Introduction: Navigating the Global Market for 2019 Year Sinotruk 8×4 Tipper Truck

In the dynamic landscape of global construction and mining industries, sourcing the right equipment can present a significant challenge for B2B buyers, especially when it comes to acquiring reliable heavy-duty vehicles like the 2019 Year Sinotruk 8×4 Tipper Truck. This guide serves as a comprehensive resource, designed to equip international buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Saudi Arabia—with the critical insights needed for informed decision-making.

Within these pages, we will explore various aspects of the Sinotruk 8×4 Tipper Truck, including its technical specifications, performance capabilities, and potential applications across different industries. Additionally, we will provide valuable information on vetting suppliers, understanding pricing structures, and navigating shipping logistics, ensuring that you can make strategic purchasing decisions that align with your operational needs.

By leveraging this guide, buyers can enhance their understanding of the Sinotruk 8×4 Tipper Truck’s advantages, ultimately leading to improved efficiency and productivity in their projects. Our goal is to empower you with the knowledge necessary to confidently select the right equipment that meets both budgetary and operational requirements in an increasingly competitive marketplace.

Understanding 2019 Year Sinotruk 8×4 Tipper Truck Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| SINOTRUK HOWO 8×4 371HP | 371hp engine, 40t payload, 7800mm cargo box size | Construction, mining, heavy materials | Pros: High payload capacity; durable. Cons: Limited customization options. |

| SINOTRUK HOWO 8×4 400HP | 400hp engine, 25m³ capacity, optional crane attachment | Infrastructure projects, waste management | Pros: Powerful engine; versatile with crane option. Cons: Higher initial investment. |

| SINOTRUK A7 8×4 Tipper | 380hp engine, advanced safety features, Euro IV standard | Road construction, logistics | Pros: Eco-friendly; enhanced driver comfort. Cons: Potentially higher maintenance costs. |

| SINOTRUK 8×4 6×4 Tipper | 6×4 drivetrain option, lower payload (25t) | Urban construction, smaller projects | Pros: Maneuverable in tight spaces; cost-effective. Cons: Lower capacity compared to 8×4 models. |

| SINOTRUK HOWO 8×4 Mining Tipper | Heavy-duty design, reinforced chassis, high torque | Mining, heavy-duty transport | Pros: Built for rugged conditions; high durability. Cons: Heavier weight may reduce fuel efficiency. |

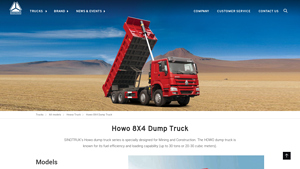

What are the key characteristics of the SINOTRUK HOWO 8×4 371HP Tipper Truck?

The SINOTRUK HOWO 8×4 371HP is a robust vehicle ideal for demanding applications such as construction and mining. With a powerful 371hp engine and a substantial payload capacity of 40 tons, it is designed to handle heavy materials efficiently. The 7800mm cargo box size provides ample space for various materials, making it a preferred choice for B2B buyers in industries that require reliable transportation of bulk goods. Buyers should consider its durability and performance in harsh conditions, although customization options may be limited.

How does the SINOTRUK HOWO 8×4 400HP differ in applications?

The SINOTRUK HOWO 8×4 400HP variant stands out with its higher horsepower and the option for an attached crane, enhancing its versatility for infrastructure projects and waste management. This model features a 25m³ capacity, making it suitable for transporting larger loads. B2B buyers in sectors requiring additional lifting capabilities will find this model advantageous, despite the higher initial investment compared to other models. Its powerful engine ensures efficient operation, but potential buyers should assess their budget against the benefits of added functionality.

What advantages does the SINOTRUK A7 8×4 Tipper offer?

The SINOTRUK A7 8×4 Tipper is engineered with advanced safety features and meets Euro IV emission standards, making it an eco-friendly choice for road construction and logistics. Its 380hp engine offers a balance of power and efficiency, appealing to B2B buyers focused on sustainability. The enhanced driver comfort and safety features are significant selling points, although buyers should be prepared for potentially higher maintenance costs associated with advanced technology.

In which scenarios would a SINOTRUK 8×4 6×4 Tipper be preferred?

The SINOTRUK 8×4 6×4 Tipper is tailored for urban construction and smaller projects due to its maneuverability in tight spaces. With a lower payload capacity of 25 tons, it serves as a cost-effective solution for companies that do not require the heft of larger trucks. B2B buyers looking for a practical, budget-friendly option will appreciate this model, though its reduced capacity compared to the 8×4 models may limit its use in heavy-duty applications.

What makes the SINOTRUK HOWO 8×4 Mining Tipper suitable for rugged conditions?

Designed specifically for mining and heavy-duty transport, the SINOTRUK HOWO 8×4 Mining Tipper features a reinforced chassis and high torque for superior performance in rugged environments. This model is ideal for B2B buyers in the mining sector who prioritize durability and reliability. While it excels in harsh conditions, buyers should consider that its heavier weight may impact fuel efficiency, making it essential to evaluate operational costs against performance benefits.

Key Industrial Applications of 2019 Year Sinotruk 8×4 Tipper Truck

| Industry/Sector | Specific Application of 2019 Year Sinotruk 8×4 Tipper Truck | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Transportation of construction materials like sand, gravel, and concrete | Enhances project efficiency by reducing delivery times | Assess payload capacity and durability for heavy loads |

| Mining | Hauling extracted minerals and ore from mines to processing plants | Increases productivity by facilitating heavy loads transport | Evaluate engine power and fuel efficiency for long hauls |

| Agriculture | Transporting agricultural products, such as grains and fertilizers | Supports timely delivery for harvest and distribution | Consider customization options for cargo box size and type |

| Waste Management | Collecting and transporting waste materials to disposal sites | Improves operational efficiency in waste collection | Ensure compliance with local regulations on emissions and safety |

| Road Maintenance & Repair | Moving road construction materials and equipment to work sites | Streamlines maintenance operations, reducing downtime | Check for compatibility with various types of road materials |

How is the 2019 Year Sinotruk 8×4 Tipper Truck Used in Construction?

