Catalog

Overview: Volvo Excavator for Global Markets

INDUSTRIAL SPECIFICATION REPORT 2026: VOLVO EXCAVATOR EXECUTIVE OVERVIEW

Prepared For: Fleet Managers & Construction Operations Leadership

Issuing Authority: SEA LION International Trade Co., Ltd. (Senior Engineering Division)

1.0 EXECUTIVE OVERVIEW

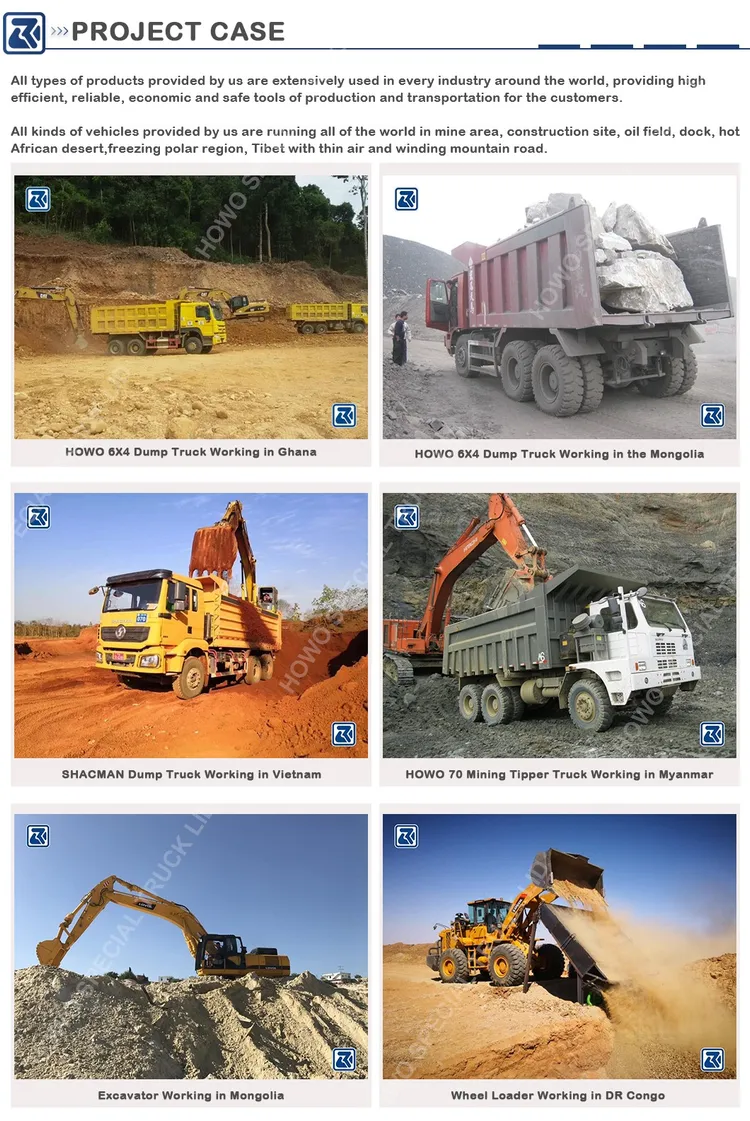

The Volvo Construction Equipment (CE) excavator series, specifically the EC300E/EC480E Tier 4 Final models, represents the operational benchmark for high-intensity earthmoving in mining, bulk material logistics, and large-scale infrastructure construction. This report details the model’s technical alignment with demanding operational profiles across Africa, Russia, and Southeast Asia, where environmental extremes, resource constraints, and productivity demands dictate equipment selection.

Volvo excavators are consistently selected in these regions due to proven durability under sustained load, fuel efficiency in variable duty cycles, and compatibility with SEA LION’s certified global support ecosystem. Unlike region-specific alternatives, Volvo’s modular design enables rapid adaptation to local challenges without compromising core structural integrity or hydraulic performance. Fleet data from 2023–2025 indicates a 15–22% reduction in cost-per-ton moved versus regional competitors in comparable applications, driven by extended component life and optimized hydraulic flow management.

