Introduction: Navigating the Global Market for diesel Fuel Dump Truck

In an increasingly competitive global market, sourcing the right diesel fuel dump truck can present a formidable challenge for B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. With diverse applications ranging from construction to waste management, the demand for reliable and efficient dump trucks is paramount. This guide serves as a comprehensive resource for international buyers, detailing various types of diesel fuel dump trucks, their specific applications, and critical factors to consider during the purchasing process.

As you navigate through this guide, you will find actionable insights on supplier vetting, enabling you to discern trustworthy manufacturers from less reputable ones. We’ll delve into cost considerations, helping you establish a budget that aligns with your operational needs while ensuring you receive value for your investment. Additionally, we will explore the latest trends and technologies in the dump truck market, allowing you to make informed decisions that enhance your fleet’s efficiency and reliability.

By equipping you with the knowledge necessary to evaluate options effectively, this guide empowers B2B buyers to make strategic purchasing decisions that meet their unique operational requirements. Whether you are in Saudi Arabia, Nigeria, or elsewhere, understanding the nuances of the diesel fuel dump truck market will be crucial in optimizing your logistics and enhancing your business’s productivity.

Understanding diesel Fuel Dump Truck Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Dump Truck | Conventional design, single or tandem axle, versatile | Construction, landscaping, road maintenance | Pros: Versatile, easy to operate; Cons: Limited payload capacity compared to larger models. |

| Articulated Dump Truck | Jointed design for better maneuverability | Mining, quarrying, rough terrain hauling | Pros: Superior off-road capability; Cons: More expensive and complex maintenance. |

| Tri-Axle Dump Truck | Three axles for enhanced load capacity | Heavy construction, waste management | Pros: High load capacity; Cons: Requires more maintenance and can be less maneuverable. |

| Side Dump Truck | Unloads material from the side, often with a tilting mechanism | Road construction, debris removal | Pros: Fast unloading; Cons: Limited to specific applications, higher initial cost. |

| Transfer Dump Truck | Equipped with a trailer for extra payload capacity | Large-scale construction, aggregate transport | Pros: Increased payload efficiency; Cons: Requires more driving skill and can be cumbersome. |

What Are the Key Characteristics of Standard Dump Trucks?

Standard dump trucks are the most widely recognized type, characterized by their straightforward design, typically featuring a single or tandem axle configuration. They are versatile and can handle a variety of materials, making them suitable for applications such as construction, landscaping, and road maintenance. When purchasing, buyers should consider factors such as payload capacity, engine power, and the type of transmission, as these elements can significantly affect operational efficiency.

How Do Articulated Dump Trucks Differ in Design and Functionality?

Articulated dump trucks are designed with a joint between the cab and the dump box, allowing for improved maneuverability, especially in challenging terrains. This design makes them ideal for mining, quarrying, and transporting materials over rough ground. Key purchasing considerations include engine performance, off-road capabilities, and the truck’s weight distribution, as these factors impact both performance and safety in rugged environments.

What Advantages Do Tri-Axle Dump Trucks Offer for Heavy Hauling?

Tri-axle dump trucks are equipped with three axles, providing enhanced stability and a higher payload capacity, which is crucial for heavy construction projects and waste management operations. Buyers should evaluate the truck’s gross vehicle weight rating (GVWR) and the type of materials it will transport to ensure optimal performance. While these trucks can carry heavier loads, they require more frequent maintenance and can be less maneuverable in tight spaces.

Why Choose a Side Dump Truck for Specialized Applications?

Side dump trucks are specialized vehicles that unload materials from the side, often using a tilting mechanism. This feature allows for faster unloading, making them particularly useful in road construction and debris removal. However, their specialized nature may limit their versatility. When considering a side dump truck, buyers should assess the types of projects they will undertake and the truck’s unloading speed and efficiency to determine its suitability.

What Makes Transfer Dump Trucks Efficient for Large-Scale Operations?

Transfer dump trucks are unique in that they consist of a standard dump truck coupled with a trailer, enabling them to carry significantly larger payloads. This configuration is particularly advantageous for large-scale construction projects and aggregate transportation. Buyers should focus on the truck’s towing capacity, engine specifications, and overall maneuverability when making a purchase. While they offer increased efficiency, they require skilled drivers and can be challenging to navigate in congested areas.

Key Industrial Applications of diesel Fuel Dump Truck

| Industry/Sector | Specific Application of diesel Fuel Dump Truck | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Transporting materials like sand, gravel, and asphalt | Efficient delivery of bulk materials to job sites | Reliability, payload capacity, and fuel efficiency |

| Mining | Hauling ore and waste materials | Streamlined operations and reduced transportation costs | Durability, off-road capabilities, and maintenance support |

| Agriculture | Moving soil, compost, and fertilizers | Enhanced productivity in land preparation and crop management | Versatility, loading capacity, and ease of operation |

| Waste Management | Collecting and transporting construction debris | Improved waste disposal efficiency and compliance | Load capacity, durability, and environmental compliance |

| Infrastructure Development | Delivering materials for road and bridge construction | Timely project completion and cost savings | Reliability, fuel type compatibility, and service availability |

How is Diesel Fuel Dump Truck Used in the Construction Industry?

In the construction sector, diesel fuel dump trucks are essential for transporting bulk materials such as sand, gravel, and asphalt to various job sites. These trucks enable construction companies to maintain a steady supply of materials, ensuring projects progress without delays. Buyers in this sector should consider the truck’s reliability and payload capacity, as well as fuel efficiency, to optimize operational costs, especially in regions with challenging terrains like those found in parts of Africa and South America.