In the construction industry, the 2019 Year Sinotruk 8×4 Tipper Truck is primarily utilized for transporting essential materials such as sand, gravel, and concrete to various project sites. With a substantial payload capacity of up to 40 tons, this truck enables contractors to optimize their delivery schedules, thereby reducing project timelines and costs. Buyers in this sector should consider the truck’s durability and performance under heavy loads to ensure consistent operations on rugged terrains.

What Role Does the Sinotruk 8×4 Tipper Truck Play in Mining Operations?

In mining applications, the Sinotruk 8×4 Tipper Truck is indispensable for hauling extracted minerals and ore from remote mining sites to processing facilities. Its powerful engine and robust build allow it to handle the challenging conditions typical of mining operations. For international buyers, especially in regions like Africa and South America, assessing the truck’s fuel efficiency and maintenance requirements is crucial, as these factors significantly impact operational costs and productivity.

How Can Farmers Benefit from the Sinotruk 8×4 Tipper Truck?

Agricultural businesses utilize the 2019 Year Sinotruk 8×4 Tipper Truck for transporting various products, including grains and fertilizers. This truck enhances logistical capabilities, ensuring that farmers can deliver their products to markets promptly, which is vital during harvest seasons. Buyers should explore customization options for the cargo box to match specific agricultural needs, maximizing the truck’s utility across different types of loads.

In What Ways Does the Sinotruk 8×4 Tipper Truck Aid Waste Management?

In the waste management sector, the Sinotruk 8×4 Tipper Truck is employed to collect and transport waste materials to disposal sites efficiently. Its robust design and substantial payload capacity improve the effectiveness of waste collection operations. For international buyers, it is essential to ensure that the truck complies with local environmental regulations, including emissions standards, to avoid penalties and enhance sustainability efforts.

How is the Sinotruk 8×4 Tipper Truck Essential for Road Maintenance?

The truck also plays a critical role in road maintenance and repair, moving construction materials and heavy equipment to various work sites. By streamlining the transportation of these materials, it reduces downtime and enhances the efficiency of maintenance operations. Buyers should evaluate the truck’s compatibility with different types of road materials and its overall reliability to ensure it meets the demands of rigorous roadwork.

3 Common User Pain Points for ‘2019 Year Sinotruk 8×4 Tipper Truck’ & Their Solutions

Scenario 1: Navigating High Operational Costs in Transportation

The Problem:

B2B buyers often face the challenge of high operational costs associated with transporting materials using heavy vehicles like the 2019 Sinotruk 8×4 Tipper Truck. Fuel consumption rates, maintenance expenses, and the cost of labor can significantly affect profit margins, especially in regions where fuel prices are volatile, such as in parts of Africa and South America. These escalating costs can lead to budget overruns and make it difficult to remain competitive.

The Solution:

To manage and reduce operational costs, buyers should focus on optimizing the truck’s fuel efficiency and maintenance schedules. The 2019 Sinotruk 8×4 Tipper Truck has a fuel consumption rate of approximately 35 liters per 100 kilometers. B2B buyers can implement fuel management systems that monitor fuel usage in real-time, providing insights into driving patterns and potential inefficiencies. Additionally, establishing a regular maintenance program can help prolong the vehicle’s lifespan and prevent costly repairs. This includes routine checks on the engine, transmission, and tires, which are crucial for ensuring optimal performance and fuel efficiency. By training drivers on efficient driving techniques, such as smooth acceleration and braking, companies can further reduce fuel consumption and improve overall operational efficiency.

Scenario 2: Ensuring Compliance with Local Regulations

The Problem:

Another significant pain point for international B2B buyers is ensuring compliance with varying local regulations regarding emissions and vehicle specifications. For instance, different countries in Europe and the Middle East have stringent Euro emission standards that must be adhered to, and failure to comply can result in hefty fines and restrictions on vehicle operation.

The Solution:

Buyers should prioritize sourcing trucks that meet or exceed local regulatory standards. The 2019 Sinotruk 8×4 Tipper Truck is equipped with an engine that complies with Euro II emission standards, making it suitable for many international markets. Buyers should conduct thorough research on the specific emissions regulations applicable in their operational regions. It may also be beneficial to engage with local regulatory bodies or consult with compliance experts to ensure that all aspects of the truck meet local laws. When purchasing, buyers can request modifications or upgrades to the vehicle to meet higher emission standards if necessary. This proactive approach not only avoids potential fines but also enhances the company’s reputation as a responsible and compliant business partner.

Scenario 3: Managing Downtime Due to Maintenance Issues

The Problem:

Downtime due to maintenance issues is a critical concern for B2B buyers. The 2019 Sinotruk 8×4 Tipper Truck, while robust, can still experience mechanical failures that halt operations and lead to lost revenue. For companies that rely heavily on timely transport for projects, unplanned maintenance can severely disrupt schedules and client relationships.

