Introduction: Navigating the Global Market for truck Tractor Units

In an increasingly competitive landscape, sourcing reliable truck tractor units can pose significant challenges for international B2B buyers. With a diverse array of models and manufacturers available, navigating the complexities of quality, pricing, and suitability for specific applications is critical. This comprehensive guide aims to illuminate the multifaceted global market for truck tractor units, providing insights into various types, applications, and the nuances of supplier vetting.

From understanding the differences between conventional and specialized units to evaluating costs and financing options, this resource is designed to empower decision-makers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Vietnam and Brazil. By equipping buyers with the knowledge needed to make informed choices, this guide addresses crucial considerations that can impact operational efficiency and profitability.

As the demand for robust transport solutions continues to rise, having a thorough understanding of the market landscape will enable businesses to secure the most suitable equipment for their logistics needs. With actionable insights and expert recommendations, this guide serves as an essential tool for navigating the global market, ensuring that international buyers can confidently select the right truck tractor units for their operations.

Understanding truck Tractor Units Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conventional Tractor | Standard configuration, typically 4×2 or 6×2 axles | Long-haul freight transport | Pros: Versatile, widely available. Cons: May lack specialized features for niche applications. |

| Heavy-Duty Tractor | Robust design, higher horsepower (500+ HP) | Heavy freight, construction materials | Pros: Superior towing capacity. Cons: Higher operational costs and maintenance. |

| Flatbed Tractor | Flatbed design for versatile cargo transport | Construction, agriculture, logistics | Pros: Flexibility in cargo types. Cons: Limited protection from elements. |

| Refrigerated Tractor | Equipped with refrigeration units for temperature control | Food and pharmaceutical transport | Pros: Essential for perishable goods. Cons: Higher initial investment. |

| Electric Tractor | Powered by electric batteries, low emissions | Urban logistics, short-haul transport | Pros: Eco-friendly, lower fuel costs. Cons: Limited range and charging infrastructure. |

What are the Characteristics of Conventional Tractors?

Conventional tractors are the backbone of long-haul freight transport, characterized by their standard 4×2 or 6×2 axle configurations. These tractors are designed for versatility, allowing them to handle various types of trailers, including flatbeds and refrigerated units. For B2B buyers, the primary consideration is the balance between upfront costs and operational efficiency, as conventional tractors are widely available and supported by extensive service networks.

How Do Heavy-Duty Tractors Stand Out?

Heavy-duty tractors are built for demanding applications, featuring robust frames and engines that typically exceed 500 horsepower. They are essential for transporting heavy freight or construction materials. B2B buyers should focus on the total cost of ownership, including fuel efficiency and maintenance, as these tractors can incur higher operational costs. However, their superior towing capacity justifies the investment for businesses dealing with heavy loads.

What Makes Flatbed Tractors a Flexible Choice?

Flatbed tractors offer a unique advantage for businesses needing to transport diverse cargo types, from machinery to building materials. Their open design allows for easy loading and unloading, making them a favorite in construction and agriculture. Buyers should evaluate the types of loads they frequently transport, as flatbeds provide flexibility but lack the protection that enclosed trailers offer.

Why Choose Refrigerated Tractors for Temperature-Sensitive Cargo?

Refrigerated tractors are specifically designed to transport temperature-sensitive goods, such as food and pharmaceuticals. Equipped with advanced refrigeration units, these tractors ensure that products remain within safe temperature ranges during transport. B2B buyers need to consider the higher initial investment and operational costs associated with these vehicles, but the ability to transport perishables securely can be a significant competitive advantage.

What are the Advantages and Challenges of Electric Tractors?

Electric tractors are gaining traction in urban logistics due to their low emissions and reduced fuel costs. These tractors are ideal for short-haul transport where charging infrastructure is available. B2B buyers should weigh the environmental benefits against the limitations of range and the current state of charging facilities. While the initial investment may be higher, the long-term savings on fuel and maintenance can make electric tractors an attractive option for forward-thinking businesses.

Key Industrial Applications of truck Tractor Units

| Industry/Sector | Specific Application of truck Tractor Units | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Transportation | Long-haul freight transportation | Efficient transport of goods over long distances | Consider fuel efficiency, maintenance support, and load capacity. |

| Construction | Heavy equipment transport to job sites | Timely delivery of machinery, reducing project delays | Look for durability, towing capacity, and compatibility with equipment. |

| Agriculture | Transporting agricultural products and machinery | Streamlined supply chain for perishable goods | Assess payload capacity, off-road capability, and engine power. |

| Mining | Hauling materials from mines to processing facilities | Enhanced productivity and reduced operational costs | Evaluate ruggedness, maintenance needs, and fuel type. |

| Waste Management | Collection and transport of waste materials | Improved efficiency in waste disposal processes | Focus on load capacity, emissions standards, and reliability. |

How Are Truck Tractor Units Used in Logistics and Transportation?

