Introduction: Navigating the Global Market for xe in 2 bnh

In an increasingly interconnected world, navigating the global market for xe in 2 bnh presents unique challenges for international B2B buyers. Sourcing the right models—whether it’s scooters, motorcycles, or electric bikes—requires a nuanced understanding of regional preferences, pricing structures, and supplier reliability. This guide is designed to address these complexities by offering comprehensive insights into various types of two-wheeled vehicles, their applications, and the critical factors to consider when selecting suppliers.

Buyers from Africa, South America, the Middle East, and Europe—including key markets like Germany and Saudi Arabia—will find actionable information on current market trends, cost analysis, and effective supplier vetting strategies. With a focus on empowering informed purchasing decisions, this guide equips businesses with the knowledge needed to identify quality products that meet their specific needs.

From understanding pricing variances to evaluating the technological advancements in electric models, we delve into every aspect of the xe market. By providing detailed analyses and practical tips, we aim to simplify the sourcing process, ensuring that buyers can confidently navigate the diverse landscape of two-wheeled vehicles and make decisions that align with their business objectives.

Understanding xe in 2 bnh Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Scooters | Lightweight, automatic transmission, compact design. | Urban delivery, short-distance commuting. | Pros: Easy to operate, fuel-efficient. Cons: Limited power for long distances. |

| Motorcycles | Manual transmission, higher speed capabilities. | Long-distance travel, freight transport. | Pros: Greater speed and range. Cons: Requires more skill to operate. |

| Electric Bikes | Eco-friendly, low running costs, and quiet operation. | Urban commuting, eco-friendly logistics. | Pros: Low maintenance, sustainable. Cons: Limited range, charging infrastructure needed. |

| Sport Bikes | High performance, advanced technology, and agility. | Racing, high-speed deliveries. | Pros: Exceptional speed and handling. Cons: Higher cost, less comfort for long rides. |

| Cruisers | Comfortable seating, large engines, and stable ride. | Leisure travel, long-distance tours. | Pros: Comfortable for long rides, strong presence. Cons: Heavier, less maneuverable in tight spaces. |

What Are the Key Characteristics of Scooters in B2B Applications?

Scooters are designed for urban environments, offering agility and ease of use. They typically feature automatic transmissions, making them accessible for a wider range of operators. This type of vehicle is particularly suited for businesses engaged in short-distance deliveries, such as food services or small package logistics. When considering a scooter, B2B buyers should evaluate factors like fuel efficiency, maintenance costs, and local regulations regarding scooter use.

How Do Motorcycles Serve B2B Needs?

Motorcycles are a versatile option for businesses requiring speed and longer-range capabilities. With manual transmissions, they cater to skilled riders and are ideal for freight transport and long-distance travel. Companies in sectors such as courier services or logistics may find motorcycles beneficial for covering greater distances quickly. Key considerations for B2B buyers include the motorcycle’s fuel consumption, insurance costs, and rider training requirements.

Why Are Electric Bikes Gaining Popularity Among B2B Buyers?

Electric bikes are increasingly becoming a popular choice for businesses focused on sustainability and cost-efficiency. These bikes operate quietly and have lower running costs compared to traditional fuel-powered vehicles. Their eco-friendly nature aligns with many corporate social responsibility goals, making them attractive for urban commuting or last-mile delivery services. B2B buyers should consider charging infrastructure and battery life when evaluating electric bikes for their fleets.

What Advantages Do Sport Bikes Offer for Business Use?

Sport bikes are engineered for high performance, making them suitable for racing and high-speed deliveries. Their advanced technology and agility can provide businesses with a competitive edge in sectors that prioritize speed. However, the higher cost and the need for skilled riders can be barriers for some companies. B2B buyers should assess the trade-off between performance and practicality, especially for regular use.

How Can Cruisers Benefit Long-Distance Travel Businesses?

Cruisers are tailored for comfort and stability, making them ideal for long-distance travel or leisure tours. Their larger engines and comfortable seating arrangements allow for extended riding periods without fatigue. Businesses that focus on tourism or long-haul transport may find cruisers particularly valuable. When purchasing cruisers, B2B buyers should examine aspects such as fuel efficiency and rider comfort to ensure they meet operational needs effectively.

Key Industrial Applications of xe in 2 bnh

| Industry/Sector | Specific Application of xe in 2 bnh | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation | Last-mile delivery services with scooters | Cost-effective and efficient urban logistics | Durability, fuel efficiency, and maintenance support |

| Tourism and Leisure | Rental services for scooters and motorcycles | Enhanced customer experience and mobility | Fleet management solutions and insurance coverage |

| Agriculture | Utility vehicles for farm maintenance | Increased productivity and reduced manual labor | Terrain adaptability and load capacity |

| Emergency Services | Rapid response vehicles for medical emergencies | Timely assistance and improved response times | Reliability, speed, and maintenance service availability |

| Urban Mobility | Eco-friendly commuting options for city workers | Reduced carbon footprint and operational costs | Battery life, charging infrastructure, and local regulations |

How is xe in 2 bnh Used in Transportation for Last-Mile Delivery?

In the transportation sector, ‘xe in 2 bnh’ plays a critical role in last-mile delivery services, utilizing scooters for quick and efficient urban logistics. These vehicles are ideal for navigating congested city streets, allowing businesses to meet the growing demand for fast delivery. For international B2B buyers, particularly in regions like Africa and South America, sourcing durable and fuel-efficient models is essential to ensure operational reliability and minimize maintenance costs.