The Solution:

To mitigate downtime, buyers should invest in a comprehensive maintenance strategy that includes predictive maintenance practices. This involves using telematics and diagnostic tools to monitor the truck’s performance and identify potential issues before they become serious problems. Regular inspections should be scheduled based on usage patterns rather than just time intervals. Establishing partnerships with reliable local service providers can also ensure quick access to repairs and parts, minimizing the time the truck is out of service. Additionally, maintaining a stock of critical spare parts can prevent delays in repairs. By focusing on proactive maintenance and quick response times, companies can significantly reduce the likelihood of extended downtime, ensuring that their operations run smoothly and efficiently.

Strategic Material Selection Guide for 2019 Year Sinotruk 8×4 Tipper Truck

When selecting materials for the 2019 Year Sinotruk 8×4 Tipper Truck, it is essential to consider various factors that influence performance, durability, and cost-effectiveness. Below, we analyze four common materials used in the construction of this truck, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of Steel in the Sinotruk 8×4 Tipper Truck?

Steel is widely used in the chassis and body of the Sinotruk 8×4 Tipper Truck due to its strength and versatility. Key properties include high tensile strength, excellent impact resistance, and good weldability. Steel can withstand high pressures and temperatures, making it suitable for heavy-duty applications.

Pros: Steel is highly durable and offers excellent structural integrity, which is critical for transporting heavy loads. It is also relatively low-cost compared to other materials.

Cons: Steel is susceptible to corrosion, especially in harsh environments, unless adequately treated with coatings or galvanization. Additionally, its weight can affect fuel efficiency.

Impact on Application: Steel is compatible with various media, including aggregates and construction materials, making it ideal for construction and mining applications.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Africa and the Middle East should ensure that steel grades used meet local environmental and operational conditions.

How Does Aluminum Benefit the Performance of the Tipper Truck?

Aluminum is increasingly utilized in components like the cargo box due to its lightweight and corrosion-resistant properties. It offers a good strength-to-weight ratio, which enhances fuel efficiency.

Pros: Aluminum is resistant to rust and corrosion, reducing maintenance costs over time. Its lightweight nature allows for higher payload capacities.

Cons: The initial cost of aluminum is higher than steel, and its lower tensile strength may require thicker sections, which can offset some weight savings.

Impact on Application: Aluminum is suitable for transporting a variety of materials, including aggregates and waste, without adding significant weight to the vehicle.

Considerations for International Buyers: Buyers should ensure that the aluminum used complies with international standards and is suitable for the specific environmental conditions of their regions, such as high humidity or saline environments.

What Role Does Rubber Play in the Tipper Truck’s Performance?

Rubber is primarily used in tires and suspension components. Its key properties include excellent shock absorption and flexibility, which contribute to ride comfort and stability.

Pros: Rubber provides good traction and durability, essential for off-road conditions. It also helps in reducing noise and vibration, enhancing driver comfort.

Cons: Rubber can degrade over time due to exposure to UV rays and extreme temperatures, necessitating regular maintenance and replacement.

Impact on Application: The choice of rubber compounds can significantly influence the truck’s performance in various terrains, making it crucial for applications in construction and mining.

Considerations for International Buyers: Buyers should verify that the rubber meets local regulations regarding environmental impact and performance standards.

How Does Composite Material Enhance the Tipper Truck’s Efficiency?

Composite materials, such as fiberglass-reinforced plastics, are used in some truck components for their lightweight and high strength. These materials are resistant to corrosion and can be molded into complex shapes.

Pros: Composites are lightweight, which can improve fuel efficiency and payload capacity. They also offer excellent resistance to environmental factors.

Cons: Composites can be more expensive and may require specialized manufacturing processes, which can complicate production.

Impact on Application: Composites are suitable for non-structural components, reducing overall weight while maintaining performance.

Considerations for International Buyers: It is essential for buyers to assess the availability of composite materials and their compatibility with local manufacturing capabilities.

Summary of Material Selection for Sinotruk 8×4 Tipper Truck

| Material | Typical Use Case for 2019 Year Sinotruk 8×4 Tipper Truck | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chassis and body construction | High durability and strength | Susceptible to corrosion | Low |

| Aluminum | Cargo box and lightweight components | Corrosion resistance and lightweight | Higher initial cost | Med |

| Rubber | Tires and suspension components | Good traction and shock absorption | Degrades over time | Low |

| Composite | Non-structural components | Lightweight and corrosion-resistant | Higher cost and manufacturing complexity | High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions that align with operational needs and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for 2019 Year Sinotruk 8×4 Tipper Truck

What Are the Key Stages in the Manufacturing Process of the 2019 Year Sinotruk 8×4 Tipper Truck?

The manufacturing process of the 2019 Year Sinotruk 8×4 Tipper Truck involves several key stages that ensure the vehicle meets the high standards expected in the global market. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the careful selection and preparation of raw materials, primarily high-strength steel for the chassis and aluminum for lighter components. Quality assurance starts here, as materials undergo rigorous testing for durability and compliance with international standards.

-

Forming: Advanced techniques such as stamping, welding, and bending are employed to shape the raw materials into the truck’s components. CNC machines are often used for precision cutting, ensuring that parts fit together seamlessly. This stage is crucial for maintaining structural integrity and performance under load.

-

Assembly: Once the components are formed, they are assembled using automated and manual processes. Skilled workers ensure that each part is correctly installed, from the engine to the hydraulic systems. This stage is critical for the truck’s operational reliability and longevity.

-

Finishing: The final stage involves painting and coating the truck to protect against corrosion and wear. This includes applying multiple layers of paint and a final inspection for any defects. The finishing process not only enhances the truck’s aesthetic appeal but also adds to its durability.

How Is Quality Control Integrated Throughout the Manufacturing Process?