In the logistics and transportation sector, truck tractor units are essential for long-haul freight operations. They facilitate the movement of large volumes of goods across vast distances, ensuring timely deliveries. Buyers in this sector should prioritize fuel efficiency and maintenance support when sourcing units, as these factors significantly impact operational costs and delivery timelines. Additionally, considering the load capacity is vital to meet the demands of various freight types.

What Role Do Truck Tractor Units Play in Construction?

In construction, truck tractor units are crucial for transporting heavy equipment to job sites. Their ability to haul large machinery ensures that projects remain on schedule, minimizing downtime. Buyers should focus on the durability and towing capacity of these units, as they must withstand rough terrains and heavy loads. Compatibility with various construction equipment is also an important consideration to ensure seamless operations.

How Are Truck Tractor Units Applied in Agriculture?

Truck tractor units are widely used in agriculture for transporting products and machinery. They streamline the supply chain, particularly for perishable goods that require timely delivery to markets. Buyers in the agricultural sector should assess the payload capacity and off-road capabilities of tractor units, as these factors influence their effectiveness in rural areas. Engine power is another key requirement, especially for navigating challenging terrains.

What Benefits Do Truck Tractor Units Provide in Mining Operations?

In the mining industry, truck tractor units are instrumental in hauling materials from extraction sites to processing facilities. Their robust design and high load capacities enhance productivity and reduce operational costs. When sourcing tractor units for mining, it is critical to evaluate their ruggedness and maintenance needs, as these units operate in harsh environments. Fuel type considerations are also essential, particularly in regions with specific fuel availability.

How Do Truck Tractor Units Enhance Waste Management?

Truck tractor units are pivotal in waste management for the collection and transport of waste materials. They improve the efficiency of waste disposal processes, enabling timely and effective waste management solutions. Buyers in this sector should focus on load capacity, emissions standards, and the reliability of the units, as these factors directly impact operational efficiency and compliance with environmental regulations.

3 Common User Pain Points for ‘truck Tractor Units’ & Their Solutions

Scenario 1: Navigating High Maintenance Costs for Truck Tractor Units

The Problem: One of the most pressing challenges B2B buyers face with truck tractor units is the high and often unpredictable maintenance costs. For companies operating in regions like Africa and South America, where access to parts and qualified technicians can be limited, unexpected breakdowns can severely disrupt logistics and increase operational costs. Moreover, many buyers may not have a clear understanding of the long-term maintenance requirements of different models, which can lead to costly surprises after purchase.

The Solution: To mitigate maintenance costs, buyers should conduct comprehensive research on the specific models they are considering, focusing on the total cost of ownership rather than just the initial purchase price. This includes looking into the availability of spare parts, the frequency of required maintenance, and the reputation of the manufacturer for reliability. Additionally, buyers should consider investing in models that are known for durability and lower maintenance needs, such as those from Volvo or Scania. Forming partnerships with local service providers who specialize in these tractor units can also ensure timely repairs, reducing downtime and costs. Finally, establishing a proactive maintenance schedule based on the manufacturer’s recommendations can help anticipate and manage potential issues before they escalate into major repairs.

Scenario 2: Ensuring Compliance with Regional Regulations

The Problem: B2B buyers often struggle with compliance related to emissions and safety regulations, especially when operating across multiple countries. For instance, European standards for emissions are significantly stricter than those in other regions, which can lead to confusion when sourcing truck tractor units. A lack of understanding about these regulations can result in hefty fines, operational delays, and even the inability to use certain vehicles in specific markets.

The Solution: To navigate regulatory complexities, it is essential for buyers to stay informed about the legal requirements in each country where they plan to operate. Collaborating with local experts or consultants who specialize in transportation compliance can provide invaluable insights. When purchasing truck tractor units, buyers should prioritize models that meet or exceed local emissions standards, such as Euro 6 for Europe or similar benchmarks for other regions. Additionally, manufacturers often provide documentation and support regarding compliance, which can help buyers ensure their fleet adheres to regulations. Building a relationship with a reliable dealer who understands the regulatory landscape can also facilitate smoother transactions and help avoid compliance-related issues.

Scenario 3: Selecting the Right Truck Tractor Unit for Diverse Loads

The Problem: B2B buyers frequently face difficulties in selecting the appropriate truck tractor units for varying types of cargo. For instance, transporting heavy machinery requires different specifications compared to hauling refrigerated goods. Misjudging the capabilities of a unit can lead to overloading, increased wear and tear, or even safety hazards, all of which can disrupt operations and lead to financial losses.

The Solution: Buyers should perform a thorough analysis of their typical cargo requirements and the routes they will operate on before making a purchase. This involves assessing load weight, dimensions, and the specific needs of the cargo (such as temperature control for perishables). When evaluating truck tractor units, it is important to consider factors such as engine power, axle configuration, and trailer compatibility. Utilizing tools like load calculators or consulting with logistics experts can help in making informed decisions. Additionally, buyers should consider versatile units that can be easily adapted for different types of loads, providing greater flexibility in operations. Investing in a fleet management system can also enhance efficiency by tracking loads and performance, ensuring that the right unit is deployed for each job.