What is the Role of xe in 2 bnh in Tourism and Leisure?

In the tourism and leisure industry, ‘xe in 2 bnh’ serves as an attractive option for rental services offering scooters and motorcycles. This enhances customer experience by providing convenient mobility solutions for tourists exploring urban areas or scenic routes. For B2B buyers in Europe and the Middle East, considerations include fleet management capabilities and comprehensive insurance coverage to protect their assets and ensure customer safety.

How Does xe in 2 bnh Support Agriculture?

The agricultural sector benefits from ‘xe in 2 bnh’ through the use of utility vehicles designed for farm maintenance tasks. These vehicles significantly increase productivity by reducing the manual labor required for tasks such as transporting goods or equipment across expansive fields. Buyers in regions with challenging terrains, such as certain parts of Africa, must prioritize sourcing vehicles that can adapt to varied landscapes while meeting load capacity requirements.

Why is xe in 2 bnh Important for Emergency Services?

In emergency services, ‘xe in 2 bnh’ vehicles are vital for rapid response, particularly in medical emergencies where every second counts. These vehicles allow paramedics to navigate through traffic quickly, ensuring timely assistance to those in need. For international buyers, especially in urbanized regions of Saudi Arabia and Germany, sourcing reliable and fast vehicles, along with ensuring maintenance service availability, is crucial for operational success.

How Does xe in 2 bnh Facilitate Urban Mobility?

‘xe in 2 bnh’ also contributes to urban mobility by providing eco-friendly commuting options for city workers. With the growing emphasis on reducing carbon footprints, these vehicles present a sustainable alternative to traditional transport methods. Buyers should consider battery life and the availability of charging infrastructure to ensure their fleets can operate efficiently within local regulations, particularly in progressive markets across Europe.

3 Common User Pain Points for ‘xe in 2 bnh’ & Their Solutions

Scenario 1: Navigating Price Fluctuations in ‘xe in 2 bnh’

The Problem: B2B buyers often face significant challenges when dealing with the volatile pricing of motorcycles and scooters in the ‘xe in 2 bnh’ market. Prices can fluctuate rapidly due to factors like currency exchange rates, import tariffs, and local demand. This unpredictability can lead to budget overruns and complicate procurement processes, especially for businesses looking to maintain a consistent fleet of vehicles for delivery or transportation services.

The Solution: To effectively manage price fluctuations, B2B buyers should adopt a proactive sourcing strategy that includes establishing long-term relationships with multiple suppliers. Engaging in bulk purchasing agreements can lock in prices for an extended period, providing financial predictability. Additionally, utilizing market intelligence tools to track price trends can inform better timing for purchases. Buyers should also consider diversifying their inventory by including different brands and models that offer similar functionalities, enabling them to pivot quickly in response to price changes without sacrificing operational efficiency.

Scenario 2: Ensuring Quality and Reliability of ‘xe in 2 bnh’ Products

The Problem: Quality assurance is a major concern for B2B buyers, particularly in markets where the quality of motorcycles and scooters can vary significantly between manufacturers. Poor-quality vehicles can lead to high maintenance costs, reduced employee productivity, and potential safety risks. This is especially critical for companies that rely on these vehicles for logistics and delivery services, as any downtime can directly impact customer satisfaction and profitability.

The Solution: To mitigate quality concerns, B2B buyers should prioritize suppliers with established reputations for quality and reliability. Conducting thorough due diligence, including visiting manufacturing facilities and reviewing product certifications, can provide insights into a supplier’s commitment to quality. Implementing a trial period for new vehicle models before full-scale procurement can also help assess reliability in real-world conditions. Additionally, building a feedback loop with drivers can help identify any performance issues early, allowing for timely interventions and adjustments.

Scenario 3: Understanding Regulatory Compliance for ‘xe in 2 bnh’

The Problem: B2B buyers must navigate a complex web of regulatory requirements when sourcing motorcycles and scooters, which can differ widely by region. Regulations regarding emissions, safety standards, and vehicle registration can be daunting and may vary significantly across countries, especially for buyers operating in diverse markets like Africa, South America, and the Middle East. Non-compliance can result in fines, legal issues, and reputational damage.

The Solution: To ensure compliance, B2B buyers should invest in understanding the regulatory landscape of each market they operate in. This includes consulting with legal experts or industry associations that specialize in vehicle regulations. Developing a compliance checklist that outlines necessary certifications, safety standards, and documentation required for registration can streamline the procurement process. Furthermore, partnering with suppliers who are familiar with local regulations can provide additional assurance that all vehicles meet necessary compliance standards. Regular training sessions for procurement teams on regulatory updates can also help keep the organization informed and agile in adapting to changes.

Strategic Material Selection Guide for xe in 2 bnh

What Are the Key Materials Used in xe in 2 bnh and Their Properties?

In the manufacturing of ‘xe in 2 bnh’, the selection of materials is crucial for ensuring performance, durability, and compliance with international standards. Here, we analyze four common materials used in this industry, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Steel Perform as a Material for xe in 2 bnh?

