Introduction: Navigating the Global Market for 10-wheel Heavy Duty Used Dumper Truck

In today’s competitive landscape, sourcing a reliable 10-wheel heavy duty used dumper truck presents a significant challenge for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. With fluctuating market conditions, varying quality standards, and diverse supplier capabilities, making an informed purchasing decision is crucial. This comprehensive guide delves into the multifaceted world of 10-wheel heavy duty used dumper trucks, exploring different types, their applications across various industries, and key factors for supplier vetting.

Buyers will gain valuable insights into the operational versatility of these trucks, capable of handling substantial loads in construction, mining, and agricultural sectors. Furthermore, the guide addresses cost considerations, providing a framework for understanding pricing trends and negotiating deals that align with budgetary constraints.

By empowering buyers with the knowledge needed to evaluate their options effectively, this guide serves as a vital resource for navigating the complexities of the global used truck market. Whether you are in Brazil looking for robust machinery to support infrastructure development or in Nigeria sourcing equipment for mining operations, our insights will help you make strategic decisions that drive your business forward.

Understanding 10-wheel Heavy Duty Used Dumper Truck Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard 10-Wheel Dump Truck | 10 wheels, typically 6×4 configuration, high payload | Construction, landscaping, mining | Pros: Versatile, widely available; Cons: May lack specialized features. |

| Heavy-Duty Off-Road Dump Truck | Reinforced chassis, larger tires, enhanced suspension | Mining, logging, rough terrain work | Pros: Superior durability, off-road capability; Cons: Higher maintenance costs. |

| Tipper Dump Truck | Hydraulic tipping mechanism, larger dump body | Construction, waste management | Pros: Efficient unloading, increased productivity; Cons: Requires more space for maneuvering. |

| Mini Dump Truck | Smaller size, lower payload capacity | Urban construction, small projects | Pros: Easy to navigate in tight spaces; Cons: Limited payload capacity. |

| Specialized Dump Truck | Custom-built for specific tasks (e.g., concrete) | Specialized construction, demolition | Pros: Tailored for specific applications; Cons: Higher upfront investment. |

What Are the Key Characteristics of Standard 10-Wheel Dump Trucks?

Standard 10-wheel dump trucks are commonly used in various industries, characterized by their robust 6×4 configuration and high payload capacity. They are suitable for construction, landscaping, and mining applications, making them a versatile choice for B2B buyers. When purchasing, consider the truck’s engine power, hydraulic system efficiency, and overall condition to ensure it meets your operational needs.

How Do Heavy-Duty Off-Road Dump Trucks Differ from Standard Models?

Heavy-duty off-road dump trucks are designed with reinforced chassis and larger tires, making them ideal for rugged terrains, such as mining and logging sites. Their enhanced suspension systems allow for better stability and load handling on uneven surfaces. B2B buyers should evaluate the truck’s off-road capabilities, fuel efficiency, and service history, as maintenance costs may be higher due to their specialized design.

What Advantages Do Tipper Dump Trucks Offer in B2B Operations?

Tipper dump trucks feature a hydraulic tipping mechanism that allows for quick and efficient unloading of materials. This design is particularly advantageous in construction and waste management, where time is critical. When considering a tipper truck, assess the hydraulic system’s reliability and the truck’s overall maneuverability, as these factors can significantly affect productivity on job sites.

Why Choose Mini Dump Trucks for Urban Construction Projects?

Mini dump trucks are smaller in size and have a lower payload capacity, making them ideal for urban construction and smaller projects. Their compact design allows for easy navigation in tight spaces, which is often a challenge in city environments. Buyers should consider the truck’s maneuverability, payload capabilities, and engine efficiency, especially for frequent short-haul operations.

What Should Buyers Know About Specialized Dump Trucks?

Specialized dump trucks are custom-built for specific tasks, such as transporting concrete or other specialized materials. These trucks can significantly enhance productivity in specialized construction and demolition projects. However, they often come with a higher upfront investment. B2B buyers should weigh the benefits of increased efficiency against the initial costs and ensure that the truck meets the specific needs of their operations.

Key Industrial Applications of 10-wheel Heavy Duty Used Dumper Truck

| Industry/Sector | Specific Application of 10-wheel Heavy Duty Used Dumper Truck | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Transporting aggregates, soil, and debris on construction sites | Enhances efficiency in site logistics, reducing downtime | Assess truck capacity, engine power, and maintenance history |

| Mining | Hauling minerals and ores from extraction sites to processing facilities | Increases productivity and reduces manual labor costs | Ensure compatibility with terrain and load specifications |

| Agriculture | Delivering soil, fertilizers, and harvested crops | Streamlines farm operations and improves yield management | Evaluate payload capacity and durability for rough terrain |

| Waste Management | Collecting and transporting waste materials to disposal sites | Supports effective waste management and environmental compliance | Check for operational reliability and fuel efficiency |

| Infrastructure Development | Moving materials for road and bridge construction | Facilitates timely project completion and cost management | Consider vehicle lifespan, availability of spare parts |

How is a 10-wheel Heavy Duty Used Dumper Truck Utilized in the Construction Industry?

In the construction sector, 10-wheel heavy-duty used dumper trucks are essential for transporting aggregates, soil, and debris from one site to another. They help streamline logistics on construction sites, significantly reducing downtime and enhancing operational efficiency. Buyers in this field should prioritize trucks with high payload capacities and robust engines to handle heavy loads, while also reviewing maintenance records to ensure reliability.