Strategic Material Selection Guide for truck Tractor Units

What are the Key Materials Used in Truck Tractor Units?

When selecting materials for truck tractor units, it is essential to consider their properties and how they influence performance, durability, and cost-effectiveness. Here, we analyze four common materials used in the manufacturing of truck tractor units: steel, aluminum, composite materials, and rubber.

How Does Steel Impact the Performance of Truck Tractor Units?

Key Properties: Steel is known for its high tensile strength and excellent durability, making it suitable for high-stress applications. It can withstand extreme temperatures and pressures, which is critical for truck tractor units that operate under heavy loads.

Pros & Cons: The primary advantage of steel is its strength and longevity, which translates into lower maintenance costs over time. However, steel is relatively heavy, which can impact fuel efficiency. Additionally, it is susceptible to corrosion if not properly treated, requiring additional protective coatings.

Impact on Application: Steel is often used in the chassis, axles, and frames of truck tractor units due to its strength. However, buyers must consider corrosion resistance, especially in regions with high humidity or exposure to salt, such as coastal areas in South America or the Middle East.

Considerations for International Buyers: Compliance with international standards such as ASTM A36 or DIN 17100 is crucial. Buyers should also consider local regulations regarding emissions and weight limits, which can vary significantly across regions like Europe and Africa.

What Role Does Aluminum Play in Truck Tractor Units?

Key Properties: Aluminum is lightweight and has good corrosion resistance, making it an attractive alternative to steel in many applications. It can handle moderate temperatures and pressures effectively.

Pros & Cons: The major advantage of aluminum is its reduced weight, which enhances fuel efficiency and payload capacity. However, aluminum is generally more expensive than steel and may not provide the same level of strength, making it less suitable for heavy-duty applications without reinforcement.

Impact on Application: Aluminum is commonly used for body panels and certain structural components. Its corrosion resistance is particularly beneficial in humid environments, making it a preferred choice in tropical regions like Brazil and Southeast Asia.

Considerations for International Buyers: Buyers should ensure that aluminum components meet standards like ASTM B221 and consider the cost implications, especially in regions where aluminum is less readily available.

How Do Composite Materials Enhance Truck Tractor Unit Design?

Key Properties: Composite materials, often made from a combination of plastics and fibers, offer excellent strength-to-weight ratios and corrosion resistance. They can be engineered to withstand various environmental conditions.

Pros & Cons: Composites are lightweight and can be molded into complex shapes, allowing for innovative designs. However, they can be more expensive to manufacture and repair compared to traditional materials like steel and aluminum.

Impact on Application: Composites are increasingly used in interior components and some exterior applications where weight savings are crucial. Their resistance to corrosion makes them ideal for applications in harsh environments, such as the Middle East.

Considerations for International Buyers: Buyers should be aware of the specific manufacturing standards for composites, such as ASTM D3039. Understanding local supply chains for composite materials is also essential, particularly in emerging markets.

What is the Importance of Rubber in Truck Tractor Units?

Key Properties: Rubber is highly flexible and has excellent vibration-damping properties, making it essential for components such as tires, seals, and suspension systems.

Pros & Cons: The primary advantage of rubber is its ability to absorb shocks and vibrations, enhancing ride comfort and vehicle longevity. However, rubber can degrade over time due to exposure to UV light and ozone, necessitating regular maintenance and replacement.

Impact on Application: Rubber is critical for tires and suspension components, which directly affect performance and safety. The choice of rubber compounds can significantly influence traction and wear resistance.

Considerations for International Buyers: Buyers must consider local climate conditions, which can affect rubber performance. Compliance with international tire standards, such as ECE R30, is also vital for ensuring safety and performance.

Summary Table of Material Selection for Truck Tractor Units

| Material | Typical Use Case for Truck Tractor Units | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chassis, axles, frames | High strength and durability | Heavy and prone to corrosion | Medium |

| Aluminum | Body panels, structural components | Lightweight and corrosion-resistant | More expensive, lower strength | High |

| Composite | Interior components, lightweight parts | Excellent strength-to-weight ratio | Higher manufacturing costs | High |

| Rubber | Tires, seals, suspension systems | Vibration damping and flexibility | Degrades over time | Medium |

This strategic material selection guide provides B2B buyers with critical insights into the materials used in truck tractor units, enabling informed decisions that align with regional requirements and operational needs.

In-depth Look: Manufacturing Processes and Quality Assurance for truck Tractor Units

What Are the Key Stages in the Manufacturing Process of Truck Tractor Units?

The manufacturing process of truck tractor units involves several critical stages that ensure the final product meets stringent quality and performance standards. Understanding these stages is essential for B2B buyers looking to procure reliable equipment.

1. Material Preparation: Sourcing and Selection

The journey of a truck tractor unit begins with material preparation. Manufacturers source high-quality raw materials, such as steel, aluminum, and composite materials. These materials are selected based on their mechanical properties, weight, and cost-effectiveness.