Steel is widely used in the construction of various components in ‘xe in 2 bnh’, primarily due to its excellent strength-to-weight ratio and durability. Key properties include high tensile strength and resistance to deformation under load. However, its susceptibility to corrosion can be a significant drawback unless adequately treated or alloyed.

Pros: Steel is relatively inexpensive and easy to manufacture, making it a cost-effective choice for mass production. Its durability ensures a long lifespan, which is essential for vehicles exposed to harsh conditions.

Cons: The need for protective coatings to prevent rust can increase manufacturing complexity and costs. Additionally, in regions with high humidity or saline environments, unprotected steel components can deteriorate quickly.

What Role Does Aluminum Play in the Manufacturing of xe in 2 bnh?

Aluminum is increasingly favored in the automotive industry for its lightweight properties, which enhance fuel efficiency and performance. It has excellent corrosion resistance and thermal conductivity, making it suitable for engine components and body panels.

Pros: The lightweight nature of aluminum contributes to better fuel economy and handling. It also requires less energy to transport due to its lower weight, which can be a significant advantage for international shipping.

Cons: Aluminum is generally more expensive than steel and can be more challenging to work with in terms of welding and forming. This can lead to higher production costs, particularly for complex designs.

How Does Plastic Compare in Terms of Versatility for xe in 2 bnh?

Plastics, particularly engineering-grade polymers, are utilized in various applications, including interior components and fairings. They offer excellent design flexibility and can be molded into complex shapes with relative ease.

Pros: Plastics are lightweight and resistant to corrosion, making them ideal for components exposed to moisture. They also provide good thermal and electrical insulation.

Cons: While plastics can be cost-effective, their long-term durability is often less than that of metals. Additionally, they may not perform well under high temperatures or heavy loads, which can limit their application in critical structural components.

What Are the Benefits of Using Composite Materials in xe in 2 bnh?

Composite materials, such as carbon fiber reinforced polymers, are becoming popular in high-performance applications due to their exceptional strength-to-weight ratio. They are particularly advantageous in racing and premium vehicles where performance is paramount.

Pros: Composites offer superior strength while being significantly lighter than metals, which can lead to improved performance and fuel efficiency. They are also resistant to corrosion and can be tailored for specific applications.

Cons: The primary drawback is the high cost of materials and manufacturing processes, which can be prohibitive for mass-market vehicles. Additionally, the recycling of composites is more complicated than that of metals.

Summary of Material Selection for xe in 2 bnh

| Material | Typical Use Case for xe in 2 bnh | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frame and structural components | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Body panels and engine components | Lightweight and corrosion-resistant | Higher cost and manufacturing complexity | High |

| Plastic | Interior components and fairings | Design flexibility and lightweight | Lower durability under stress | Low |

| Composites | High-performance applications | Exceptional strength-to-weight ratio | High cost and complex recycling | High |

By understanding the properties and implications of these materials, international B2B buyers can make informed decisions that align with their specific needs and regional considerations, such as compliance with local standards and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for xe in 2 bnh

What Are the Key Stages in the Manufacturing Process of xe in 2 bnh?

The manufacturing process for xe in 2 bnh typically involves several critical stages that ensure both efficiency and quality. Understanding these stages is essential for B2B buyers looking to partner with reliable suppliers.

-

Material Preparation

The first step involves sourcing high-quality raw materials such as steel, aluminum, and plastics. Suppliers often engage in thorough evaluations of material specifications to ensure compliance with international standards. Effective material preparation includes cutting, shaping, and treating these materials to enhance durability and performance. -

Forming Techniques

Forming is a vital part of the manufacturing process, involving techniques such as stamping, forging, and casting. Each technique is selected based on the specific component being produced. For instance, stamping is commonly used for creating body panels, while forging may be used for critical engine components. Advanced technologies, such as CNC machining, are increasingly employed to enhance precision and reduce waste. -

Assembly Process

The assembly stage is where components come together to form the final product. This involves both manual labor and automated processes, ensuring that each motorcycle is built to exact specifications. Assembly lines are often designed for flexibility, allowing manufacturers to adapt quickly to changing demands. Key considerations during assembly include ergonomic designs for workers and the integration of advanced technologies like robotics to improve efficiency and consistency. -

Finishing Touches

Once assembled, the products undergo finishing processes, which may include painting, polishing, and quality checks. This stage not only enhances the aesthetic appeal but also protects against environmental factors. Techniques like powder coating are often used for durability, especially in regions with harsh climates, making the product more appealing to international buyers.

How Is Quality Assurance Implemented in the Manufacturing of xe in 2 bnh?

Quality assurance (QA) is crucial in ensuring that the final products meet both industry standards and customer expectations. Here are the essential components of QA in the manufacturing of xe in 2 bnh.

-

Adhering to International Standards

Manufacturers often comply with international quality standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific standards like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards may apply, depending on the components produced. These certifications are vital for B2B buyers, as they indicate that the products meet rigorous safety and quality benchmarks. -

Quality Control Checkpoints

The QA process includes several critical checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production line to ensure they meet specified quality standards.

– In-Process Quality Control (IPQC): During the manufacturing process, various checks are conducted to monitor and maintain quality. This includes inspecting dimensions, tolerances, and assembly accuracy.

– Final Quality Control (FQC): Once the product is completed, a thorough inspection is performed to ensure it meets all quality and performance standards before it is shipped to clients. -

Common Testing Methods

Various testing methods are employed to validate the quality of the products. These may include:

– Functional Testing: Ensures that the motorcycle operates as intended.