What Role Does a 10-wheel Dumper Truck Play in the Mining Sector?

In mining operations, these dumper trucks are crucial for hauling minerals and ores from extraction sites to processing facilities. Their ability to carry substantial loads minimizes the need for manual labor and enhances overall productivity. International buyers, particularly in regions like Africa and South America, should focus on trucks that can navigate rugged terrains and meet specific load requirements, ensuring they can withstand the demanding conditions typical of mining environments.

How Can a 10-wheel Dumper Truck Benefit Agricultural Operations?

In agriculture, 10-wheel dumper trucks are utilized for transporting soil, fertilizers, and harvested crops, which are vital for efficient farm management. Their use can streamline operations, leading to improved yield management and reduced labor costs. Buyers should consider trucks with durable construction and sufficient payload capacity to handle the diverse materials commonly transported on farms, especially in regions with challenging terrains.

What is the Importance of 10-wheel Dumper Trucks in Waste Management?

In the waste management industry, these trucks are employed to collect and transport waste materials to disposal sites. Their role is pivotal in ensuring effective waste management and compliance with environmental regulations. Buyers should evaluate the operational reliability and fuel efficiency of the trucks, as these factors directly impact cost-effectiveness and sustainability in waste transportation.

How Do 10-wheel Dumper Trucks Support Infrastructure Development Projects?

For infrastructure development, such as road and bridge construction, 10-wheel dumper trucks are indispensable for moving materials efficiently. They facilitate timely project completion and help manage costs effectively. Buyers in this sector should consider the lifespan of the vehicle and the availability of spare parts, ensuring that their investment remains viable over the long term, particularly in regions where maintenance services may be limited.

3 Common User Pain Points for ’10-wheel Heavy Duty Used Dumper Truck’ & Their Solutions

Scenario 1: Navigating Uncertainties in Equipment Condition

The Problem: B2B buyers often face significant uncertainty regarding the condition of used 10-wheel heavy-duty dumper trucks. Without a clear understanding of the truck’s maintenance history, operational hours, and potential hidden defects, buyers may end up investing in equipment that could lead to costly repairs or operational downtime. This uncertainty is especially pronounced when sourcing from international suppliers, where physical inspections may not be feasible.

The Solution: To mitigate these risks, buyers should prioritize due diligence when sourcing used dumper trucks. This includes asking for comprehensive service records, maintenance logs, and inspection reports. Engaging with reputable dealers who provide warranties or guarantees on their vehicles can also enhance buyer confidence. Additionally, utilizing third-party inspection services can provide an unbiased assessment of the truck’s condition before purchase. These proactive measures help ensure that buyers invest in reliable equipment, reducing the likelihood of unexpected costs and operational disruptions.

Scenario 2: Overcoming Compliance and Regulatory Challenges

The Problem: Compliance with local regulations and standards can pose a significant challenge for international buyers of heavy-duty dumper trucks. Different countries have varying emissions standards, safety regulations, and import requirements. Failure to adhere to these regulations can lead to fines, operational delays, and even the inability to use the purchased truck within the buyer’s country.

The Solution: To navigate these complexities, buyers should conduct thorough research on the regulatory landscape in their respective countries before purchasing a used dumper truck. Collaborating with local legal and compliance experts can provide valuable insights into necessary certifications and modifications needed for the truck to meet local standards. Additionally, buyers should seek out suppliers who specialize in international sales and can assist with compliance documentation and modifications. This proactive approach ensures that the purchased trucks are not only compliant but also ready for immediate deployment upon arrival.

Scenario 3: Addressing Performance and Load Capacity Concerns

The Problem: Another common pain point for B2B buyers is the concern over the performance and load capacity of used 10-wheel heavy-duty dumper trucks. Buyers may worry that the truck’s specifications do not meet their specific operational needs, leading to inefficiencies or safety issues during heavy hauling tasks. This is particularly critical in industries such as construction and mining, where load requirements are stringent.

The Solution: To address these concerns, buyers should conduct a detailed assessment of their operational needs prior to purchasing a dumper truck. This includes calculating the average load weights, types of materials to be transported, and the terrain conditions the truck will encounter. Buyers should then match these requirements with the truck’s specifications, including its payload capacity, engine power, and transmission type. Engaging with suppliers who offer customization options or specialized vehicles can also provide tailored solutions that better fit the buyer’s needs. Furthermore, prospective buyers should request trial runs or demonstrations when possible to evaluate the truck’s performance in real-world conditions before finalizing the purchase. This ensures that the equipment acquired will meet operational demands effectively and safely.

Strategic Material Selection Guide for 10-wheel Heavy Duty Used Dumper Truck

What Are the Common Materials Used in 10-Wheel Heavy Duty Used Dumper Trucks?

When selecting materials for 10-wheel heavy-duty used dumper trucks, several factors come into play, including performance, cost, and regional compliance. Here, we analyze four common materials used in the construction of these trucks, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

Steel: The Backbone of Heavy-Duty Trucks

Key Properties: Steel is renowned for its strength and durability, with a high tensile strength that allows it to withstand heavy loads and harsh conditions. It typically has a temperature rating suitable for a wide range of environments and exhibits good resistance to wear and tear.

Pros & Cons: The primary advantage of steel is its robustness, making it ideal for the structural components of dumper trucks. However, it is susceptible to corrosion if not properly treated, which can lead to increased maintenance costs. The manufacturing complexity is moderate, as steel can be easily welded and shaped.