Advanced technologies, such as computer-aided design (CAD) and finite element analysis (FEA), are often employed to evaluate material performance under various stress conditions. This ensures that only the best materials are chosen, which directly influences the durability and reliability of the finished product.

2. Forming: Transforming Raw Materials into Components

Once materials are prepared, they undergo various forming processes. Common techniques include stamping, bending, and welding. For instance, the chassis is typically formed through stamping and welding of steel sheets, while the cab might be constructed using aluminum for lightweight benefits.

Modern manufacturers also utilize advanced forming techniques like hydroforming and laser cutting, allowing for more complex shapes and improved strength-to-weight ratios. These processes not only enhance the structural integrity of the units but also contribute to fuel efficiency, an important consideration for buyers.

3. Assembly: Bringing Components Together

The assembly stage is where all the components come together to form a complete truck tractor unit. This process is often divided into sub-assemblies, including the drivetrain, cab, and chassis. Each sub-assembly undergoes rigorous inspections to ensure that they meet the required specifications before being integrated into the final product.

Automation plays a significant role in assembly, with robotic systems used for repetitive tasks, enhancing precision and reducing human error. This level of automation also allows for scalability, enabling manufacturers to respond quickly to market demand.

4. Finishing: Surface Treatment and Quality Enhancements

The finishing stage involves surface treatments that protect the vehicle from corrosion and improve aesthetics. Techniques such as powder coating, painting, and galvanizing are commonly used. These processes not only enhance the visual appeal of the truck tractor units but also extend their lifespan by providing protective barriers against environmental factors.

Additionally, finishing touches may include the installation of electronic systems and components that contribute to the vehicle’s functionality and safety.

How Is Quality Assurance Integrated into Truck Tractor Unit Manufacturing?

Quality assurance is a pivotal aspect of the manufacturing process, ensuring that every truck tractor unit produced meets international and industry-specific standards. This focus on quality is crucial for B2B buyers who need assurance of product reliability.

Relevant International Standards for Quality Assurance

Manufacturers often adhere to internationally recognized quality management systems, such as ISO 9001. This standard provides a framework for consistent quality improvement and customer satisfaction. In the truck industry, compliance with additional standards like CE marking in Europe and API (American Petroleum Institute) standards for specific components is also common.

These certifications not only validate the manufacturer’s commitment to quality but also enhance buyer confidence, particularly for international transactions.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): Raw materials are inspected upon delivery to ensure they meet specified standards. This step is critical as the quality of materials directly affects the final product.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is performed to ensure that each component meets quality standards. This includes dimensional checks and functional tests.

-

Final Quality Control (FQC): Once the truck tractor unit is fully assembled, a comprehensive inspection is conducted. This may include performance testing, safety checks, and compliance verification against industry standards.

What Testing Methods Are Commonly Used to Ensure Quality in Truck Tractor Units?

Testing methods vary based on the components and intended use of the truck tractor units. Commonly employed methods include:

-

Functional Testing: Ensures that all systems, including brakes, steering, and electronic components, operate as intended.

-

Durability Testing: Simulates real-world conditions to assess the vehicle’s performance over time. This may involve stress testing and fatigue testing.

-

Environmental Testing: Evaluates the vehicle’s ability to withstand harsh conditions, such as extreme temperatures and humidity.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must ensure that suppliers adhere to robust quality control practices to mitigate risks associated with procurement. Here are strategies to verify QC:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and adherence to industry standards. This provides firsthand insight into the supplier’s operations.

-

Requesting Quality Reports: Buyers can request documentation of quality control processes, including test results and compliance certificates. This transparency is essential for building trust.

-

Third-Party Inspections: Engaging independent inspection agencies can offer an unbiased evaluation of the manufacturing processes and final products. This is particularly beneficial for international transactions where buyers may not be able to conduct physical inspections.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, understanding the nuances of quality control is vital. Different regions may have varying standards and regulations. Buyers from Africa, South America, the Middle East, and Europe should be aware of:

-

Regional Compliance Requirements: Familiarize themselves with local regulations and standards that may differ from international norms. This ensures that the procured units are compliant with local laws.

-

Cultural Differences in Business Practices: Recognizing and respecting cultural differences can facilitate smoother negotiations and partnerships. Building relationships with suppliers can enhance collaboration on quality assurance.

-

Logistical Considerations: International shipping can impact the quality of the product during transit. Buyers should discuss packaging and handling procedures with suppliers to minimize risks.

By understanding these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions, ensuring that they procure reliable and high-quality truck tractor units that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘truck Tractor Units’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers interested in procuring truck tractor units. Sourcing such heavy machinery requires careful consideration of various factors, from technical specifications to supplier reliability. Following this checklist will help ensure a successful procurement process that meets your operational needs.

1. Define Your Technical Specifications

Establishing clear technical specifications is essential for aligning your needs with available options. Consider factors such as engine power, axle configuration, fuel type, and any specific features that may enhance performance. This clarity will facilitate a more targeted search, helping you identify tractor units that meet your operational requirements.

