Introduction: Navigating the Global Market for j2c l6e

In an increasingly interconnected world, sourcing the right electric mini cargo van, such as the J2C L6e, presents a significant challenge for international B2B buyers. This vehicle is not just a mode of transportation; it represents a strategic investment in efficiency, sustainability, and operational flexibility. As urban logistics evolve, businesses are seeking reliable solutions for short-distance transportation and distribution, especially in bustling cities across Africa, South America, the Middle East, and Europe. This guide is designed to empower decision-makers by providing a comprehensive overview of the J2C L6e, including its diverse applications in logistics, cold chain transportation, and urban delivery services.

Throughout this guide, we will delve into the various configurations of the J2C L6e, assess its performance metrics such as load capacity and cruising range, and explore the advantages of integrating this vehicle into your logistics operations. Additionally, we will offer insights into the supplier vetting process, cost considerations, and best practices for procurement. By equipping B2B buyers with actionable insights and expert knowledge, this guide facilitates informed purchasing decisions, enabling businesses to navigate the complexities of the global market with confidence. Whether you are in Vietnam looking to enhance your delivery fleet or in Germany seeking sustainable transport solutions, the J2C L6e could be the key to unlocking new efficiencies in your operations.

Understanding j2c l6e Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| J2-C L6e Electric Mini Cargo Van | Pure electric, 330kg load capacity, 100-200 km range | Urban delivery, short-distance logistics | Pros: Eco-friendly, cost-effective for short routes. Cons: Limited range for long-distance transport. |

| J2-C L6e Electric Mini Refrigerator Car | Equipped with refrigeration, temperature control -18°C to 5°C | Cold chain logistics, food delivery | Pros: Ideal for temperature-sensitive goods. Cons: Higher initial investment due to refrigeration technology. |

| J2-C L6e Electric Express Delivery Vehicle | Enhanced speed, optimized for express delivery services | E-commerce, urgent deliveries | Pros: Fast delivery capabilities. Cons: May have a higher operating cost due to speed enhancements. |

| J2-C L6e Electric Utility Vehicle | Versatile design for various utility tasks | Maintenance, municipal services | Pros: Multifunctional, adaptable to different roles. Cons: May require additional modifications for specific tasks. |

| J2-C L6e Electric Mini Shuttle Vehicle | Designed for passenger transport, compact size | Shuttle services, small group transport | Pros: Efficient for urban transportation. Cons: Limited passenger capacity compared to larger vehicles. |

What are the Key Characteristics of the J2-C L6e Electric Mini Cargo Van?

The J2-C L6e Electric Mini Cargo Van is designed primarily for urban environments, boasting a load capacity of 330 kg and an operational range of 100-200 km. This model is particularly suitable for businesses engaged in short-distance deliveries, such as local retailers or logistics companies. When considering this vehicle, B2B buyers should evaluate the total cost of ownership, including maintenance and charging infrastructure, to ensure it aligns with their operational needs.

How Does the J2-C L6e Electric Mini Refrigerator Car Benefit Cold Chain Logistics?

The J2-C L6e Electric Mini Refrigerator Car is specifically tailored for the cold chain sector, featuring advanced refrigeration systems that can maintain temperatures between -18°C and 5°C. This vehicle is essential for transporting perishable goods, such as food and pharmaceuticals, which require strict temperature control. Buyers must consider the upfront investment and potential energy costs associated with maintaining refrigeration, as well as the vehicle’s compliance with local regulations regarding food transport.

Why Choose the J2-C L6e Electric Express Delivery Vehicle for Fast Logistics?

The J2-C L6e Electric Express Delivery Vehicle is optimized for speed and efficiency, making it an ideal choice for businesses in the e-commerce sector that require rapid delivery services. With enhanced acceleration and a streamlined design, this vehicle can meet the demands of urgent deliveries. Buyers should weigh the benefits of improved delivery times against the potential for higher operational costs and ensure that their logistics strategy supports the use of such vehicles.

What Makes the J2-C L6e Electric Utility Vehicle Versatile for Various Applications?

The J2-C L6e Electric Utility Vehicle stands out for its adaptability across multiple sectors, including municipal services and maintenance operations. Its versatile design allows for modifications to suit various tasks, from waste collection to street maintenance. B2B buyers should consider the vehicle’s compatibility with their existing fleet and the potential need for customizations to maximize its utility.

How Can the J2-C L6e Electric Mini Shuttle Vehicle Enhance Urban Transportation?

Designed for passenger transport, the J2-C L6e Electric Mini Shuttle Vehicle offers a compact solution for urban environments. This vehicle is particularly beneficial for shuttle services in business districts or airports, providing efficient transport for small groups. Buyers need to assess the vehicle’s capacity and ensure it meets their passenger transport requirements while considering the operational efficiency of electric vehicles in urban settings.