– Durability Testing: Simulates real-world conditions to assess the longevity of components.

– Safety Testing: Checks for compliance with safety regulations, such as brake performance and electrical system integrity.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential to mitigate risks.

-

Conducting Supplier Audits

Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control practices. Audits can be performed by the buyer’s quality assurance team or through third-party agencies specializing in supplier evaluations. This process helps in assessing the supplier’s adherence to international standards and their overall production capabilities. -

Requesting Quality Assurance Reports

Buyers should ask for comprehensive quality assurance reports from suppliers. These reports typically detail the QA processes, testing results, and compliance with relevant standards. Such documentation can provide reassurance about the supplier’s commitment to quality. -

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can further validate the supplier’s quality claims. These agencies can conduct independent inspections at various stages of the manufacturing process, offering an unbiased view of the product quality. This is particularly important for international buyers who may not have the resources to conduct on-site inspections.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, B2B buyers must navigate several quality control nuances:

-

Understanding Local Standards and Regulations

Different regions may have unique quality standards and regulations that manufacturers must comply with. Buyers should familiarize themselves with these local requirements to ensure that the products they source are compliant. This is especially critical for markets like Europe, where CE certification is often mandatory. -

Cultural and Communication Considerations

Quality control processes can vary significantly across cultures. Understanding these differences and establishing clear communication channels with suppliers can help mitigate misunderstandings and ensure that quality expectations are met. -

Building Long-Term Relationships

Establishing strong relationships with suppliers can lead to better quality outcomes. Long-term partnerships often encourage suppliers to invest in quality improvements, as they are more likely to prioritize the needs of a trusted buyer. Regular communication and feedback loops can enhance this relationship, ensuring that quality remains a focal point.

By understanding these manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when sourcing xe in 2 bnh. Prioritizing quality and establishing robust verification processes will ultimately lead to successful partnerships and high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘xe in 2 bnh’

Introduction

In the competitive landscape of international business, procuring ‘xe in 2 bnh’ (two-wheeled vehicles) requires a strategic approach to ensure quality, reliability, and cost-effectiveness. This checklist serves as a practical guide for B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe. Follow these steps to streamline your sourcing process and make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Clearly outlining the technical specifications of the vehicles you need is the foundation of a successful procurement process. This includes engine type, fuel efficiency, load capacity, and safety features. Understanding these parameters helps in aligning your requirements with supplier offerings and ensures that the vehicles meet your operational needs.

- Consider the market: Research the specific demands of your target market to tailor your specifications accordingly.

- Future-proofing: Think about potential future needs, such as electric or hybrid options, which may be relevant in your region.

Step 2: Conduct Market Research

Before diving into supplier selection, it’s essential to conduct thorough market research. Analyze current trends, pricing structures, and competitor offerings in the two-wheeled vehicle market. This information will give you a benchmark for evaluating suppliers and understanding the landscape.

- Utilize industry reports: Look for reports that provide insights into market dynamics and emerging technologies.

- Engage with local distributors: They can offer valuable insights into consumer preferences and competitive pricing.

Step 3: Evaluate Potential Suppliers

Vet potential suppliers rigorously to ensure they can meet your specifications and quality standards. Request detailed company profiles, case studies, and references from other businesses in similar sectors.

- Check certifications: Ensure suppliers hold relevant certifications that validate their manufacturing processes and quality control measures.

- Visit production facilities: If possible, arrange for site visits to assess the manufacturing capabilities and adherence to safety standards.

Step 4: Request Samples and Specifications

Once you have shortlisted potential suppliers, request samples of the vehicles to evaluate their quality and performance. This step is crucial for assessing whether the products align with your defined specifications.

- Test performance: Conduct thorough tests to evaluate ride quality, fuel efficiency, and overall durability.

- Inspect build quality: Look for craftsmanship and materials used, as these factors directly affect longevity and user satisfaction.

Step 5: Negotiate Terms and Conditions

Effective negotiation can significantly impact the overall cost and terms of your procurement. Discuss pricing, payment terms, delivery schedules, and warranty options with your suppliers.

- Explore volume discounts: If you plan to order in bulk, inquire about discounts that can reduce overall costs.

- Clarify after-sales support: Ensure that the supplier offers adequate support for maintenance and repairs, which is vital for long-term partnerships.

Step 6: Finalize Your Order and Monitor Delivery

After negotiations, finalize your order by signing contracts that clearly outline all agreed-upon terms. Monitor the delivery process closely to ensure compliance with the agreed schedule and quality.

- Set up a tracking system: Implement a system to track shipment progress and address any delays proactively.

- Conduct a final inspection: Upon arrival, inspect the vehicles thoroughly to ensure they match the specifications and quality promised.

Step 7: Establish a Relationship with Suppliers

Building a strong relationship with your suppliers can lead to better terms and more favorable conditions in future transactions. Maintain open lines of communication and provide feedback on their products and services.

- Regular check-ins: Schedule periodic reviews to discuss performance and address any emerging issues.

- Consider joint ventures: Explore opportunities for collaboration on new models or market expansion, which can be mutually beneficial.

By following this checklist, B2B buyers can enhance their sourcing strategy for ‘xe in 2 bnh’, ensuring a successful procurement process that meets their business needs and market demands.

