Introduction: Navigating the Global Market for runhorse j2

Navigating the complexities of sourcing the Runhorse J2, a versatile electric logistics vehicle, can be a daunting challenge for international B2B buyers. As businesses increasingly prioritize sustainability and efficiency, the demand for electric vehicles like the Runhorse J2 has surged, particularly in regions such as Africa, South America, the Middle East, and Europe. This comprehensive guide aims to equip you with the essential insights needed to make informed purchasing decisions.

We will explore various aspects of the Runhorse J2, including its specifications, applications in logistics and transportation, and the benefits of utilizing electric vehicles in your fleet. Additionally, we’ll provide strategies for vetting suppliers effectively, understanding cost implications, and navigating import regulations specific to your region. The guide is designed to empower B2B buyers from diverse markets, such as Nigeria and Germany, enabling them to overcome challenges related to sourcing and integrating electric vehicles into their operations.

By leveraging the information provided in this guide, you will not only enhance your understanding of the Runhorse J2 but also ensure that your investments align with your business objectives and sustainability goals. Together, let’s unlock the potential of electric logistics solutions to drive growth and innovation in your enterprise.

Understanding runhorse j2 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Runhorse J2-C | EEC approved, compact size, cargo capacity of 330kg | Urban logistics, delivery services | Pros: Efficient for last-mile deliveries; Cons: Limited speed (max 45 km/h). |

| Runhorse J2-P | Mini refrigerator design for cold chain transportation | Food and beverage logistics | Pros: Ideal for temperature-sensitive goods; Cons: Higher initial investment. |

| Runhorse J2 Passenger Vehicle | Designed for passenger transport, customizable colors | Employee shuttles, tourism | Pros: Comfortable for short trips; Cons: Limited range compared to larger vehicles. |

| Runhorse J2 Electric Tricycle | Three-wheel design, lightweight, lower cost | Personal transport, rural mobility | Pros: Cost-effective; Cons: Less stability than four-wheel options. |

| Runhorse J2 with Lithium Upgrade | Adaptable for lithium battery conversion | Eco-friendly fleets, sustainable transport | Pros: Longer battery life; Cons: Requires technical knowledge for retrofitting. |

What are the Characteristics and Suitability of Runhorse J2-C?

The Runhorse J2-C is a versatile electric vehicle tailored for urban logistics. With a compact design and a cargo capacity of 330 kg, it is well-suited for last-mile delivery in congested city environments. Businesses looking to enhance their delivery efficiency will find this model appealing, particularly for operations in densely populated areas. However, its maximum speed of 45 km/h may limit its use in high-traffic situations, requiring careful consideration of delivery routes.

How Does the Runhorse J2-P Meet Cold Chain Requirements?

The Runhorse J2-P is specifically engineered for cold chain logistics, featuring a mini refrigerator design. This vehicle is essential for businesses in the food and beverage sector that require consistent temperature control during transport. Its ability to maintain the integrity of perishable goods is a significant advantage, though the upfront investment can be higher compared to standard delivery vehicles. Companies must evaluate their cold chain needs to determine if the J2-P aligns with their operational goals.

What Advantages Does the Runhorse J2 Passenger Vehicle Offer?

Designed for passenger transport, the Runhorse J2 Passenger Vehicle provides a comfortable and customizable ride. This model is ideal for businesses looking to shuttle employees or provide tourist services, enhancing the customer experience. However, its limited range compared to larger vehicles may pose challenges for longer trips. Buyers should assess their specific transport needs and consider the J2’s capacity to meet those demands effectively.

Why Consider the Runhorse J2 Electric Tricycle for Personal Transport?

The Runhorse J2 Electric Tricycle offers an economical solution for personal transport, especially in rural areas. Its lightweight and three-wheel design make it an affordable option for individuals or small businesses needing mobility solutions. While it provides cost savings, potential buyers should be aware of its stability limitations compared to four-wheel vehicles, which may impact safety and comfort on uneven terrain.

What are the Benefits and Considerations of Upgrading to Lithium Batteries in Runhorse J2?

For businesses aiming for sustainability, the Runhorse J2 with a lithium upgrade presents an attractive option. Lithium batteries offer a longer lifespan and improved performance compared to traditional lead-acid batteries, making this vehicle suitable for eco-conscious fleets. However, retrofitting the vehicle to accommodate lithium batteries requires technical expertise, which may be a barrier for some buyers. Companies should weigh the environmental benefits against the technical challenges involved in making this upgrade.

Key Industrial Applications of runhorse j2

| Industry/Sector | Specific Application of runhorse j2 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Delivery | Last-mile delivery for e-commerce and retail goods | Efficient transport of goods in urban and suburban areas, reducing carbon footprint | Consider local regulations, charging infrastructure, and payload capacity. |

| Cold Chain Logistics | Refrigerated transport for perishable goods | Ensures freshness of food and pharmaceuticals, minimizing spoilage | Verify temperature control capabilities and battery life for extended use. |

| Urban Transportation | Short-distance passenger transport | Cost-effective and eco-friendly solution for urban mobility | Assess vehicle size for urban environments and compliance with local transport laws. |

| Agriculture | Transport of agricultural products and tools | Enhances mobility on farms, facilitating timely delivery of goods | Evaluate terrain compatibility and loading capacity for agricultural equipment. |

| Hospitality and Tourism | Shuttle services for hotels and tourist attractions | Provides guests with a unique and sustainable transport option | Consider branding opportunities and passenger comfort features. |

How is the Runhorse J2 Used in the Logistics and Delivery Sector?

