Introduction: Navigating the Global Market for loder riksha

In today’s rapidly evolving global marketplace, sourcing the right loder riksha can pose significant challenges for international B2B buyers. With a variety of models available, including petrol and electric options, understanding the unique specifications and applications of these cargo vehicles is crucial for optimizing logistics and enhancing operational efficiency. This guide provides a comprehensive exploration of the loder riksha market, covering different types, their applications in various sectors, supplier vetting processes, and cost considerations.

Navigating through the complexities of this industry can empower buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Vietnam and Germany—to make informed purchasing decisions. By addressing critical questions about performance, durability, and maintenance, this guide equips businesses with the insights needed to select the most suitable loder riksha for their operational needs.

Furthermore, we delve into essential topics such as warranty terms, after-sales service, and the importance of reliable suppliers, ensuring that buyers are not only selecting high-quality vehicles but are also establishing partnerships that foster long-term success. With this resource, international buyers can confidently engage in the loder riksha market, transforming challenges into opportunities for growth and efficiency.

Understanding loder riksha Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 100cc Cargo Loader | Compact size, economical fuel consumption | Small deliveries, urban logistics | Pros: Cost-effective, easy to maneuver. Cons: Limited cargo capacity. |

| 250cc Garbage Loader | Enhanced power, specialized for waste management | Waste collection, municipal services | Pros: High load capacity, robust design. Cons: Higher operational costs. |

| 300cc Rickshaw Loader | Powerful engine, versatile for various terrains | General cargo transport, e-commerce | Pros: Excellent performance, durable. Cons: May require more maintenance. |

| Electric Rickshaw Loader | Eco-friendly, lower operational costs | Urban transport, last-mile delivery | Pros: Sustainable, quiet operation. Cons: Limited range, charging infrastructure needed. |

| Semi-Cabin Loader | Enclosed cabin for driver protection, larger cargo area | Freight transport, agricultural use | Pros: Weather protection, increased safety. Cons: Heavier, may reduce fuel efficiency. |

What Are the Characteristics of the 100cc Cargo Loader?

The 100cc Cargo Loader is designed for urban environments where space and fuel efficiency are paramount. Its compact size allows it to navigate through narrow streets easily, making it ideal for small deliveries in congested areas. B2B buyers should consider its low purchase price and operating costs, but be aware that its cargo capacity is limited, which may not suit larger logistics operations.

How Does the 250cc Garbage Loader Stand Out?

The 250cc Garbage Loader is tailored for waste management, featuring a robust design that can handle heavy loads. Its enhanced power makes it suitable for municipal services and waste collection in both urban and rural settings. While it offers significant load capacity and durability, buyers should evaluate the higher operational costs associated with its maintenance and fuel consumption.

What Makes the 300cc Rickshaw Loader a Versatile Option?

The 300cc Rickshaw Loader is recognized for its powerful engine, enabling it to perform well across diverse terrains. This versatility makes it suitable for general cargo transport and e-commerce applications, where reliability is crucial. While it delivers excellent performance and durability, potential buyers should consider the frequency of maintenance required to keep it in optimal condition.

Why Choose an Electric Rickshaw Loader for Sustainable Transport?

Electric Rickshaw Loaders are an eco-friendly alternative, appealing to businesses focused on sustainability. They have lower operational costs due to reduced fuel expenses and are quieter, making them suitable for urban transport and last-mile delivery. However, buyers must consider the limited range and the need for adequate charging infrastructure, which can impact operational efficiency.

What Advantages Does a Semi-Cabin Loader Provide?

The Semi-Cabin Loader offers an enclosed cabin, providing protection for the driver and a larger cargo area. This feature is advantageous for freight transport and agricultural uses, particularly in adverse weather conditions. While it enhances safety and comfort, buyers should be mindful that the added weight may lead to reduced fuel efficiency compared to lighter models.

Key Industrial Applications of loder riksha

| Industry/Sector | Specific Application of loder riksha | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics & Delivery | Last-mile delivery in urban areas | Efficient transport of goods in congested city environments | Durability, fuel efficiency, and payload capacity must be prioritized. |

| Agriculture | Transport of produce from farms to markets | Reduces time and labor costs, enhancing supply chain efficiency | Consider terrain adaptability and cargo space for different produce types. |

| Waste Management | Collection and transport of waste | Streamlines waste collection processes, improving urban hygiene | Reliability in harsh conditions and ease of maintenance are crucial. |

| Construction | Transport of materials on-site | Facilitates quick movement of heavy materials, improving project timelines | Load capacity and engine power are vital for heavy-duty applications. |

| Retail | Mobile retail outlets | Expands market reach by allowing businesses to operate in various locations | Customization options for branding and cargo space for diverse products. |

How is loder riksha utilized in logistics and delivery?