Comprehensive Cost and Pricing Analysis for xe in 2 bnh Sourcing

What Are the Key Cost Components in ‘xe in 2 bnh’ Sourcing?

When analyzing the cost structure for sourcing ‘xe in 2 bnh’, several components contribute to the final pricing. Understanding these elements is crucial for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

-

Materials: The choice of materials significantly impacts the cost. High-quality materials typically lead to higher prices but can enhance durability and performance. Buyers should evaluate the trade-off between cost and quality when selecting suppliers.

-

Labor: Labor costs vary by region and can be influenced by local wage standards and skill levels. In emerging markets, labor may be less expensive, which can result in lower manufacturing costs. However, this may also affect the quality of workmanship.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, maintenance, and administrative costs. Efficient manufacturing processes can help minimize overhead, leading to more competitive pricing.

-

Tooling: The initial investment in tooling and equipment can be substantial, especially for custom or specialized designs. Buyers should consider these costs when evaluating suppliers and factor them into the total cost of ownership.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes can incur additional costs. However, investing in QC can prevent costly defects and returns, making it a worthwhile expense in the long run.

-

Logistics: Transportation and shipping costs are critical in determining the final price. Factors such as distance, shipping methods, and customs duties must be carefully considered, especially for international buyers.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary significantly. Understanding the typical margins within the industry can help buyers negotiate better pricing.

How Do Price Influencers Affect Sourcing Decisions?

Several key influencers can impact the pricing of ‘xe in 2 bnh’:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in discounted pricing due to economies of scale. Buyers should assess their purchasing capacity and negotiate favorable terms.

-

Specifications and Customization: Customized products or specific design requirements may increase costs. Buyers should clearly communicate their specifications to avoid unexpected charges.

-

Materials and Quality Certifications: The use of certified materials can elevate costs but may also be essential for compliance with local regulations and standards. Buyers should weigh the importance of certifications against budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge higher prices due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterm affects the distribution of costs and risks between buyers and sellers. Understanding the implications of different Incoterms can lead to more informed sourcing decisions.

What Are the Best Buyer Tips for Cost-Efficiency in International Sourcing?

B2B buyers looking to source ‘xe in 2 bnh’ should consider the following strategies:

-

Negotiate Wisely: Build strong relationships with suppliers and leverage your purchasing power to negotiate better prices. Always be prepared with data on market rates to support your position.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the upfront costs but also the long-term implications of maintenance, operation, and potential resale value. This comprehensive view can lead to better purchasing decisions.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, trade tariffs, and regional pricing strategies. These factors can significantly affect overall costs and should be factored into budgeting.

-

Research Local Markets: Understanding the local market dynamics, including demand trends and competitor pricing, can provide valuable insights that aid in negotiations and sourcing strategies.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and other factors. Buyers are encouraged to conduct thorough market research and engage directly with suppliers for the most accurate pricing information.

Alternatives Analysis: Comparing xe in 2 bnh With Other Solutions

Introduction to Alternatives for ‘Xe in 2 Bnh’

In the dynamic landscape of B2B solutions, selecting the right technology or method is critical for achieving operational efficiency and cost-effectiveness. ‘Xe in 2 bnh’ represents a specific product or service that may cater to unique market needs, particularly in the automotive and transportation sectors. However, it is essential to evaluate comparable solutions to ensure that buyers make informed decisions that align with their organizational goals.

Comparison Table

| Comparison Aspect | Xe In 2 Bnh | Electric Scooters | Traditional Motorbikes |

|---|---|---|---|

| Performance | Moderate speed, good for urban commuting | High torque, rapid acceleration | High speed, longer range |

| Cost | Medium-range pricing | Varies widely, often higher upfront costs | Generally lower than electric but higher than xe in 2 bnh |

| Ease of Implementation | Easy to integrate into urban transport systems | Requires charging infrastructure | Widely available, minimal setup needed |

| Maintenance | Low maintenance costs | Higher due to battery replacement | Regular maintenance required, more complex |

| Best Use Case | Urban environments, short commutes | Eco-friendly transport, city commuting | Long-distance travel, highway use |

Detailed Breakdown of Alternatives

Electric Scooters

Electric scooters have gained significant traction as a sustainable alternative to traditional urban transportation methods. They offer high torque and rapid acceleration, making them an attractive choice for quick commutes. However, their higher upfront costs and dependency on charging infrastructure can be a barrier for some businesses. Maintenance can also be more complex due to the need for battery replacements, which can impact overall operational costs.

Traditional Motorbikes

Traditional motorbikes provide a robust solution for long-distance travel and are generally cost-effective compared to electric alternatives. They offer high speeds and a longer range, making them suitable for various applications, from delivery services to personal use. However, they require regular maintenance, which can add to the total cost of ownership. Additionally, they may not be as environmentally friendly as electric options, making them less appealing for businesses focused on sustainability.

Conclusion: How to Choose the Right Solution

When evaluating ‘xe in 2 bnh’ against alternatives like electric scooters and traditional motorbikes, B2B buyers should consider their specific operational needs, budget constraints, and environmental goals. If urban commuting and low maintenance are priorities, ‘xe in 2 bnh’ may be the optimal choice. However, for those requiring higher speeds or longer ranges, traditional motorbikes could serve better. Ultimately, a thorough analysis of performance, cost, and maintenance needs will guide buyers in selecting the most suitable transportation solution for their business.