2. Conduct Market Research

Understanding the market landscape is critical for making informed decisions. Research different brands, models, and price points to gauge what is available and what fits your budget. Pay attention to user reviews and industry reports that highlight reliability, maintenance costs, and overall performance, as these insights can significantly influence your choice.

3. Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is crucial. Look for well-established companies with a proven track record in the industry. Request company profiles, case studies, and references from other buyers in similar regions or industries to validate their claims and assess their reliability.

- Check for certifications: Ensure that suppliers have relevant certifications, such as ISO or CE, which demonstrate adherence to quality and safety standards.

- Review their inventory: A diverse inventory indicates a supplier’s capability to meet varied customer needs.

4. Request Detailed Quotes

Once you have shortlisted potential suppliers, request detailed quotes that outline the costs involved. A comprehensive quote should include not just the price of the tractor units, but also any additional costs such as shipping, taxes, and warranties. Comparing these quotes will help you make a cost-effective decision.

5. Verify After-Sales Support and Warranty Terms

After-sales support is a critical aspect of any equipment purchase. Ensure that the supplier offers robust after-sales services, including maintenance, repairs, and availability of spare parts. Additionally, review warranty terms carefully to understand what is covered and for how long, as this can save you significant costs in the long run.

6. Assess Financing Options

Investigate financing options available through suppliers or third-party lenders. Many suppliers offer flexible financing plans that can ease the burden of upfront costs. Understanding your financing options will allow you to choose a payment structure that aligns with your cash flow requirements.

7. Finalize the Purchase Agreement

Before sealing the deal, ensure that all terms are clearly outlined in a purchase agreement. This document should cover payment terms, delivery timelines, warranty details, and any other agreements made during negotiations. A well-defined contract protects both parties and minimizes the risk of misunderstandings.

By following this checklist, B2B buyers can navigate the complexities of sourcing truck tractor units effectively, ensuring a purchase that aligns with their operational goals and budgetary constraints.

Comprehensive Cost and Pricing Analysis for truck Tractor Units Sourcing

What Are the Key Cost Components in Truck Tractor Units Sourcing?

When sourcing truck tractor units, understanding the cost structure is essential for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly influences the cost. High-quality steel, advanced composites, and eco-friendly materials tend to be more expensive but can enhance durability and performance, which is particularly important for long-haul operations.

-

Labor: Labor costs vary widely depending on the region and the complexity of the manufacturing process. Skilled labor is often needed for assembly and quality assurance, which can increase overall costs.

-

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead, impacting the final price.

-

Tooling: The initial investment in tooling for production can be substantial. Custom tooling for specific tractor configurations or features will add to the upfront costs but can lead to better precision and quality.

-

Quality Control: Implementing rigorous QC processes ensures that the tractor units meet required standards and specifications, which can add to costs but ultimately reduces the risk of defects.

-

Logistics: Shipping costs can be a significant part of the total expense, especially for international buyers. Factors like shipping distance, mode of transport, and customs duties should be considered.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market conditions, competition, and perceived value.

How Do Price Influencers Affect Truck Tractor Units?

Several factors influence the pricing of truck tractor units, which B2B buyers should carefully consider:

-

Volume/MOQ: Bulk purchasing often results in lower unit prices. Establishing a minimum order quantity (MOQ) can lead to better pricing and negotiating power.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials: The choice between standard and premium materials can affect pricing. Buyers should evaluate the long-term benefits of investing in higher-quality materials.

-

Quality and Certifications: Certifications such as ISO or Euro standards can enhance product value and justify higher prices. Buyers should verify the supplier’s adherence to these standards.

-

Supplier Factors: Supplier reputation, production capacity, and reliability can influence pricing. Established suppliers may command higher prices due to their track record.

-

Incoterms: The terms of shipping and delivery (Incoterms) can significantly impact total costs. Buyers should negotiate terms that minimize their risk and liability.

What Are the Best Buyer Tips for Cost-Efficiency?

To maximize cost-efficiency when sourcing truck tractor units, consider the following strategies:

-

Negotiation: Engage in open negotiations with suppliers. Discuss pricing, payment terms, and potential discounts for bulk purchases.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes purchase price, maintenance, fuel consumption, and depreciation. This holistic view can inform better purchasing decisions.

-

Pricing Nuances for International Buyers: Understand local market conditions and currency fluctuations. Buyers in Africa, South America, the Middle East, and Europe should be aware of how these factors affect pricing.

-

Research and Comparison: Conduct thorough market research and compare multiple suppliers. Utilize platforms such as Mascus and Autoline to gather data on pricing and available units.

-

Long-Term Relationships: Building long-term relationships with suppliers can lead to better pricing and priority service in the future.

Disclaimer on Indicative Prices

Prices for truck tractor units can vary widely based on specifications, condition (new or used), and market dynamics. The figures presented in this analysis are indicative and should be verified with suppliers for the most accurate quotes. Always factor in additional costs such as shipping, taxes, and customs duties when making purchasing decisions.