Impact on Application: Steel is compatible with various media, including aggregates and construction materials. Its strength ensures that it can handle heavy payloads without deforming.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the steel used complies with local standards, such as ASTM or DIN. Corrosion resistance is particularly important in humid or coastal areas.

Aluminum: Lightweight and Corrosion-Resistant

Key Properties: Aluminum is lightweight yet strong, with excellent corrosion resistance. It has a lower density than steel, making it easier to handle and transport.

Pros & Cons: The main advantage of aluminum is its weight savings, which can improve fuel efficiency and payload capacity. However, it is generally more expensive than steel and can be less durable under extreme conditions. The manufacturing process can be more complex due to the need for specialized welding techniques.

Impact on Application: Aluminum is ideal for applications where weight reduction is critical, such as in the truck body and components. Its corrosion resistance makes it suitable for environments where exposure to moisture is common.

Considerations for International Buyers: Buyers in Europe and the Middle East may prefer aluminum for its lightweight properties, but they should be aware of the higher costs. Compliance with standards such as JIS for aluminum alloys is essential.

Composite Materials: Innovative and Versatile

Key Properties: Composites, often made from a combination of materials like fiberglass and resin, offer unique properties such as high strength-to-weight ratios and excellent corrosion resistance.

Pros & Cons: The key advantage of composites is their versatility; they can be molded into complex shapes and are resistant to many chemicals. However, they can be more expensive to produce and may require specialized manufacturing processes.

Impact on Application: Composites are particularly useful for non-structural components or panels, where weight savings can enhance overall vehicle performance.

Considerations for International Buyers: Buyers should evaluate the availability of composite materials in their region, as well as any specific manufacturing capabilities required. Compliance with international standards for composite materials is also crucial.

Rubber: Essential for Traction and Durability

Key Properties: Rubber is flexible and resilient, with excellent abrasion resistance and the ability to withstand varying temperatures.

Pros & Cons: The main advantage of rubber is its ability to provide traction and shock absorption, making it ideal for tires and suspension components. However, it can degrade over time due to UV exposure and ozone, necessitating regular replacement.

Impact on Application: Rubber is crucial for the tires of dumper trucks, ensuring adequate grip on various terrains, especially in construction sites.

Considerations for International Buyers: Buyers should consider the climate of their operating regions, as extreme temperatures can affect rubber performance. Compliance with local tire standards is also important.

Summary Table

| Material | Typical Use Case for 10-wheel Heavy Duty Used Dumper Truck | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, chassis | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Truck body, lightweight components | Lightweight, excellent corrosion resistance | Higher cost, less durable | High |

| Composite | Non-structural panels, custom shapes | Versatile, high strength-to-weight ratio | Expensive, specialized manufacturing | High |

| Rubber | Tires, suspension components | Provides traction and shock absorption | Degrades over time | Medium |

This analysis provides a comprehensive overview of the materials commonly used in 10-wheel heavy-duty used dumper trucks, helping international B2B buyers make informed decisions based on their specific needs and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for 10-wheel Heavy Duty Used Dumper Truck

What Are the Main Stages in the Manufacturing Process of 10-wheel Heavy Duty Used Dumper Trucks?

The manufacturing process of 10-wheel heavy-duty used dumper trucks involves several key stages, each critical to ensuring the durability and performance of the final product. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

This initial stage focuses on sourcing high-quality raw materials, such as high-strength steel for the chassis and durable composites for body components. Suppliers must ensure that materials meet specific industry standards to enhance longevity and reduce maintenance costs. For international B2B buyers, verifying the source and quality of these materials is crucial, as this can directly impact the truck’s performance and reliability.

Forming

In the forming stage, raw materials are shaped using various techniques, including stamping, welding, and bending. Advanced technologies like CNC (Computer Numerical Control) machining are often employed to achieve precise dimensions and tolerances. This accuracy is essential for ensuring that components fit together seamlessly during assembly. For buyers from regions like Africa and South America, understanding these processes can aid in evaluating a manufacturer’s capability to produce robust and reliable trucks.

Assembly

The assembly stage involves integrating various components, including the engine, transmission, and hydraulic systems. Skilled technicians utilize standardized procedures to ensure that each truck meets design specifications. The use of modular assembly techniques allows for efficient production and flexibility in customization, catering to the specific needs of different markets. B2B buyers should inquire about the assembly practices and workforce expertise to gauge the quality assurance measures in place.

Finishing

Finishing processes include painting, coating, and surface treatments designed to protect the truck from environmental factors and enhance aesthetic appeal. Quality control checks are performed at this stage to ensure that the finished product adheres to all visual and functional specifications. Buyers can assess the quality of finishes by requesting samples or photographs of previous work to ensure that they align with their expectations.

How Is Quality Assurance Implemented in the Manufacturing of 10-wheel Heavy Duty Used Dumper Trucks?

Quality assurance (QA) is a fundamental aspect of the manufacturing process, ensuring that the trucks meet stringent international and industry-specific standards. Several frameworks and checkpoints are involved in maintaining high-quality outputs.

What International Standards Should Buyers Be Aware Of?

Many manufacturers adhere to international standards such as ISO 9001, which outlines the requirements for a quality management system. Compliance with this standard indicates that the manufacturer has established processes to ensure consistent quality and customer satisfaction. Additionally, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply depending on the truck’s intended use and market. For buyers in Europe and the Middle East, these certifications may be particularly relevant.

What Are the Key Quality Control Checkpoints?