In the logistics sector, loder riksha is primarily employed for last-mile delivery, particularly in densely populated urban areas. Their compact size allows for maneuverability in narrow streets where larger vehicles may struggle. These vehicles address the challenge of timely deliveries, reducing congestion and improving overall delivery efficiency. B2B buyers should consider factors such as durability and fuel efficiency when sourcing, ensuring that the vehicles can withstand daily operational demands.

What role does loder riksha play in agriculture?

In agriculture, loder riksha serves as a vital link between farms and markets, transporting fresh produce efficiently. This reduces the time between harvest and sale, which is critical for perishable goods. By minimizing labor costs and enhancing the supply chain, these vehicles significantly benefit farmers and distributors. Buyers should focus on the vehicle’s adaptability to various terrains and its cargo space to accommodate different types of produce when sourcing.

How does loder riksha enhance waste management?

Loder riksha is increasingly used in waste management, where they facilitate the collection and transport of waste materials. Their design allows for efficient navigation in urban environments, making waste collection more effective and timely. By streamlining these processes, businesses can contribute to improved urban hygiene and environmental sustainability. Buyers in this sector should prioritize the vehicle’s reliability in harsh conditions and ease of maintenance to ensure consistent performance.

What advantages does loder riksha provide in construction?

In the construction industry, loder riksha is invaluable for transporting materials on-site. Their ability to quickly move heavy materials helps improve project timelines and labor efficiency. This application addresses the challenge of material logistics within construction zones, where space is often limited. Buyers need to consider the load capacity and engine power of these vehicles to ensure they meet the demands of heavy-duty applications.

How can loder riksha benefit retail businesses?

Retail businesses utilize loder riksha as mobile outlets, allowing them to reach customers in various locations. This flexibility expands market reach and enhances customer engagement. By using these vehicles, retailers can adapt to changing market demands and consumer preferences. When sourcing, buyers should look for customization options that allow for branding and sufficient cargo space to accommodate diverse products, ensuring a tailored approach to their retail strategy.

3 Common User Pain Points for ‘loder riksha’ & Their Solutions

Scenario 1: Limited Cargo Capacity Leading to Inefficiency

The Problem: Many businesses, especially in emerging markets, face challenges with transporting goods due to limited cargo capacity in their current vehicles. For instance, a local retailer in Africa may find that their existing delivery trucks are too large for narrow urban streets, leading to inefficiencies. They struggle with timely deliveries and increased fuel costs, as they often have to make multiple trips to meet customer demands. This not only affects operational efficiency but can also lead to customer dissatisfaction and lost revenue.

The Solution: To overcome this challenge, B2B buyers should consider investing in a loader rickshaw, specifically models like the 300cc Rickshaw Loader. This three-wheeler is designed for urban settings, offering a compact size while maintaining a substantial cargo capacity. When sourcing a loader rickshaw, it’s essential to assess the specific weight and volume needs of your business. Engaging with suppliers who provide customization options can ensure the rickshaw meets your unique requirements. Additionally, consider opting for a model equipped with a robust engine and durable construction to handle diverse road conditions while maximizing efficiency in deliveries.

Scenario 2: High Maintenance Costs and Downtime

The Problem: Businesses often grapple with high maintenance costs and unexpected downtimes of their transportation vehicles, which can severely disrupt operations. A logistics company in South America may experience frequent breakdowns with their aging fleet, leading to delays in service delivery and increased repair expenses. This situation is compounded when spare parts are hard to find or expensive, resulting in prolonged downtime and loss of business.

The Solution: To mitigate these issues, B2B buyers should focus on sourcing loader rickshaws from reputable manufacturers known for their reliability and after-sales support. For example, selecting models like the Petrol Rickshaw Loader can offer better durability and easier access to spare parts. When purchasing, inquire about warranty services and the availability of local service centers that can provide prompt repairs. It’s also advisable to implement a proactive maintenance schedule, which could include regular inspections and timely replacements of wear-and-tear components. This approach not only extends the life of the vehicle but also helps maintain consistent operational efficiency.

Scenario 3: Regulatory Compliance and Safety Standards

The Problem: Navigating regulatory compliance and safety standards can be a daunting task for businesses using loader rickshaws, especially in regions with strict vehicle regulations. A transportation company in the Middle East might find itself struggling to meet local safety regulations, resulting in fines or even the suspension of operations. This problem is often exacerbated by a lack of awareness about specific requirements for commercial vehicles.

The Solution: To address this pain point, B2B buyers should conduct thorough research into the local regulations governing commercial transportation. Partnering with suppliers who are well-versed in these regulations can provide crucial insights. When purchasing a loader rickshaw, buyers should ensure that the vehicle complies with local safety standards, which may include features such as proper lighting, seat belts, and robust braking systems. It’s also beneficial to invest in training for drivers on safety protocols and vehicle handling, which can further enhance compliance and reduce liability risks. Engaging with local regulatory bodies can also provide updates on any changes in legislation that could affect operations.