What Role Do Diesel Fuel Dump Trucks Play in the Mining Industry?

In mining operations, diesel fuel dump trucks are utilized to haul ore and waste materials from extraction sites to processing plants or disposal areas. Their robust design allows them to navigate rough terrains, ensuring efficient material transport. For international buyers, particularly in the Middle East and Africa, sourcing trucks that offer durability and off-road capabilities is crucial, as these factors directly impact the operational efficiency and cost-effectiveness of mining activities.

How Are Diesel Fuel Dump Trucks Beneficial to Agriculture?

In agriculture, diesel fuel dump trucks are used for transporting soil, compost, and fertilizers, which are vital for land preparation and crop management. By facilitating quick and efficient delivery of these materials, these trucks enhance the overall productivity of agricultural operations. Buyers should focus on the versatility and loading capacity of the trucks, ensuring they can handle various types of materials and terrain, which is particularly important in regions with diverse agricultural practices.

Why Are Diesel Fuel Dump Trucks Important in Waste Management?

For waste management companies, diesel fuel dump trucks serve the critical function of collecting and transporting construction debris and other waste materials. These trucks improve disposal efficiency and help businesses comply with local environmental regulations. When sourcing, businesses should prioritize load capacity and durability, as well as the truck’s ability to operate in urban environments where maneuverability may be a concern, especially in densely populated areas in Europe and the Middle East.

How Do Diesel Fuel Dump Trucks Support Infrastructure Development?

In infrastructure development, diesel fuel dump trucks are vital for delivering materials necessary for road and bridge construction projects. Their ability to transport large quantities of materials quickly contributes to timely project completion and cost savings. Buyers need to ensure that the trucks they select are reliable and compatible with the fuel types available in their regions, as this can significantly affect maintenance and operational costs, especially in developing markets in Africa and South America.

3 Common User Pain Points for ‘diesel Fuel Dump Truck’ & Their Solutions

Scenario 1: High Operational Costs and Inefficiency in Fuel Consumption

The Problem: Many B2B buyers, especially those operating in regions like Africa and South America, face the challenge of high operational costs associated with diesel fuel dump trucks. Fluctuating fuel prices and inefficient fuel consumption can severely impact profit margins. Buyers often find that their trucks consume more fuel than expected, leading to increased running costs and reduced competitiveness in the market. This issue is particularly pronounced in construction and mining sectors where trucks are frequently loaded and driven over rough terrains.

The Solution: To combat high fuel costs, buyers should invest in advanced fuel management systems that monitor and optimize fuel consumption. Implementing telematics solutions can provide real-time data on fuel usage, allowing fleet managers to identify inefficiencies and adjust driving behaviors. Additionally, selecting diesel dump trucks equipped with fuel-efficient engines and automatic transmissions can enhance performance and reduce consumption. Regular maintenance and proper tire inflation are also crucial; they can significantly impact fuel efficiency, making it vital to establish a routine maintenance schedule that includes checking and replacing air filters, lubricating moving parts, and ensuring tires are properly inflated.

Scenario 2: Lack of Reliable Maintenance and Support Services

The Problem: Another common pain point for international B2B buyers is the lack of reliable maintenance and after-sales support for diesel fuel dump trucks. In many regions, especially in the Middle East and parts of Africa, access to qualified service centers and genuine spare parts can be limited. This can lead to prolonged downtime during repairs, which ultimately affects project timelines and profitability.

The Solution: To mitigate this risk, buyers should prioritize purchasing from manufacturers and dealers that offer comprehensive after-sales support and a strong service network. Before making a purchase, it’s essential to inquire about the availability of service centers and the lead times for spare parts. Establishing a maintenance contract with a reputable service provider can also ensure regular inspections and timely repairs, minimizing downtime. Furthermore, investing in training for on-site mechanics can empower local teams to handle routine maintenance and minor repairs, reducing dependency on external service providers.

Scenario 3: Adapting to Local Regulations and Compliance Issues

The Problem: B2B buyers in diverse markets often struggle to navigate the complex landscape of local regulations regarding diesel emissions and safety standards. In regions like Europe and North America, stringent environmental regulations require compliance with specific emissions standards, which can be a source of confusion and concern for buyers looking to import or operate diesel fuel dump trucks.

The Solution: To address compliance challenges, buyers should conduct thorough research on the local regulations governing diesel emissions in their operating regions. Engaging with local regulatory bodies or industry associations can provide clarity on the requirements. Additionally, choosing diesel dump trucks that are compliant with the latest emissions standards (such as Euro 6 in Europe) will not only ensure legal operation but can also enhance the company’s reputation as an environmentally responsible business. Buyers should also consider investing in retrofit technologies or cleaner fuel options that reduce emissions, further aligning with sustainability goals while meeting regulatory requirements. Regular training sessions for staff on compliance issues can also help in staying updated with changing regulations and best practices.

Strategic Material Selection Guide for diesel Fuel Dump Truck

What Are the Key Materials Used in Diesel Fuel Dump Trucks?

When selecting materials for diesel fuel dump trucks, it is essential to consider their properties, durability, and suitability for specific applications. Here, we analyze four common materials used in the construction of these vehicles: steel, aluminum, composite materials, and rubber.

How Does Steel Perform in Diesel Fuel Dump Truck Applications?

Steel is the most widely used material in the construction of dump truck bodies and frames due to its exceptional strength and durability. It typically has a high tensile strength, allowing it to withstand heavy loads and harsh operating conditions. Steel also exhibits good corrosion resistance when properly treated, making it suitable for environments where exposure to moisture and chemicals is a concern.