Quality control (QC) is an integral part of the manufacturing process for the Sinotruk 8×4 Tipper Truck, ensuring that each vehicle meets international standards. The QC process can be broken down into several key checkpoints and methods.

-

International Standards Compliance: The manufacturing facility typically adheres to ISO 9001 standards, which ensure consistent quality management systems. Additionally, compliance with industry-specific standards such as CE for Europe and API for oil and gas applications is crucial for market acceptance.

-

Key QC Checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify their quality and compliance with specifications.

– In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted at various stages to catch defects early. This includes monitoring the precision of CNC machining and the integrity of welds.

– Final Quality Control (FQC): After assembly, each truck undergoes a comprehensive inspection, including functional tests of the hydraulic system, engine performance, and safety features. -

Common Testing Methods: Various testing methods are utilized, including:

– Load Testing: Ensures the truck can handle specified payloads without compromising safety.

– Performance Testing: Evaluates speed, fuel efficiency, and braking systems.

– Durability Testing: Simulates real-world conditions to assess long-term performance.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure product reliability and compliance with local regulations.

-

Conducting Supplier Audits: Buyers should perform regular audits of potential suppliers to assess their manufacturing processes and quality control measures. This includes reviewing their facilities, equipment, and workforce qualifications.

-

Requesting Quality Control Reports: Buyers can ask for detailed QC reports that outline the testing methods used, results obtained, and any corrective actions taken. This transparency builds trust and ensures that the supplier adheres to quality standards.

-

Engaging Third-Party Inspection Services: Utilizing third-party inspectors to conduct independent evaluations can provide an unbiased assessment of the supplier’s quality control processes. These inspections can occur at various stages, from material procurement to final assembly.

-

Understanding Certification Nuances: Buyers should be aware of the specific certifications required for their region. For instance, while CE certification is essential for European markets, similar certifications might differ in Africa or the Middle East. Understanding these nuances can help buyers avoid compliance issues.

How Do Quality Assurance Practices Impact the Reliability of the Sinotruk 8×4 Tipper Truck?

The quality assurance practices implemented throughout the manufacturing process significantly impact the reliability and performance of the Sinotruk 8×4 Tipper Truck. By adhering to stringent quality control measures, the manufacturer ensures that each truck is built to withstand the demands of heavy-duty applications.

-

Enhanced Performance: Rigorous testing and quality checks contribute to the truck’s ability to perform efficiently under load. The attention to detail in the manufacturing process results in fewer breakdowns and maintenance issues.

-

Increased Longevity: Quality materials and precise engineering extend the lifespan of the truck. Buyers can expect a better return on investment as the vehicle remains operational longer, reducing downtime and repair costs.

-

Safety Assurance: Effective quality assurance practices enhance safety features, ensuring that the truck complies with international safety standards. This is particularly important for buyers operating in regions with challenging terrains and conditions.

Conclusion: Why Quality Control Matters for International B2B Buyers

For international B2B buyers considering the 2019 Year Sinotruk 8×4 Tipper Truck, understanding the manufacturing processes and quality assurance practices is vital. These insights not only help in assessing the reliability of the product but also assist in making informed purchasing decisions that align with operational requirements and regional standards. By prioritizing quality, buyers can ensure that they invest in vehicles that meet their business needs and expectations for performance and durability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘2019 Year Sinotruk 8×4 Tipper Truck’

When considering the procurement of a 2019 Year Sinotruk 8×4 Tipper Truck, having a structured sourcing checklist can streamline the process and ensure you make an informed decision. This guide outlines essential steps to help B2B buyers navigate their purchasing journey effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for aligning your needs with the truck’s capabilities. Consider aspects such as engine power (e.g., 371hp or 400hp options), payload capacity (typically up to 40 tons), and dimensions of the cargo box (e.g., 7800x2300x1200 mm). This step ensures that the truck you choose meets the operational demands of your projects.

Step 2: Research Potential Suppliers

Conduct thorough research on suppliers specializing in Sinotruk vehicles. Look for companies with a solid reputation in your region, particularly in Africa, South America, and the Middle East. Utilize online platforms, industry forums, and trade shows to gather information about suppliers, ensuring they have a track record of reliability and quality.

Step 3: Evaluate Supplier Certifications

Before making a purchase, verify that your potential suppliers possess the necessary certifications and licenses. This includes checking for ISO certifications, compliance with local and international safety standards, and any relevant emissions certifications (e.g., Euro II or Euro IV). Certifications are indicators of a supplier’s commitment to quality and environmental standards.

Step 4: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations that break down costs, including the base price of the truck, shipping, and any optional features. Pay attention to the payment terms, lead times, and warranty conditions. This clarity will help you compare offers effectively and understand the total investment required.

Step 5: Inspect the Trucks in Person (if possible)

If feasible, arrange to inspect the trucks at the supplier’s facility. This step allows you to assess the build quality, functionality, and any additional features firsthand. Look for any signs of wear or defects and ensure that all components meet your specifications. A physical inspection can prevent future issues and ensure you receive a reliable product.

Step 6: Review After-Sales Support and Parts Availability

Investigate the after-sales support provided by your supplier. Access to spare parts, maintenance services, and technical support is essential for minimizing downtime. Ensure that the supplier can offer timely assistance and that spare parts are readily available in your region, which is critical for the longevity of your investment.

Step 7: Finalize the Purchase Agreement

After completing the previous steps, draft a comprehensive purchase agreement that outlines all terms discussed, including delivery timelines, payment schedules, and warranty details. This document should protect both parties and clearly define expectations. Ensure that you have legal counsel review the agreement to safeguard your interests.