Strategic Material Selection Guide for loder riksha

What Are the Common Materials Used in Loder Riksha Manufacturing?

When selecting materials for loder riksha, it is crucial to consider performance, durability, cost-effectiveness, and compliance with international standards. Below is an analysis of three common materials used in the construction of loder riksha, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Steel Perform as a Material for Loder Riksha?

Steel is a prevalent choice for loder riksha frames and structural components due to its high strength-to-weight ratio. It can withstand high stress and impact, making it suitable for transporting heavy loads. Steel’s temperature and pressure ratings are generally high, allowing it to perform well in various environmental conditions. However, steel is susceptible to corrosion, particularly in humid or coastal regions, necessitating protective coatings or galvanization.

Pros: Steel is durable, widely available, and cost-effective. It can be easily welded and fabricated, simplifying manufacturing processes.

Cons: The need for corrosion resistance treatments can increase overall costs. Additionally, steel is heavier than some alternative materials, potentially affecting fuel efficiency.

For international buyers, compliance with standards such as ASTM A36 (for structural steel) is essential. Buyers from regions like Europe may prefer steel that meets EN 10025 standards, ensuring quality and reliability.

What Role Does Aluminum Play in Loder Riksha Design?

Aluminum is increasingly used in loder riksha due to its lightweight nature and excellent corrosion resistance. This material can significantly reduce the overall weight of the vehicle, enhancing fuel efficiency and payload capacity. Aluminum’s thermal and electrical conductivity also makes it suitable for components requiring heat dissipation.

Pros: Aluminum is resistant to rust and corrosion, making it ideal for various climates. Its lightweight nature improves performance and reduces operational costs.

Cons: Aluminum can be more expensive than steel, and its manufacturing processes may require specialized equipment, increasing complexity.

International buyers should consider compliance with standards like ASTM B221 for aluminum extrusions. In markets such as South America and Africa, where cost sensitivity is high, the initial investment in aluminum may be a barrier despite its long-term benefits.

Why is Plastic an Emerging Material for Loder Riksha Components?

Plastics, particularly high-density polyethylene (HDPE) and polypropylene, are gaining traction in loder riksha manufacturing for non-structural components like body panels and storage bins. These materials offer excellent resistance to chemicals and UV radiation, making them suitable for various applications.

Pros: Plastics are lightweight, cost-effective, and easy to mold into complex shapes. They also provide good insulation properties.

Cons: Plastics generally have lower strength compared to metals and may not withstand high-impact forces as effectively. Their long-term durability can also be a concern in harsh environments.

B2B buyers should be aware of compliance with standards such as ASTM D638 for tensile properties of plastics. In Europe, adherence to REACH regulations regarding chemical safety is crucial for plastic components.

Summary of Material Selection for Loder Riksha

The following table summarizes the key insights regarding material selection for loder riksha:

| Material | Typical Use Case for loder riksha | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frame and structural components | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Body panels and structural elements | Lightweight and corrosion-resistant | Higher cost and manufacturing complexity | High |

| Plastic | Non-structural components like panels | Lightweight and cost-effective | Lower strength and durability | Low |

In conclusion, selecting the appropriate material for loder riksha involves balancing performance, cost, and compliance with international standards. Understanding the properties and implications of each material can help B2B buyers make informed decisions that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for loder riksha

What Are the Main Stages in the Manufacturing Process of Loader Rickshaws?

The manufacturing process of loader rickshaws typically involves several key stages that ensure the final product meets performance and durability standards. Understanding these stages is crucial for B2B buyers seeking reliable suppliers.

1. Material Preparation

The first step in manufacturing loader rickshaws is the selection and preparation of raw materials. Common materials include high-strength steel for the frame, aluminum for the body, and various composites for interior components. Suppliers usually source materials from certified vendors to ensure quality. The materials undergo rigorous testing for tensile strength and corrosion resistance before being approved for use.

2. Forming

Once the materials are prepared, the next stage is forming. This involves cutting, bending, and shaping the raw materials into the required components. Advanced techniques such as CNC machining and laser cutting are often employed for precision. Automated presses are used to create the body panels and frame components, ensuring consistency and reducing human error.

3. Assembly

After forming, the components move to the assembly line. Here, skilled technicians assemble the various parts, including the engine, transmission, and cargo area. This stage often employs a combination of manual labor and robotic assistance to enhance efficiency. During assembly, parts are fitted and secured with bolts, welds, or adhesives, depending on the design specifications.

4. Finishing

The final stage in manufacturing is finishing, which involves painting, coating, and detailing the loader rickshaw. This not only enhances aesthetics but also protects the vehicle from environmental factors. High-quality paints and coatings are applied, often using automated spray booths to achieve uniform coverage. The vehicles then undergo a thorough inspection to ensure that all components are correctly installed and that the finish meets quality standards.