Pros: Steel is relatively inexpensive compared to other materials, making it a cost-effective choice for manufacturers. Its high strength-to-weight ratio ensures that dump trucks can carry significant payloads without compromising structural integrity.

Cons: However, steel is heavier than alternatives like aluminum, which can impact fuel efficiency. Additionally, untreated steel is prone to rust, necessitating regular maintenance and protective coatings.

Impact on Application: Steel’s compatibility with various media makes it suitable for transporting aggregates, sand, and other construction materials. However, buyers should consider the specific environmental conditions, especially in humid or coastal regions.

International Considerations: Buyers from regions like Africa and the Middle East should ensure compliance with local regulations regarding emissions and safety standards. Familiarity with ASTM standards can facilitate quality assurance.

What Role Does Aluminum Play in Diesel Fuel Dump Truck Design?

Aluminum is increasingly popular for dump truck bodies due to its lightweight properties. It offers excellent corrosion resistance, making it ideal for applications where exposure to water and chemicals is frequent. Aluminum can also be easily molded and shaped, allowing for innovative designs.

Pros: The primary advantage of aluminum is its weight reduction, which can enhance fuel efficiency and payload capacity. It is also resistant to rust, reducing maintenance costs over time.

Cons: However, aluminum is generally more expensive than steel, which can increase the overall cost of the dump truck. It may also have lower tensile strength, requiring careful design to ensure structural integrity under heavy loads.

Impact on Application: Aluminum is suitable for transporting lighter materials, such as agricultural products or recyclables. Buyers should evaluate whether the weight savings justify the higher initial costs.

International Considerations: In Europe, compliance with DIN standards is crucial for ensuring that aluminum components meet safety and performance criteria. Buyers should also consider the availability of aluminum in their local markets.

How Do Composite Materials Enhance Diesel Fuel Dump Trucks?

Composite materials, such as fiberglass-reinforced plastics, are gaining traction in the dump truck industry due to their lightweight and high-strength characteristics. These materials offer excellent resistance to corrosion and impact, making them suitable for demanding applications.

Pros: Composites can significantly reduce vehicle weight, improving fuel efficiency and payload capacity. They also require minimal maintenance and have a long service life.

Cons: The primary drawback is the higher manufacturing complexity and cost associated with composites. Additionally, they may not be as widely available as steel or aluminum, depending on the region.

Impact on Application: Composites are particularly effective for specialized applications, such as transporting hazardous materials, where corrosion resistance is paramount.

International Considerations: Compliance with JIS standards is important for buyers in Asia, while European buyers should consider EU regulations regarding composite materials.

What Is the Importance of Rubber in Diesel Fuel Dump Trucks?

Rubber is predominantly used in the tires and seals of diesel fuel dump trucks. It offers excellent flexibility and resilience, making it essential for maintaining traction and ensuring a tight seal against contaminants.

Pros: Rubber provides good shock absorption and is resistant to wear, which is critical for vehicles operating on rough terrain.

Cons: However, rubber can degrade over time due to UV exposure and harsh chemicals, necessitating regular replacement.

Impact on Application: The performance of rubber components directly affects the truck’s handling and safety, particularly in off-road conditions.

International Considerations: Buyers should be aware of local regulations regarding tire specifications and environmental impact, particularly in regions with stringent vehicle emissions standards.

Summary Table of Material Selection for Diesel Fuel Dump Trucks

| Material | Typical Use Case for diesel Fuel Dump Truck | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Dump truck frames and bodies | High strength and durability | Heavier than alternatives | Medium |

| Aluminum | Lightweight dump truck bodies | Excellent corrosion resistance | Higher cost than steel | High |

| Composite | Specialized applications (e.g., hazardous) | Lightweight and low maintenance | Higher manufacturing complexity | High |

| Rubber | Tires and seals | Good shock absorption and flexibility | Degrades over time | Medium |

This comprehensive analysis of materials highlights the critical considerations for international B2B buyers of diesel fuel dump trucks. Understanding the properties, advantages, and limitations of each material can aid in making informed purchasing decisions that align with operational needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for diesel Fuel Dump Truck

What Are the Key Stages in the Manufacturing Process of Diesel Fuel Dump Trucks?

The manufacturing process of diesel fuel dump trucks involves several critical stages, each designed to ensure that the final product meets rigorous performance and safety standards. Understanding these stages can help B2B buyers make informed decisions when sourcing trucks for their operations.

1. Material Preparation: What Raw Materials Are Used?

The manufacturing process begins with the selection and preparation of raw materials. Key materials include high-strength steel for the chassis and dump body, aluminum for weight reduction, and various alloys for components like axles and transmissions. Suppliers often adhere to international standards, ensuring that materials are sourced from reputable vendors. This stage may involve cutting, shaping, and treating materials to enhance durability and resistance to corrosion.

2. Forming: How Are the Components Shaped?

During the forming stage, raw materials are transformed into components through processes such as stamping, welding, and machining. Advanced techniques like robotic welding ensure precision and consistency in joining parts, while CNC (Computer Numerical Control) machining is used to create intricate components with tight tolerances. This stage is crucial for creating the structural integrity of the dump truck, as it influences its ability to withstand heavy loads.

3. Assembly: What Happens During the Assembly Phase?

The assembly stage involves the integration of various components into a complete truck. This includes mounting the chassis, installing the engine, transmission, and hydraulic systems, and attaching the dump body. Quality control checks are often conducted at this point to ensure that all systems are installed correctly and function as intended. For B2B buyers, understanding the assembly process can provide insights into the craftsmanship and attention to detail that goes into each truck.