By following these steps, B2B buyers can confidently navigate the procurement process for a 2019 Year Sinotruk 8×4 Tipper Truck, ensuring they make a well-informed and strategic purchase that aligns with their operational needs.

Comprehensive Cost and Pricing Analysis for 2019 Year Sinotruk 8×4 Tipper Truck Sourcing

What Are the Key Cost Components for the 2019 Year Sinotruk 8×4 Tipper Truck?

When sourcing the 2019 Sinotruk 8×4 Tipper Truck, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The truck’s construction relies heavily on high-quality steel and components, which are subject to market fluctuations. Prices for raw materials can vary, impacting the overall cost.

-

Labor: Labor costs in China can influence the manufacturing price. The complexity of the truck’s assembly and the skill level required for specialized tasks can lead to variations in labor expenses.

-

Manufacturing Overhead: This includes costs related to the factory’s operation, such as utilities, maintenance, and administrative expenses. Efficient production processes can help minimize these costs.

-

Tooling: Custom tooling might be necessary for specific configurations or modifications. This one-time cost can be significant, especially for unique specifications.

-

Quality Control (QC): Ensuring that each truck meets stringent quality standards incurs additional costs. Regular inspections and testing are essential to maintain the truck’s reliability and safety.

-

Logistics: Transportation costs to deliver the trucks to international markets must be considered. Factors like shipping method (e.g., container vs. RoRo), distance, and port fees will influence logistics expenses.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This can vary based on market competition and demand.

What Influences Pricing for the Sinotruk 8×4 Tipper Truck?

Several factors can affect the pricing of the 2019 Sinotruk 8×4 Tipper Truck:

-

Volume/MOQ: Bulk purchases often lead to discounted prices. Suppliers may offer better rates for larger orders, which can significantly reduce the cost per unit.

-

Specifications/Customization: Additional features or modifications, such as enhanced payload capacity or specialized cargo boxes, can increase the base price. Customization may also require unique materials or additional labor.

-

Materials: The choice of materials can greatly affect the truck’s cost. Higher-grade materials may enhance durability but come at a premium.

-

Quality/Certifications: Trucks that meet international quality standards and certifications may carry higher prices due to the added assurance of reliability and safety.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Well-established suppliers may charge more due to their proven track record.

-

Incoterms: The agreed terms of shipping can also impact pricing. FOB (Free on Board) and CIF (Cost, Insurance, and Freight) terms will affect the total landed cost for buyers.

How Can Buyers Negotiate for Better Pricing and Cost-Efficiency?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, strategic negotiation can yield favorable pricing:

-

Leverage Volume: If you anticipate future needs, consider negotiating a long-term contract that guarantees supply and potentially lowers the unit cost.

-

Explore Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the costs associated with maintenance, fuel efficiency, and resale value. A slightly higher upfront cost might be justified by lower operational expenses.

-

Understand Pricing Nuances: Be aware of seasonal fluctuations in pricing and demand, which can affect costs. Timing your purchase to align with off-peak seasons can lead to savings.

-

Engage in Transparent Communication: Building a relationship with suppliers can foster trust and lead to better terms. Open discussions about budget constraints can encourage suppliers to offer discounts or flexible payment terms.

Conclusion: What Should Buyers Remember About Indicative Prices?

Prices for the 2019 Sinotruk 8×4 Tipper Truck can range significantly based on the factors mentioned above, with indicative prices typically falling between $56,950 and $72,050 depending on specifications and optional features. However, it is crucial for buyers to recognize that these prices may fluctuate based on market conditions and individual supplier policies. Always confirm current pricing directly with suppliers to ensure accuracy before making any commitments.

Alternatives Analysis: Comparing 2019 Year Sinotruk 8×4 Tipper Truck With Other Solutions

Introduction to Alternative Solutions for Tipper Trucks

In the heavy-duty trucking industry, especially in markets across Africa, South America, the Middle East, and Europe, businesses often seek robust and reliable solutions for transporting materials. The 2019 Year Sinotruk 8×4 Tipper Truck is one such option, but it’s crucial for B2B buyers to explore alternative solutions that may offer different advantages. Comparing various options can help organizations identify the best fit for their operational needs, budget constraints, and specific use cases.

Comparison Table

| Comparison Aspect | 2019 Year Sinotruk 8X4 Tipper Truck | Alternative 1: FAW 8×4 Tipper Truck | Alternative 2: Dongfeng 8×4 Tipper Truck |

|---|---|---|---|

| Performance | 371hp, 40t payload | 380hp, 40t payload | 400hp, 40t payload |

| Cost | $56,950 (FOB) | $58,000 (FOB) | $60,000 (FOB) |

| Ease of Implementation | Moderate (customization options available) | High (standardized configurations) | Moderate (customization options available) |

| Maintenance | Moderate (availability of parts) | Low (widespread service network) | Moderate (parts availability varies) |

| Best Use Case | Construction, mining | General construction, urban transport | Heavy-duty mining, large-scale projects |

Detailed Breakdown of Alternatives

Alternative 1: FAW 8×4 Tipper Truck

The FAW 8×4 Tipper Truck is a competitive alternative that offers a slightly higher horsepower at 380hp, making it suitable for heavy hauling operations. Its payload capacity matches that of the Sinotruk model at 40 tons. The initial cost is slightly higher, but the ease of implementation is enhanced due to more standardized configurations, which can be beneficial for companies looking for quick deployment. Maintenance is rated low, as FAW has a well-established service network, ensuring parts and servicing are readily available. However, buyers should consider the potential trade-off in customization options compared to the Sinotruk.