What Quality Assurance Measures Are Typically Implemented in Loader Rickshaw Manufacturing?

Quality assurance (QA) is critical in the manufacturing of loader rickshaws, ensuring that each vehicle meets international standards and customer expectations. For B2B buyers, understanding these QA measures is essential for making informed procurement decisions.

International and Industry-Specific Standards

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards demonstrates a commitment to continuous improvement and customer satisfaction. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for fuel-related components may also be applicable.

Key Quality Control Checkpoints

Quality control is typically integrated at multiple stages of the manufacturing process:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified quality standards. This step prevents subpar materials from entering the production line.

-

In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are conducted to verify that components are being formed and assembled according to specifications. This may include measuring dimensions, inspecting welds, and ensuring that assembly procedures are followed.

-

Final Quality Control (FQC): Once assembly is complete, each loader rickshaw undergoes a comprehensive inspection. This includes functional tests, road tests, and visual inspections to ensure that the vehicle meets all operational and aesthetic standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to verify the quality control practices of potential suppliers. Here are several effective strategies:

Conducting Audits

One of the most effective ways to assess a supplier’s quality assurance measures is through on-site audits. During an audit, buyers can evaluate the supplier’s manufacturing processes, quality control checkpoints, and overall facility conditions. This firsthand observation helps in understanding the supplier’s commitment to quality.

Reviewing Quality Reports

Requesting detailed quality reports from suppliers can provide valuable insights into their QA practices. These reports should outline the results of various quality inspections, compliance with international standards, and any corrective actions taken for non-conformities. Regular reporting indicates a systematic approach to quality management.

Engaging Third-Party Inspection Services

For added assurance, buyers can engage third-party inspection services to conduct independent quality evaluations. These services offer unbiased assessments of the manufacturing process and finished products, ensuring that they meet both international standards and the buyer’s specific requirements.

What Are the Nuances of Quality Control and Certification for International B2B Buyers?

B2B buyers, especially those from diverse markets like Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality control and certification:

Understanding Regional Standards

Different regions may have unique regulations and standards that affect quality assurance. For instance, while CE certification is essential for products sold in Europe, other markets may have different requirements. Buyers should familiarize themselves with the relevant standards in their target markets to ensure compliance.

Importance of Documentation

Comprehensive documentation is crucial for international trade. Buyers should require suppliers to provide all necessary certificates, quality reports, and compliance documents. This documentation not only facilitates smoother customs processes but also serves as proof of the supplier’s commitment to quality.

Building Long-Term Relationships with Suppliers

Establishing long-term relationships with reliable suppliers can enhance quality assurance. Suppliers who value their partnerships are more likely to prioritize quality and transparency in their operations. Regular communication and feedback can help strengthen these relationships, ensuring that quality standards are consistently met.

In summary, understanding the manufacturing processes and quality assurance measures for loader rickshaws is vital for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they partner with suppliers who are committed to delivering high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘loder riksha’

Introduction:

This practical sourcing guide aims to provide international B2B buyers with a comprehensive checklist for procuring ‘loder riksha’ (loader rickshaws). With the growing demand for efficient transportation solutions in various sectors, understanding the procurement process is essential for making informed decisions. This checklist will help streamline your sourcing efforts, ensuring you choose the right vehicle for your business needs.

-

Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications of the loader rickshaw you need. Consider factors such as engine capacity (e.g., 100cc, 300cc), load capacity, and fuel type (petrol, electric).

– Performance Requirements: Determine the types of terrain and weather conditions the vehicle will be operating in.

– Cargo Needs: Establish how much weight and volume the rickshaw needs to carry. -

Research Potential Suppliers

Conduct thorough research to identify reliable suppliers. Look for manufacturers with a strong reputation in the industry and positive customer feedback.

– Supplier Background: Investigate their history, production capabilities, and market presence, particularly in regions relevant to your needs.

– Product Range: Ensure they offer a variety of loader rickshaws to meet different specifications. -

Evaluate Supplier Certifications

Verify that potential suppliers have the necessary certifications and compliance with international quality standards. This is crucial to ensure product safety and reliability.

– ISO Certifications: Look for ISO 9001 or similar certifications that indicate quality management practices.

– Local Compliance: Ensure they meet local regulations and standards for vehicle manufacturing. -

Request Product Samples or Demonstrations

Before making a significant investment, request product samples or arrange for demonstrations of the loader rickshaw. This allows you to assess the quality and performance firsthand.

– Test Drive: Evaluate the vehicle’s handling, power, and comfort during the demonstration.