Key Industrial Applications of j2c l6e

| Industry/Sector | Specific Application of j2c l6e | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Distribution | Urban Last-Mile Delivery | Reduces delivery time and costs for short-distance urban routes | Assess battery range and load capacity to match delivery needs |

| Food and Beverage | Cold Chain Transportation | Maintains product integrity and quality during transport | Ensure refrigeration efficiency and compliance with local regulations |

| E-commerce | Package Delivery Services | Enhances customer satisfaction with timely deliveries | Evaluate vehicle size for package dimensions and weight limits |

| Healthcare | Medical Supply Transport | Ensures timely delivery of critical medical supplies | Confirm temperature control features and reliability standards |

| Retail | In-Store Inventory Restocking | Streamlines inventory management and reduces downtime | Consider vehicle adaptability for varied retail environments |

How is the j2c l6e Used in Logistics and Distribution for Urban Last-Mile Delivery?

The j2c l6e electric mini cargo van is particularly effective in urban logistics, where efficient last-mile delivery is crucial. With a load capacity of 330 kg and a cruising range of 100-200 km, it is ideal for navigating congested city streets. Businesses can significantly reduce delivery times and costs by utilizing this vehicle for short-distance transport. International buyers should assess the vehicle’s battery range and load capacity to ensure it meets their specific delivery requirements.

What Role Does the j2c l6e Play in Cold Chain Transportation for Food and Beverage?

In the food and beverage sector, the j2c l6e can be equipped as a refrigerated transport vehicle, maintaining temperatures between -18°C and 5°C. This capability is essential for preserving the quality and safety of perishable goods during transit. As international regulations on food safety become stricter, businesses must ensure that their cold chain logistics are compliant. Buyers should prioritize refrigeration efficiency and verify that the vehicle meets local health and safety standards.

How Can E-commerce Companies Benefit from Using the j2c l6e for Package Delivery?

E-commerce businesses can leverage the j2c l6e for efficient package delivery services, enhancing customer satisfaction through timely deliveries. The vehicle’s compact size allows it to navigate narrow urban streets, making it a suitable option for densely populated areas. When sourcing this vehicle, companies should evaluate its size against typical package dimensions and weight limits to optimize delivery operations.

In What Ways Does the j2c l6e Support Healthcare Supply Chains?

The j2c l6e is also valuable in the healthcare sector, where timely delivery of medical supplies can be critical. Its electric design offers a quiet operation, making it suitable for hospitals and clinics. When sourcing, businesses must confirm the vehicle’s temperature control features and reliability standards, ensuring that sensitive medical supplies remain secure during transport.

How Does the j2c l6e Facilitate Retail Inventory Restocking?

In retail environments, the j2c l6e can streamline in-store inventory restocking processes. Its electric operation reduces emissions, aligning with sustainability goals while also enhancing operational efficiency. Retailers should consider the vehicle’s adaptability for various store layouts and ensure that it can accommodate the volume of goods typically transported. This can lead to reduced downtime and improved inventory management.

3 Common User Pain Points for ‘j2c l6e’ & Their Solutions

Scenario 1: Navigating Limited Cargo Capacity for Urban Deliveries

The Problem: B2B buyers in urban logistics often grapple with the challenge of selecting vehicles that can efficiently navigate city streets while accommodating sufficient cargo loads. The J2-C L6e, with its load capacity of 330 kg, may seem adequate, but businesses frequently find that this is insufficient for peak delivery times or when handling bulk orders. This limitation can lead to delays in service, increased operational costs, and ultimately, dissatisfied customers.

The Solution: To maximize the J2-C L6e’s effectiveness, businesses should consider optimizing their delivery routes and schedules. Implementing a route planning software can help identify the most efficient paths for deliveries, thereby reducing the number of trips required. Additionally, businesses should invest in modular shelving or cargo management systems within the vehicle to better utilize the available space. Training staff on efficient loading techniques can also ensure that each trip is maximized, allowing for more deliveries per vehicle use. Regularly reviewing and adjusting delivery strategies based on seasonal demand can further enhance the operational efficiency of the J2-C L6e.

Scenario 2: Managing Temperature-Controlled Logistics Challenges

The Problem: For companies involved in the cold chain logistics sector, maintaining the integrity of temperature-sensitive goods during transportation is crucial. The J2-C L6e is equipped with a refrigeration system capable of controlling temperatures from -18°C to 5°C, yet buyers often face difficulties in ensuring that these systems function optimally over time. Failure to maintain proper temperatures can lead to spoilage, financial losses, and regulatory non-compliance.

The Solution: To address these concerns, buyers should prioritize regular maintenance of the J2-C L6e’s refrigeration system. Establishing a scheduled maintenance plan that includes inspections of the cooling units, temperature calibration checks, and refrigerant levels will help ensure consistent performance. Additionally, integrating temperature monitoring technology can provide real-time data on the conditions within the cargo area, allowing for immediate corrective actions if temperatures deviate from the desired range. Training drivers on best practices for loading and unloading temperature-sensitive goods can also mitigate risks associated with thermal fluctuations during transit.

Scenario 3: Ensuring Compliance with Local Regulations

The Problem: International B2B buyers must navigate a complex web of local regulations regarding electric vehicles, particularly in urban environments where emissions restrictions are stringent. The J2-C L6e, being an electric mini cargo van, is well-positioned to meet many of these regulations, but buyers often struggle to keep up with varying requirements across different regions. Non-compliance can lead to fines, increased operational costs, and damage to a company’s reputation.