In the logistics and delivery sector, the Runhorse J2 is employed for last-mile delivery, particularly for e-commerce and retail goods. Its compact size allows it to navigate urban environments effectively, while its electric powertrain supports sustainability initiatives. Businesses benefit from reduced operational costs and a lower carbon footprint. For international buyers, it’s crucial to consider local regulations regarding electric vehicles and the availability of charging infrastructure to ensure seamless operations.

What Role Does the Runhorse J2 Play in Cold Chain Logistics?

The Runhorse J2 is particularly valuable in cold chain logistics, where it serves as a refrigerated transport solution for perishable goods. By maintaining the necessary temperature for products like food and pharmaceuticals, it minimizes spoilage and waste. Buyers must evaluate the vehicle’s temperature control capabilities and battery life to ensure it meets their operational needs, especially in regions with varying climates such as Africa and South America.

How Can the Runhorse J2 Enhance Urban Transportation Solutions?

In urban transportation, the Runhorse J2 provides a cost-effective and eco-friendly option for short-distance passenger transport. Its low-speed design makes it ideal for city commutes, reducing traffic congestion and emissions. For B2B buyers in Europe, such as Germany, assessing the vehicle’s compliance with local transport laws and its size for urban environments is essential for effective integration into existing transport networks.

How is the Runhorse J2 Beneficial in Agriculture?

The Runhorse J2 serves as a versatile transport option on agricultural lands, facilitating the movement of products and tools. Its electric design allows for quiet operation, which is beneficial in rural settings. Buyers should consider the vehicle’s loading capacity and compatibility with various terrains to ensure it meets the demands of agricultural logistics, particularly in expansive areas found in regions like South America and Africa.

What Advantages Does the Runhorse J2 Offer for the Hospitality and Tourism Industry?

In the hospitality and tourism sector, the Runhorse J2 can be utilized for shuttle services, enhancing guest experiences with sustainable transport options. This adds a unique selling point for hotels and attractions aiming to promote eco-friendly practices. When sourcing, businesses should focus on branding opportunities and the comfort features of the vehicle to meet the expectations of tourists, particularly in popular destinations across the Middle East and Europe.

3 Common User Pain Points for ‘runhorse j2’ & Their Solutions

Scenario 1: Challenges with Electric Vehicle Compliance and Documentation

The Problem: B2B buyers, particularly in regions like Africa and South America, often encounter significant hurdles when navigating the regulatory landscape for electric vehicles, such as the Runhorse J2. These challenges can include obtaining necessary certifications, understanding local compliance requirements, and dealing with complex import regulations. For instance, a logistics company in Nigeria may find itself unable to clear its shipment due to missing or incorrect documentation, leading to delays and additional costs. This not only affects the company’s operational timeline but also its bottom line.

The Solution: To navigate these compliance challenges effectively, B2B buyers should engage with a reliable local distributor or a customs broker familiar with electric vehicle regulations. Before purchasing, it’s crucial to request comprehensive documentation from the supplier, including EEC certification and any other relevant compliance papers. Buyers should also proactively research their country’s specific import requirements for electric vehicles. Leveraging local legal expertise can help in understanding the nuances of the documentation process, ensuring all paperwork is correctly completed before shipment. By establishing a relationship with a knowledgeable local partner, businesses can streamline the import process and mitigate risks associated with compliance issues.

Scenario 2: Technical Support and Maintenance Difficulties

The Problem: After acquiring the Runhorse J2, many B2B buyers find themselves struggling with technical support and maintenance. Given the vehicle’s reliance on specialized electric components, such as lithium battery systems, buyers may face difficulties sourcing replacement parts or receiving adequate technical assistance. A company in Germany, for example, may find that its J2 requires a specific controller card for lithium batteries, but the original supplier is unresponsive or lacks the necessary parts, resulting in costly downtime.

The Solution: To address this issue, buyers should prioritize establishing a comprehensive maintenance and support plan before making a purchase. This includes identifying local service providers or mechanics who specialize in electric vehicles and can offer support for the Runhorse J2. Buyers can also engage with online forums and communities focused on electric vehicle maintenance, where they can share experiences and gather information on troubleshooting and sourcing parts. Additionally, negotiating a warranty or service agreement that includes access to spare parts and technical support can provide peace of mind and ensure that any issues are resolved quickly, minimizing operational disruptions.

Scenario 3: Limited Range and Charging Infrastructure Concerns

The Problem: Another significant pain point for B2B buyers is the limited range of electric vehicles like the Runhorse J2, which can be as low as 45 km/h. This limitation can be particularly problematic for businesses that rely on long-distance logistics or need to operate in areas with insufficient charging infrastructure. A logistics company in the Middle East may struggle to deliver goods efficiently due to the J2’s range constraints, leading to delays and potentially lost business opportunities.