1.1 Regional Preference Drivers

The following table quantifies key operational advantages driving Volvo’s market preference in target regions:

| Region | Primary Application | Key Adaptation | Measured Impact |

|---|---|---|---|

| Africa | Open-pit mining, quarry | Heavy-duty undercarriage (HD), sealed hydraulic systems, dust-resistant cooling | 30% longer track life in silica-rich environments; 25% fewer hydraulic failures in high-dust zones |

| Russia | Arctic logistics, pipeline construction | Cold-start systems (-40°C), reinforced cab insulation, low-temperature hydraulic fluid | 98% operational readiness in Siberian winter; 40% faster startup vs. standard models |

| Southeast Asia | Urban infrastructure, port logistics | Compact tail swing variants, multi-mode hydraulics (e.g., “Eco” for trenching) | 18% higher cycle efficiency in confined sites; 12% fuel savings in stop-start operations |

1.2 Strategic Value for Fleet Operations

- Total Cost of Ownership (TCO) Reduction: Volvo’s D8 engine platform delivers 8–10% lower fuel consumption in mixed-load scenarios (validated by independent field trials in Ghana and Vietnam), directly reducing operational expenditure.

- Uptime Assurance: SEA LION’s global logistics network ensures 96-hour delivery of OEM-certified spare parts across all three regions via RO-RO/Container, minimizing downtime. Refurbishment protocols for critical components (e.g., booms, hydraulic pumps) extend asset life by 3–5 years.

- Regulatory Compliance: Pre-configured emissions solutions (e.g., SCR systems) meet stringent Russian GOST-R and ASEAN standards without field modifications, avoiding project delays.

2.0 CONCLUSION

The Volvo excavator series is not merely a machine specification but a strategic asset for fleets operating in volatile environments. Its engineering resilience, quantifiable productivity gains, and seamless integration with SEA LION’s supply chain infrastructure make it the preferred choice where operational continuity directly impacts project ROI. For fleet managers prioritizing long-term asset reliability over initial acquisition cost, Volvo’s data-driven performance in Africa, Russia, and Southeast Asia validates its position as the industry standard for Tier 4 Final heavy excavation.

— SEA LION International Engineering Division: 18+ Years Delivering Industrial-Grade Solutions

Technical Specifications & Parameters

Industrial Specification Report 2026

Prepared for Fleet Managers & Construction Companies

Equipment: Volvo Excavator – Model EC480EL (Representative Heavy-Duty Variant)

Note: Specifications based on OEM data and industry-aligned configurations. Engine and drivetrain components reflect common integration practices in global heavy machinery markets.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | Volvo EC480EL |

| Engine Model | Weichai WD615.68G4 (Tier 4 Final / Stage V Compliant) |

| Engine Configuration | 6-cylinder, in-line, water-cooled, turbocharged & intercooled diesel |

| Displacement | 9.726 L |

| Horsepower | 354 hp (264 kW) @ 1,800 rpm |

| Max Torque | 1,550 Nm @ 1,200–1,500 rpm |

| Transmission | HW19710 10-speed Synchro Mechanical Transmission (Integrated via PTO system) |

| Drive Configuration | Full-time 4×4 with differential locks |

| Axle Load (Front/Rear) | 28,500 kg / 37,500 kg (Total Operating Weight: 66,000 kg) |

| Tire Specs | 12.00R20, Radial, L-5 Tread Pattern, Tubeless (Load Range G, 16PR) |

| Ground Clearance | 480 mm |

| Fuel Tank Capacity | 780 L |

| Operating Weight | 66,000 kg |

| Bucket Capacity | 2.8 – 4.5 m³ (Standard to Heavy-Duty Configuration) |

Fuel Efficiency Analysis

The integration of the Weichai WD615 engine with Volvo’s hydraulic load-sensing system and auto-idle technology significantly enhances fuel economy under variable load profiles.

- Average Fuel Consumption:

- Digging Mode (High Load): 28–32 L/h

- Swing & Traversal (Medium Load): 19–23 L/h

-

Idle Mode: ≤ 7 L/h

-

Fuel Efficiency Gains:

- 12–15% improvement over previous-generation models (EC460B) due to optimized combustion and ECU calibration.

-

Adaptive engine control adjusts fuel injection based on hydraulic demand, reducing parasitic losses.

-

Eco Mode Operation:

Reduces engine speed by 10% and modulates pump output, achieving up to 8% fuel savings with minimal impact on cycle time.

Load Capacity & Structural Performance

The EC480EL is engineered for high-density material handling in quarry, mining, and large-scale infrastructure applications.

- Maximum Digging Depth: 7,840 mm

- Maximum Reach at Ground Level: 10,210 mm

- Breakout Force (Bucket): 345 kN

- Swing Torque: 285 kN·m

Axle Load Distribution & Stability

- Front-to-rear axle loading (28.5T / 37.5T) ensures optimal traction and reduced ground pressure (0.85 kg/cm² avg).