The Solution: To effectively manage compliance challenges, businesses should establish a comprehensive understanding of the regulatory landscape in each operational area. This can be achieved by partnering with local logistics consultants or regulatory experts who specialize in transportation compliance. Regular training sessions for staff on the latest regulations can also ensure that everyone is informed and prepared to adapt to changes. Moreover, investing in compliance management software can streamline the process of tracking and adhering to regulations, making it easier to ensure that the J2-C L6e remains compliant with all local requirements. By proactively engaging with local authorities and industry groups, companies can stay ahead of regulatory changes and foster positive relationships within the communities they serve.

Strategic Material Selection Guide for j2c l6e

What Are the Key Materials Used in the j2c l6e Electric Mini Cargo Van?

When considering the j2c l6e electric mini cargo van, material selection plays a crucial role in ensuring optimal performance, durability, and compliance with international standards. Below, we analyze four common materials used in the construction of this vehicle, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Steel Contribute to the j2c l6e’s Structural Integrity?

Key Properties: Steel is renowned for its high tensile strength and durability, making it ideal for the chassis and structural components of the j2c l6e. It can withstand significant loads and impacts, essential for a vehicle designed for transportation.

Pros & Cons: The primary advantage of steel is its robustness, which translates into a longer lifespan and better safety ratings. However, it is susceptible to corrosion if not properly treated, which can lead to increased maintenance costs. Additionally, steel can be heavier than alternative materials, potentially affecting energy efficiency.

Impact on Application: Steel’s strength makes it suitable for heavy-duty applications, ensuring the vehicle can handle various loads, including cargo and refrigerated goods.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure that the steel used complies with local standards (e.g., ASTM, DIN). Corrosion resistance treatments may be necessary in humid or coastal environments.

What Role Does Aluminum Play in Enhancing Vehicle Efficiency?

Key Properties: Aluminum is lightweight yet strong, providing excellent corrosion resistance and thermal conductivity. This makes it suitable for components like body panels and engine parts.

Pros & Cons: The primary advantage of aluminum is its weight-saving properties, which enhance fuel efficiency and range for electric vehicles. However, it is typically more expensive than steel and may require specialized manufacturing processes, which can complicate production.

Impact on Application: The reduced weight of aluminum contributes to better energy efficiency, making it a favorable choice for electric vehicles like the j2c l6e, where range is critical.

Considerations for International Buyers: Buyers in Europe, particularly Germany, may prefer aluminum for its recyclability and compliance with stringent environmental regulations. Understanding local recycling policies can also influence material selection.

How Does Composite Material Influence Vehicle Performance?

Key Properties: Composites, such as fiberglass or carbon fiber, offer high strength-to-weight ratios and excellent resistance to environmental factors.

Pros & Cons: Composites are advantageous in reducing vehicle weight while maintaining strength, which can improve performance and efficiency. However, they can be more expensive and complex to manufacture, requiring specialized skills and equipment.

Impact on Application: Composites are particularly beneficial for non-structural components, enhancing aesthetic appeal while contributing to overall vehicle performance.

Considerations for International Buyers: Buyers from the Middle East may find composites appealing due to their resistance to extreme temperatures. However, they should be aware of any import tariffs or regulations regarding composite materials.

What Advantages Does Plastic Offer for Specific Components?

Key Properties: Plastics are lightweight, corrosion-resistant, and can be molded into complex shapes, making them suitable for various components, including interior fittings and non-structural parts.

Pros & Cons: The main advantage of plastics is their cost-effectiveness and versatility in design. However, they may not provide the same level of durability as metals and can degrade under UV exposure if not treated.

Impact on Application: Plastics can be used in areas where weight savings are crucial without compromising structural integrity, such as in interior components.

Considerations for International Buyers: Buyers should consider the environmental impact of plastics and ensure compliance with regulations regarding plastic use in their respective countries, particularly in Europe, where sustainability is a priority.

Summary of Material Selection for j2c l6e

| Material | Typical Use Case for j2c l6e | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chassis and structural components | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Body panels and engine parts | Lightweight, enhances efficiency | Higher cost and complexity | High |

| Composite | Non-structural components | High strength-to-weight ratio | Expensive and complex to manufacture | High |

| Plastic | Interior fittings and non-structural parts | Cost-effective and versatile | Less durable, UV degradation | Low |

This strategic material selection guide provides B2B buyers with critical insights into the materials used in the j2c l6e, aiding in informed purchasing decisions that align with regional standards and operational requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for j2c l6e

What Are the Main Stages in the Manufacturing Process for the J2C L6E Electric Mini Cargo Van?

The manufacturing process of the J2C L6E Electric Mini Cargo Van involves several key stages that ensure a high-quality end product. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The initial step in the manufacturing process involves sourcing and preparing raw materials, such as high-strength steel for the frame and advanced polymers for the body. Suppliers must adhere to stringent quality standards to ensure that materials meet the specific requirements for durability and performance.