The Solution: To overcome range and infrastructure challenges, businesses should conduct a thorough assessment of their operational routes and charging needs before purchasing the Runhorse J2. It’s advisable to map out the logistics routes to ensure that charging stations are available within a reasonable distance. Companies can also consider investing in portable charging solutions or establishing partnerships with local charging station providers to expand access to charging infrastructure. Additionally, exploring fleet management software can assist in optimizing routes and ensuring that vehicles are charged adequately before embarking on longer trips. By strategically planning for charging needs, businesses can leverage the Runhorse J2’s capabilities without compromising operational efficiency.

Strategic Material Selection Guide for runhorse j2

What are the Key Materials Used in the Runhorse J2 and Their Properties?

The Runhorse J2, an electric logistics vehicle, utilizes various materials that significantly impact its performance, durability, and overall suitability for international markets. Understanding these materials can help B2B buyers make informed decisions.

What are the Key Properties and Considerations for Steel in the Runhorse J2?

Steel is a primary material in the construction of the Runhorse J2, particularly in its chassis and frame. Key properties of steel include high tensile strength, excellent durability, and good weldability. It can withstand various environmental conditions, making it suitable for diverse climates.

Pros: Steel offers exceptional strength and durability, making it ideal for heavy loads and rough terrain. It is also relatively cost-effective compared to other materials.

Cons: Steel is prone to corrosion if not properly treated, which can be a concern in humid or coastal environments. Additionally, its weight can affect the vehicle’s overall efficiency.

Impact on Application: Steel’s strength allows the J2 to carry a maximum load of 330 kg, essential for logistics operations. However, buyers in regions with high humidity, like parts of Africa and South America, should consider corrosion-resistant coatings.

Considerations for International Buyers: Compliance with international standards, such as ASTM for steel grades, is crucial. Buyers should also consider local regulations regarding vehicle weight limits and emissions.

How Does Aluminum Enhance Performance in the Runhorse J2?

Aluminum is often used in components such as body panels and certain structural elements of the Runhorse J2. Its key properties include lightweight, corrosion resistance, and good thermal conductivity.

Pros: Aluminum significantly reduces the overall weight of the vehicle, enhancing energy efficiency and range. Its resistance to corrosion makes it suitable for various climates.

Cons: While aluminum is lightweight, it is generally more expensive than steel and can be less durable under heavy loads if not properly designed.

Impact on Application: The use of aluminum improves the vehicle’s range and efficiency, making it ideal for urban logistics where energy consumption is a concern.

Considerations for International Buyers: Compliance with standards like DIN for aluminum alloys is necessary. Buyers should also consider the availability of aluminum in their region, as it may affect lead times and costs.

What Role Does Plastic Play in the Runhorse J2’s Design?

Plastics are used in various non-structural components of the Runhorse J2, including interior fittings and some exterior elements. Key properties include lightweight, flexibility, and resistance to corrosion and chemicals.

Pros: Plastics help reduce the overall weight of the vehicle, contributing to better fuel efficiency. They also offer design flexibility and can be molded into complex shapes.

Cons: Plastics may not provide the same level of durability as metals, especially in high-stress applications. They can also degrade under UV exposure if not properly treated.

Impact on Application: The lightweight nature of plastics aids in enhancing the vehicle’s energy efficiency, making it suitable for last-mile delivery services.

Considerations for International Buyers: Buyers should be aware of the types of plastics used and their compliance with regulations in their region, particularly regarding recyclability and environmental impact.

How Does the Use of Lithium-Ion Batteries Affect the Runhorse J2?

Lithium-ion batteries are integral to the Runhorse J2’s electric powertrain. Key properties include high energy density, long cycle life, and relatively low self-discharge rates.

Pros: These batteries provide a longer range and faster charging times compared to traditional lead-acid batteries, making them ideal for logistics applications.

Cons: The initial cost of lithium-ion batteries is higher, and they require specific handling and recycling processes.

Impact on Application: The use of lithium-ion batteries enhances the vehicle’s performance, allowing for efficient operations in urban environments.

Considerations for International Buyers: Compliance with international safety standards for battery transport and disposal is essential. Buyers should also consider local regulations on battery recycling and disposal.

Summary Table of Material Selection for Runhorse J2

| Material | Typical Use Case for runhorse j2 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chassis and frame | High strength and durability | Prone to corrosion | Medium |

| Aluminum | Body panels and structural elements | Lightweight and corrosion-resistant | More expensive and less durable under load | High |

| Plastic | Interior fittings and non-structural parts | Lightweight and flexible | Less durable and UV degradation potential | Low |

| Lithium-Ion Battery | Electric powertrain | Longer range and faster charging | Higher initial cost and specific handling | High |

This comprehensive analysis of materials used in the Runhorse J2 provides B2B buyers with critical insights into their properties, advantages, and considerations for international markets, ensuring informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for runhorse j2

What Are the Main Stages in the Manufacturing Process of Runhorse J2?

The manufacturing of the Runhorse J2 involves several critical stages that ensure the vehicle meets both performance and quality standards. Each stage is designed to optimize efficiency and maintain high-quality output.

Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. High-strength steel and lightweight aluminum alloys are commonly used to construct the chassis and body of the J2. These materials are sourced from reputable suppliers who adhere to international quality standards. Before being utilized, materials undergo rigorous testing to confirm their structural integrity and resistance to environmental factors, which is crucial for longevity in diverse climates.

Forming and Fabrication

Once the materials are prepared, they are shaped and formed using advanced techniques such as stamping, bending, and welding. Computer Numerical Control (CNC) machines are often employed for precision cutting and shaping, ensuring that components fit together seamlessly. The forming process is critical for achieving the desired dimensions and structural strength of the vehicle.

Assembly

The assembly stage involves the integration of various components, including the electric drive system, suspension, and interior fittings. Skilled technicians follow standardized assembly procedures to ensure each unit meets the specifications outlined in the design phase. The use of modular assembly techniques allows for efficient production and easier maintenance.

Finishing

After assembly, the vehicle undergoes a finishing process that includes painting, coating, and detailing. This not only enhances the aesthetic appeal but also provides protection against corrosion and wear. The finishing stage is crucial for ensuring that the Runhorse J2 can withstand various environmental conditions, especially in regions with high humidity or temperature fluctuations.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is a cornerstone of the manufacturing process for the Runhorse J2. It ensures that the final product meets both regulatory standards and customer expectations.

What International Standards Govern Runhorse J2 Quality Assurance?

Runhorse adheres to various international quality standards, including ISO 9001, which focuses on quality management systems. This certification requires ongoing monitoring and improvement of manufacturing processes. Additionally, the J2 complies with European Community (CE) standards, ensuring it meets safety and environmental requirements for vehicles sold in Europe.

What Are the Key Quality Control Checkpoints?

Quality control is integrated at multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process to identify and address any defects early.

- Final Quality Control (FQC): Each finished vehicle undergoes a comprehensive inspection, including functional tests, to verify that it operates correctly and meets all specifications.

What Testing Methods Are Commonly Used for Runhorse J2?

Various testing methods are employed to validate the performance and safety of the J2. These include:

- Dynamic Testing: Evaluating the vehicle’s performance under real-world conditions.

- Electrical Testing: Ensuring that the electric drive system functions correctly and efficiently.

- Safety Testing: Assessing the vehicle’s compliance with safety regulations, including crash tests and stability assessments.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control processes of their suppliers.

What Audit Processes Should Buyers Consider?

Conducting supplier audits is one of the most effective ways to verify quality control. Buyers should look for suppliers that allow on-site visits or provide detailed reports on their quality management practices. This can include assessments of their manufacturing facilities, employee training programs, and adherence to international quality standards.

How Important Are Quality Reports and Certifications?

Requesting quality reports and certifications from suppliers is essential. These documents can provide insights into the supplier’s quality assurance practices and compliance with industry standards. Buyers should ensure that these documents are current and relevant, reflecting the latest quality assessments.

Should Buyers Utilize Third-Party Inspections?

Employing third-party inspection services can offer an additional layer of assurance. Independent inspectors can provide unbiased evaluations of the manufacturing processes and final products, ensuring that they meet agreed-upon specifications. This is particularly important for international transactions, where language barriers and cultural differences may complicate direct communication.

What Are the Quality Control and Certification Nuances for International Buyers?

Understanding the nuances of quality control and certification is crucial for international buyers. Different regions may have varying standards and regulations that affect vehicle compliance.

How Do Regional Regulations Impact Quality Standards?

For example, vehicles sold in Europe must meet stringent EU regulations, while those intended for markets in Africa or South America may face different requirements. Buyers should familiarize themselves with the specific regulations applicable to their region and ensure that suppliers can comply with these standards.

What Role Do Local Partnerships Play in Quality Assurance?

Establishing partnerships with local entities can facilitate better communication and understanding of quality expectations. Local representatives can help navigate the complexities of regulations and ensure that suppliers meet the necessary quality standards.

Conclusion

The manufacturing processes and quality assurance practices for the Runhorse J2 are designed to ensure that the vehicle meets high standards of performance and safety. By understanding these processes, B2B buyers can make informed decisions, ensuring they receive a product that aligns with their operational needs and regional regulations. Through diligent verification of supplier quality control measures, buyers can mitigate risks and secure reliable partnerships in the evolving electric vehicle market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘runhorse j2’

Introduction

This sourcing guide is designed to assist international B2B buyers in navigating the procurement process for the Runhorse J2 electric vehicle. With its compact size and efficient design, the J2 serves various logistical and transportation needs. This checklist will ensure you make informed decisions while sourcing this innovative vehicle, taking into consideration important technical specifications, supplier credibility, and logistical aspects.

1. Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements for the Runhorse J2. Consider factors such as cargo capacity, maximum speed, and dimensions.

– Key Specifications to Define:

– Loading capacity (e.g., 330kg).

– Dimensions (e.g., 2890x1180x1780mm).

– Speed requirements (e.g., max speed of 45 km/h).

2. Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers for the Runhorse J2. This step is crucial to ensure reliability and quality.