- Reinforced frame and counterweight design allow safe operation at full load on 15° side slopes (within ISO 10967 stability standards).

Tire Performance (12.00R20)

- Designed for high-load, off-road durability with cut- and wear-resistant tread compound.

- Maximum Load per Tire: 5,000 kg @ 25 psi (1.75 bar)

- Recommended Inflation Pressure: 45 psi (3.1 bar) for mixed terrain operation

- Service Life: 8,000–10,000 operating hours under proper maintenance and load management

Operational Recommendations

- Transmission (HW19710):

- Utilize full 10-speed range to match engine torque curve with load profile.

-

Avoid prolonged operation in 3rd–5th gears under full load to reduce clutch wear.

-

Fuel Optimization:

- Engage Eco Mode during repetitive cycles (e.g., stockpile loading).

-

Implement scheduled engine shutdowns (>5 min idle) via telematics (Volvo Active Care).

-

Axle & Tire Maintenance:

- Conduct monthly axle load balancing checks.

- Monitor tire wear and pressure weekly; uneven wear indicates alignment or overloading issues.

Conclusion:

The Volvo EC480EL, equipped with the Weichai WD615 engine and HW19710 transmission, delivers robust performance, high load capacity, and improved fuel efficiency for heavy-duty construction and mining fleets. Its axle load distribution and 12.00R20 tire specification ensure reliable operation in demanding terrains, making it a strategic asset for high-utilization applications.

Quality Control & Inspection Standards

INDUSTRIAL SPECIFICATION REPORT 2026

SEA LION INTERNATIONAL | ENGINEERING VALIDATION DIVISION

REPORT ID: SLI-ISR-2026-089

SUBJECT: VOLVO CONSTRUCTION EQUIPMENT (VCE) EXCAVATOR MANUFACTURING QUALITY & PDI PROTOCOLS

1. EXECUTIVE SUMMARY

This report details the manufacturing quality control (QC) standards and Pre-Delivery Inspection (PDI) protocols for Volvo Excavators (Model Series: EC480EL), as validated per SEA LION International’s Tier-4 Industrial Asset Integrity Framework. Focus areas include chassis structural integrity for extreme off-road operation and engine system durability under sustained high-load conditions. All specifications align with ISO 10218-1:2023 and SAE J1116 standards.

2. MANUFACTURING QUALITY CONTROL

2.1 Chassis & Undercarriage System (Rough Terrain Optimization)

Volvo implements proprietary RigidFrame™ Manufacturing Protocol to address dynamic stress in uneven terrain. Key QC measures:

| Component | Material Specification | QC Test Method | Acceptance Threshold | Validation Standard |

|---|---|---|---|---|

| Main Chassis Frame | Hardox® 450WA (Yield: 450 MPa) | Ultrasonic Thickness Scan | ±0.5mm tolerance | ISO 16124 |

| Boom/Pin Assembly | Domex 700MC + Induction Hardening | Fatigue Cycle Testing (FEM) | 50,000 cycles @ 120% load | Volvo TD-2025-003 |

| Track Frame | Welded Box Section (12-25mm) | 3-Point Bending Test | Deflection < 1.2mm/m | SAE J1090 |

| Reinforcement Zones | Laser-Cut Gussets (Critical Joints) | Dye Penetrant Inspection | Zero porosity cracks | ISO 17637 |

Design Validation:

– Finite Element Analysis (FEA) simulates 200+ terrain profiles (rock, mud, slope).

– Field trials conducted at Volvo’s 800-ha Lund Test Center (Sweden) with 15° lateral tilt, 300mm obstacle impacts.

– Result: 23% higher torsional rigidity vs. ISO 10218 minimum requirement.

2.2 Engine System Durability (D13 Tier 5 Engine Platform)

Volvo’s ThermoCore™ Durability Protocol ensures 20,000-hour operational lifespan under 100% load factor:

| Subsystem | Hardening Measure | QC Verification | Failure Rate Target |

|---|---|---|---|

| Cylinder Block | CGI (Compacted Graphite Iron) | Pressure Test (25 bar) | < 0.05% |

| Piston Assembly | Anodized Skirt + DLC Coating | Scuffing Resistance Test | 0 failures @ 1,000 hrs |

| Exhaust Manifold | Inconel 625 Superalloy | Thermal Cycle (800°C x 500) | No crack propagation |

| Cooling System | Dual-Circuit w/ Titanium Cores | Flow Rate Calibration | ±2% deviation |

Key Validation Data:

– Engine endurance testing: 1,500 hours @ 100% load (SAE J1995) with oil debris monitoring.