Quality control is typically segmented into three main checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC involves inspecting raw materials and components upon arrival to ensure they meet specified standards before production begins.

- IPQC monitors the manufacturing process, checking for any deviations from the established procedures. This step is crucial for identifying issues early in the production cycle, allowing for corrective actions to be taken promptly.

- FQC is conducted once the trucks are fully assembled, focusing on functional tests and final inspections to verify that the product meets all performance criteria.

What Common Testing Methods Are Used in Quality Assurance for Dumper Trucks?

A variety of testing methods are employed to ensure the reliability and safety of dumper trucks. These include:

- Static and Dynamic Load Testing: Assessing the truck’s ability to handle specified weight loads under both static and moving conditions.

- Hydraulic System Testing: Evaluating the functionality of hydraulic components, crucial for dump functionality.

- Brake Testing: Ensuring that the braking system performs adequately under various conditions.

- Emissions Testing: Verifying that the truck complies with environmental regulations, particularly important for buyers in regions with stringent emissions standards.

How Can B2B Buyers Verify Supplier Quality Control?

International B2B buyers need to conduct thorough due diligence to verify the quality control practices of potential suppliers. This can be achieved through:

- Supplier Audits: Regular audits can help assess the manufacturing processes, quality management systems, and compliance with international standards. Buyers should request audit reports and certifications as part of their evaluation process.

- Quality Reports: Suppliers should provide detailed quality reports that outline testing methods, results, and any corrective actions taken. This transparency is essential for building trust.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control practices. This is particularly valuable for buyers who may not have the expertise to evaluate these aspects independently.

What Nuances Should International Buyers Consider Regarding Quality Control?

When sourcing 10-wheel heavy-duty used dumper trucks, international buyers from regions like Africa, South America, and the Middle East should be aware of specific nuances in quality control:

- Regulatory Compliance: Different regions may have unique regulatory requirements regarding vehicle emissions, safety, and performance. Buyers should ensure that suppliers are compliant with local regulations to avoid issues during importation.

- Cultural and Communication Barriers: Understanding cultural differences in business practices can facilitate smoother negotiations and clearer communication regarding quality expectations.

- After-Sales Support: Quality assurance does not end with the sale. Buyers should inquire about the availability of after-sales support, including warranty conditions and service agreements, which can significantly impact the long-term performance of the dumper trucks.

In conclusion, understanding the manufacturing processes and quality assurance measures of 10-wheel heavy-duty used dumper trucks is essential for B2B buyers. By familiarizing themselves with these aspects, buyers can make informed decisions, ensuring that they acquire vehicles that meet their operational needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ’10-wheel Heavy Duty Used Dumper Truck’

Introduction

Acquiring a 10-wheel heavy-duty used dumper truck can be a strategic investment for businesses involved in construction, mining, or logistics. This guide serves as a practical checklist to help B2B buyers navigate the sourcing process effectively, ensuring they make informed decisions that align with their operational needs and budget considerations.

Step 1: Define Your Technical Specifications

Before beginning the procurement process, it’s vital to outline the specific technical requirements for the dumper truck. Consider factors such as payload capacity, engine power, and transmission type.

– Payload Capacity: Determine the weight of the materials you intend to transport.

– Engine Power: Choose an engine that meets your operational demands, typically ranging from 300 HP to 500 HP for heavy-duty trucks.

Step 2: Set a Budget

Establishing a clear budget is essential to avoid overspending and ensure that the procurement aligns with financial constraints.

– Total Cost of Ownership: Factor in not just the purchase price, but also maintenance, fuel efficiency, and potential repairs.

– Financing Options: Explore financing or leasing options that may offer more flexibility in cash flow management.

Step 3: Research Reputable Suppliers

Thorough research on potential suppliers will help you identify those who can meet your needs reliably.

– Supplier Reviews: Look for testimonials and case studies from previous buyers, especially from similar industries or regions.

– Industry Reputation: Engage in industry forums or trade associations to gather insights about reputable suppliers.

Step 4: Verify Equipment Condition

Assessing the condition of the used dumper trucks is critical to ensuring you make a worthwhile investment.

– Inspection Reports: Request detailed inspection reports that outline the truck’s condition, including mechanical and structural integrity.

– Test Drives: Whenever possible, conduct a test drive to evaluate performance and handling.

Step 5: Check Compliance and Certifications

Ensure that the dumper truck complies with local regulations and industry standards to avoid future legal complications.

– Certification Verification: Confirm that the truck has the necessary certifications for emissions and safety standards in your region.

– Warranty Options: Investigate warranty options that could provide additional security in case of equipment failure.

Step 6: Negotiate Terms and Pricing

Engaging in negotiations can lead to better pricing and terms, which can significantly affect your overall investment.

– Flexible Payment Terms: Discuss options for payment plans or discounts for bulk purchases.

– Inclusions: Clarify what is included in the sale, such as spare parts, servicing, or training for operators.

Step 7: Finalize Purchase and Arrange Logistics

Once all terms are agreed upon, finalize the purchase and plan for transportation or delivery of the dumper truck.

– Delivery Arrangements: Coordinate with the supplier to ensure timely delivery that aligns with your operational schedule.

– Post-Purchase Support: Establish a communication line with the supplier for ongoing support and maintenance guidance.

By following this structured checklist, B2B buyers can ensure a more efficient and effective sourcing process for 10-wheel heavy-duty used dumper trucks, ultimately leading to better operational outcomes.