Alternatives Analysis: Comparing truck Tractor Units With Other Solutions

Understanding Alternative Solutions to Truck Tractor Units

In the transportation and logistics sector, truck tractor units are a popular choice for hauling goods over long distances. However, several alternative solutions can also achieve similar goals. Understanding these options can help B2B buyers make informed decisions based on their specific requirements, such as cost, performance, and operational efficiency. This section compares truck tractor units with two viable alternatives: articulated lorries and container trucks.

Comparison Table

| Comparison Aspect | Truck Tractor Units | Articulated Lorries | Container Trucks |

|---|---|---|---|

| Performance | High towing capacity; efficient for long hauls | Versatile; can handle various loads | Ideal for intermodal transport; great for heavy loads |

| Cost | Moderate to high initial investment; fuel-efficient | Generally lower initial cost; variable operating costs | High initial investment; cost-effective for bulk transport |

| Ease of Implementation | Requires training for drivers; more complex maintenance | Easier to operate; less specialized training needed | Requires knowledge of container handling; specific regulations |

| Maintenance | Regular maintenance needed; parts can be expensive | Lower maintenance costs; simpler systems | Maintenance tied to container integrity; less frequent service |

| Best Use Case | Long-distance transport of heavy goods | Flexible cargo transport, especially in urban areas | Efficient for shipping goods via multiple transport modes |

What Are the Pros and Cons of Articulated Lorries?

Articulated lorries, also known as articulated trucks, consist of a tractor unit and a semi-trailer. This configuration allows for greater flexibility in cargo types and sizes. One of the main advantages of articulated lorries is their lower initial cost compared to truck tractor units. They are easier to operate and require less specialized training, making them accessible for a broader range of drivers.

However, articulated lorries may not perform as well in terms of towing capacity, particularly for very heavy loads. Their maneuverability is advantageous in urban settings, but they may not be the best choice for long-distance hauls when compared to truck tractor units. Additionally, while they generally have lower maintenance costs, the complexity of their systems can lead to more frequent repairs if not properly managed.

What Are the Advantages and Disadvantages of Container Trucks?

Container trucks are designed specifically for transporting intermodal containers, making them an ideal choice for companies involved in international shipping. The primary advantage of container trucks is their efficiency in loading and unloading, allowing for quick transitions between different modes of transport, such as ships and trains. This adaptability makes them an essential part of global supply chains.

On the downside, container trucks typically involve a higher initial investment than truck tractor units. Additionally, they require specialized knowledge regarding container handling and compliance with specific transport regulations. While they are cost-effective for bulk transport, their operational complexities and higher maintenance tied to container integrity can pose challenges for some businesses.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right transportation solution, B2B buyers should consider several factors, including the nature of the goods being transported, the distances involved, and the operational capabilities of their workforce. Truck tractor units offer robust performance for heavy loads over long distances, making them ideal for dedicated freight haulers. In contrast, articulated lorries may be better suited for flexible urban deliveries, while container trucks excel in intermodal logistics. By evaluating these aspects against their operational needs and budget constraints, buyers can make a well-informed decision that aligns with their strategic objectives.

Essential Technical Properties and Trade Terminology for truck Tractor Units

What Are the Key Technical Properties of Truck Tractor Units?

When considering the purchase of truck tractor units, understanding their technical specifications is crucial for making informed decisions. Here are some essential technical properties that B2B buyers should be aware of:

-

Axle Configuration

The axle configuration of a truck tractor unit indicates how many axles it has and their arrangement. Common configurations include 4×2, 6×2, and 8×4. The configuration affects the vehicle’s load capacity, handling, and maneuverability. For businesses, selecting the right axle configuration is vital to ensure compliance with local regulations and to optimize performance based on the intended load and terrain. -

Engine Power (Horsepower)

Engine power, measured in horsepower (HP), determines the vehicle’s ability to perform under load and its fuel efficiency. For instance, a tractor unit with 500 HP can haul heavier loads more efficiently than one with 300 HP. B2B buyers should assess engine power to match their operational needs, particularly in industries requiring consistent heavy hauling. -

Fuel Type and Efficiency

Most truck tractor units operate on diesel fuel, although alternative fuels are gaining traction. Fuel efficiency, often expressed in miles per gallon (MPG), directly impacts operational costs. Choosing a fuel-efficient model can result in significant savings over time, making this an important consideration for B2B buyers focused on reducing total cost of ownership. -

Suspension Type

The type of suspension (air, spring, or a combination) affects ride quality, load distribution, and overall vehicle stability. Air suspension provides better comfort and load management, especially for long hauls, while spring suspension may be more cost-effective. Understanding the suspension system helps buyers select units that align with their specific transport needs and preferences. -

Emission Standards (Euro Standards)

Compliance with emission standards, such as Euro 6, is crucial for operating in many regions, particularly in Europe. These standards regulate the amount of pollutants a vehicle can emit, influencing both purchase decisions and operational capabilities. B2B buyers must ensure that the units they purchase meet local environmental regulations to avoid penalties and support sustainability goals.