-

Forming: This stage encompasses various techniques such as stamping, bending, and welding. For the J2C L6E, precision stamping is often used to create complex shapes for the body panels, while robotic welding technology ensures consistent and high-strength joints. The use of CNC (Computer Numerical Control) machines is common in this phase to enhance accuracy and reduce waste.

-

Assembly: Once the individual components are formed, they are transported to the assembly line, where skilled workers and automated systems come together. The assembly process typically follows a modular approach, allowing for the efficient integration of systems such as the electric drivetrain, refrigeration units, and cargo compartments. Quality checks at this stage are crucial to ensure that all components fit correctly and function as intended.

-

Finishing: The final stage of manufacturing includes painting, coating, and detailing. Advanced finishing techniques, such as electrostatic painting, provide a durable and aesthetically pleasing surface while ensuring corrosion resistance. Additionally, thorough cleaning processes are implemented to eliminate any contaminants that could affect the vehicle’s performance.

How is Quality Assurance Integrated Throughout the Manufacturing Process?

Quality assurance (QA) is an integral part of the manufacturing process for the J2C L6E, ensuring that the vehicle meets both international standards and customer expectations. The QA process includes adherence to relevant international standards, such as ISO 9001, as well as industry-specific certifications like CE marking for products sold within the European market.

-

International Standards and Certifications: ISO 9001 outlines a framework for quality management systems that organizations can implement to enhance customer satisfaction and ensure consistent quality. For the J2C L6E, obtaining CE certification demonstrates compliance with European health, safety, and environmental protection standards, which is particularly important for B2B buyers in Europe.

-

Quality Control Checkpoints: The QA process is structured around several critical checkpoints:

– Incoming Quality Control (IQC): This phase involves inspecting raw materials and components upon arrival to ensure they meet specified standards before they are used in production.

– In-Process Quality Control (IPQC): Throughout the manufacturing stages, continuous monitoring and inspections are performed. This includes checks during forming and assembly to identify any deviations from quality standards early in the process.

– Final Quality Control (FQC): After assembly, the completed vehicles undergo comprehensive testing and inspections to confirm that they meet performance specifications and safety standards. This includes dynamic tests to evaluate handling, braking, and overall functionality.

What Common Testing Methods Are Used to Ensure Quality?

To maintain high-quality standards, various testing methods are employed at different stages of the manufacturing process. These methods include:

-

Mechanical Testing: This includes tensile, compression, and fatigue tests to assess the strength and durability of materials used in the J2C L6E. Such tests ensure that components can withstand operational stresses.

-

Electrical Testing: Given that the J2C L6E is an electric vehicle, electrical components undergo rigorous testing to verify performance, safety, and compliance with electrical standards. This may include insulation resistance testing and load testing.

-

Environmental Testing: The vehicle is subjected to environmental simulations to test its performance under various climatic conditions, which is particularly relevant for B2B buyers in diverse regions such as Africa and the Middle East.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must conduct thorough due diligence when selecting suppliers for the J2C L6E to ensure quality and reliability. Here are actionable strategies for verifying supplier quality control processes:

-

Supplier Audits: Performing on-site audits allows buyers to assess the manufacturing processes, quality control systems, and adherence to international standards. Audits can provide insight into the supplier’s commitment to quality and their ability to meet production demands.

-

Quality Control Reports: Requesting detailed quality control reports can provide buyers with transparency regarding the supplier’s QA processes, including data on testing results and compliance with relevant certifications.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can provide an unbiased evaluation of the manufacturing facilities and processes. These agencies can conduct inspections at various stages, from raw material sourcing to final product testing, ensuring that the supplier meets the required standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International buyers, particularly those from Africa, South America, the Middle East, and Europe, must navigate various quality control and certification nuances when sourcing the J2C L6E. Key considerations include:

-

Understanding Regional Standards: Different regions have specific regulations and standards that must be adhered to. For example, vehicles sold in Europe must comply with stringent EU regulations, while those in Africa may have different local standards.

-

Navigating Import Regulations: Buyers should be aware of import regulations that may affect the certification and quality requirements for the J2C L6E. This includes tariffs, taxes, and compliance documentation necessary for smooth customs clearance.

-

Cultural Considerations: Cultural differences can impact quality expectations and perceptions. B2B buyers must communicate clearly with suppliers about quality standards and expectations to avoid misunderstandings.

In conclusion, understanding the manufacturing processes and quality assurance measures for the J2C L6E Electric Mini Cargo Van is essential for B2B buyers. By focusing on the details of manufacturing stages, quality control checkpoints, testing methods, and supplier verification strategies, buyers can make informed decisions that align with their operational needs and market standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘j2c l6e’

Introduction

This practical sourcing guide is designed to assist international B2B buyers in procuring the J2-C L6e Electric Mini Cargo Van. With its robust design and suitability for short-distance urban deliveries, understanding the procurement process is essential. This checklist will guide you through the critical steps to ensure a successful purchase.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements for the J2-C L6e. Consider factors such as load capacity (up to 330kg), cruising range (100km-200km), and specific features like refrigeration for cold chain transport. Establishing these specifications will help you communicate effectively with suppliers and ensure the vehicle meets your operational needs.