Essential Technical Properties and Trade Terminology for xe in 2 bnh

What Are the Key Technical Properties of ‘xe in 2 bnh’?

Understanding the technical specifications of ‘xe in 2 bnh’ is essential for B2B buyers as it directly impacts product performance, durability, and compliance with regional regulations. Here are critical specifications to consider:

-

Engine Displacement

Engine displacement is a measure of the engine’s size, typically expressed in cubic centimeters (cc). It indicates the engine’s power potential; higher displacement often correlates with increased horsepower and torque. For international buyers, especially in regions with strict emissions regulations, knowing the engine displacement helps in assessing compliance with local laws. -

Fuel Efficiency (Consumption Rate)

This property measures how much fuel the vehicle consumes over a set distance, usually expressed in liters per 100 kilometers (L/100km) or miles per gallon (MPG). Fuel efficiency is vital for B2B buyers concerned about operating costs and environmental impact. Lower consumption rates can lead to significant savings and reduced carbon footprints. -

Brake System Type

The type of braking system (e.g., hydraulic disc brakes, drum brakes) affects safety and maintenance requirements. Hydraulic disc brakes provide better stopping power and heat dissipation, making them preferable for high-performance models. Buyers must evaluate the trade-offs between performance and maintenance costs when selecting models. -

Weight Capacity (Payload)

This specification refers to the maximum weight a vehicle can safely carry, including passengers and cargo. Understanding payload capacity is crucial for businesses that rely on transportation for goods. Overloading can lead to mechanical failures and legal issues, making it imperative for buyers to match vehicle specifications with their operational needs. -

Material Composition

The materials used in vehicle construction, such as steel, aluminum, or composite materials, influence durability, weight, and repairability. For B2B buyers, selecting vehicles made with high-quality materials can reduce long-term maintenance costs and enhance vehicle lifespan, which is essential for fleet operations.

What Are Common Trade Terms in the ‘xe in 2 bnh’ Industry?

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B landscape. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers ensure they are sourcing high-quality components that meet industry standards. -

MOQ (Minimum Order Quantity)

MOQ specifies the least number of units a supplier is willing to sell. This term is significant for B2B buyers who need to manage inventory levels and cash flow effectively. Negotiating favorable MOQs can reduce upfront costs and inventory risks. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and availability for specific products. This formal request allows buyers to compare offers and make informed decisions. It’s essential for ensuring transparency and competitiveness in pricing. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risk allocation, and delivery obligations, facilitating smoother transactions. -

Lead Time

Lead time refers to the duration from placing an order to its delivery. Understanding lead times is crucial for inventory management and production planning. Buyers should evaluate lead times to ensure they align with operational timelines and customer expectations. -

Warranty Period

The warranty period indicates the duration for which the manufacturer guarantees the vehicle against defects. For B2B buyers, a longer warranty can signify higher product quality and lower risk, making it an essential consideration in the purchasing decision.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their business needs and operational strategies.

Navigating Market Dynamics and Sourcing Trends in the xe in 2 bnh Sector

Market Overview & Key Trends in the xe in 2 bnh Sector

The xe in 2 bnh sector is experiencing dynamic shifts driven by globalization, evolving consumer preferences, and technological advancements. Internationally, demand for two-wheeled vehicles is on the rise, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Factors such as urbanization, increased fuel prices, and the need for efficient transportation solutions are propelling this growth. In regions like Africa and South America, where traffic congestion is prevalent, two-wheelers offer a practical alternative to traditional vehicles.

Emerging trends such as e-mobility are gaining traction, with electric scooters and motorcycles becoming increasingly popular. This shift is supported by advancements in battery technology and a growing emphasis on reducing carbon footprints. B2B buyers should pay attention to manufacturers who are investing in electric models, as these vehicles are not only eco-friendly but often come with lower operating costs.

Additionally, the incorporation of smart technologies, such as IoT connectivity and advanced safety features, is transforming the market landscape. International buyers should seek suppliers who are embracing these innovations, as they enhance the user experience and provide competitive advantages. Staying informed about these trends will be crucial for B2B buyers looking to make strategic purchasing decisions in a rapidly evolving market.

How Is Sustainability Influencing Sourcing Decisions in the xe in 2 bnh Sector?

Sustainability has emerged as a key consideration for B2B buyers in the xe in 2 bnh sector. The environmental impact of manufacturing and operating two-wheelers is under scrutiny, making it imperative for companies to prioritize ethical sourcing and sustainability practices. This includes evaluating the lifecycle of vehicles, from raw material extraction to end-of-life recycling.

Buyers are increasingly looking for suppliers who adhere to green certifications and utilize sustainable materials in their production processes. This shift not only aligns with global sustainability goals but also meets consumer demand for environmentally responsible products. Companies that demonstrate a commitment to sustainability can differentiate themselves in the competitive landscape, appealing to eco-conscious buyers.

Moreover, establishing ethical supply chains is crucial. Buyers should ensure that their suppliers maintain transparency and uphold fair labor practices throughout the sourcing process. By prioritizing sustainability and ethical sourcing, companies can enhance their brand reputation and foster long-term relationships with their clientele, ultimately driving growth in the xe in 2 bnh sector.