Alternative 2: Dongfeng 8×4 Tipper Truck

The Dongfeng 8×4 Tipper Truck stands out with its 400hp engine, providing additional power for challenging hauling tasks. Similar to the Sinotruk, it supports a 40-ton payload capacity. This model’s higher cost reflects its advanced features and capabilities. The ease of implementation is moderate, as it offers customization but may require more time for configuration. Maintenance can be a concern due to variable parts availability, depending on the region. Dongfeng trucks are ideal for heavy-duty mining operations and large-scale projects where power is a critical factor.

Conclusion: Choosing the Right Tipper Truck for Your Needs

When selecting a tipper truck, B2B buyers must evaluate their specific operational requirements, including load capacity, performance, and budget. The 2019 Year Sinotruk 8×4 Tipper Truck is a robust choice with competitive pricing and a good balance of performance and maintenance. However, alternatives like the FAW and Dongfeng models provide valuable options that may better suit particular use cases, such as immediate deployment or heavy-duty applications. Analyzing these factors in conjunction with the unique demands of your business will ensure a well-informed decision that aligns with your logistics strategy.

Essential Technical Properties and Trade Terminology for 2019 Year Sinotruk 8×4 Tipper Truck

What Are the Essential Technical Properties of the 2019 Year Sinotruk 8×4 Tipper Truck?

When considering the purchase of the 2019 Sinotruk 8×4 Tipper Truck, understanding its technical specifications is crucial for making informed decisions that align with operational requirements. Here are some key properties:

-

Horsepower and Engine Specifications

The Sinotruk 8×4 Tipper Truck is equipped with a robust 371hp engine, specifically the WD615.47 model. This high horsepower is vital for hauling heavy loads, making it suitable for construction and mining applications. A powerful engine ensures better performance and efficiency, especially in challenging terrains. -

Payload Capacity

This model boasts a payload capacity ranging from 25 to 40 tons, depending on the density of the materials being transported. This flexibility is critical for B2B buyers, as it allows for the transportation of various materials, optimizing logistics and reducing the number of trips required. -

Cargo Box Dimensions

The cargo box size measures 7800 × 2300 × 1200 mm, providing ample space for various loads. Understanding cargo dimensions is essential for buyers to ensure that the truck can accommodate their specific transport needs and comply with local regulations regarding vehicle size. -

Fuel Efficiency

With a fuel consumption rate of approximately 35 liters per 100 kilometers, this truck balances power with efficiency. For businesses operating on tight margins, fuel efficiency can significantly impact operational costs, making it an essential consideration. -

Transmission and Gearbox

The truck features a HW19710 transmission with a 10-speed gearbox, allowing for smooth gear transitions and adaptability to various driving conditions. This is particularly important for companies that require versatility in their fleet to handle different terrains. -

Suspension System

The vehicle’s suspension system, which includes 14/13 leaf springs, contributes to stability and comfort while driving under heavy loads. A well-designed suspension system is essential for minimizing wear and tear on the vehicle, which can lead to lower maintenance costs over time.

What Are Common Trade Terms Relevant to the 2019 Sinotruk 8×4 Tipper Truck?

Understanding industry jargon is equally important for making informed purchasing decisions. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of the Sinotruk 8×4 Tipper Truck, knowing the OEM can help buyers ensure they are purchasing genuine parts for maintenance and repairs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding the MOQ can help in budgeting and planning purchases, especially when considering fleet expansion or replacement. -

RFQ (Request for Quotation)

An RFQ is a standard business process to invite suppliers to bid on specific products or services. This is a crucial step for buyers looking to obtain competitive pricing for the Sinotruk 8×4 Tipper Truck, ensuring they get the best value for their investment. -

Incoterms (International Commercial Terms)

These are a set of rules that define the responsibilities of sellers and buyers for the delivery of goods under sales contracts. Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities associated with international purchases of the Sinotruk truck. -

FOB (Free on Board)

FOB indicates that the seller is responsible for the goods until they are loaded onto the shipping vessel. This term is important for B2B buyers to know as it outlines liability and cost responsibilities during the shipping process. -

Lead Time

Lead time is the period from the initiation of an order to its completion. Understanding lead times is critical for businesses planning their operations and logistics, especially when integrating new equipment like the Sinotruk 8×4 Tipper Truck into their fleet.

In summary, a thorough understanding of the technical properties and trade terminology related to the 2019 Year Sinotruk 8×4 Tipper Truck can empower B2B buyers to make informed decisions that enhance their operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the 2019 Year Sinotruk 8×4 Tipper Truck Sector

What Are the Current Market Dynamics and Key Trends Influencing the 2019 Year Sinotruk 8×4 Tipper Truck Sector?

The global demand for heavy-duty vehicles, particularly tipper trucks, is being driven by a surge in construction and mining activities across various regions, especially in Africa, South America, and the Middle East. In 2019, the Sinotruk 8×4 Tipper Truck emerged as a significant player in the market, characterized by its robust performance and versatility. Key trends include the growing adoption of advanced telematics and digital solutions that enhance fleet management and operational efficiency. B2B buyers are increasingly focused on data-driven decision-making to optimize their logistics and reduce operational costs.

Moreover, the competitive landscape is evolving with the entry of new players and the expansion of existing manufacturers. This has led to increased price competition, compelling buyers to seek high-quality products at lower costs. International buyers are also prioritizing suppliers with reliable after-sales services and readily available spare parts, as these factors significantly influence total cost of ownership. In regions like Nigeria and Saudi Arabia, the emphasis on local sourcing and partnerships is gaining traction, enabling businesses to navigate tariffs and logistical challenges more effectively.