Step 2: Research Potential Suppliers

Invest time in identifying reliable suppliers of the J2-C L6e. Look for manufacturers with a strong reputation in the electric vehicle sector. Utilize industry directories, trade shows, and online platforms to create a list of potential suppliers. A well-researched supplier list can significantly streamline your procurement process.

Step 3: Evaluate Supplier Capabilities

It’s crucial to assess the capabilities of each supplier on your list. Request detailed company profiles and inquire about their production capacity, quality assurance processes, and any certifications they hold (e.g., ISO certifications). Understanding their capabilities will give you confidence in their ability to meet your order requirements.

Step 4: Request Quotes and Compare Pricing

Once you have narrowed down your list, request formal quotes from each supplier. Ensure that the quotes include not just the base price of the J2-C L6e but also any additional costs such as shipping, taxes, and potential duties. Comparing these quotes will help you identify the best value for your investment.

Step 5: Verify Supplier Certifications

Confirm that the suppliers possess relevant certifications and compliance with international standards. This includes checking for safety certifications and environmental compliance, particularly for electric vehicles. Certification verification is essential to ensure you are sourcing a product that meets regulatory requirements in your region.

Step 6: Conduct Site Visits or Virtual Tours

If feasible, arrange site visits to the supplier’s manufacturing facility or request virtual tours. This step allows you to assess the production environment and quality control measures firsthand. Observing the manufacturing process can provide deeper insights into the supplier’s operational capabilities and commitment to quality.

Step 7: Finalize Terms and Place Your Order

Once you are satisfied with your chosen supplier, finalize the terms of your purchase agreement. This should include payment terms, delivery schedules, and warranties. Clearly outlining these terms helps to protect your interests and ensures that both parties are aligned on expectations.

By following this step-by-step checklist, you can navigate the procurement process for the J2-C L6e Electric Mini Cargo Van with confidence, ensuring a successful acquisition that meets your business needs.

Comprehensive Cost and Pricing Analysis for j2c l6e Sourcing

What Are the Key Cost Components for j2c l6e Sourcing?

When analyzing the cost structure for sourcing the j2c l6e, several components come into play. The primary cost components include:

-

Materials: The raw materials required for manufacturing the j2c l6e, such as steel, plastics, and electronic components, significantly influence the overall cost. The choice of materials can vary based on quality and specifications, affecting both price and performance.

-

Labor: Labor costs are pivotal in the manufacturing process. Skilled labor is often required for assembly and quality control, which can vary widely depending on the country of origin and local wage standards.

-

Manufacturing Overhead: This includes indirect costs such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these overheads, benefiting the overall pricing strategy.

-

Tooling: Initial tooling and setup costs can be substantial, especially for customized versions of the j2c l6e. These costs are often amortized over the production run, impacting the pricing for smaller orders.

-

Quality Control (QC): Ensuring that the j2c l6e meets quality standards is critical. Investment in QC processes can lead to higher upfront costs but can reduce long-term expenses related to defects and returns.

-

Logistics: Shipping costs, including freight, customs duties, and insurance, are essential considerations, especially for international buyers. Efficient logistics can minimize costs and ensure timely delivery.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market conditions and competition. Understanding the competitive landscape can help buyers negotiate better terms.

How Do Price Influencers Impact j2c l6e Costs?

Several factors influence the pricing of the j2c l6e, and understanding these can provide buyers with a strategic advantage:

-

Volume/MOQ: Larger order quantities often lead to reduced per-unit costs due to economies of scale. Establishing minimum order quantities (MOQ) can help suppliers manage production efficiency, which can be beneficial for buyers looking to negotiate lower prices.

-

Specifications and Customization: Custom features or specifications can significantly affect pricing. Buyers should clearly define their needs to avoid unexpected costs later in the process.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (ISO, CE, etc.) can influence both cost and market acceptance. Higher quality standards typically lead to increased costs but can enhance the product’s longevity and performance.

-

Supplier Factors: The reputation, reliability, and location of suppliers can impact pricing. Suppliers with established track records may charge a premium, but they can also offer reliability that mitigates risks.

-

Incoterms: Understanding the implications of different Incoterms (International Commercial Terms) is crucial. These terms define the responsibilities of buyers and sellers in international transactions, affecting shipping costs and risk management.

What Are Effective Buyer Tips for Negotiating j2c l6e Prices?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, strategic negotiation and cost management are essential:

-

Negotiate Terms and Pricing: Establish a relationship with suppliers and be prepared to negotiate terms. Leverage volume commitments and long-term contracts to secure better pricing.

-

Focus on Cost-Efficiency: Look beyond the initial purchase price to consider total cost of ownership (TCO). Evaluate factors such as maintenance costs, lifespan, and energy efficiency.