What Are Common Trade Terms Used in the Truck Tractor Unit Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common trade terms relevant to truck tractor units:

-

OEM (Original Equipment Manufacturer)

OEM refers to the company that produces the original equipment used in a vehicle. Buyers should consider OEM parts for repairs and replacements to ensure compatibility and reliability, as these parts often come with warranties and adhere to industry standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to assess their purchasing power and budget. It helps in planning inventory and managing costs effectively, especially for businesses looking to maintain a fleet. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price quotes on specified goods or services. It is a vital step in the procurement process, allowing businesses to compare prices and terms before making purchasing decisions. Crafting a detailed RFQ can lead to better pricing and terms. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions, including shipping and delivery. Familiarity with these terms helps B2B buyers understand their obligations and costs related to transportation and risk management. -

VIN (Vehicle Identification Number)

The VIN is a unique code assigned to each vehicle for identification. It is essential for tracking vehicle history, ownership, and compliance with regulations. Buyers should always verify the VIN to ensure the legitimacy of the vehicle and its specifications. -

TCO (Total Cost of Ownership)

TCO encompasses all costs associated with purchasing and operating a vehicle over its lifetime, including acquisition, maintenance, fuel, and resale value. Understanding TCO allows B2B buyers to make more informed decisions that align with their financial goals and operational strategies.

By grasping these essential technical properties and trade terms, B2B buyers can navigate the truck tractor unit market more effectively, ensuring they make choices that align with their operational needs and budgetary constraints.

Navigating Market Dynamics and Sourcing Trends in the truck Tractor Units Sector

What Are the Key Market Trends Influencing the Truck Tractor Units Sector?

The global truck tractor units market is experiencing significant transformation driven by a combination of technological advancements, shifting consumer preferences, and regulatory changes. Key market drivers include the increasing demand for freight transportation, particularly in emerging markets such as Africa and South America, where infrastructure development is on the rise. Additionally, the trend towards e-commerce is escalating the need for efficient logistics solutions, driving up the demand for tractor units that can handle diverse loads and terrains.

Emerging technologies are playing a pivotal role in sourcing trends within the sector. The adoption of telematics and IoT devices allows for real-time tracking of vehicles, enhancing operational efficiency and reducing maintenance costs. Furthermore, digital marketplaces are revolutionizing how buyers source equipment, providing access to a broader range of used and new tractor units from global suppliers. This has particularly benefitted international buyers by streamlining the procurement process, allowing them to compare options and pricing more effectively.

In regions like the Middle East and Europe, there is a noticeable shift towards electric and hybrid tractor units, reflecting a growing emphasis on sustainability and fuel efficiency. As regulatory bodies tighten emissions standards, manufacturers are pivoting towards greener technologies, which is a crucial consideration for B2B buyers looking to invest in future-proof equipment.

How Does Sustainability Influence Sourcing Decisions in the Truck Tractor Units Market?

Sustainability has become a cornerstone of sourcing strategies for international B2B buyers in the truck tractor units sector. The environmental impact of traditional diesel-powered vehicles is prompting companies to seek alternatives that align with their corporate social responsibility goals. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainability, including those that offer electric or hybrid models, which significantly reduce carbon emissions.

Ethical sourcing is another critical aspect, as buyers are now more aware of their supply chain’s social implications. This includes ensuring that materials used in manufacturing tractor units are sourced responsibly, minimizing the environmental footprint, and promoting fair labor practices. Certifications such as ISO 14001 (Environmental Management) and ISO 50001 (Energy Management) are becoming essential benchmarks for suppliers, as they indicate adherence to internationally recognized sustainability standards.

Moreover, the push for sustainable practices is leading to innovations in materials used for truck manufacturing. Lightweight materials that enhance fuel efficiency and recyclable components are increasingly prevalent, enabling buyers to make greener choices without compromising on performance.

How Has the Truck Tractor Units Sector Evolved Over Time?

The evolution of the truck tractor units sector is marked by significant technological and regulatory advancements. Originally designed for basic transportation needs, these vehicles have transformed into sophisticated machines equipped with advanced features such as automated driving systems, enhanced fuel efficiency technologies, and telematics.

In the early 20th century, tractor units were primarily powered by gasoline engines, but the shift to diesel engines in the mid-century marked a turning point, offering better fuel economy and torque for heavy loads. The late 20th and early 21st centuries saw the introduction of computerized systems, improving reliability and performance. Today, the market is increasingly focused on sustainability, with electric and hybrid options emerging as viable alternatives to traditional models.

This historical progression highlights the sector’s adaptability to changing market demands and technological advancements, making it essential for B2B buyers to remain informed about these trends to make strategic procurement decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of truck Tractor Units

-

How do I choose the right truck tractor unit for my business needs?