– Inspect Features: Check for additional features that may enhance operational efficiency, such as cargo compartments and safety features. -

Discuss Warranty and After-Sales Support

Clarify the warranty terms and after-sales support offered by the supplier. A solid warranty and responsive after-sales service are essential for long-term satisfaction.

– Warranty Duration: Understand what is covered under the warranty and for how long.

– Service Availability: Inquire about the availability of spare parts and the supplier’s responsiveness to service requests. -

Compare Pricing and Payment Terms

Obtain quotes from multiple suppliers and compare pricing based on the specifications and features of the loader rickshaw. Also, assess the payment terms offered.

– Total Cost of Ownership: Consider not just the purchase price but also maintenance and operational costs.

– Flexible Payment Options: Look for suppliers who offer installment plans or financing options that suit your budget. -

Finalize the Purchase Agreement

Once you have selected a supplier, ensure that all terms are clearly documented in a purchase agreement. This should include specifications, pricing, delivery timelines, and any service commitments.

– Legal Review: Consider having a legal professional review the agreement to protect your interests.

– Delivery and Installation: Confirm delivery schedules and whether the supplier will assist with installation or training on vehicle operation.

By following this checklist, B2B buyers can make informed decisions when sourcing loader rickshaws, ultimately leading to successful procurement and enhanced operational efficiency.

Comprehensive Cost and Pricing Analysis for loder riksha Sourcing

What Are the Key Cost Components in Sourcing Loader Rickshaws?

When sourcing loader rickshaws, it’s crucial to understand the various cost components involved in their production. The primary components include:

-

Materials: The cost of raw materials such as steel, plastics, and engine components can significantly impact the overall price. Higher quality materials often lead to increased durability and performance, which may justify a higher upfront cost.

-

Labor: Labor costs vary by region and can be influenced by local wage standards. Countries with lower labor costs may offer competitive pricing, but this can sometimes result in lower quality.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead costs, contributing to lower prices.

-

Tooling: Custom tooling required for specialized designs or modifications can add to initial expenses. However, investing in tooling can lead to long-term cost savings for bulk orders.

-

Quality Control (QC): Rigorous QC processes ensure that the rickshaws meet safety and performance standards. While this adds to production costs, it is essential for ensuring product reliability, especially in competitive markets.

-

Logistics: Shipping and handling costs are critical, particularly for international buyers. Factors such as distance, shipping method, and potential tariffs should be considered when calculating total logistics costs.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. Understanding the margins in your sourcing market can help in negotiating better deals.

How Do Price Influencers Affect Loader Rickshaw Sourcing?

Several factors can influence the pricing of loader rickshaws, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often attract discounts. Understanding the supplier’s MOQ can help in negotiating better pricing.

-

Specifications and Customization: Custom features or specifications will increase the cost. Clearly defining your requirements upfront can minimize unexpected expenses.

-

Materials and Quality Certifications: Higher-quality materials and certified products (e.g., ISO certifications) can lead to higher prices but may be necessary for compliance with local regulations.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more but often provide better quality assurance and after-sales support.

-

Incoterms: Understanding the terms of delivery (e.g., FOB, CIF) is essential for calculating total costs. Incoterms dictate who is responsible for shipping, insurance, and tariffs, impacting overall pricing.

What Negotiation Strategies Should International Buyers Use?

For buyers from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings:

-

Research and Benchmarking: Familiarize yourself with market prices and competitor offerings to strengthen your negotiation position.

-

Build Long-term Relationships: Establishing a rapport with suppliers can lead to better pricing and more favorable terms over time.

-

Be Clear About Your Requirements: Clearly communicating your needs can help suppliers provide accurate quotes and avoid misunderstandings that lead to additional costs.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, fuel efficiency, and lifespan when assessing overall value.

-

Flexibility in Payment Terms: Offering to pay upfront or negotiating extended payment terms can sometimes lead to discounts.

What Should Buyers Know About Pricing Nuances in Different Regions?

Pricing nuances can vary significantly based on geographic location:

-

Africa and South America: Local economic conditions may lead to fluctuating prices. Buyers should be prepared for potential changes in costs due to currency fluctuations and import tariffs.

-

Middle East: Strong demand for durable, high-performance vehicles can drive prices up, particularly for quality-certified products.

-

Europe: Compliance with strict regulations may increase costs, but it also ensures safety and reliability, which can be attractive selling points in local markets.

Disclaimer on Pricing

It’s important to note that prices can vary widely based on the aforementioned factors, and the figures provided are indicative. Buyers should conduct thorough due diligence and obtain multiple quotes to ensure they receive competitive pricing for their specific needs.

Alternatives Analysis: Comparing loder riksha With Other Solutions

Introduction: Understanding the Need for Alternatives to Loder Riksha

In the landscape of commercial transportation solutions, the loder riksha presents a unique blend of efficiency and versatility. However, businesses often seek alternatives that can better meet specific operational demands or budget constraints. Evaluating these alternatives allows B2B buyers to make informed decisions that align with their logistical requirements and economic considerations.