– Tips for Supplier Research:

– Look for suppliers with a strong online presence and positive customer reviews.

– Check for any certifications or awards that may indicate product quality, such as EEC approval.

3. Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is essential to ensure compliance with international safety and quality standards.

– What to Check:

– EEC (European Economic Community) certification for vehicles.

– Any other relevant industry standards that may apply in your region.

4. Step 4: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations to compare pricing and terms.

– Key Elements to Include in Quotations:

– FOB (Free On Board) prices, including any additional fees.

– Delivery timelines and payment terms.

– Warranty and service agreements.

5. Step 5: Assess Logistics and Shipping Options

Understanding logistics is vital in the procurement process, especially for international shipping.

– Logistics Considerations:

– Inquire about shipping costs and options (e.g., sea freight).

– Confirm lead times for delivery (e.g., approximately 2 weeks after payment).

– Consider using your own forwarder or the supplier’s recommended services.

6. Step 6: Conduct Supplier Interviews

Engage in direct communication with potential suppliers to clarify any uncertainties and gauge their responsiveness.

– Questions to Ask:

– Inquire about after-sales support and spare parts availability.

– Ask about their experience with international clients and handling customs.

7. Step 7: Finalize Contractual Terms

Once you have selected a supplier, finalize the contractual terms to protect your investment.

– Contractual Elements to Confirm:

– Payment terms and conditions.

– Delivery schedules and penalties for delays.

– Clauses for quality assurance and dispute resolution.

By following this structured checklist, B2B buyers can effectively navigate the complexities of sourcing the Runhorse J2, ensuring a successful procurement process that meets their operational needs.

Comprehensive Cost and Pricing Analysis for runhorse j2 Sourcing

What Are the Key Cost Components in Sourcing Runhorse J2?

When analyzing the cost structure of the Runhorse J2, several components contribute significantly to the overall price. The primary cost components include:

-

Materials: The choice of materials directly affects the manufacturing cost. The Runhorse J2 utilizes high-quality components, including electric motors and lithium batteries, which can vary in price based on sourcing and quality. For instance, opting for higher-grade lithium batteries can enhance performance and longevity but may increase upfront costs.

-

Labor: Labor costs in manufacturing play a crucial role in the pricing of the J2. Labor expenses can fluctuate based on the region of production and the expertise required for assembly, especially for electric vehicles that demand specialized skills.

-

Manufacturing Overhead: This encompasses utilities, facilities maintenance, and administrative costs. Efficient manufacturing processes can help in minimizing overhead, which in turn influences the final pricing of the vehicle.

-

Tooling: Initial investments in tooling for production can be substantial. However, these costs are typically amortized over larger production runs, making it crucial for buyers to consider Minimum Order Quantities (MOQs) that can help spread these costs.

-

Quality Control (QC): Ensuring that each vehicle meets safety and performance standards incurs costs. Rigorous QC processes are essential for maintaining the vehicle’s reliability and compliance with international certifications, particularly for markets in Europe and North America.

-

Logistics: Transportation and shipping costs, particularly for international buyers, can significantly impact the total cost. Factors such as distance, shipping methods, and local tariffs should be accounted for in the final pricing.

-

Margin: Suppliers typically include a margin to cover their costs and generate profit. Understanding the supplier’s pricing strategy can help buyers negotiate more effectively.

How Do Price Influencers Affect Runhorse J2 Pricing?

Several factors can influence the pricing of the Runhorse J2:

-

Volume/MOQ: Bulk purchasing can lead to significant discounts. Suppliers often provide lower per-unit costs for higher order quantities, making it beneficial for buyers to assess their needs carefully.

-

Specifications/Customization: Customization options can increase the base price. Buyers should weigh the benefits of tailored specifications against the additional costs involved.

-

Materials: The choice of materials affects both cost and performance. Opting for premium materials may enhance durability and efficiency but will also raise the initial investment.

-

Quality/Certifications: Vehicles meeting stringent international standards may come with a higher price tag. Buyers should consider whether these certifications are necessary for their market to justify the additional expense.

-

Supplier Factors: Supplier reputation, reliability, and after-sales support can influence pricing. Established suppliers with a track record may charge more due to their perceived value.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) is essential for international buyers. The chosen terms can affect shipping costs, insurance, and liability during transit, influencing the total landed cost of the vehicle.

What Tips Can Help International Buyers Optimize Costs?

-

Negotiate Pricing: Engaging in negotiations can yield significant savings. Buyers should be prepared with market research and competitor pricing to strengthen their position.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational costs, and potential resale value. A lower upfront cost may not always equate to better long-term value.

-

Understand Pricing Nuances: International buyers, especially from regions like Africa and South America, should be aware of local tariffs and import duties that may affect the overall cost structure.

-

Explore Shipping Options: Evaluating different shipping methods and timelines can help in reducing logistics costs. Consider whether faster shipping is necessary or if slower, more economical options suffice.

-

Leverage Local Partnerships: Establishing relationships with local distributors can facilitate smoother transactions and provide insights into market-specific pricing and regulations.

In summary, a thorough understanding of the cost components, price influencers, and strategic negotiation can empower international buyers to make informed decisions when sourcing the Runhorse J2. The emphasis on Total Cost of Ownership will ensure that investments align with long-term operational goals.