4. Finishing: What Are the Final Touches?

Finishing includes painting, coating, and applying protective treatments to enhance durability and aesthetic appeal. Manufacturers may use eco-friendly paints and coatings to comply with environmental regulations. This stage also involves final quality checks and preparations for delivery, ensuring that the truck meets all specifications before it leaves the factory.

What Quality Assurance Standards Are Relevant for Diesel Fuel Dump Trucks?

Quality assurance (QA) is vital in the manufacturing of diesel fuel dump trucks, ensuring that products meet international and industry-specific standards. For B2B buyers, understanding these standards can aid in supplier selection and risk management.

ISO 9001: Why Is This Standard Important?

ISO 9001 is a widely recognized quality management system standard that outlines requirements for a quality management system (QMS). Manufacturers adhering to ISO 9001 demonstrate their commitment to consistent quality and customer satisfaction. This certification can be a strong indicator of a supplier’s reliability, especially for international buyers.

CE Marking: What Does It Indicate?

For buyers in Europe, CE marking is essential as it signifies that a product complies with EU safety, health, and environmental protection standards. The CE mark assures buyers that the dump truck meets EU regulations, making it a critical consideration for suppliers targeting the European market.

API Standards: How Do They Apply to Heavy-Duty Trucks?

The American Petroleum Institute (API) sets standards for oil and gas equipment, including components used in diesel engines. Compliance with API standards can assure buyers that the trucks are equipped with high-quality, reliable components, particularly important for those in regions with stringent energy regulations.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are integral to ensuring that the manufacturing process adheres to established standards. These checkpoints can be categorized into three main areas:

1. Incoming Quality Control (IQC): How Are Materials Inspected?

IQC involves the inspection of raw materials upon arrival at the manufacturing facility. This step ensures that materials meet specified quality standards before they enter the production process. Buyers should inquire about a supplier’s IQC procedures, as rigorous inspections can prevent defects in the final product.

2. In-Process Quality Control (IPQC): What Is Monitored During Production?

During the production process, IPQC involves ongoing monitoring and testing of components and assemblies. This may include dimensional checks, functional testing of systems, and inspections for welding quality. Effective IPQC helps identify issues early, minimizing the risk of defects in the finished truck.

3. Final Quality Control (FQC): What Are the Last Steps Before Delivery?

FQC is the final checkpoint before a dump truck is shipped to customers. This stage involves comprehensive testing, including performance tests, safety inspections, and verification of all specifications. A thorough FQC process can provide B2B buyers with confidence in the reliability and performance of their purchased trucks.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, verifying a supplier’s quality control processes is crucial to mitigating risks associated with procurement. Here are some effective methods:

1. Conducting Supplier Audits: What to Look For?

Performing on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control practices. During an audit, buyers should assess the supplier’s adherence to quality standards, equipment maintenance, and employee training protocols.

2. Requesting Quality Control Reports: What Information Is Essential?

Buyers should request detailed quality control reports from suppliers, including information on testing procedures, inspection results, and any corrective actions taken for defects. These reports can offer transparency and help buyers assess the supplier’s commitment to quality.

3. Engaging Third-Party Inspectors: How Can They Help?

Utilizing third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes. These inspectors can conduct checks at various stages of production, ensuring that the manufacturer meets all specified standards before delivery.

What Are the Quality Control Nuances for International Buyers?

International buyers must navigate unique challenges related to quality control, particularly when sourcing from different regions. Understanding these nuances can enhance procurement strategies:

1. Compliance with Local Regulations: What Should Buyers Know?

Different regions may have specific regulations and standards governing the manufacturing of diesel fuel dump trucks. Buyers should familiarize themselves with local compliance requirements in their target markets, such as emissions standards in Europe or safety regulations in Africa.

2. Cultural Considerations: How Do They Impact Quality?

Cultural differences can influence quality perceptions and practices. Buyers should consider local manufacturing practices and quality expectations when evaluating suppliers. Establishing clear communication channels can help bridge any cultural gaps.

3. Currency and Logistics: What Are the Implications?

International procurement often involves currency fluctuations and logistics challenges. Buyers should account for these factors when negotiating contracts and establishing quality benchmarks to ensure that quality is maintained throughout the supply chain.

By understanding the manufacturing processes and quality assurance practices associated with diesel fuel dump trucks, B2B buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diesel Fuel Dump Truck’

Introduction

Sourcing a diesel fuel dump truck requires a systematic approach to ensure you make informed decisions that align with your operational needs and budget. This guide provides a step-by-step checklist for B2B buyers, focusing on critical factors that affect procurement, especially for international markets in Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before you start contacting suppliers, clearly outline the specifications required for your dump truck. Consider factors such as payload capacity, engine type, transmission, and body material. This ensures that you evaluate trucks that meet your specific operational demands, reducing the risk of mismatches and subsequent costs.

- Payload Capacity: Determine the maximum weight the truck needs to carry.

- Engine Requirements: Assess if you need a high horsepower engine for more demanding tasks.

Step 2: Research and Identify Potential Suppliers

Begin your search for reputable suppliers in the market. Utilize online platforms, industry directories, and trade shows to compile a list of potential vendors. Selecting suppliers with a solid reputation can significantly influence the quality and reliability of your procurement process.

- Online Research: Use platforms like Commercial Truck Trader to find listings.

- Local Dealers: Engage with local dealerships in your region for immediate support and service.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with industry standards. This is crucial to ensure that the trucks meet safety and performance regulations in your region, which can vary significantly across different countries.

- ISO Certifications: Look for ISO 9001 or similar certifications indicating quality management.