Comparison Table

| Comparison Aspect | Loder Riksha | Electric Cargo Bikes | Small Delivery Trucks |

|---|---|---|---|

| Performance | 300cc engine; efficient for urban and rural settings | Limited speed; ideal for short distances | Higher speed; suitable for longer routes |

| Cost | Moderate initial investment; lower operational costs | Lower purchase cost; high battery replacement cost | Higher upfront and maintenance costs |

| Ease of Implementation | Simple to deploy; minimal training required | Requires charging infrastructure; easy to operate | Requires driver training; more complex logistics |

| Maintenance | Relatively low; parts readily available | Low maintenance; battery management needed | Higher maintenance; more complex mechanical systems |

| Best Use Case | Urban deliveries; construction sites | Eco-friendly urban transport; short-distance delivery | Long-distance deliveries; bulk transportation |

Detailed Breakdown of Alternatives

Electric Cargo Bikes

Electric cargo bikes are an increasingly popular alternative for last-mile delivery and short-distance transport. Their low purchase price and minimal maintenance make them attractive for businesses focused on sustainability. However, their range is limited by battery capacity, and they require charging infrastructure, which may not be feasible in all locations. They excel in urban areas where traffic congestion is a concern, but their performance can falter on longer routes or rough terrain.

Small Delivery Trucks

Small delivery trucks offer a robust alternative for businesses needing to transport larger quantities of goods over longer distances. With higher speeds and greater payload capacities, these vehicles are ideal for logistics companies and retailers. However, they come with higher initial costs and maintenance requirements compared to loder riksha. Additionally, the need for a qualified driver adds complexity to operational deployment, making them less accessible for smaller enterprises.

Conclusion: Choosing the Right Solution for Your Business Needs

Selecting the optimal transportation solution requires careful consideration of various factors, including performance, cost, and specific operational requirements. For businesses focused on urban deliveries with budget constraints, the loder riksha remains a compelling choice due to its efficiency and lower operational costs. However, if sustainability and short-distance transport are priorities, electric cargo bikes may be preferable. Conversely, for companies requiring higher speed and capacity for longer distances, small delivery trucks could be the ideal fit. Ultimately, understanding your logistical demands and budgetary constraints will guide you toward the most suitable solution for your business.

Essential Technical Properties and Trade Terminology for loder riksha

What Are the Essential Technical Properties of a Loader Rickshaw?

When considering the acquisition of loader rickshaws, it is crucial for B2B buyers to understand the essential technical properties that define these vehicles. Here are key specifications that impact performance, durability, and overall value:

-

Engine Capacity (cc): The engine capacity of a loader rickshaw is typically expressed in cubic centimeters (cc). For example, models may range from 100cc to 300cc. A higher engine capacity usually translates to increased power and load-bearing capability, which is vital for businesses requiring efficient cargo transport in various terrains.

-

Payload Capacity: This refers to the maximum weight that the rickshaw can carry, usually expressed in kilograms (kg). Understanding the payload capacity is crucial for businesses to ensure compliance with local regulations and to optimize transportation efficiency. For instance, a rickshaw with a 1000kg payload capacity would be ideal for heavy goods distribution.

-

Fuel Type and Efficiency: Loader rickshaws can be powered by petrol, diesel, or electricity. Fuel efficiency, typically measured in kilometers per liter (km/l), is a critical consideration for operational costs. Electric models may offer lower running costs and environmental benefits, appealing to businesses focused on sustainability.

-

Construction Materials: The materials used in the rickshaw’s frame and body significantly affect its durability and longevity. High-grade steel or reinforced composites are preferable for their strength and resistance to wear and tear, especially in harsh working conditions. Buyers should assess the materials used to ensure they meet their operational needs.

-

Suspension System: A robust suspension system enhances the ride quality and stability of the rickshaw, especially when navigating rough terrains. Features such as full-floating axles and shock absorbers can improve handling and comfort, which is essential for long-distance transportation of goods.

-

Turning Radius: The turning radius indicates how tightly a loader rickshaw can turn. A smaller turning radius is advantageous for maneuvering in congested urban environments. Businesses should consider this specification to enhance operational efficiency, particularly in crowded areas.

What Are Common Trade Terms Used in the Loader Rickshaw Industry?

Understanding industry terminology is essential for effective communication and negotiation in the loader rickshaw market. Here are some common trade terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of loader rickshaws, knowing the OEM can help buyers assess the quality and reliability of the vehicle components.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for buyers to plan their procurement strategy, as it can affect inventory management and cash flow.

-

RFQ (Request for Quotation): An RFQ is a document that a buyer sends to suppliers requesting a price quote for a specific quantity of goods. This is an essential step in the procurement process, allowing buyers to compare prices and terms from multiple suppliers.