Comprehensive Cost and Pricing Analysis for 10-wheel Heavy Duty Used Dumper Truck Sourcing

What Are the Key Cost Components in Sourcing a 10-wheel Heavy Duty Used Dumper Truck?

When sourcing a 10-wheel heavy-duty used dumper truck, understanding the cost structure is crucial. The primary cost components include:

-

Materials: The bulk of costs arises from the truck’s materials, which include the chassis, engine, transmission, and dump bed. The quality of these materials can significantly affect durability and performance.

-

Labor: Labor costs encompass both manufacturing and assembly processes. Skilled labor is required to ensure that the truck meets necessary safety and operational standards.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, rent, and equipment depreciation. Efficient manufacturing practices can help reduce these overhead costs.

-

Tooling: If customization is involved, tooling costs may increase. Specialized tools are necessary for modifications or repairs, impacting the overall price.

-

Quality Control (QC): Ensuring that the trucks meet industry standards requires investment in quality control processes. This can involve inspections, testing, and certifications, which are essential for maintaining safety and reliability.

-

Logistics: Shipping and handling costs vary based on the distance and mode of transport. International buyers should factor in potential tariffs and customs duties as part of their logistics costs.

-

Margin: Suppliers typically add a profit margin to cover their costs and generate profit. This margin can vary based on competition and the perceived value of the truck.

How Do Price Influencers Affect the Cost of a 10-wheel Heavy Duty Used Dumper Truck?

Several factors can influence the pricing of used dumper trucks:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in discounted pricing. Buyers should assess their needs and consider bulk purchasing to reduce unit costs.

-

Specifications and Customization: Custom features such as enhanced engine performance or specialized dump bed designs can lead to higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Trucks made from higher-quality materials or those that meet specific certifications often come at a premium. Buyers should weigh the benefits of investing in quality against budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a proven track record may charge more but offer better after-sales support and warranty options.

-

Incoterms: Understanding Incoterms is essential for international transactions. These terms define responsibilities for shipping, insurance, and tariffs, which can significantly impact the total cost of ownership.

What Buyer Tips Can Help Navigate the Sourcing Process for 10-wheel Heavy Duty Used Dumper Trucks?

International B2B buyers should consider several strategies to maximize cost efficiency:

-

Negotiation: Engage in negotiations with suppliers to secure better pricing. Understanding the market value and being prepared to walk away can strengthen your position.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price. Factor in maintenance, fuel consumption, and potential downtime costs. A lower upfront cost may lead to higher long-term expenses.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and local economic conditions in the supplier’s country, which can impact pricing. Additionally, local regulations and customs duties should be factored into the total cost.

-

Research and Compare: Investigate various suppliers and their offerings. Utilize online marketplaces and auction sites to compare prices and specifications effectively.

-

Request Detailed Quotes: Ensure that quotes include all potential costs, including shipping, handling, and any applicable taxes. This transparency helps in making informed decisions.

Conclusion

In conclusion, sourcing a 10-wheel heavy-duty used dumper truck involves careful consideration of various cost components and pricing influencers. By employing strategic buying practices and understanding the total cost of ownership, international B2B buyers can make informed decisions that align with their operational needs and budget constraints. Always remember that the prices listed in marketplaces are indicative and may vary based on the specific circumstances of each transaction.

Alternatives Analysis: Comparing 10-wheel Heavy Duty Used Dumper Truck With Other Solutions

In the world of heavy-duty transportation and construction, selecting the right equipment is crucial for efficiency and cost-effectiveness. While the 10-wheel heavy-duty used dumper truck is a popular choice for various applications, buyers may also consider alternative solutions that could potentially meet their operational needs. Below, we compare the 10-wheel dumper truck against two viable alternatives: articulated dump trucks and flatbed trucks.

| Comparison Aspect | 10-Wheel Heavy Duty Used Dumper Truck | Articulated Dump Truck | Flatbed Truck |

|---|---|---|---|

| Performance | High load capacity, ideal for rough terrain | Excellent for uneven surfaces, flexible in load types | Versatile for various cargo types, not specialized for loose materials |

| Cost | Moderate initial investment; lower resale value | Higher initial cost; better resale value | Generally lower cost; varies widely based on customization |

| Ease of Implementation | Requires driver training; easy to operate | Requires specialized training; more complex | Easy to operate; minimal training needed |

| Maintenance | Regular maintenance required; parts readily available | Higher maintenance costs; parts can be harder to find | Lower maintenance; parts easily sourced |

| Best Use Case | Construction, mining, and large-scale earthmoving | Construction sites with uneven terrain | Transporting building materials, machinery, or pallets |

How Do Articulated Dump Trucks Compare to 10-Wheel Dumper Trucks?

Articulated dump trucks are designed for off-road applications, featuring a flexible joint between the cab and the dump box, allowing for better maneuverability on rough terrains. They typically offer a higher payload capacity and are adept at navigating challenging environments. However, they come with a higher upfront cost and require specialized training for drivers, which can increase overall operational expenses. Their maintenance can also be more complex, leading to higher costs over time.

What Advantages Do Flatbed Trucks Offer Compared to 10-Wheel Dumper Trucks?

Flatbed trucks are incredibly versatile, capable of transporting a wide variety of loads, including oversized materials and machinery. They usually have a lower purchase price than both 10-wheel dumper and articulated trucks, making them an attractive option for businesses on a budget. Their simplicity in operation means less training is required for drivers. However, flatbed trucks are not designed for transporting loose materials like sand or gravel, which limits their application compared to dumper trucks.