Alternatives Analysis: Comparing runhorse j2 With Other Solutions

Understanding Alternatives to Runhorse J2 for Electric Logistics Vehicles

In the competitive landscape of electric logistics vehicles, the Runhorse J2 stands out for its compact design and utility. However, businesses need to evaluate alternative options that may align better with their specific operational needs. This comparison analyzes the Runhorse J2 against two viable alternatives in the electric vehicle market, highlighting their performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Runhorse J2 | Alternative 1: Chanje V8070 | Alternative 2: Nissan e-NV200 |

|---|---|---|---|

| Performance | Max speed of 45 km/h, 330 kg load capacity | Max speed of 70 km/h, 900 kg load capacity | Max speed of 90 km/h, 770 kg load capacity |

| Cost | Approx. $4,890 FOB price | Approx. $39,000 | Approx. $30,000 |

| Ease of Implementation | Moderate; requires dealer support | Moderate; needs specialized training | Easy; established service network available |

| Maintenance | Low; electric drivetrain minimizes upkeep | Moderate; requires regular software updates | Low; Nissan has a robust support network |

| Best Use Case | Short-range urban deliveries | Medium to long-range logistics | Versatile urban and suburban deliveries |

Detailed Breakdown of Alternatives

Chanje V8070

The Chanje V8070 is a medium-duty electric van designed for larger logistics operations. With a maximum speed of 70 km/h and a load capacity of 900 kg, it offers significant performance advantages over the Runhorse J2. However, the initial investment is substantially higher, making it less accessible for smaller businesses. The vehicle requires specialized training for implementation, and while maintenance is moderate due to the software updates needed, it still benefits from a growing support network. This vehicle is ideal for companies that need to transport larger loads over longer distances, particularly in urban settings.

Nissan e-NV200

The Nissan e-NV200 is another compelling alternative, designed with versatility in mind. It boasts a maximum speed of 90 km/h and a load capacity of 770 kg, making it suitable for various delivery tasks. While its price point is lower than the Chanje V8070, it still requires a significant investment. The e-NV200 benefits from Nissan’s established service network, making maintenance easier and more reliable. Its ease of implementation and lower operating costs position it as a strong choice for businesses looking for a dependable electric vehicle for urban and suburban deliveries.

Conclusion: How to Choose the Right Electric Vehicle Solution

When selecting an electric vehicle for logistics, B2B buyers should consider their specific operational needs, including the typical load weight, distance traveled, and budget constraints. The Runhorse J2 offers an affordable entry point for small businesses focused on short-range deliveries, while the Chanje V8070 and Nissan e-NV200 cater to larger operations needing more capacity and speed. Ultimately, the right choice will depend on balancing performance capabilities with cost-effectiveness and ease of maintenance to ensure long-term operational efficiency.

Essential Technical Properties and Trade Terminology for runhorse j2

What Are the Key Technical Properties of the Runhorse J2?

When considering the purchase of the Runhorse J2, understanding its technical specifications is crucial for B2B buyers. Here are some of the essential properties to note:

-

Dimensions and Cargo Capacity

– Size: 2890 mm x 1180 mm x 1780 mm

– Cargo Box Size: 875 mm x 1080 mm x 995 mm

– Curb Weight: 500 kg

– Loading Capacity: 330 kg

– Importance: These dimensions and capacities are vital for logistics and transportation planning. Knowing the size helps determine if the vehicle can fit into designated loading areas or storage facilities, while the loading capacity is critical for understanding how much cargo can be transported per trip. -

Maximum Speed and Performance

– Max Speed: 45 km/h

– Importance: The maximum speed is essential for route planning and delivery schedules. For businesses involved in logistics and transportation, this speed ensures timely deliveries while complying with local regulations regarding low-speed vehicles. -

Power Source and Efficiency

– Fuel Type: Battery Electric Vehicle (BEV)

– Charging Time: Fast charging capabilities (2-3 hours)

– Importance: As electric vehicles become more prevalent, understanding the power source and charging efficiency can influence operational costs. Businesses should consider the availability of charging stations and the implications for fleet management. -

Seating and Accessibility

– Seating Capacity: 1 seat

– Design: Mini van suitable for light cargo

– Importance: The design and seating capacity indicate the vehicle’s suitability for specific business operations, particularly in urban environments where space is limited. A single-seater can be ideal for deliveries in congested areas. -

Compliance and Certification

– EEC Approved (L6e)

– Importance: Compliance with regional regulations ensures that the vehicle can be legally operated in the target market. This certification is crucial for buyers to avoid potential fines and ensure safety standards.

What Are Common Trade Terms Relevant to the Runhorse J2?

