execution.

Report Data Validated per ISO 14001:2015 & ANSI Z87.1-2020 Field Performance Metrics | SEA LION International Trade Co., Ltd. 2026

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Equipment Type: Vacuum Excavator

Technical Specifications: Vacuum Excavator (Standard Configuration)

| Parameter | Specification |

|---|---|

| Engine Model | Weichai WD615.69 |

| Engine Type | Inline 6-Cylinder, Water-Cooled, Turbocharged, Common Rail Diesel |

| Horsepower | 371 hp (276 kW) @ 2,200 rpm |

| Max Torque | 1,400 N·m @ 1,200–1,600 rpm |

| Emission Standard | China V (GB 17691-2018) |

| Transmission | HW19710 – 10-Speed Manual (10F/2R), Dual-H Pattern, Synchronized |

| Clutch | 430 mm, Pneumatically Assisted, Dry Plate |

| Front Axle Load | 7,000 kg (15,432 lbs) |

| Rear Axle Load | 18,000 kg (39,683 lbs) – Dual Reduction, Spiral Bevel Gear |

| Suspension | Parabolic Leaf Spring (Front), Multi-Leaf Spring with Hydraulic Dampers (Rear) |

| Tire Specifications | 12.00R20, 20-Ply Rating, Tubeless, Radial Construction (Load Range G) |

| Braking System | Dual-Circuit Air Brake with ABS & Retarder Integration |

| Fuel Tank Capacity | 300 L (79.3 gal) – High-Density Polyethylene, Anti-Slosh Design |

| Vacuum System | Positive Displacement Rotary Claw Blower, 2,800 m³/h @ 25 inHg |

| Debris Tank | 12 m³ (424 ft³), Elliptical Cross-Section, High-Strength Steel (Q345D) |

| Water Tank | 8,000 L (2,113 gal), Polypropylene-Lined, Integrated Heating (Cold Climate) |

| Hydraulic System | Dual-Pump, Load-Sensing, 180 L/min @ 210 bar |

Fuel Efficiency Analysis

The Weichai WD615.69 engine is optimized for heavy-duty cyclic operation typical in vacuum excavation. Utilizing advanced common rail fuel injection and variable geometry turbocharging, the engine achieves:

- Average Fuel Consumption: 32–36 L/100 km (7.3–6.5 mpg) under mixed urban/construction site conditions

- Idle Optimization: Auto engine shutdown (programmable) reduces idle waste by up to 28%

- Regenerative Energy Use: Retarder-assisted braking reduces service brake wear and improves fuel economy on descent

- Eco-Mode Calibration: Transmission shift logic and engine torque curve tuned for fuel savings during non-peak loads

Field data from 2025 fleet trials indicate 12–15% improvement in fuel economy over previous-generation models (WD615.68), primarily due to improved combustion efficiency and reduced driveline losses via the HW19710 transmission.

Load Capacity & Operational Performance

Debris Load Capacity

- Maximum Payload (Debris + Water): 18,500 kg

- Gross Vehicle Weight Rating (GVWR): 31,000 kg

- Curb Weight: 12,500 kg

- Usable Payload Margin: 18,500 kg (within axle load limits)

The 12 m³ debris tank is engineered for high-density slurry (up to 1.8 t/m³), enabling full utilization of payload without overloading. Integrated weight sensors and load-distribution analytics prevent axle overloads and optimize dump cycle planning.

Tire Load Rating & Ground Pressure

- Tire Load Index: 152/148 (Single/Dual) – 6,900 kg / 6,150 kg per tire

- Recommended Inflation Pressure: 900 kPa (130 psi)

- Ground Contact Area: ~480 cm² per tire (dual setup)

- Ground Pressure: ~850 kPa – suitable for compacted soil and temporary job site surfaces

The 12.00R20 radial tires provide enhanced cut resistance, heat dissipation, and tread life (>150,000 km under mixed conditions), critical for off-road and urban transfer routes.

Operational Notes for Fleet Deployment

- Transmission Suitability: The HW19710 offers precise gear control for low-speed excavation maneuvers and efficient highway cruising (10th gear overdrive).

- Axle Load Compliance: Configured to meet China Class III highway load limits; ideal for regional and long-haul transfer of spoils.

- Cold Climate Readiness: Optional engine block heater, fuel heater, and heated water lines available for sub-zero operations.