-

Understand Pricing Nuances: Be aware of regional pricing differences, currency fluctuations, and tariffs that may affect the final cost. Engaging local experts can provide insights into market dynamics.

-

Conduct Thorough Research: Investigate multiple suppliers to compare costs, quality, and delivery times. A well-informed buyer is better positioned to negotiate favorable terms.

-

Request Detailed Quotes: Ensure that quotes include all potential costs, including logistics and duties. This transparency helps avoid surprises and facilitates informed decision-making.

Disclaimer

The prices and cost structures mentioned herein are indicative and can vary based on numerous factors, including market conditions and supplier negotiations. Buyers should conduct thorough due diligence and consider engaging with multiple suppliers to obtain the best pricing tailored to their specific needs.

Alternatives Analysis: Comparing j2c l6e With Other Solutions

Understanding Alternatives in the Electric Cargo Van Market

In the competitive landscape of logistics and urban transportation, choosing the right electric cargo vehicle is crucial for businesses seeking efficiency, sustainability, and cost-effectiveness. The J2C L6E Electric Mini Cargo Van, designed for short-distance urban deliveries, is one option among several. This analysis compares the J2C L6E with other viable alternatives to help B2B buyers make informed decisions based on their specific needs.

Comparison Table

| Comparison Aspect | J2C L6E | Alternative 1: Renault Kangoo Z.E. | Alternative 2: Nissan e-NV200 |

|---|---|---|---|

| Performance | Load capacity: 330 kg; Range: 100-200 km | Load capacity: 650 kg; Range: 230 km | Load capacity: 700 kg; Range: 200 km |

| Cost | Competitive pricing | Higher upfront costs; lower operating costs | Moderate pricing; tax incentives available |

| Ease of Implementation | Simple setup; suitable for urban areas | Requires infrastructure for charging | Requires infrastructure; versatile in urban and rural areas |

| Maintenance | Low maintenance; electric components | Moderate maintenance; dealer support | Moderate maintenance; good parts availability |

| Best Use Case | Short-distance urban deliveries | Multi-purpose delivery; small businesses | Versatile for urban and suburban deliveries |

Detailed Breakdown of Alternatives

Renault Kangoo Z.E.

The Renault Kangoo Z.E. is a well-established electric cargo vehicle known for its larger load capacity of 650 kg and a cruising range of up to 230 km. This makes it suitable for businesses that require more flexibility in their delivery routes. However, it comes with a higher upfront cost, which can be a barrier for smaller companies. On the upside, its operational efficiency and availability of dealer support for maintenance make it a reliable choice for businesses focused on medium-distance logistics.

Nissan e-NV200

The Nissan e-NV200 offers a balanced approach with a load capacity of 700 kg and a range of approximately 200 km. Its design allows for both urban and suburban deliveries, making it a versatile option for businesses operating in diverse environments. While its pricing is moderate, potential buyers may benefit from tax incentives, which can offset some initial costs. However, like the Kangoo, it requires proper charging infrastructure, which may limit its use in areas with inadequate support.

Conclusion: How to Choose the Right Electric Cargo Solution

When selecting an electric cargo vehicle, B2B buyers should consider several factors, including performance, cost, ease of implementation, and maintenance requirements. The J2C L6E stands out for its targeted design for short-distance urban deliveries and competitive pricing. However, for businesses that require more capacity or longer ranges, alternatives like the Renault Kangoo Z.E. and Nissan e-NV200 may be better suited. Ultimately, the decision should align with the specific logistics needs, budget constraints, and operational capabilities of the business. By carefully evaluating these aspects, buyers can select the most effective solution for their transportation requirements.

Essential Technical Properties and Trade Terminology for j2c l6e

What Are the Key Technical Specifications of the j2c l6e Electric Mini Cargo Van?

Understanding the technical specifications of the j2c l6e is crucial for B2B buyers, particularly those involved in logistics and distribution. Here are the essential technical properties that define this electric mini cargo van:

-

Load Capacity (330 kg)

The j2c l6e is designed to carry a maximum load of 330 kg. This specification is vital for businesses that require efficient transport of goods, ensuring that the vehicle can handle the weight of the cargo without compromising performance. For B2B buyers, understanding load capacity helps in assessing whether the vehicle meets their logistics needs. -

Cruising Range (100 km – 200 km)

With a cruising range between 100 km to 200 km on a single charge, the j2c l6e is ideally suited for urban delivery and short-distance transportation. This range provides flexibility for businesses that require frequent deliveries within city limits, thus optimizing operational efficiency. Buyers should consider this range in relation to their delivery routes and frequency. -

Temperature Control (-18°C to 5°C)

For businesses involved in cold chain logistics, the j2c l6e can be equipped with a refrigeration system that maintains temperatures between -18°C and 5°C. This feature is essential for transporting perishable goods, pharmaceuticals, and other temperature-sensitive products. Understanding this specification is crucial for industries that rely on strict temperature controls. -

Electric Powertrain

The j2c l6e operates on a fully electric powertrain, which offers significant benefits over traditional fuel-powered vehicles, including lower operating costs and reduced environmental impact. B2B buyers should evaluate the advantages of electric vehicles in terms of sustainability and long-term savings. -

Compact Design

The vehicle’s compact design facilitates maneuverability in urban environments, making it easier to navigate congested streets and tight delivery spots. This is particularly important for businesses that operate in city centers where space is limited.