What Has Been the Evolution of the xe in 2 bnh Sector?

The xe in 2 bnh sector has evolved significantly over the past few decades, transitioning from traditional combustion engines to innovative electric and hybrid models. Initially dominated by gas-powered scooters and motorcycles, the market has gradually adapted to changing consumer preferences and regulatory pressures regarding emissions.

In the early 2000s, the introduction of more fuel-efficient models marked a pivotal shift, addressing the rising fuel costs and environmental concerns. As technology advanced, manufacturers began exploring electric alternatives, leading to the current trend of e-mobility. This evolution reflects a broader global movement towards sustainability and innovation, making the xe in 2 bnh sector a focal point for B2B buyers looking to invest in future-ready solutions.

Understanding this historical context is vital for international buyers, as it highlights the sector’s adaptability and the importance of aligning sourcing strategies with emerging trends and consumer expectations. As the market continues to evolve, staying abreast of these changes will be essential for making informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of xe in 2 bnh

-

How do I source reliable suppliers for xe in 2 bnh?

To source reliable suppliers for xe in 2 bnh, start by researching industry-specific directories and trade platforms. Attend trade shows and exhibitions relevant to the motorcycle industry in your target regions. Verify suppliers through customer references and reviews, and assess their production capabilities and quality control processes. It’s also beneficial to conduct on-site visits or audits if possible, ensuring that suppliers comply with international standards and can meet your specific requirements. -

What is the best type of xe in 2 bnh for urban transportation?

The best type of xe in 2 bnh for urban transportation typically includes scooters and lightweight motorcycles. These vehicles offer excellent fuel efficiency, maneuverability, and ease of parking in crowded city environments. Models like the Honda Lead or Yamaha NVX are popular choices due to their reliability and user-friendly features. Consider factors such as maintenance costs, availability of spare parts, and after-sales service when selecting the most suitable model for urban commuting. -

What customization options are available when ordering xe in 2 bnh?

Most manufacturers and suppliers offer various customization options for xe in 2 bnh, including color choices, engine specifications, and accessory packages. You can request specific features such as enhanced safety systems, advanced technology integrations, or tailored designs to meet regional preferences. Discuss your requirements with potential suppliers early in the negotiation process to ensure they can accommodate your customization needs without significant delays. -

What are the typical minimum order quantities (MOQs) for xe in 2 bnh?

Minimum order quantities (MOQs) for xe in 2 bnh can vary widely depending on the supplier and the specific models being ordered. Generally, MOQs range from 50 to several hundred units per order. It’s advisable to negotiate MOQs based on your market demand and inventory capabilities. Some suppliers may offer lower MOQs for first-time buyers or for specific models, so it’s worth inquiring about flexibility in order sizes. -

What payment terms should I expect when importing xe in 2 bnh?

Payment terms for importing xe in 2 bnh typically involve a deposit upfront (often 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or installment payments, especially for larger orders. Always clarify payment methods accepted (e.g., wire transfers, letters of credit) and ensure that you understand any associated fees. It’s crucial to have a clear contract that outlines payment schedules to avoid misunderstandings. -

How can I ensure quality assurance (QA) for xe in 2 bnh?

To ensure quality assurance (QA) for xe in 2 bnh, establish clear quality standards in your purchase agreement. Request samples or prototypes before committing to large orders, and consider conducting third-party inspections during production and before shipment. Many manufacturers provide certifications that meet international quality standards, so verify these credentials. Regular communication with your supplier about quality expectations is essential for maintaining product standards. -

What logistics considerations should I be aware of when importing xe in 2 bnh?

When importing xe in 2 bnh, consider logistics factors such as shipping methods, customs regulations, and lead times. Choose between air freight for faster delivery or sea freight for cost efficiency, depending on your urgency and budget. Ensure compliance with local import regulations and tariffs, and work with a freight forwarder who can navigate the complexities of international shipping. Planning for potential delays at customs is also crucial to avoid disruptions in your supply chain. -

How do I handle warranty claims for xe in 2 bnh?

Handling warranty claims for xe in 2 bnh involves establishing a clear understanding of the warranty terms with your supplier. Ensure that you have documentation detailing the warranty coverage, including what is included and the duration. In case of a claim, promptly notify the supplier and provide evidence of the issue, such as photos or reports. Discuss the process for repairs or replacements and clarify who bears the shipping costs for returned items. Having a streamlined process in place will help minimize downtime for your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Xe In 2 Bnh Manufacturers & Suppliers List

1. Giá Xe Hai Bánh – Tra Cứu Giá Xe Máy Chính Hãng

Domain: giaxe.2banh.vn

Introduction: This company, Giá Xe Hai Bánh – Tra Cứu Giá Xe Máy Chính Hãng, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Yamaha – Cygnus XR, CFMoto – 750SR-S, QJMotor – Hong 250 CITY SE, Sleek –

Domain: 2banh.vn

Introduction: 1. Cygnus XR: Mẫu xe ga thể thao mới của Yamaha, thế hệ thứ 7.

2. CFMoto 750SR-S: Sportbike 750cc, phân khúc bị lãng quên.

3. QJMotor Hong 250 CITY SE 2026: Giá 55 triệu Đồng, mới ra mắt.

4. Sleek EV Play 1.0 Pro: Xe điện, tốc độ 90 km/h, quãng đường 150 km, sạc nhanh 1 giờ, giá 59.900 Baht (khoảng 40 triệu đồng).