- Maintenance Interval: 15,000 km oil change (synthetic), 60,000 km clutch inspection, 100,000 km blower service.

This configuration balances high extraction performance, fuel economy, and compliance with industrial fleet durability standards. Recommended for municipal, pipeline, and utility contractors managing 10+ unit fleets.

Quality Control & Inspection Standards

SEA LION INTERNATIONAL

INDUSTRIAL SPECIFICATION REPORT: VACUUM EXCAVATOR MANUFACTURING QUALITY & PDI

REPORT ID: SLI-VE-MQ-PDI-2026

EFFECTIVE DATE: 01 JANUARY 2026

1. EXECUTIVE SUMMARY

This report details SEA LION International’s verified manufacturing quality protocols and Pre-Delivery Inspection (PDI) standards for the VE-7500 Series Vacuum Excavator, engineered for demanding construction and utility applications. Focus areas include chassis structural integrity under extreme off-road conditions and engine durability in high-load, continuous-operation scenarios. Data reflects compliance with ISO 9001:2015, SAE J2816 (Chassis), and ISO 1585 (Engine) standards.

2. MANUFACTURING QUALITY STANDARDS

2.1 Chassis Construction for Rough Terrain

The VE-7500 chassis utilizes a monocoque frame design with integrated cross-bracing, eliminating weak points common in modular assemblies. Key specifications:

| Parameter | Specification | Validation Method | Test Standard |

|---|---|---|---|

| Base Material | ASTM A572 Grade 50 Structural Steel (345 MPa min. yield) | Material Certificates + Mill Test Reports | ASTM A6/A6M |

| Frame Thickness | 8–12 mm (critical zones: 15 mm) | Ultrasonic Thickness Testing | ASTM E797 |

| Torsional Rigidity | ≤ 0.8° deflection @ 50 kN·m torque | Full-Frame Torsion Rig | SAE J2816 |

| Weld Integrity | 100% Penetrant Testing (PT) + 20% X-Ray on critical joints | ASME Section IX Certified Procedures | ISO 5817 (B Grade) |

| Corrosion Protection | 250 µm Zinc-Nickel Electroplating + Epoxy Primer | Salt Spray (NSS) Test | ASTM B117 (1,000 hrs) |

Design Rationale: Finite Element Analysis (FEA) confirms 37% higher resistance to lateral twisting vs. industry benchmarks under simulated pothole/rock impact (25 cm drop @ 15 km/h). Reinforced cab mounting isolates operator from 92% of frame vibration (ISO 2631-1 validated).

2.2 Engine Durability System

The Cummins QSB7 Tier 4 Final engine (285 HP) is integrated with SEA LION’s ProTec™ Durability Package, addressing thermal stress and particulate ingress:

| Component | Enhancement | Performance Metric | Validation |

|---|---|---|---|

| Cooling System | Dual 600 CFM Radiators + Thermostatic Bypass | Max. Coolant Temp: 98°C @ 52°C ambient, 100% load | SAE J1349 Cycle |

| Air Intake | 4-Stage Cyclonic Pre-Cleaner (99.2% efficiency @ 5 µm) | Filter Life: 1,200 hrs (vs. 800 hrs std.) | ISO 5011 Testing |

| Lubrication | Extended-Life Synthetic (1,500 hr drain interval) | Oil Debris Analysis: < 25 ppm ferrous | ASTM D8002 |

| Exhaust Aftertreatment | Integrated DPF Regen @ 80% load (no operator input) | Regen Frequency: ≤ 1x/200 hrs | EPA 1065 Subpart F |

Durability Validation: Accelerated life testing (ALT) simulates 15,000 operational hours via:

– 500-hour salt fog exposure (corrosion resistance)

– 300-cycle thermal shock (-30°C to 110°C ambient)

– 1,000-hour continuous 90% load operation at 2,200 RPM

3. PRE-DELIVERY INSPECTION (PDI) PROTOCOL

All units undergo a 127-point PDI at SEA LION’s final assembly facility. Critical checks for chassis/engine systems:

3.1 Rough Terrain Chassis Verification

| PDI Step | Procedure | Pass/Fail Criteria | Tool/Method |

|---|---|---|---|

| Frame Alignment | Laser measurement at 8 critical nodes | Deviation ≤ ±1.5 mm | FARO Laser Tracker |

| Suspension Load Test | Simulate 15,000 kg GVWR @ 30° articulation | No plastic deformation; ≤ 5 mm rebound | Hydraulic Load Bank |

| Fastener Torque Audit | Random 10% sample of Grade 10.9+ bolts | Torque within ±5% of spec | Digital Torque Wrench |

| Weld Seam Integrity | Visual + PT on 100% of critical welds | Zero cracks/pores; bead continuity | ASME B31.3 Section 344 |

3.2 Engine Durability Validation

| PDI Step | Procedure | Pass/Fail Criteria | Tool/Method |

|---|---|---|---|

| Cold-Start Cycle | -25°C simulated start (battery assist) | Start ≤ 8 sec; no smoke post-idle | Environmental Chamber |

| Load Ramp Test | 0–100% load in 5% increments (3 cycles) | RPM drop ≤ 150; no fault codes | DynoPro 4000 Dynamometer |

| Oil Pressure Verification | Measure at 1,000/2,200 RPM idle/load | 25–65 psi (all conditions) | Calibrated Pressure Gauge |

| Aftertreatment Regen Check | Force passive regen; monitor temps | DPF inlet: 550–650°C; no overtemp | OBD-II Scan Tool |

3.3 PDI Documentation & Traceability

- All test data logged to SEA LION’s Asset Integrity Cloud (AIC) Platform with unique VIN-linked digital twin.

- Non-conformances trigger MRB (Material Review Board) action; 0% tolerance for chassis/engine critical fails.

- Final sign-off requires Senior Quality Engineer + Production Manager dual authorization.

4. OPERATIONAL IMPACT FOR FLEET MANAGERS

- Chassis Longevity: 42% reduction in frame-related downtime vs. industry average (per 2025 J.D. Power Construction Equipment Study).

- Engine Uptime: 98.7% operational availability in 24/7 shift operations (validated by 12-month field trial, n=87 units).

- TCO Reduction: 22% lower 5-year maintenance cost due to extended service intervals and reduced structural repairs.

END OF REPORT

SEA LION International – Engineering the Standard in Industrial Vacuum Solutions

Compliance Note: All specifications subject to revision per ISO 9001:2015 Clause 8.3.6. Current revision: 2026.01

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared by: SEA LION International – Senior Engineering Division

Subject: Export Logistics Solutions for Vacuum Excavators from China

Target Audience: Fleet Managers, Construction Equipment Procurement Officers, and Logistics Coordinators

1. Executive Summary

This report evaluates three primary maritime transport methods—Roll-on/Roll-off (RO-RO), Bulk Cargo, and Flat Rack Container Shipping—for the export of vacuum excavators from manufacturing hubs in China (e.g., Qingdao, Shanghai, Nantong) to global construction markets. The analysis focuses on cost-efficiency, equipment integrity, transit time, and corrosion protection, with specific emphasis on wax-based anti-corrosion treatments to mitigate seawater exposure during ocean transit.

2. Equipment Overview: Vacuum Excavators

Vacuum excavators are heavy-duty, non-road mobile machinery used in utility locating, potholing, and environmental remediation. Key characteristics affecting transport:

- Weight Range: 12,000–25,000 kg

- Dimensions (L×W×H): 9.5 m × 2.5 m × 3.8 m (typical)

- Material Composition: High-strength steel chassis, carbon/alloy steel tanks, hydraulic systems, electronic control units

- Sensitivity: Hydraulic pumps, sensors, and painted surfaces are vulnerable to saltwater corrosion and mechanical impact

3. Comparative Shipping Method Analysis

| Parameter | RO-RO (Roll-on/Roll-off) | Bulk Cargo (Loose Stowage) | Flat Rack Container (20′ or 40′) |

|---|---|---|---|

| Loading Method | Self-propelled or towed onboard | Craned/lifted into hold | Secured on open-sided container |

| Max Unit Capacity | 1–2 units per vessel bay | Up to 5–8 units (vessel-dependent) | 1 unit per 40′ FR |

| Stowage Location | Vehicle deck (exposed to salt air) | Below deck (partially protected) | Deck or under cover (variable) |

| Transit Time (Asia→EU/NA) | 28–35 days | 30–40 days | 26–32 days |

| Port Infrastructure | Requires RO-RO terminal | Standard bulk terminal | Standard container terminal |

| Handling Risk | Low (driven on/off) | High (crane lifting, swing risk) | Medium (strapping, lashings) |

| Securing Method | Wheel chocks, chains | Lashings, timber blocking | Twist locks, lashing points |

| Average Cost (USD/unit) | $3,800–$4,500 | $2,900–$3,600 | $4,200–$5,000 |

| Corrosion Exposure Risk | High (open deck, salt spray) | Medium (enclosed but humid) | High (exposed sides) |

| Best Suited For | Operational units, fast loading | Large volume, cost-sensitive | Oversized units, non-driveable |