How Is Sustainability and Ethical Sourcing Impacting the 2019 Year Sinotruk 8×4 Tipper Truck Market?

Sustainability has become a crucial consideration for B2B buyers in the heavy-duty vehicle sector, reflecting a broader global shift towards environmentally responsible practices. The Sinotruk 8×4 Tipper Truck is designed to meet Euro II emissions standards, but there is a growing expectation for manufacturers to adopt even stricter environmental guidelines. Buyers are increasingly looking for trucks that not only comply with emissions regulations but also utilize sustainable materials and processes in their manufacturing.

Ethical sourcing is gaining importance as companies strive to establish transparent supply chains. This involves ensuring that raw materials used in production, such as steel and rubber, are sourced from suppliers who adhere to ethical labor practices and environmental standards. Certifications such as ISO 14001 for environmental management systems are becoming key differentiators for suppliers in the bidding process. By investing in ‘green’ technologies and sustainable practices, suppliers can enhance their appeal to conscientious buyers, thereby gaining a competitive edge in the market.

What Is the Evolution and Historical Context of the Sinotruk 8×4 Tipper Truck?

The Sinotruk brand has a rich history dating back to its establishment in 1956, becoming a pioneer in the Chinese heavy-duty truck manufacturing sector. The introduction of the 8×4 Tipper Truck model reflects Sinotruk’s commitment to innovation and adapting to market demands. Over the years, advancements in engineering have enabled the production of vehicles that combine power, durability, and efficiency. The 8×4 configuration, known for its excellent load capacity and stability, has become particularly popular in construction and mining sectors globally.

As the demand for heavy-duty trucks grew in emerging markets, Sinotruk has continuously evolved its product offerings, incorporating advanced technologies to enhance performance and fuel efficiency. This evolution is crucial for B2B buyers looking for reliable and efficient vehicles that can withstand the rigors of demanding environments while also addressing sustainability concerns. The ongoing development of the Sinotruk 8×4 Tipper Truck is a testament to the brand’s ability to adapt to changing market dynamics and customer needs, making it a solid choice for international B2B buyers in 2019 and beyond.

Frequently Asked Questions (FAQs) for B2B Buyers of 2019 Year Sinotruk 8×4 Tipper Truck

-

How do I choose the right Sinotruk 8×4 Tipper Truck for my needs?

Selecting the appropriate Sinotruk 8×4 Tipper Truck involves considering several factors such as payload capacity, engine power, and the specific applications you have in mind. For instance, the 2019 model offers a payload capacity of up to 40 tons, making it ideal for heavy-duty tasks like construction and mining. Additionally, assess the terrain and operational conditions in your region, as this will influence your choice of specifications, including engine power and drive model. -

What are the key specifications of the 2019 Sinotruk 8×4 Tipper Truck?

The 2019 Sinotruk 8×4 Tipper Truck is equipped with a powerful 371hp engine, a 10-speed transmission, and a robust payload capacity of 25-40 tons depending on the material’s density. Its cargo box dimensions measure 7800×2300×1200 mm, which provides ample space for various materials. Additionally, it features a hydraulic steering system for enhanced maneuverability and a fuel consumption rate of approximately 35 L/100km, making it efficient for long hauls. -

What customization options are available for the Sinotruk 8×4 Tipper Truck?

Buyers can customize the Sinotruk 8×4 Tipper Truck to meet specific operational needs. Customizations may include variations in loading capacity, cargo box design, and additional features such as cranes or specialized lifting equipment. Depending on your requirements, suppliers often offer options for different colors, branding, and additional safety features, ensuring the truck meets both functional and aesthetic preferences. -

What are the minimum order quantities (MOQ) for purchasing Sinotruk trucks?

The minimum order quantity for purchasing Sinotruk 8×4 Tipper Trucks can vary by supplier but typically starts at one unit. However, bulk orders may be encouraged with discounts or better payment terms. It is advisable to discuss your needs with the supplier to negotiate the best deal, especially if you are considering a fleet purchase for large-scale operations. -

What payment terms should I expect when buying Sinotruk trucks?

Payment terms can differ among suppliers, but a common structure includes a 30% deposit upon order confirmation, with the remaining 70% due prior to shipment. Additionally, some suppliers may offer flexible payment options based on your creditworthiness or established relationships. Always clarify the payment structure and any potential additional costs, such as shipping or customs duties, before finalizing your purchase. -

How can I ensure quality assurance when purchasing a Sinotruk 8×4 Tipper Truck?

To ensure quality assurance, work with reputable suppliers who provide detailed product specifications, warranty information, and after-sales support. Requesting a pre-shipment inspection can also help verify the truck’s condition and compliance with your requirements. Additionally, reviewing customer testimonials and case studies can provide insights into the supplier’s reliability and product performance. -

What logistics considerations should I be aware of when importing Sinotruk trucks?

When importing Sinotruk trucks, consider logistics factors such as shipping methods, customs clearance, and delivery timelines. Common shipping options include container and flat rack transport, depending on your destination. Be sure to work with a logistics partner experienced in heavy machinery to navigate the complexities of international shipping, including tariffs and local regulations that may affect delivery. -

What is the expected lifespan and maintenance schedule for the Sinotruk 8×4 Tipper Truck?