Conclusion: Which Solution Should B2B Buyers Choose?

When considering the right equipment for heavy-duty hauling, B2B buyers should assess their specific needs, including the type of materials being transported, the terrain of job sites, and budget constraints. A 10-wheel heavy-duty dumper truck excels in construction and mining applications where high load capacities are essential. Alternatively, articulated dump trucks might be preferable for operations in challenging terrains, while flatbed trucks serve well in more general transport tasks. By carefully evaluating these aspects, buyers can make an informed decision that aligns with their operational requirements and financial goals.

Essential Technical Properties and Trade Terminology for 10-wheel Heavy Duty Used Dumper Truck

What Are the Key Technical Properties of a 10-Wheel Heavy Duty Used Dumper Truck?

Understanding the technical specifications of a 10-wheel heavy-duty used dumper truck is crucial for making informed purchasing decisions. Here are some essential properties to consider:

-

Payload Capacity

– Definition: This refers to the maximum weight the dumper truck can carry, typically measured in pounds or kilograms.

– Importance: A higher payload capacity increases operational efficiency, allowing businesses to transport more material in a single trip, thus reducing transportation costs and time. -

Engine Power (HP)

– Definition: This measures the engine’s horsepower (HP), indicating the truck’s ability to perform under load.

– Importance: Higher horsepower is essential for navigating rough terrains and carrying heavy loads. It directly influences the truck’s performance, fuel efficiency, and longevity. -

Wheelbase Length

– Definition: The distance between the front and rear axles, usually measured in inches or millimeters.

– Importance: A longer wheelbase provides better stability and load distribution, which is vital for safety during transportation. It also affects maneuverability, especially in tight spaces. -

Transmission Type

– Definition: This indicates whether the truck has an automatic or manual transmission system.

– Importance: Automatic transmissions are easier to operate, especially for less experienced drivers, while manual transmissions may offer better control and fuel efficiency in rugged conditions. -

Tire Specifications

– Definition: Refers to the size and type of tires used on the dumper truck.

– Importance: Tire specifications affect traction, durability, and overall performance. Selecting the right tires is crucial for operating in various environments, such as construction sites or off-road conditions. -

Dump Body Material

– Definition: The type of material used for the dump body, typically steel or aluminum.

– Importance: The choice of material impacts the truck’s weight, durability, and resistance to corrosion. Steel is robust and suitable for heavy loads, while aluminum is lighter and offers better fuel efficiency.

What Are Common Trade Terms Used in the Dumper Truck Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– Definition: Refers to the company that manufactures the original parts or equipment for the truck.

– Importance: Knowing whether parts are OEM can influence maintenance costs and the reliability of the truck. OEM parts are typically more expensive but are generally of higher quality. -

MOQ (Minimum Order Quantity)

– Definition: The minimum number of units a supplier is willing to sell in a single order.

– Importance: Understanding MOQ helps buyers determine if a supplier meets their purchasing needs, especially when looking to stock multiple trucks or parts. -

RFQ (Request for Quotation)

– Definition: A formal process where buyers request price quotes from suppliers for specific products or services.

– Importance: An RFQ helps buyers gather competitive pricing and terms, facilitating better negotiation and decision-making. -

Incoterms (International Commercial Terms)

– Definition: A set of standardized terms defining the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms clarifies shipping responsibilities, insurance, and risk management, which is vital for international B2B transactions. -

Lead Time

– Definition: The time taken from placing an order to the delivery of the product.

– Importance: Understanding lead times helps businesses plan their operations and inventory management effectively, ensuring they have the necessary equipment when needed. -

Warranty Period

– Definition: The duration during which the manufacturer or seller guarantees the product against defects or failures.

– Importance: A longer warranty period provides peace of mind for buyers, indicating the manufacturer’s confidence in the product’s quality and durability.

By comprehensively understanding these technical properties and trade terms, international B2B buyers can make informed decisions that enhance their operational efficiency and profitability in the heavy-duty dumper truck market.

Navigating Market Dynamics and Sourcing Trends in the 10-wheel Heavy Duty Used Dumper Truck Sector

What Are the Key Market Dynamics and Trends Influencing the 10-Wheel Heavy Duty Used Dumper Truck Sector?

The global market for 10-wheel heavy-duty used dumper trucks is experiencing significant shifts driven by various factors. Increased urbanization and infrastructure development, particularly in developing regions like Africa and South America, are propelling demand for robust hauling solutions. Countries such as Brazil and Nigeria are investing heavily in infrastructure projects, which creates a favorable environment for used dumper trucks. Additionally, the rising cost of new equipment is pushing buyers towards the used market, where they can find high-quality options at more competitive prices.

Emerging technologies are also influencing the sourcing landscape. Digital marketplaces and auction platforms are streamlining the buying process, enabling international B2B buyers to access a wider range of options. These platforms often feature detailed listings, including specifications and performance history, allowing for informed purchasing decisions. The use of data analytics is becoming increasingly important, helping buyers identify trends in pricing and availability, which can lead to strategic purchasing.

Furthermore, there is a growing emphasis on supplier transparency and performance history. Buyers are increasingly seeking vendors who provide not only quality equipment but also verifiable maintenance records and performance metrics. This trend is particularly relevant in regions where the operational reliability of heavy-duty trucks directly impacts project timelines and profitability.

How Does Sustainability and Ethical Sourcing Impact the 10-Wheel Heavy Duty Used Dumper Truck Market?