What Are Common Trade Terms Relevant to the j2c l6e?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms associated with the j2c l6e:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of the j2c l6e, understanding OEM relationships can help buyers assess the quality and reliability of components used in the vehicle. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. For businesses considering purchasing the j2c l6e, knowing the MOQ can impact budgeting and inventory planning, especially if the vehicle is part of a larger fleet acquisition. -

RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer requests price quotations from suppliers. For B2B buyers, submitting an RFQ for the j2c l6e allows them to compare prices and terms from various suppliers, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. Familiarity with these terms is crucial when negotiating shipping and delivery logistics for the j2c l6e, as they define who bears the risk and cost at various stages of transportation. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until it is fulfilled. Understanding lead times for the j2c l6e is essential for businesses to plan their operations effectively, especially in industries where timely deliveries are critical.

By grasping these technical specifications and trade terms, B2B buyers can make more informed decisions, ensuring that the j2c l6e meets their operational requirements and aligns with their business goals.

Navigating Market Dynamics and Sourcing Trends in the j2c l6e Sector

What Are the Key Market Drivers and Trends Influencing the j2c l6e Sector?

The j2c l6e sector, particularly characterized by electric mini cargo vans, is witnessing significant market dynamics driven by sustainability, urbanization, and advancements in technology. The global push towards electric vehicles (EVs) is reshaping logistics and transportation, particularly in urban areas where emissions regulations are stringent. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe (notably Germany and Vietnam), the demand for efficient, low-emission delivery solutions is surging.

Emerging trends include the integration of smart technologies, such as IoT for fleet management and real-time tracking, which enhance operational efficiency. Additionally, the rise of e-commerce has created a need for last-mile delivery solutions that are both agile and environmentally friendly. Companies are increasingly opting for electric vans like the j2c l6e for their ability to navigate urban settings with ease while meeting regulatory requirements.

Moreover, supply chain resilience has become a priority, leading to a focus on local sourcing and partnerships that can support sustainable practices. As global markets adapt to these changes, buyers should seek suppliers who are not only responsive to current trends but also proactive in adopting innovative technologies that align with long-term sustainability goals.

How Is Sustainability Shaping Sourcing Strategies in the j2c l6e Sector?

Sustainability has emerged as a critical factor in the sourcing strategies of B2B buyers in the j2c l6e sector. The environmental impact of traditional delivery vehicles has prompted a shift towards electric models that produce zero emissions, significantly reducing the carbon footprint of logistics operations. This transition is particularly vital for businesses aiming to meet growing consumer and regulatory expectations regarding sustainability.

Ethical sourcing practices are also gaining traction, with companies prioritizing suppliers that adhere to environmental standards and sustainable production processes. Certifications like ISO 14001 for environmental management and adherence to green materials in manufacturing are becoming essential for establishing credibility and trust in supply chains.

For B2B buyers, this means actively seeking partnerships with manufacturers who prioritize sustainable practices, such as the use of recyclable materials in the production of electric vehicles and adherence to ethical labor practices. Investing in suppliers with a robust sustainability framework not only enhances brand reputation but also drives long-term operational efficiencies and compliance with international environmental regulations.

What Is the Historical Context Behind the j2c l6e Sector’s Development?

The evolution of the j2c l6e sector can be traced back to the increasing recognition of the need for sustainable transport solutions. The rise of electric vehicles in the early 21st century, driven by technological advancements and a growing awareness of climate change, laid the groundwork for the development of electric cargo vans.

Initially, electric vehicles faced challenges such as limited range and high costs. However, continuous improvements in battery technology and reductions in manufacturing costs have made electric mini cargo vans like the j2c l6e more accessible to businesses. The sector has now matured into a viable alternative for urban logistics, catering to a diverse range of industries, from food delivery to e-commerce.

This historical context highlights the importance of adaptability and innovation in the j2c l6e sector, signaling to international B2B buyers that the future will be shaped by ongoing advancements in technology and a commitment to sustainability. Understanding this evolution is essential for making informed sourcing decisions that align with both current market demands and future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of j2c l6e

-

1. How do I ensure the quality of the j2c l6e before purchasing?

To ensure the quality of the j2c l6e, request detailed specifications and certifications from the supplier. Conduct a thorough vetting process by checking their reputation, reviews, and previous client feedback. If feasible, arrange for a factory visit or request product samples to assess build quality and performance. Additionally, inquire about the supplier’s quality assurance processes, such as inspections and testing protocols, to ensure they meet international standards. -

2. What customization options are available for the j2c l6e?

Customization options for the j2c l6e may include modifications to the cargo area, branding options, and various configurations for refrigeration units. Discuss your specific requirements with potential suppliers to determine their capabilities and flexibility. It’s essential to communicate your needs clearly and understand any associated costs and lead times for custom features to ensure the vehicle meets your operational demands. -