-

Incoterms (International Commercial Terms): These are a set of pre-defined commercial terms published by the International Chamber of Commerce (ICC). Understanding Incoterms is vital for buyers as they define the responsibilities of buyers and sellers in international transactions, particularly concerning shipping and delivery.

-

Lead Time: This refers to the time it takes from placing an order until the goods are delivered. Knowing the lead time is essential for businesses to plan their logistics and ensure timely availability of loader rickshaws for operational needs.

-

Warranty Period: The warranty period is the duration during which the manufacturer agrees to repair or replace faulty parts. Understanding the warranty terms can provide buyers with confidence in the reliability of their investment and reduce potential long-term costs.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when investing in loader rickshaws, ultimately enhancing their operational efficiency and profitability.

Navigating Market Dynamics and Sourcing Trends in the loder riksha Sector

What Are the Key Drivers and Trends Shaping the Loader Rickshaw Market?

The loader rickshaw market is experiencing significant growth, driven by urbanization, rising demand for last-mile delivery solutions, and the increasing need for efficient transportation in congested areas. As cities expand, the need for versatile vehicles that can navigate narrow streets and heavy traffic becomes paramount. Loader rickshaws, particularly those with 300cc engines, have emerged as a preferred choice due to their balance of power and efficiency, making them suitable for various cargo types in both urban and rural settings.

Emerging B2B technology trends are influencing sourcing strategies within this sector. Digital platforms for procurement and supply chain management are gaining traction, enabling buyers to compare products, evaluate suppliers, and streamline their purchasing processes. Additionally, the rise of electric and hybrid loader rickshaws reflects a growing preference for environmentally friendly options, spurred by government incentives and changing consumer attitudes towards sustainability. International buyers, particularly from Africa and South America, are increasingly looking for suppliers who can provide customized solutions tailored to local market needs.

The loader rickshaw market is also characterized by dynamic competition, with numerous manufacturers emerging from countries like China and India, offering a range of products that cater to various budget segments. Buyers should be aware of regional differences in quality standards and regulatory requirements, which can impact sourcing decisions.

How Can B2B Buyers Address Sustainability and Ethical Sourcing in the Loader Rickshaw Market?

Sustainability has become a crucial consideration for businesses in the loader rickshaw sector. The environmental impact of traditional fuel-based vehicles is prompting buyers to seek alternatives that minimize carbon footprints. This shift is leading to an increased demand for electric and hybrid loader rickshaws, which offer significant reductions in emissions and lower operational costs over time.

Ethical sourcing is equally important, as businesses look to build supply chains that prioritize social responsibility. Buyers should investigate their suppliers’ practices, ensuring that they adhere to fair labor standards and sustainable manufacturing processes. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Utilizing green materials in the production of loader rickshaws is another aspect of sustainability. Buyers should inquire about the use of recyclable components and environmentally friendly manufacturing processes. By prioritizing suppliers who align with these values, businesses can enhance their corporate social responsibility profiles while meeting consumer demand for sustainable products.

What Is the Historical Context of Loader Rickshaws That B2B Buyers Should Know?

The loader rickshaw has evolved significantly since its inception, originally designed as a simple form of transportation in densely populated regions. Over the years, advancements in engine technology and vehicle design have transformed these three-wheelers into robust cargo carriers capable of handling diverse loads.

In the early 2000s, the loader rickshaw began gaining traction in developing markets, especially in Asia, where it became an essential tool for small businesses and logistics operators. Its compact size and maneuverability made it ideal for urban environments, where larger vehicles struggle to operate. Today, loader rickshaws are recognized not only for their practicality but also for their potential to contribute to economic development, providing jobs and supporting local commerce.

As international B2B buyers explore this sector, understanding its evolution can provide valuable insights into market expectations and the opportunities for innovative solutions that cater to modern transportation needs.

Frequently Asked Questions (FAQs) for B2B Buyers of loder riksha

-

How do I solve issues with the durability of loader rickshaws?

To ensure the durability of loader rickshaws, it’s essential to select vehicles constructed from high-quality materials and designed for rigorous use. Look for suppliers that offer robust warranties and have a proven track record in the industry. Regular maintenance, such as timely servicing and using genuine parts, can also mitigate wear and tear. Additionally, inquire about the vehicle’s performance in various environmental conditions, as this can impact its longevity. -

What is the best engine size for a loader rickshaw used in urban areas?

For urban settings, a loader rickshaw with an engine size between 250cc to 300cc is generally ideal. This range provides a balance of power and efficiency, allowing for effective maneuverability in congested streets while carrying adequate cargo loads. Ensure that the engine meets local emissions regulations, as this is increasingly important in urban areas aiming for sustainability. -

How can I vet suppliers of loader rickshaws for reliability?