- Environmental Compliance: Confirm that the vehicles meet emissions standards relevant to your location.

Step 4: Request Quotes and Compare Pricing

Once you have a shortlist of suppliers, request detailed quotes. Compare not just the prices but also the terms of sale, warranty options, and after-sales support. Understanding the total cost of ownership, including maintenance and fuel efficiency, is essential for budgeting.

- Breakdown of Costs: Ensure the quote includes all potential costs, such as shipping and import duties.

- Financing Options: Inquire about financing or leasing options available for larger purchases.

Step 5: Inspect the Trucks Thoroughly

If possible, conduct an on-site inspection of the trucks you are considering. This allows you to assess their condition and functionality, especially for used models. Look for signs of wear and tear that may not be evident in photos.

- Physical Inspection: Check the body, engine condition, and interior features.

- Test Drive: If feasible, take the truck for a test drive to evaluate performance.

Step 6: Review Warranty and Service Agreements

Before finalizing your purchase, carefully review the warranty and service agreements offered by the supplier. A strong warranty can save you significant costs in the long run and ensure peace of mind.

- Coverage Details: Understand what is included and excluded in the warranty.

- Service Availability: Confirm that the supplier offers service support in your region for maintenance and repairs.

Step 7: Finalize the Purchase Agreement

Once you are satisfied with all aspects of the truck and supplier, proceed to finalize the purchase agreement. Ensure that all terms discussed are documented, including payment terms, delivery schedules, and any contingencies.

- Clear Documentation: Ensure all agreements are in writing to prevent future disputes.

- Payment Security: Consider secure payment methods that protect both parties.

By following this checklist, you will enhance your chances of successfully sourcing a diesel fuel dump truck that meets your operational needs while navigating the complexities of international procurement.

Comprehensive Cost and Pricing Analysis for diesel Fuel Dump Truck Sourcing

What Are the Key Cost Components of Diesel Fuel Dump Trucks?

When sourcing diesel fuel dump trucks, understanding the cost structure is essential. The primary cost components include:

-

Materials: The quality and type of materials used significantly impact pricing. For instance, high-strength steel for dump bodies or advanced composites can increase costs but enhance durability and performance.

-

Labor: Labor costs can vary based on the region and skill level required for assembly and customization. Countries with lower labor costs may offer competitive pricing, but ensure that the quality of workmanship meets international standards.

-

Manufacturing Overhead: This encompasses utilities, facilities, and indirect labor. Efficient manufacturing processes can help minimize these costs, resulting in more competitive pricing.

-

Tooling: The initial investment in specialized tools for production can affect pricing. Suppliers with advanced tooling may provide better quality and faster turnaround times.

-

Quality Control (QC): Robust QC measures ensure that the trucks meet safety and performance standards. While this may increase upfront costs, it can reduce long-term expenses related to repairs and warranty claims.

-

Logistics: Transportation costs from the manufacturing site to the buyer’s location can vary widely. Factors such as distance, mode of transport, and current fuel prices play a crucial role in logistics costs.

-

Margin: Suppliers typically include a profit margin that reflects their business model, market demand, and competition. Understanding this margin can aid in negotiations.

How Do Price Influencers Affect Diesel Fuel Dump Truck Sourcing?

Several factors influence the pricing of diesel fuel dump trucks, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to better pricing due to economies of scale. Buyers should assess their needs and consider bulk purchasing to reduce costs.

-

Specifications and Customization: Custom features, such as enhanced payload capacity or specific engine types, can increase costs. Clearly defining requirements can help manage expenses.

-

Materials: The choice of materials impacts not only the initial cost but also the truck’s longevity and maintenance needs. Investing in higher-quality materials may yield savings over the truck’s lifecycle.

-

Quality Certifications: Trucks that meet international quality standards (e.g., ISO certifications) may have higher upfront costs but can offer long-term reliability and lower operational costs.

-

Supplier Factors: Supplier reputation, reliability, and after-sales support are critical. A well-regarded supplier may charge a premium, but their service and product quality can justify the cost.

-

Incoterms: Understanding international shipping terms (Incoterms) is vital. These terms dictate who bears the cost and risk at each stage of the shipping process, impacting overall pricing.

What Are Effective Buyer Tips for Negotiating Diesel Fuel Dump Truck Prices?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant savings:

-

Research and Benchmarking: Gather pricing data from multiple suppliers to understand market rates. Use this information to negotiate better terms.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, fuel efficiency, and resale value. A slightly higher upfront cost may lead to lower operational costs over time.

-

Be Clear About Specifications: Providing detailed specifications can reduce misunderstandings and ensure you receive the right product at the right price.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Regular communication and feedback can foster trust and collaboration.

-

Understand Local Market Conditions: Economic factors, currency fluctuations, and local regulations can influence pricing. Staying informed can help you navigate these challenges effectively.