5. SYM Fiddle DX 158: Thiết kế thanh lịch, tiêu thụ 1.66L/100km, sắp bán tại Việt Na…

3. Honda – Wave 110 RSX Upgrade

Domain: vnexpress.net

Registered: 2000 (25 years)

Introduction: This company, Honda – Wave 110 RSX Upgrade, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Shop2banh – Phụ Tùng Xe Máy Chất Lượng

Domain: shop2banh.vn

Introduction: Phụ tùng xe máy chất lượng giá tốt nhất thị trường. Danh mục sản phẩm bao gồm: Đồ chơi xe máy (Tay thắng, Phụ kiện, Bao tay, Kính chiếu hậu, Đèn led, Đĩa xe máy), Phụ tùng thay thế (Phuộc, Nhông sên dĩa, Bố thắng, Mâm, Bugi, Bình ắc quy, Dây Curoa, Bộ nồi, Lọc gió, Lọc nhớt, Heo dầu, Khóa, Pô), Vỏ xe máy (Lốp xe từ các thương hiệu như Michelin, Dunlop, Maxxis, Pirelli, Aspira, Continental, ChengSh…

5. LIT Motors – C1 Electric Vehicle

Domain: vietnamnet.vn

Introduction: LIT Motors C1 is a two-wheeled electric vehicle designed for urban traffic. It operates like a car but has a motorcycle-like structure. Key specifications include:

– Price: approximately 24,000 USD (500 million VND)

– Range: can travel over 320 km on a full charge

– Speed: can reach 100 km/h in under 6 seconds

– Weight: around 360 kg

– Width: approximately 1 meter

– Features: two comfortable…

6. Công ty TNHH Châu Bảo Long – In vé giữ xe 2 liên

Domain: vegiuxe.com

Registered: 2013 (12 years)

Introduction: – Product Name: In vé giữ xe 2 liên (2-part parking tickets)

– Availability: In stock

– Contact: 0903 650 199 – Mr Châu

– Company: Công ty TNHH Châu Bảo Long

– Experience: Over 10 years in the industry

– Features:

– Customizable design with unique security features

– Competitive pricing, no intermediaries

– Clear serial number arrangement for easy tracking

– High-quality paper used, no rec…

7. Toyota – INNOVA 2.0E 2025

Domain: toyota.com.vn

Introduction: Toyota INNOVA 2.0E 2025

– Số chỗ ngồi: 8 chỗ

– Kiểu dáng: Đa dụng

– Nhiên liệu: Xăng

– Xuất xứ: Việt Nam

– Giá từ: 755.000.000 VNĐ

– Động cơ: 1TR-FE với VVT-i kép, công suất và mô men cao hơn, tiết kiệm nhiên liệu

– Hộp số: 6 cấp chuyển số êm ái

– Hệ thống treo: Tay đòn kép phía trước, liên kết bốn điểm phía sau

– An toàn: Tối đa 7 túi khí, khung xe GOA, hệ thống hỗ trợ lực phanh khẩn cấp BA

– Các…

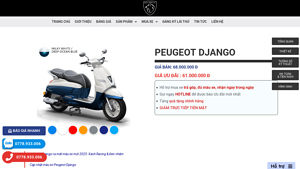

8. Peugeot – Django 125

Domain: hcmpeugeot.com

Registered: 2021 (4 years)

Introduction: Peugeot Django 125

– Giá bán: 68.000.000 đ

– Giá ưu đãi: 61.000.000 đ

– Hỗ trợ mua xe trả góp

– Động cơ: Xăng, Easy-Motion EURO 4, phun xăng điện tử EFI

– Dung tích động cơ: 125 cc

– Công suất cực đại: 10 Hp tại 8500 rpm

– Mô-men xoắn cực đại: 8,9 Nm tại 7000 rpm

– Hộp số: Vô cấp

– Kích thước (DxRxC): 1925 x 710 x 1150 mm

– Chiều dài trục cơ sở: 1350 mm

– Chiều cao yên: 770 mm

– Khối lượng không t…

Strategic Sourcing Conclusion and Outlook for xe in 2 bnh

In today’s competitive landscape, strategic sourcing for motorcycles (xe in 2 bánh) is not merely a procurement function but a critical pathway to unlocking value and driving growth in international markets. By leveraging comprehensive market insights and understanding the diverse needs of regions such as Africa, South America, the Middle East, and Europe, businesses can tailor their sourcing strategies to enhance operational efficiencies and reduce costs. The emerging trends in electric and hybrid motorcycle models also present unique opportunities for B2B buyers, allowing them to meet the growing consumer demand for sustainable transportation solutions.

Investing in strategic sourcing enables businesses to foster strong supplier relationships and ensures access to innovative products that align with market expectations. As the motorcycle industry evolves, companies that prioritize adaptability and market responsiveness will be better positioned to capitalize on new opportunities.

Looking ahead, B2B buyers are encouraged to engage proactively with suppliers, embrace new technologies, and invest in sustainable practices. By doing so, they not only secure competitive advantages but also contribute positively to the global transition towards greener transportation. Now is the time to take action and redefine your sourcing strategies for a more prosperous future in the motorcycle market.