Sustainability is becoming a central theme in the procurement process for heavy-duty used dumper trucks. As environmental regulations tighten globally, buyers are increasingly considering the environmental impact of their purchases. This includes assessing the lifecycle emissions of used trucks and their potential for refurbishment. Opting for vehicles that have been well-maintained can extend their lifespan and reduce the need for new manufacturing, which is inherently resource-intensive.

Ethical sourcing is equally important, particularly in regions where supply chain integrity can be compromised. Buyers are encouraged to partner with suppliers who adhere to ethical practices and maintain transparency in their operations. Certifications related to environmental standards and fair labor practices are becoming critical factors in the decision-making process. These certifications not only enhance a company’s reputation but also align with the growing consumer demand for responsible business practices.

Moreover, initiatives promoting ‘green’ materials and technologies are gaining traction. Buyers are now looking for trucks that incorporate eco-friendly features, such as lower emissions engines or materials sourced from sustainable suppliers. This shift not only addresses regulatory compliance but also appeals to a broader customer base that values sustainability.

What Is the Historical Context of the 10-Wheel Heavy Duty Used Dumper Truck Sector?

The evolution of the 10-wheel heavy-duty used dumper truck sector reflects broader trends in the construction and logistics industries. Initially, dumper trucks were primarily used for basic transportation of materials on construction sites. However, advancements in engineering and technology over the decades have transformed them into versatile vehicles capable of handling various applications, including mining, waste management, and large-scale infrastructure projects.

The rise of the used truck market can be traced back to the economic pressures that led businesses to seek cost-effective solutions. As new truck prices soared, the appeal of high-quality used options became more pronounced, particularly in developing economies where budget constraints are common. The integration of technology in the resale market, including online platforms and auction services, has further accelerated this trend, making it easier for buyers to access a diverse range of vehicles while ensuring they get value for their investment.

In summary, understanding the market dynamics, sustainability considerations, and historical context surrounding the 10-wheel heavy-duty used dumper truck sector equips international B2B buyers with the insights needed to navigate their purchasing decisions effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of 10-wheel Heavy Duty Used Dumper Truck

-

How do I choose the right supplier for a 10-wheel heavy-duty used dumper truck?

Selecting a reliable supplier involves several key steps. First, research the supplier’s reputation through online reviews and ratings, particularly from other international buyers. Request references and contact previous clients to gain insight into their experiences. Verify the supplier’s certifications and compliance with international standards, especially for the regions you plan to operate in. Finally, consider suppliers who offer warranties or guarantees on their vehicles, which can provide additional peace of mind. -

What are the main factors to consider when purchasing a used dumper truck?

When buying a used dumper truck, focus on the truck’s condition, including mileage, maintenance history, and any signs of wear or damage. Assess the truck’s specifications to ensure it meets your operational needs, such as load capacity and engine power. Additionally, consider the availability of spare parts and service support in your region, as this can affect maintenance costs and downtime. Lastly, evaluate the total cost of ownership, which includes purchase price, operating costs, and potential resale value. -

What should I know about shipping logistics for a used dumper truck?

Shipping logistics can significantly impact your purchase process. Understand the shipping methods available, such as container shipping or roll-on/roll-off (RoRo), and choose one that fits your timeline and budget. Calculate the total shipping costs, including freight charges, insurance, customs duties, and any applicable taxes. Ensure that the supplier provides the necessary documentation for customs clearance. It’s also beneficial to work with a logistics partner experienced in international shipping to navigate potential challenges. -

What are the typical payment terms for purchasing a used dumper truck?

Payment terms can vary widely among suppliers. Common arrangements include upfront payments, deposits with balance due upon delivery, or payment upon receipt of shipping documents. Always clarify the payment structure before finalizing the deal. Consider utilizing secure payment methods such as escrow services, which can protect both parties. Additionally, negotiate terms that allow for inspections upon arrival to ensure the truck meets your expectations before final payment. -

How can I customize a used dumper truck to fit my needs?

Many suppliers offer customization options for used dumper trucks. You can typically request modifications such as changes to the truck’s bed size, additional safety features, or specific paint colors. Discuss your requirements with the supplier early in the negotiation process to ensure they can accommodate your requests. Keep in mind that customization may affect delivery times and costs, so factor this into your overall budget and timeline. -

What quality assurance practices should I look for when buying a used dumper truck?

Quality assurance is crucial in ensuring the reliability of your purchase. Look for suppliers who conduct thorough inspections and provide detailed reports on the truck’s condition. Ask for information on the quality control processes they follow, such as certification by third-party inspectors. Additionally, ensure that the supplier offers a warranty or guarantee that covers potential defects or issues that may arise after the sale. -

What are the typical minimum order quantities (MOQ) for purchasing used dumper trucks?

Minimum order quantities can vary by supplier and region. Some suppliers may allow for single-unit purchases, while others might have an MOQ of two or more trucks. It’s essential to clarify these terms upfront, especially if you are considering a larger fleet purchase. If you only need one truck, seek suppliers who are flexible with MOQs or consider partnering with other businesses to meet quantity requirements. -

How do I handle after-sales service and support for a used dumper truck?