Disclaimer on Indicative Prices

Prices for diesel fuel dump trucks can fluctuate based on market conditions, regional demand, and supplier strategies. The examples provided are indicative and should be used as a reference point only. Always conduct thorough research and engage directly with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing diesel Fuel Dump Truck With Other Solutions

Exploring Alternatives to Diesel Fuel Dump Trucks

When considering heavy-duty transportation and material handling solutions, diesel fuel dump trucks are a popular choice due to their efficiency and robustness. However, various alternatives offer distinct advantages that may better suit specific operational needs. This analysis compares diesel fuel dump trucks with electric dump trucks and articulated dump trucks, providing insights into their relative performance and application.

| Comparison Aspect | Diesel Fuel Dump Truck | Electric Dump Truck | Articulated Dump Truck |

|---|---|---|---|

| Performance | High power and capacity; suited for heavy loads | Limited range but growing power; ideal for urban areas | Excellent off-road capability; flexible in tight spaces |

| Cost | Higher upfront and operational costs due to fuel | Initial high investment; lower running costs | Moderate upfront cost; fuel-efficient with lower maintenance |

| Ease of Implementation | Widely available; established technology | Requires charging infrastructure; gaining acceptance | Versatile design; easy to integrate into existing fleets |

| Maintenance | Regular maintenance needed; parts widely available | Lower maintenance; fewer moving parts | Requires specialized maintenance; robust design |

| Best Use Case | Construction, mining, and heavy-duty applications | Urban construction and environmentally sensitive areas | Construction sites with uneven terrain and tight spaces |

In-Depth Analysis of Alternatives

What Are the Benefits and Drawbacks of Electric Dump Trucks?

Electric dump trucks are gaining traction as an eco-friendly alternative to traditional diesel models. They produce zero emissions during operation, making them ideal for urban construction sites where air quality regulations are stringent. However, their range is limited, and they require a reliable charging infrastructure, which may not be feasible in remote locations. The initial investment is typically higher than diesel counterparts, but lower operational costs can lead to savings over time.

Why Consider Articulated Dump Trucks?

Articulated dump trucks excel in off-road conditions, making them suitable for construction sites with uneven terrain. Their flexible design allows for maneuverability in tight spaces, which is a significant advantage on crowded job sites. While they are generally more fuel-efficient than traditional rigid dump trucks, they may require specialized maintenance and are not as powerful as diesel dump trucks for heavy loads. Articulated dump trucks are often a preferred choice for projects that demand adaptability and versatility.

How Can B2B Buyers Make the Right Choice for Their Needs?

Selecting the appropriate solution depends heavily on the specific requirements of your operations. For projects with heavy lifting and tough terrains, diesel fuel dump trucks remain a reliable option due to their proven performance and widespread availability. However, if your focus is on sustainability and urban projects, investing in electric dump trucks could align better with regulatory demands and corporate responsibility goals. Meanwhile, articulated dump trucks provide a middle ground, offering both versatility and efficiency in varied environments. Ultimately, a thorough assessment of project demands, budget constraints, and long-term operational goals will guide B2B buyers to the best solution for their specific needs.

Essential Technical Properties and Trade Terminology for diesel Fuel Dump Truck

What Are the Essential Technical Properties of Diesel Fuel Dump Trucks?

Understanding the technical specifications of diesel fuel dump trucks is crucial for international buyers, especially when considering the demands of diverse operational environments. Here are several key properties that should be evaluated:

1. Payload Capacity

Payload capacity indicates the maximum weight a dump truck can carry, typically expressed in tons. This specification is vital for B2B buyers because it directly affects operational efficiency and profitability. Choosing a truck with an appropriate payload capacity ensures compliance with local regulations and optimizes delivery times for materials.

2. Engine Power and Type

The engine power, usually measured in horsepower (HP), determines the truck’s performance capabilities. Diesel engines are preferred for dump trucks due to their durability and fuel efficiency. A powerful engine can handle heavy loads and steep inclines, making it essential for construction and mining operations. Buyers should assess the engine type to ensure it meets their operational needs while considering maintenance and fuel costs.

3. Transmission System

The type of transmission—automatic or manual—affects the driving experience and overall efficiency. Automatic transmissions are generally easier to operate and can enhance productivity by allowing drivers to focus on load management rather than gear shifting. For B2B buyers, understanding the transmission system can influence driver comfort and operational costs.

4. Dump Body Material and Design

The dump body is typically made from steel or aluminum, each offering different advantages. Steel is more durable and better suited for heavy-duty applications, while aluminum is lighter and may improve fuel efficiency. The design, including the angle of the dump bed and tailgate configuration, also impacts unloading efficiency. Buyers should consider these factors to ensure the truck meets their specific material handling requirements.

5. Axle Configuration

Dump trucks can have various axle configurations, such as single, tandem, or tri-axle setups. The axle configuration affects load distribution, stability, and maneuverability. For instance, tri-axle dump trucks provide better stability under heavy loads, making them ideal for construction sites. Buyers must consider the terrain and load types when selecting an axle configuration.

6. Braking System

The braking system is critical for safety, especially when transporting heavy loads. Most dump trucks utilize air brakes, which are more effective for larger vehicles. Understanding the braking system can help buyers ensure their equipment meets safety standards and operational demands.

What Are Common Trade Terms Related to Diesel Fuel Dump Trucks?

Familiarity with trade terminology is essential for B2B buyers to navigate negotiations and contracts effectively. Here are several important terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. When purchasing a dump truck, buyers should consider OEM parts for reliability and compatibility, ensuring that replacement parts are readily available.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers planning bulk purchases, as it can influence overall costs and inventory management.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products or services. Buyers should prepare a detailed RFQ to receive accurate pricing and terms, facilitating better decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms helps buyers manage logistics effectively and avoid unexpected costs.

5. Lead Time

Lead time is the amount of time it takes from placing an order to receiving the product. For B2B buyers, knowing the lead time is vital for project planning and ensuring that equipment is available when needed.

6. Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product. Understanding warranty terms can protect buyers from unexpected repair costs and ensure product quality, which is particularly important for large investments like dump trucks.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when investing in diesel fuel dump trucks, ultimately enhancing operational efficiency and profitability.

Navigating Market Dynamics and Sourcing Trends in the diesel Fuel Dump Truck Sector

What Are the Current Market Dynamics and Key Trends Influencing Diesel Fuel Dump Trucks?