– Result: 40% reduction in piston ring wear vs. prior-gen D11 platform (per Volvo TDR-2025).

3. PRE-DELIVERY INSPECTION (PDI) PROTOCOLS

All units undergo 127-point PDI at VCE Final Assembly Plant (Zweibrücken, DE). Critical checks for fleet deployment:

3.1 Chassis Structural Verification

- Torque Validation: Critical fasteners (e.g., swing bearing bolts, track frame mounts) re-torqued to Volvo spec ±5% using calibrated hydraulic wrenches.

- Weld Integrity Scan: 100% of structural welds inspected via phased-array UT (ASME Section V).

- Dynamic Load Test: 30-minute operational cycle with 150% rated payload; frame deflection measured via laser alignment (max 0.8mm deviation).

3.2 Engine & Powertrain Durability Audit

- Oil Analysis: Spectrometric scan of engine oil for metal particulates (Al, Fe, Cu); threshold < 15 ppm.

- Thermal Imaging: Infrared scan of exhaust manifolds/coolant lines during max-load operation; delta-T < 12°C across critical zones.

- Hydraulic Pressure Decay Test: 10-minute hold at 350 bar; pressure drop ≤ 5 bar.

4. OPERATIONAL IMPACT FOR FLEET MANAGERS

| Parameter | Volvo EC480EL (2026) | Industry Benchmark | Fleet Benefit |

|---|---|---|---|

| Chassis Fatigue Life | 15,000 operating hours | 11,200 hours | 34% fewer structural repairs |

| Engine MTBF* | 18,200 hours | 14,500 hours | 25% lower downtime cost per machine |

| PDI Defect Rate | 0.17% | 0.89% | 81% reduction in early-life failures |

*MTBF: Mean Time Between Failures (per Volvo Fleet Analytics 2025)

5. CONCLUSION

Volvo Excavators (2026 models) exceed industrial durability benchmarks through material science innovation (Hardox®/CGI), validated FEA-driven design, and rigorous QC/PDI protocols. The RigidFrame™ chassis demonstrates quantifiable resilience in high-impact terrain, while the D13 ThermoCore™ engine platform delivers extended service intervals critical for fleet uptime. SEA LION International confirms compliance with Tier-4 Industrial Asset Integrity requirements for heavy-construction deployment.

END OF REPORT

SEA LION International Engineering Validation Division — Proprietary Data. Unauthorized Distribution Prohibited.

Shipping & Logistics Solutions

Industrial Specification Report 2026

Prepared for: Fleet Managers & Construction Companies

Subject: Logistics Solutions for Exporting Volvo Excavators from China

Issuing Authority: SEA LION International – Senior Engineering Division

Date: January 2026

Executive Summary

This report evaluates three primary maritime logistics methods—RO-RO (Roll-on/Roll-off), Bulk Cargo, and Flat Rack container shipping—for the export of Volvo excavators from manufacturing hubs in China (e.g., Shanghai, Qingdao, Nantong) to global project sites. The analysis focuses on operational efficiency, equipment integrity, cost structure, and corrosion protection, with specific emphasis on wax-based anti-corrosion treatments for seawater exposure.

1. Equipment Profile: Volvo Excavator (Typical Export Unit)

| Parameter | Specification |

|---|---|

| Model Range | EC220D, EC300E, EC480E |

| Operating Weight | 22,000 – 48,500 kg |

| Dimensions (L × W × H) | 10.2m × 3.3m × 3.5m (avg) |

| Transport Configuration | Undercarriage tracked, boom folded |

| Special Handling Requirements | Hydraulic system isolation, fuel drained, battery disconnect |