After-sales service is a vital component of your purchase. Confirm with the supplier what support is offered post-sale, including maintenance services, spare parts availability, and technical assistance. Establish a clear communication channel for addressing any issues that may arise after delivery. Additionally, inquire about training for your operators to ensure they can effectively and safely operate the truck, maximizing its lifespan and performance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 10-Wheel Heavy Duty Used Dumper Truck Manufacturers & Suppliers List

1. Freightliner – 10 Wheels Dump Truck

Domain: equipmtl.com

Registered: 2008 (17 years)

Introduction: 10 wheels dump truck – Used equipment sale and brokerage. Available models include: Freightliner Cascadia 2014 (CAD $61,500, 450HP, 12000/40000, 10V), International Eagle 9300 1994 (CAD $19,900, 15V), International Workstar 7500 2006 (CAD $42,500, 310HP, 16000/46000, Automatic), Kenworth T800 2005 (CAD $59,900, 385HP, 13200/40000, 10V), Mack CV713 Granite 2005 (CAD $38,900, 435HP, 20000/46000, 18V…

2. HOWO – Heavy Duty Used Howo Dump Truck

Domain: usedhowotrucks.com

Registered: 2021 (4 years)

Introduction: {“Product Name”:”Heavy Duty Used Howo Dump Truck, Howo Ten Wheeler Dump Truck”,”Place of Origin”:”CHINA”,”Brand Name”:”HOWO”,”Certification”:”CCC, ISO, CE”,”Model Number”:”ZZ3257N3847C”,”Minimum Order Quantity”:”1 unit”,”Price”:”$14000/unit-$16500/unit”,”Packaging Details”:”Nude, Waxing before delivery”,”Delivery Time”:”10-15 working days”,”Payment Terms”:”T/T, L/C, Western Union”,”Supply Ability”…

3. SINOTRUK – HOWO 6×4 Used Dump Truck

Domain: mining-dumptruck.com

Registered: 2018 (7 years)

Introduction: {“Model”:”SINOTRUK HOWO 6×4 Used Dump Truck”,”Wheels”:”10″,”Place of Origin”:”China”,”Brand Name”:”sinotruk”,”Certification”:”iso/ccc”,”Model Number”:”howo”,”Min Order”:”1 PCS”,”Price”:”Negotiable”,”Packaging”:”Nude”,”Delivery Time”:”30-45 work days”,”Payment Terms”:”L/C,T/T”,”Supply Ability”:”500 units/month”,”Transmission Type”:”Manual”,”Power”:”Diesel”,”Load Capacity”:”41-50t”,”Emission Standar…

4. Dump Truck Dispatcher – Start-Up Cost Breakdown

Domain: dumptruckdispatcher.com

Registered: 2018 (7 years)

Introduction: Start-up costs for a dump truck company include truck payment, registration, sales tax, permits and licenses, liability insurance, fuel, tires, driver wages, driver benefits, repairs and maintenance, computer, phone, office supplies, logo design, vinyl lettering for truck, business cards and brochures, bank account fees, website setup, accounting software, and dispatching software. Estimated year-…

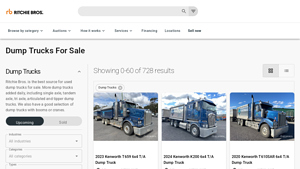

5. Ritchie Bros. – Dump Trucks for Sale

Domain: rbauction.com

Registered: 1995 (30 years)

Introduction: New & Used Dump Trucks For Sale | Ritchie Bros. Types: Single axle, tandem axle, tri axle, articulated, tipper dump trucks, dump trucks with booms or cranes. Locations: United States (517), Southern US (216), Texas (66), Florida (36), Virginia (22), Canada (111), Europe (57), Oceania (26), Middle East (10). Key Makes: Kenworth (117), Ford (90), International (86), Mack (85), Peterbilt (71). Models…

6. Kenworth – T800 Tri-Axle Dump Truck

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: 2019 KENWORTH T800 Tri-Axle Dump Truck, CUMMINS X15 / 450 hp Diesel Engine, Automatic Transmission, 75 Gal. Aluminum Fuel Tank

7. HOWO – 10 Wheels Heavy Duty Dump Truck

Domain: cnqixinggroup.com

Registered: 2021 (4 years)

Introduction: Used Dump Trucks with 10 Wheels HOWO China Tipper Truck 6×4 Middle Lift Heavy Duty Truck

– EMARK certificate

– Euro 5 Emission standard

– WEICHAI ENGINE

– FAST TRANSMISSION AND HANDE AXLE

– SKD/CKD condition options

– LHD and RHD options

Heavy duty RHD dumper truck parameters:

1. Description: heavy duty RHD dumper truck, front axle steering, rear double axles driving

2. G.V.W.: 26000kg

3. Overall…

Strategic Sourcing Conclusion and Outlook for 10-wheel Heavy Duty Used Dumper Truck

In conclusion, strategic sourcing of 10-wheel heavy-duty used dumper trucks presents a unique opportunity for international buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. The versatility and power of these trucks make them ideal for a variety of hauling tasks, essential for infrastructure development and resource extraction in these regions. Buyers can benefit from a wide range of options, from established brands like Kenworth and Peterbilt to cost-effective alternatives such as Howo, ensuring that they can find the right vehicle to fit their specific operational needs and budget constraints.

As the demand for heavy-duty machinery continues to rise globally, it is crucial for buyers to engage in thorough research and partner with reputable suppliers who offer transparency in their sourcing practices. This approach not only minimizes risks but also enhances the value derived from each purchase.

Looking ahead, the landscape for used dumper trucks is evolving, with technological advancements and sustainable practices becoming increasingly important. B2B buyers are encouraged to act now, leveraging strategic sourcing to secure the best deals and ensure their operations are equipped for future challenges. Embrace this opportunity to enhance your fleet and drive success in your projects.