Understanding industry terminology can greatly enhance communication and negotiation processes. Here are some key trade terms:

-

OEM (Original Equipment Manufacturer)

– Refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of the Runhorse J2, OEM relationships can affect parts availability and warranty services. -

MOQ (Minimum Order Quantity)

– The smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, especially when placing bulk orders for electric vehicles. -

RFQ (Request for Quotation)

– A business document used to invite suppliers to bid on specific products or services. For B2B buyers, submitting an RFQ for the Runhorse J2 allows them to compare prices and terms from multiple suppliers. -

Incoterms (International Commercial Terms)

– A set of predefined international rules that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is critical for determining who is responsible for shipping, insurance, and tariffs related to the Runhorse J2. -

Lead Time

– The time from placing an order to receiving the product. For the Runhorse J2, a lead time of approximately two weeks after payment is significant for planning deliveries and managing customer expectations. -

FCL (Full Container Load)

– Refers to a shipping arrangement where a single shipment occupies an entire container. For international buyers, understanding FCL can help optimize shipping costs when importing multiple units of the Runhorse J2.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions regarding the procurement of the Runhorse J2, ensuring that their investments align with operational needs and market regulations.

Navigating Market Dynamics and Sourcing Trends in the runhorse j2 Sector

What Are the Key Market Dynamics and Trends for the Runhorse J2 in B2B Sourcing?

The Runhorse J2 sector is experiencing significant growth driven by global shifts towards electric vehicles (EVs) and sustainable logistics solutions. As urbanization increases, particularly in emerging markets in Africa, South America, the Middle East, and Europe, there is a heightened demand for compact, efficient vehicles like the Runhorse J2. International B2B buyers are increasingly looking for alternatives to traditional fuel-based vehicles, spurred by regulatory pressures and consumer preferences for environmentally friendly options. The J2, with its compact design and electric powertrain, offers a practical solution for last-mile delivery and urban transportation.

Emerging technologies such as battery management systems and smart logistics software are reshaping the B2B landscape. Buyers are now prioritizing suppliers who integrate advanced tech solutions, enhancing vehicle performance and efficiency. Additionally, the trend towards Completely Knocked Down (CKD) kits is gaining traction, allowing buyers to assemble vehicles locally, thereby reducing customs duties and transportation costs. This flexibility is particularly appealing for businesses in regions like Nigeria and Germany, where import tariffs can significantly impact the total cost of ownership.

How Does Sustainability and Ethical Sourcing Impact the Runhorse J2 Sector?

The environmental impact of sourcing and manufacturing vehicles like the Runhorse J2 is becoming a critical concern for B2B buyers. With the automotive industry facing increasing scrutiny over its carbon footprint, companies are focusing on sustainable sourcing practices. This includes the use of recyclable materials and adherence to strict environmental regulations during production. Buyers are now seeking suppliers who can demonstrate commitment to sustainability through certifications and transparent supply chains.

Ethical sourcing is equally important, as stakeholders are increasingly aware of the social implications of their purchasing decisions. Ensuring that suppliers adhere to fair labor practices and sustainable environmental policies not only aligns with corporate social responsibility goals but also enhances brand reputation. B2B buyers should consider suppliers that provide “green” certifications and utilize sustainable materials in their products, as this not only fulfills regulatory requirements but also appeals to a growing segment of eco-conscious consumers.

What Is the Historical Context of the Runhorse J2 for B2B Buyers?

The Runhorse J2’s evolution reflects the broader trends within the electric vehicle market, which has gained momentum over the past decade. Initially focused on personal transportation, the J2 has adapted to meet the demands of commercial applications, such as cold chain logistics and urban delivery services. As battery technology has advanced and costs have decreased, the viability of electric vehicles in various sectors has improved significantly.

The introduction of EEC certifications and compliance with international standards has also positioned the Runhorse J2 as a competitive option for B2B buyers across different regions. This historical context is essential for understanding the current market landscape and the potential for future growth within the sector, particularly for international buyers seeking reliable and efficient transportation solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of runhorse j2

-

How do I ensure the quality of the Runhorse J2 before purchasing?

To ensure the quality of the Runhorse J2, it is advisable to conduct thorough research on the manufacturer. Look for certifications such as EEC approval, which indicates compliance with European standards. Request product samples or visit the factory if possible to assess manufacturing practices and quality control measures. Additionally, check for customer reviews and testimonials from other B2B buyers to gauge reliability and satisfaction levels. -

What are the best practices for vetting suppliers of Runhorse J2?

When vetting suppliers, start by verifying their business credentials and registration details. Utilize platforms like Alibaba or trade directories to find reputable suppliers with good ratings. Request references from previous clients and assess their response times and communication skills. Additionally, inquire about their production capacity, lead times, and after-sales support to ensure they can meet your business needs effectively. -

What customization options are available for the Runhorse J2?

Customization options for the Runhorse J2 typically include color selection, branding, and additional features such as refrigerated cargo space or enhanced battery capacity. Discuss your specific requirements with the supplier before placing an order. It’s also wise to confirm any additional costs associated with customizations and ensure they can be delivered within your desired timelines. -

What is the minimum order quantity (MOQ) for the Runhorse J2?

The minimum order quantity (MOQ) for the Runhorse J2 can vary by supplier. Generally, for B2B transactions, MOQs range from a single unit to several vehicles depending on the manufacturer’s policies. Confirm the MOQ with your supplier early in the negotiation process to align with your purchasing strategy and inventory needs. -

What payment terms can I expect when sourcing the Runhorse J2?