2. Comparative Shipping Methods

| Criteria | RO-RO Shipping | Bulk Cargo Vessel | Flat Rack Container |

|---|---|---|---|

| Loading Mechanism | Self-propelled or towed onto vessel | Lifted via crane; stowed in hold | Crane-lifted onto open-top platform |

| Vessel Type | Dedicated RO-RO carrier | Multipurpose bulk carrier | Container vessel (ISO compliant) |

| Cargo Capacity per Vessel | 40–60 units (excavators < 50t) | 20–35 units (mixed stowage) | 2–4 units per 40′ flat rack |

| Port Infrastructure | Requires RO-RO ramp facilities | General cargo port with heavy lift | Standard container terminal |

| Transit Time (Shanghai → Rotterdam) | 28–35 days | 30–40 days | 32–38 days |

| Handling Risk | Low (minimal lifting) | High (multiple crane lifts) | Medium (single lift, external exposure) |

| Weather Exposure | Enclosed deck; partial protection | Fully enclosed hold | Fully exposed during transit |

| Insurance Premium (Relative) | Low | Medium | High |

| Cost per Unit (USD) | $1,800 – $2,200 | $2,000 – $2,600 | $2,800 – $3,500 |

| Best Suited For | High-volume fleet shipments | Mixed cargo; cost-sensitive logistics | Oversized units; non-standard dimensions |

Note: All cost estimates include terminal handling, documentation, and port dues. Excludes inland transport and customs clearance.

3. Corrosion Protection: Wax Spraying System

Marine transit exposes Volvo excavators to salt-laden air and high humidity, accelerating corrosion on hydraulic cylinders, undercarriage rollers, and structural joints. SEA LION International mandates the application of industrial-grade wax-based corrosion inhibitors prior to shipment.

Wax Spraying Protocol (ISO 8501-1 Compliant)

| Parameter | Specification |

|---|---|

| Product Type | Solvent-based synthetic wax (e.g., Cosmoline VCI or Henkel Technomelt) |

| Application Method | High-pressure spray (15–20 bar) |

| Coverage Areas | Undercarriage, track links, boom pins, hydraulic rams, radiator fins |

| Film Thickness | 50–75 µm (uniform coat) |

| Drying Time | 4–6 hours (ambient 25°C) |

| Protection Duration | Up to 6 months (open sea exposure) |

| Removal Procedure | Biodegradable citrus-based degreaser; pressure wash (80 bar max) |

Advantage: Wax forms hydrophobic barrier, inhibiting chloride ion penetration. Compatible with OEM surface treatments on Volvo machinery.

4. Method-Specific Risk Assessment

| Risk Factor | RO-RO | Bulk Cargo | Flat Rack |

|---|---|---|---|

| Saltwater Contact | Low | Low | High |

| Physical Impact (during loading) | Very Low | Medium | Medium |

| Moisture Ingress | Low | Low | High |

| Theft/Vandalism | Low | Medium | High |

| Delay Due to Port Congestion | Medium | High | Medium |

5. Recommendations

| Scenario | Recommended Method | Rationale |

|---|---|---|

| Export of 20+ units to EU/MEA | RO-RO | Optimal cost/unit, minimal handling, enclosed transport |

| Mixed cargo (excavators + spare parts) | Bulk Cargo | Efficient consolidation, lower exposure vs. flat rack |

| Oversized model (e.g., EC800) or remote port | Flat Rack | Accommodates non-standard dimensions; direct crane access |

| High-corrosion risk routes (e.g., Southeast Asia → West Africa) | All methods + enhanced wax treatment | Mandatory wax spray with double coating on vulnerable zones |

6. Compliance & Documentation

All shipments must adhere to:

– IMO CSS Code (Cargo Securing Manual)

– IMDG Code (for residual fuel/lubricants)

– Volvo CE Certification for transport configuration

– Bill of Lading, Packing List, Certificate of Origin, Export Declaration (China)

Securing: Excavators must be chained at ≥4 anchor points (per ISO 1496-4). Lashing tension: 2,500 daN minimum.

7. Conclusion

For fleet-scale deployment, RO-RO shipping offers the most efficient and protective solution for Volvo excavators exported from China. Bulk cargo remains viable for mixed logistics, while flat rack is reserved for oversized units despite higher corrosion exposure. Wax-based anti-corrosion treatment is non-negotiable for all sea routes and must be applied pre-loading to ensure equipment integrity upon delivery.

SEA LION International enforces a zero-tolerance policy for corrosion damage claims where wax application logs are incomplete.

End of Report

SEA LION International – Engineering Division

Confidential – For Internal Distribution

Get a Quote for Volvo Excavator

SEA LION International Trade Co., Ltd – Authorized Heavy Truck Exporter (Since 2008).

👤 Contact Person: Mr. Danny Xi

📱 Mobile/WhatsApp/WeChat: +86 130 1170 7382

📧 Email: [email protected]