The diesel fuel dump truck sector is experiencing significant transformation driven by a combination of global economic factors and technological advancements. As infrastructure projects expand across Africa, South America, the Middle East, and Europe, the demand for reliable and efficient dump trucks is surging. Countries like Nigeria and Saudi Arabia are investing heavily in construction and mining, leading to increased procurement of heavy-duty vehicles. The current trend leans towards trucks with enhanced fuel efficiency and lower emissions, influenced by stringent environmental regulations.

Emerging technologies are reshaping the sourcing landscape. Digital platforms for procurement are gaining traction, enabling international buyers to access a wider range of suppliers and negotiate better deals. Additionally, telematics and IoT are being integrated into dump trucks, providing real-time data on vehicle performance and maintenance needs. This not only optimizes operational efficiency but also aids in predictive maintenance, reducing downtime for businesses.

Another critical trend is the shift towards electric and hybrid dump trucks. Although diesel remains the primary fuel type, the industry is witnessing a gradual transition towards alternative fuels, driven by the need for sustainable operations. This evolution presents opportunities for B2B buyers to explore innovative solutions that align with global sustainability goals while also meeting their operational needs.

How Are Sustainability and Ethical Sourcing Addressed in the Diesel Fuel Dump Truck Sector?

Sustainability is becoming increasingly important in the diesel fuel dump truck sector. The environmental impact of diesel vehicles has led to heightened scrutiny from governments and consumers alike, urging manufacturers to adopt greener practices. Ethical sourcing of materials, such as recycled steel for truck bodies and eco-friendly components, is now a priority for many manufacturers, reflecting a commitment to reducing the carbon footprint.

B2B buyers should consider suppliers that prioritize sustainability certifications. Certifications such as ISO 14001 for environmental management and LEED for sustainable building practices can indicate a supplier’s commitment to environmentally responsible operations. Additionally, opting for manufacturers that utilize advanced emissions control technologies can further enhance a company’s sustainability profile.

Moreover, buyers are encouraged to engage with suppliers who are transparent about their supply chain practices, ensuring that the materials used in their dump trucks are sourced ethically. This not only bolsters the credibility of the buyer’s operations but also aligns with the growing consumer demand for responsible sourcing.

What Is the Historical Context of Diesel Fuel Dump Trucks in the B2B Market?

The diesel fuel dump truck has evolved significantly since its inception in the early 20th century. Initially designed for simple hauling tasks, advancements in engine technology and materials have transformed these vehicles into sophisticated machines capable of handling heavy loads in challenging environments. The introduction of diesel engines in the mid-1900s significantly enhanced power and fuel efficiency, making them the preferred choice for construction and mining operations.

Over the decades, the market has responded to changing regulations and environmental concerns, leading to the integration of advanced technologies such as automated transmissions and telematics systems. This evolution has not only improved operational efficiency but has also positioned diesel fuel dump trucks as essential assets in the global supply chain. Today, as the industry navigates the dual pressures of performance and sustainability, the next phase of development is likely to focus on hybrid and electric alternatives, marking another significant chapter in the history of dump trucks.

In summary, international B2B buyers must stay informed about market dynamics, prioritize sustainability, and understand the historical context of diesel fuel dump trucks to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of diesel Fuel Dump Truck

-

How do I choose the right diesel fuel dump truck for my business needs?

Selecting the right diesel fuel dump truck involves evaluating your operational requirements. Consider the truck’s payload capacity, engine power, and chassis design to match your specific tasks, whether for construction, landscaping, or municipal work. Assess the truck’s durability and maintenance history, especially if considering used models. Additionally, understand local regulations regarding emissions and weight limits, as these can affect your choice. Consulting with suppliers and reviewing performance reports can also provide valuable insights into the best fit for your business. -

What are the key specifications to look for in a diesel dump truck?

When sourcing a diesel dump truck, key specifications to consider include the Gross Vehicle Weight Rating (GVWR), engine horsepower, transmission type, and dump body size. Look for trucks with robust axles and suspension systems suitable for heavy loads. Fuel efficiency and emissions ratings are increasingly important, particularly in regions with stringent environmental regulations. Additionally, consider the availability of features such as hydraulic systems for the dump bed and options for customization based on specific operational needs. -

What are the typical payment terms when purchasing a diesel fuel dump truck?

Payment terms for diesel fuel dump trucks can vary significantly by supplier and region. Common arrangements include upfront payments, installment plans, or financing options through third-party lenders. It’s crucial to clarify whether the price includes taxes, shipping, and any additional fees. Many suppliers may offer discounts for bulk purchases or prompt payment. Always negotiate terms that align with your cash flow capabilities, and consider establishing a relationship with a bank that understands equipment financing for better terms. -

How can I vet suppliers for diesel fuel dump trucks in international markets?

Vetting suppliers involves researching their reputation, financial stability, and experience in the industry. Look for online reviews, request references, and verify their business licenses. Attending trade shows or industry events can provide insights into suppliers’ credibility. Utilize platforms like Alibaba or Global Sources to assess their product offerings and customer feedback. Additionally, consider conducting site visits or requesting product samples to ensure the quality and reliability of the trucks being offered. -

What is the process for customizing a diesel dump truck for specific applications?

Customization of diesel dump trucks typically begins with discussing your specific needs with the manufacturer or dealer. This can include modifications to the dump body size, hydraulic systems, or additional features like toolboxes and tarps. Many manufacturers offer customization options, but it’s essential to communicate your requirements clearly to ensure compatibility with the truck’s specifications. Be prepared to discuss timelines and costs associated with custom features, as these can affect delivery schedules. -

What are the logistics considerations when importing diesel dump trucks?