Payment terms may vary by supplier, but common practices include a deposit upon order confirmation (often 30-50%) with the balance due before shipment. Some suppliers may also accept letters of credit or installment payments for larger orders. Always clarify payment terms upfront and ensure they are documented in the sales contract to avoid disputes later. -

How can I manage logistics and shipping for the Runhorse J2?

To manage logistics and shipping effectively, work closely with your supplier to determine the best shipping methods based on your location and budget. Options may include sea freight for bulk orders or air freight for urgent deliveries. Make sure to consider customs clearance requirements and tariffs specific to your country to avoid unexpected costs. Engaging a reputable freight forwarder can also streamline the shipping process. -

What warranty or after-sales support should I expect with the Runhorse J2?

Most suppliers offer a warranty period for the Runhorse J2, typically ranging from one to three years, covering defects in materials and workmanship. Inquire about the specifics of the warranty, including what it covers and the process for claims. Additionally, ask about after-sales support options, such as maintenance services, spare parts availability, and technical assistance to ensure long-term satisfaction with your purchase. -

How do I handle potential issues with the Runhorse J2 after purchase?

If you encounter issues with the Runhorse J2 after purchase, first consult the warranty documentation for guidance on claims. Contact your supplier immediately to report the problem, providing detailed information and any relevant documentation. Establishing a good relationship with the supplier can facilitate quicker resolutions. For ongoing issues, consider hiring a local service provider familiar with electric vehicles to assist with repairs and maintenance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Runhorse J2 Manufacturers & Suppliers List

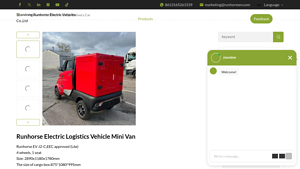

1. Runhorse – Electric Logistics Mini Van J2-C

Domain: runhorseev.com

Registered: 2023 (2 years)

Introduction: Runhorse Electric Logistics Vehicle Mini Van J2-C, EEC approved (L6e), 4 wheels, 1 seat. Size: 2890x1180x1780mm. Cargo box size: 875*1080*995mm. Hopper size: 875*1080*370mm. Curb weight: 500kg. Loading capacity: 330kg. Max speed: 45km/h. Max range: 100/190km. Power system: A/C Motor 3000W/4000W/5000W. Lithium battery: 105Ah/206Ah LiFePo4. Charging time: 3/6 hours with fast charger. Brake system: H…

2. Runhorse – J2 Mini EV

Domain: marketplace.china-crunch.com

Registered: 2021 (4 years)

Introduction: {“Product Name”: “Runhorse J2”, “Fuel Type”: “BEV”, “Body Type”: “Mini EV”, “Steering”: “LHD”, “Price”: “4,890 USD”, “FOB Price”: “4,890 USD”, “Location”: “Chengdu, Sichuan Province”, “Lead Time”: “~2 weeks after full T/T payment received”, “Dimensions (L*W*H)”: “2390*1200*1700 mm”, “Max Speed”: “45 km/h”, “Max Range”: “90 km”, “Capacity”: “2-3 persons”, “Curb Weight”: “450 kg”, “Loading Capacity”…

3. J2-P – Supermoto Launch in Panama

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, J2-P – Supermoto Launch in Panama, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Runhorse – Mini Electric Delivery Truck

Domain: cccme.cn

Registered: 2011 (14 years)

Introduction: {“Product Name”: “Mini Electric Car for Delivery”, “Model”: “Runhorse J2”, “Type”: “Pure Electric Truck”, “Dimensions (L × W × H)”: “3600 × 1345 × 1765 mm”, “Max Driving Speed”: “35/40/45 km/h”, “Max Driving Distance”: “100 km”, “Seating Capacity”: “2-3 Persons”, “Motor Options”: [{“Power”: “3000W”}, {“Power”: “4000W”}], “Battery Options”: [{“Type”: “LiFePO4”, “Capacity”: “70Ah”, “Charger”: “On-bo…

Strategic Sourcing Conclusion and Outlook for runhorse j2

As the global demand for electric vehicles continues to rise, the Runhorse J2 emerges as a strategic asset for businesses seeking to enhance their logistics and transportation capabilities. This mini electric vehicle offers a compelling balance of functionality, efficiency, and eco-friendliness, making it particularly suitable for urban environments in regions such as Africa, South America, the Middle East, and Europe. Key takeaways for B2B buyers include the J2’s competitive pricing, customizable options, and the potential for reduced operational costs through its electric powertrain.

Strategic sourcing of the Runhorse J2 allows businesses to not only meet their transportation needs but also align with global sustainability goals. The vehicle’s lightweight design and efficient cargo capacity make it an excellent choice for last-mile delivery services, especially in densely populated areas. Moreover, the availability of various configurations, such as refrigerated versions for cold chain logistics, adds versatility to your fleet.

Looking ahead, international buyers are encouraged to consider the Runhorse J2 as a pivotal addition to their operations. By leveraging its innovative features and sustainable advantages, companies can position themselves competitively in the evolving market landscape. Engage with trusted suppliers today to explore how the Runhorse J2 can drive your business forward.