3. What is the minimum order quantity (MOQ) for the j2c l6e?

The minimum order quantity (MOQ) for the j2c l6e can vary by supplier. Typically, manufacturers may set an MOQ to justify production costs and logistics. It’s advisable to discuss your purchasing needs directly with the supplier to see if they offer flexibility, especially for first-time buyers or smaller companies. Some suppliers may allow smaller orders or provide options for group purchasing with other clients. -

4. What payment terms can I expect when buying the j2c l6e?

Payment terms for purchasing the j2c l6e can range widely depending on the supplier and the buyer’s negotiation. Common options include upfront payment, partial payment upon order confirmation, and the balance upon delivery. Additionally, consider payment methods such as letters of credit or escrow services for added security. Always clarify payment terms in the contract to avoid misunderstandings and ensure a smooth transaction. -

5. How can I manage logistics and shipping for the j2c l6e?

Managing logistics for the j2c l6e involves selecting a reliable shipping partner experienced in international transport. Discuss shipping options with your supplier, including FOB (Free on Board) or CIF (Cost, Insurance, and Freight) terms. Make sure to understand customs regulations in your country and prepare necessary documentation to avoid delays. Consider using freight forwarders who can assist with the entire shipping process, including customs clearance. -

6. What are the typical delivery times for the j2c l6e?

Delivery times for the j2c l6e can vary based on factors such as production schedules, customization requirements, and shipping routes. Generally, you can expect a lead time of several weeks to a few months. For accurate timelines, inquire with the supplier about their current production capacity and estimated shipping times to your region. Keeping open communication will help manage expectations and facilitate planning for your operational needs. -

7. How do I vet potential suppliers for the j2c l6e?

Vetting suppliers for the j2c l6e involves researching their business history, production capabilities, and client references. Start by reviewing online reviews and industry forums for feedback on their reliability and product quality. Request financial statements or certifications to assess stability. If possible, visit their facility or schedule a video tour to better understand their operations and quality control processes. -

8. What after-sales support is available for the j2c l6e?

After-sales support for the j2c l6e is crucial for maintenance and operational efficiency. Inquire about warranty terms, parts availability, and technical support from the supplier. Many suppliers offer training for your staff on vehicle operation and maintenance. Ensure you have a clear understanding of the support structure in place, including how to access service centers or obtain spare parts, to minimize downtime in your logistics operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 J2C L6E Manufacturers & Suppliers List

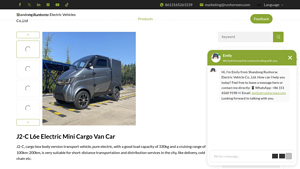

1. Run Horse – J2-C Electric Mini Cargo Van

Domain: runhorseev.com

Registered: 2023 (2 years)

Introduction: Product Name: J2-C L6e Electric Mini Cargo Van Car

Model Number: J2-C

Type: Electric Mini Cargo Van

Load Capacity: 330 kg

Cruising Range: 100 km – 200 km

Max Speed: 45 km/h

Battery: 60V/3000W – 60V/4000W AC asynchronous motor; 105Ah/206Ah LiFePO4 battery with BMS system (fast charging function)

Charging Time: 2-3 hours

Brakes: Front disc brake & rear drum brake

Tyres: Front 135/70R12 & rear 145/70…

2. Pinterest – J2-C L6E Runhorse EV

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: J2-C with L6E Runhorse EV – An environmentally sustainable and affordable option. More environmentally sustainable as they don’t emit any gases directly into the atmosphere, cheap to run and maintain, and quieter to drive.

3. YUNLONG – J2-C Electric Scooter

Domain: jp.pinterest.com

Registered: 2009 (16 years)

Introduction: YUNLONG J2-C L6e+45km/h+Li-on battery, EEC L6e Homologation, 3kw motor, 60v/206ah lithium battery with fast charge, designed for city last mile solution, contact Rachel via WhatsApp at +86-19153649065 for more details.

Strategic Sourcing Conclusion and Outlook for j2c l6e

In today’s competitive landscape, the strategic sourcing of the J2-C L6e electric mini cargo van presents a compelling opportunity for international B2B buyers. This vehicle, with its impressive load capacity of 330kg and a range of 100-200km, is designed for urban logistics, making it ideal for short-distance transportation and cold chain services. Its energy efficiency aligns with the growing demand for sustainable transport solutions, particularly in regions like Africa, South America, the Middle East, and Europe.

Investing in the J2-C L6e not only enhances operational efficiency but also positions businesses to meet evolving customer expectations for eco-friendly logistics. As industries worldwide pivot towards electric solutions, aligning sourcing strategies with these trends is crucial.

Looking ahead, organizations that prioritize sustainable sourcing will not only reduce their carbon footprint but will also tap into new markets driven by demand for greener alternatives. We encourage international buyers to explore partnerships with reputable suppliers of the J2-C L6e, ensuring a competitive edge in the rapidly transforming logistics sector. Embrace this opportunity to innovate and lead in sustainable transportation solutions.