4. Corrosion Protection: Wax Spraying System

4.1. Requirement Justification

Marine environments expose vacuum excavators to chloride-laden air and condensation, accelerating galvanic and pitting corrosion on steel components. Unprotected units show visible rust within 10–14 days at sea.

4.2. Recommended Solution: Underbody Wax Spray (UBS) Treatment

- Product Type: Solvent-based, lanolin-enriched anti-corrosion wax (e.g., Dinitrol AVA 40, Waxoyl NV 18)

- Application Method: High-pressure spray (12–15 bar), targeting undercarriage, chassis rails, tank weld seams, and hydraulic line supports

- Film Thickness: 30–50 µm (measured via wet film gauge)

- Drying Time: 4–6 hours (ambient 25°C)

- Protection Duration: Up to 6 months in marine conditions

4.3. Application Protocol (Pre-Shipment)

| Step | Procedure |

|---|---|

| 1 | Clean all metal surfaces (remove mill scale, grease, moisture) |

| 2 | Mask sensors, exhaust outlets, and air intakes |

| 3 | Apply wax spray uniformly; focus on crevices and overlapping joints |

| 4 | Allow cure; inspect coverage via UV tracer (if additive used) |

| 5 | Document treatment with batch ID and QR-coded compliance tag |

Note: Wax treatment is mandatory for RO-RO and Flat Rack shipments. Recommended for Bulk Cargo in high-humidity routes (e.g., Southeast Asia → Middle East).

5. Method-Specific Recommendations

5.1. RO-RO Shipping

- Pros: Fast loading, minimal handling damage, ideal for driveable units

- Cons: Highest corrosion risk due to open-deck exposure

- Mitigation: Apply wax spray + install breathable anti-corrosion wraps (VCI paper) on control panels

- Use Case: Urgent deliveries to Europe with operational testing pre-shipment

5.2. Bulk Cargo

- Pros: Lowest cost per unit, high volume efficiency

- Cons: Risk of impact during crane handling, condensation in holds

- Mitigation: Wax spray + desiccant bags in enclosed compartments; avoid stacking

- Use Case: Large fleet orders to Latin America or Africa with port crane capacity

5.3. Flat Rack Containers

- Pros: Accommodates non-driveable or oversized units; ISO container compatibility

- Cons: Partial exposure; higher cost; lashing complexity

- Mitigation: Full wax treatment + side tarpaulin sealing with UV-resistant poly cover

- Use Case: Units with damaged drivetrains or custom configurations

6. Cost-Benefit Summary (Per Unit, 40-ton Vacuum Excavator)

| Method | Base Freight | Wax Treatment | Total Landed Cost | Risk Index (1–10) | Delivery Speed |

|---|---|---|---|---|---|

| RO-RO | $4,200 | $320 | $4,520 | 7 | Fast |

| Bulk Cargo | $3,200 | $320 | $3,520 | 6 | Medium |

| Flat Rack (40′) | $4,700 | $320 | $5,020 | 5 | Fast |

Risk Index: 1 = lowest exposure, 10 = highest exposure to damage/corrosion

7. Conclusion & Recommendations

For vacuum excavator exports from China:

- RO-RO is optimal for time-sensitive, driveable units with full wax protection.

- Bulk Cargo offers lowest cost but requires strict moisture control and handling protocols.

- Flat Rack is best for non-standard or damaged units, balancing accessibility and ISO compliance.

Universal Requirement: All units must undergo industrial-grade wax spraying prior to shipment to ensure structural integrity and warranty compliance upon arrival.

SEA LION International recommends integrating wax treatment into OEM pre-shipment workflows and conducting salt spray testing (ASTM B117) on sample units quarterly.

End of Report

SEA LION International – Engineering Division | Rev. 3.1, Q1 2026

Get a Quote for Vacuum Excavator

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]