To vet suppliers, start by researching their reputation through online reviews and industry ratings. Request references from previous clients and evaluate their feedback regarding product quality and after-sales service. Additionally, assess the supplier’s production capabilities and certifications to ensure compliance with international standards. A site visit to their manufacturing facility can also provide insights into their operational practices and product quality. -

What are the common customization options available for loader rickshaws?

Customization options for loader rickshaws often include modifications in cargo capacity, engine type (petrol or electric), and design features such as enclosed cabins or specific color schemes. Some manufacturers offer tailored solutions to meet unique operational needs, such as temperature-controlled cargo areas for perishable goods. When discussing customization, ensure that you communicate your specific requirements clearly to the supplier. -

What is the minimum order quantity (MOQ) for loader rickshaws?

The minimum order quantity (MOQ) for loader rickshaws can vary significantly among suppliers, typically ranging from 5 to 50 units. Factors influencing MOQ include the supplier’s production capacity and the specific model you wish to order. It’s advisable to negotiate MOQs, especially if you are a smaller business or testing a new market, as many suppliers may be flexible in order to establish a long-term relationship. -

What payment terms should I expect when purchasing loader rickshaws?

Payment terms for loader rickshaw purchases generally include options such as upfront payment, deposits (often 30-50%), and balance payments upon delivery. Some suppliers may also offer financing or installment plans. Always clarify the terms in the purchase agreement and consider using secure payment methods to protect your transaction, especially when dealing with international suppliers. -

How do I ensure quality assurance (QA) when importing loader rickshaws?

To ensure quality assurance, request detailed product specifications and certifications from the supplier, such as ISO quality management standards. Conduct pre-shipment inspections through third-party services to verify that the products meet your requirements before they leave the factory. Additionally, maintaining open communication with the supplier throughout the production process can help address any potential issues early. -

What logistics considerations should I keep in mind when importing loader rickshaws?

When importing loader rickshaws, consider logistics factors such as shipping methods (sea, air, or land), customs clearance procedures, and estimated delivery times. Collaborate with a reliable freight forwarder who can navigate international shipping regulations and ensure compliance with local import laws. Additionally, factor in insurance options for your shipment to safeguard against potential damages during transit.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 Loder Riksha Manufacturers & Suppliers List

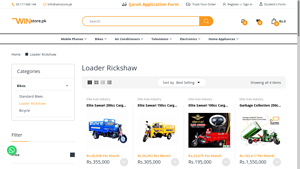

1. Facebook – United 150CC Loader Rickshaw Price

2. Elite Sawari – Loader Rickshaw Installments

Domain: winstore.pk

Registered: 2020 (5 years)

Introduction: Loader Rickshaw on Installments in Lahore Islamabad Pakistan. Available models include: 1. Elite Sawari 100cc Cargo Loader – Price: Rs.195,000, Monthly Installment: Rs.23,075. 2. Elite Sawari 150cc Cargo Loader – Price: Rs.305,000, Monthly Installment: Rs.36,092. 3. Elite Sawari 200cc Cargo Loader – Price: Rs.355,000, Monthly Installment: Rs.42,008. 4. Garbage Collection 250cc Loader – Price: Rs.1…

3. Akgev – E-Loader E-Rickshaw

Domain: akgev.com

Registered: 2023 (2 years)

Introduction: E-Loader E-Rickshaw: A sustainable urban transport solution designed for short-distance cargo and passenger transport in urban and semi-urban areas. Key features include:

– Eco-friendly: Fully electric with no tailpipe emissions, reducing carbon footprint.

– Efficiency and Versatility: Dual-purpose vehicle for both passengers and cargo, compact design for navigating congested streets.

– Low Mainte…

Strategic Sourcing Conclusion and Outlook for loder riksha

In navigating the complexities of the loader rickshaw market, international B2B buyers must prioritize strategic sourcing to ensure they acquire vehicles that not only meet their operational needs but also offer long-term value. The robust performance and reliability of models such as the 300cc rickshaw loader make them ideal for diverse commercial applications across various terrains. Additionally, considering factors such as after-sales support and customization options can significantly enhance the buyer’s experience and operational efficiency.

As buyers from Africa, South America, the Middle East, and Europe evaluate potential suppliers, it is crucial to engage with manufacturers that demonstrate a commitment to quality and customer satisfaction. A proactive approach in supplier selection will foster partnerships that are beneficial for both parties, driving growth and innovation within the logistics sector.

Looking ahead, the loader rickshaw industry is poised for continued growth, driven by urbanization and increasing demand for efficient transportation solutions. Now is the time for international buyers to explore partnerships with reputable suppliers to secure their share of this expanding market. Embrace the opportunity to enhance your logistics capabilities with strategic sourcing of loader rickshaws that can transform your business operations.