Importing diesel dump trucks involves several logistical considerations, including shipping methods, customs regulations, and import duties. Determine the best shipping option—containerized shipping or roll-on/roll-off (RoRo)—based on your budget and timeline. Ensure compliance with local regulations regarding emissions and safety standards. Work with a reliable freight forwarder who specializes in heavy equipment to navigate the complexities of documentation and customs clearance, ensuring a smooth delivery process. -

What are the common quality assurance practices for diesel dump trucks?

Quality assurance practices in the diesel dump truck industry often include rigorous inspections during manufacturing, testing of critical components, and adherence to industry standards such as ISO certifications. Before finalizing a purchase, request documentation of the truck’s inspection reports and warranties. Many suppliers also offer post-sale support, including maintenance services and spare parts availability. Engaging in a thorough pre-delivery inspection can help identify any potential issues before the truck enters service. -

What are the minimum order quantities (MOQ) for purchasing diesel dump trucks?

Minimum order quantities (MOQ) for diesel dump trucks can vary widely depending on the supplier and the region. Some manufacturers may have no MOQ for individual sales, while others might require bulk purchases to ensure cost-effectiveness. It’s essential to clarify these terms upfront to avoid unexpected costs. If you are a smaller buyer, consider forming a purchasing consortium with other companies to meet MOQ requirements and secure better pricing and terms.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Diesel Fuel Dump Truck Manufacturers & Suppliers List

1. Know-How Equipment – 105 Tons Diesel Fuel Dump Truck

Domain: know-howequipment.com

Registered: 2022 (3 years)

Introduction: 105 Tons Diesel Fuel Dump Truck

2. Facebook – Inline Fuel Pump Solution

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Inline Fuel Pump Solution, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Dump Truck Dispatcher – Start-Up Costs Breakdown

Domain: dumptruckdispatcher.com

Introduction: Start-up costs for a dump truck company include: 1. Truck Payment: $550/month for 72 months, totaling $45,000. 2. Registration: $1,600 (one-time). 3. Sales Tax: $2,700 (one-time). 4. Permits and Licenses: $200 (one-time). 5. Liability Insurance ($1M): $833/month, totaling $9,996. 6. Fuel: $3,702/month, totaling $44,424. 7. Tires: $4,000 (one-time for 10 tires). 8. Driver Wages: $4,526/month, total…

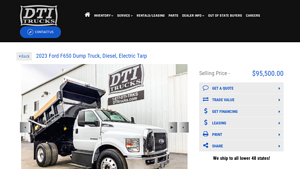

4. Ford – 2023 F650 Dump Truck

Domain: dtitrucks.com

Registered: 2007 (18 years)

Introduction: {“Year”: 2023, “Make”: “Ford”, “Model”: “F650 Dump Truck”, “Condition”: “Pre-Owned”, “Price”: “$95,500.00”, “Mileage”: “6,922 Miles”, “Engine”: “6.7L Powerstroke Turbo Diesel V8”, “Horsepower”: “270 HP”, “Transmission”: “Torqshift 6 Speed Automatic”, “GVWR”: “26,000 lbs”, “Front Axle”: “8,500 lbs”, “Rear Axle”: “17,500 lbs”, “Wheel Base”: “164 inches”, “Cab”: “Standard Cab”, “Suspension”: “Spring …

5. Dump Truck Pricing – Key Factors

Domain: badgertruck.com

Registered: 1998 (27 years)

Introduction: The cost of a dump truck can vary significantly based on several factors including the type of dump truck, its size, brand, and additional features. New dump trucks typically range from $30,000 to $200,000, while used dump trucks can be found for $10,000 to $100,000. Factors influencing the price include the truck’s capacity, whether it is a standard or specialized model, and the condition of the …

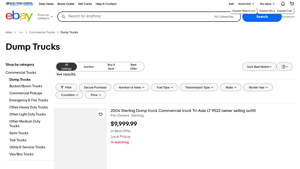

6. Dump Trucks – Various Makes & Models

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Dump Trucks available on eBay include various makes and models such as Ford, Kenworth, International, Sterling, and more. Key specifications include number of axles (Single, Tandem, Tri), fuel type (Diesel, Gas), transmission type (Automatic, Manual), and model years ranging from 1999 to 2024. Prices vary significantly, with listings under ZAR 442,268, between ZAR 442,268 to ZAR 971,219, and over …

Strategic Sourcing Conclusion and Outlook for diesel Fuel Dump Truck

In conclusion, strategic sourcing for diesel fuel dump trucks is essential for international B2B buyers seeking to optimize their procurement processes. By understanding the diverse offerings in the market, from new models to used options, buyers can make informed decisions that align with their operational needs and budget constraints. The competitive pricing landscape across various regions, including Africa, South America, the Middle East, and Europe, highlights the importance of thorough market analysis and supplier evaluation.

Investing in strategic sourcing not only ensures access to high-quality equipment but also fosters long-term partnerships with suppliers who can provide ongoing support and maintenance. As the demand for efficient and reliable dump trucks continues to grow, leveraging data-driven insights and market trends will empower buyers to stay ahead of the competition.

Looking forward, it is crucial for international buyers to actively engage with reputable suppliers and manufacturers to secure the best deals and innovations in diesel fuel dump trucks. By prioritizing strategic sourcing, businesses can enhance their fleet capabilities and drive sustainable growth in their respective markets. Now is the time to take action—explore your options and connect with trusted partners to elevate your procurement strategy.