The lifespan of the Sinotruk 8×4 Tipper Truck typically ranges from 10 to 15 years, depending on usage and maintenance practices. Regular maintenance is crucial and should include oil changes, brake inspections, and tire rotations every 5,000 to 10,000 kilometers. Establishing a routine maintenance schedule with certified mechanics can help extend the truck’s lifespan and ensure optimal performance in demanding conditions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 2019 Year Sinotruk 8X4 Tipper Truck Manufacturers & Suppliers List

1. SINOTRUK – HOWO 8X4 Tipper Truck

Domain: sinoheavyvehicles.com

Registered: 2016 (9 years)

Introduction: {“Product Name”: “SINOTRUK HOWO 8X4 Tipper truck”, “Product No.”: “ZZ3317N3867A”, “Horse Power”: “371hp”, “Drive Model”: “8×4”, “Payload”: “40t”, “Cargo Box Size”: “7800×2300×1200mm”, “Tires”: “12.00R20”, “Engine Model”: “WD615.47”, “Engine Type”: “6 cylinder in-line, water cooling, Diesel, 4 stroke direct injection”, “Maximum Output”: “371hp”, “Displacement”: “9.726L”, “Transmission”: “HW19710, 1…

2. HOWO – Sinotruk 8×4 Tipper Truck

Domain: truckstopafrica.com

Registered: 2019 (6 years)

Introduction: {“Product Name”: “Sinotruk 8×4 Tipper Truck 400HP 25m3 (With grab price option)”, “Price Range”: “$56,950.00 – $72,050.00”, “Type”: “Dump Truck”, “Traction Type”: “8×4”, “Drive Mode”: “Right Hand Drive”, “Brand”: “HOWO (SINOTRUK)”, “Best Price”: “USD56,950.00/ONE UNIT FOB PORT QINGDAO CHINA”, “Optional Features”: [{“Crane”: “+$15100.00/one set XCMG SQ4ZK2 crane with grab”}, {“Grills”: “+$100/per s…

3. Sinotruk – Tippers

Domain: truck1.eu

Introduction: {“brand”:”Sinotruk”,”model”:”Tippers”,”year”:”2019″,”drive”:”8×4″}

4. ScrapingDog – Instagram Scraping Services

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: Contact us at [email protected] for scraping Instagram. Let us know how many pages you want to scrape per month.

5. SINOTRUK – Howo 8X4 Dump Truck

Domain: howo-truck.com

Introduction: {“model”:”Howo 8X4 Dump Truck”,”manufacturer”:”SINOTRUK”,”application”:”Mining and Construction”,”drive_type”:”8×4″,”dimensions_mm”:”10245×2496×3400″,”max_load_kg”:30000,”emission_standards”:”EURO2-5″,”engine_power_hp”:”336-420hp”,”number_of_tires”:”12 wheel”,”curb_weight_kg”:14860,”gearbox_model”:”HW19710″,”gearbox_type”:”10 Forward speed gear”,”axle”:”HF9/HC16″,”tire_specification”:”12.00R20 rad…

6. Sinotruk – Howo 8×4 Dump Truck

Domain: machinio.com

Introduction: {“Brand”:”Sinotruk”,”Model”:”Howo 8×4″,”Year”:”2020″,”Mileage”:”18k Miles”,”Condition”:”Used/Excellent”,”Type”:”Dump Truck”,”Horsepower”:”380 HP”,”Wheels”:”12″,”Engine Type”:”Direct Injection”,”Location”:”Anhui, China”,”Price”:”19500 USD”}

7. SINOTRUK-HOWO – 10-Wheel Dump Truck

Domain: sinotrukhowo.cn

Registered: 2017 (8 years)

Introduction: {“Product Name”: “10-Wheel Dump Truck”, “Brand”: “SINOTRUK-HOWO”, “Model”: “ZZ3257N3647A (LHD)”, “Dimensions (LxWxH)”: “8214x2496x3386 mm”, “Cargo Body Size (LxWxH)”: “5400x2300x1500 mm”, “Cargo Body Thickness”: {“Bottom”: “8 mm”, “Side”: “6 mm”}, “Lift Type”: “Ventral lifting”, “Approaching Angle”: “19°”, “Departure Angle”: “26°”, “Overhang (Front/Rear)”: {“Front”: “1500 mm”, “Rear”: “1739 mm”}, …

8. Sinotruk – Howo 430 8×4 Tipper Truck

Domain: sinotrukghana.com

Registered: 2021 (4 years)

Introduction: Product: Sinotruk Howo 430 8×4 Tipper Truck

Key Features:

– Robust Construction: Designed for heavy-duty operations, capable of handling challenging terrains and substantial loads.

– Powerful Engines: Equipped with reliable engines that deliver high torque and horsepower for efficient hauling.

Strategic Sourcing Conclusion and Outlook for 2019 Year Sinotruk 8×4 Tipper Truck

In summary, the Sinotruk 8×4 Tipper Truck stands out as a robust and versatile solution for businesses engaged in heavy-duty transportation and construction. With a powerful 371hp engine, a significant payload capacity of up to 40 tons, and customizable options tailored to specific operational needs, it presents an attractive proposition for international buyers. The strategic sourcing of this vehicle not only ensures competitive pricing but also enhances operational efficiency, allowing businesses to optimize their logistics and project timelines.

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, investing in the Sinotruk 8×4 Tipper Truck represents an opportunity to boost productivity while adhering to stringent emission standards. With its reliable performance and durability, this truck is well-suited for challenging terrains and demanding workloads.

As you consider your options for heavy-duty vehicles, take advantage of the favorable pricing and flexible payment terms available. Engage with trusted suppliers to explore how the Sinotruk 8×4 Tipper Truck can be integrated into your fleet, setting the stage for enhanced operational success in 2019 and beyond.