Selecting the right truck tractor unit involves assessing your operational requirements, including load capacity, fuel efficiency, and terrain type. Consider the weight of the cargo you’ll transport and the distances involved. Research various models from reputable manufacturers such as Volvo, Scania, and Mercedes-Benz, focusing on specifications like horsepower and axle configuration. Additionally, evaluate the availability of spare parts and maintenance support in your region to ensure long-term operational efficiency. -

What are the key factors to consider when sourcing used truck tractor units?

When sourcing used truck tractor units, prioritize the unit’s condition, mileage, and service history. Inspect the vehicle for signs of wear and tear, and verify its maintenance records to gauge reliability. It’s also crucial to assess the vehicle’s compliance with local emission standards, especially for international purchases. Establish a clear budget that includes potential repairs or upgrades, and consider the reputation of the seller to ensure a trustworthy transaction. -

What customization options are available for truck tractor units?

Customization options for truck tractor units can include modifications to enhance performance, comfort, and efficiency. Buyers can request changes in engine specifications, cabin features, and cargo handling capabilities. Additional accessories such as GPS systems, advanced safety features, and specific body configurations can also be tailored to meet operational needs. Discuss your requirements with manufacturers or dealers to explore available customization packages that align with your business objectives. -

How can I ensure the quality of truck tractor units when purchasing internationally?

To ensure quality in international purchases, conduct thorough supplier vetting. Check for certifications, read reviews, and request references from previous buyers. Utilize third-party inspection services to assess the condition of the units before finalizing the purchase. Additionally, ensure that the supplier provides warranties or guarantees, which can offer protection against defects or performance issues post-purchase. -

What payment terms should I expect when buying truck tractor units?

Payment terms can vary significantly between suppliers and regions. Typically, you may encounter options like upfront payments, deposits with the balance due upon delivery, or financing arrangements. It’s essential to clarify payment methods, including bank transfers, letters of credit, or escrow services, to mitigate risks. Ensure that all terms are clearly outlined in the purchase agreement to avoid misunderstandings. -

What are the logistics involved in importing truck tractor units?

Importing truck tractor units involves several logistical considerations, including shipping methods, customs clearance, and delivery timelines. Choose between container shipping or roll-on/roll-off (RoRo) options based on cost and convenience. Prepare all necessary documentation, including bills of lading, customs declarations, and import permits. Working with a reliable logistics provider can streamline the process, ensuring compliance with local regulations and timely delivery to your location. -

How do I determine the minimum order quantity (MOQ) for truck tractor units?

The minimum order quantity (MOQ) for truck tractor units is typically set by the manufacturer or supplier and can vary based on the model and customization options. To determine the MOQ, directly communicate with potential suppliers and inquire about their policies. Consider your business needs and budget when assessing the MOQ, as larger orders may provide cost benefits but require upfront capital. -

What should I know about warranties and after-sales support for truck tractor units?

Warranties and after-sales support are critical components of your purchasing decision. Understand the warranty coverage, including duration and what it encompasses, such as parts and labor. Inquire about the supplier’s after-sales service, including access to spare parts and technical support. A strong after-sales program can significantly enhance the operational lifespan of your truck tractor units and minimize downtime, making it an essential consideration in your purchase.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Truck Tractor Units Manufacturers & Suppliers List

1. Mercedes-Benz – Actros 2651

Domain: mascus.com

Registered: 2000 (25 years)

Introduction: Used tractor units for sale in Mascus USA. Key manufacturers include Mercedes-Benz, Scania, and Volvo. Listings include 16,358 conventional trucks and tractor trucks available for sale, auction, or rent. Featured models include MAN TGS 18.510, Scania R 500, Volvo FH13 500, Mercedes-Benz Actros 2651, Freightliner Cascadia, and more. Prices range from $7,000 to $105,153. Equipment available across v…

2. Basworld – Trucks and Trailers

Domain: basworld.com

Registered: 2016 (9 years)

Introduction: Tractorhead, Truck, Semi-trailer, Trailer, Construction equipment, Light commercial vehicle, Farm equipment, Euronorm Configuration: Euro 6, Euro 5, Euro 4, Euro 3, Euro 2, Euro 1; Brands: DAF, Volvo, Scania, MAN, Mercedes, Iveco, Renault, Ford, Shacman, Sitrak, Unimog, Ginaf, Mitsubishi, TATRA; Configurations: 4X2, 6X2, 8X4, 6X4, 8X2, 10X4, 4X4, 6X6, 8X6, 8X8, 10X6, 10X8, 4X2 Mega; Superstructure…

3. Kenworth – T-880 Truck Tractors

Domain: autoline.com

Registered: 1997 (28 years)

Introduction: Truck tractors for sale, used truck tractors available from various brands including Kenworth, Western Star, Renault, MAN, DAF, Volvo, and Scania. Key details include:

– Kenworth T-880: Prices range from $160,000 to $175,000, model years 2022-2023, mileage between 68,400 to 141,400 mi, axle configuration 8×4, air/air suspension.

– Western Star 4900 SF: Priced at $45,000, 2014 model, 159,100 mi.

-…

4. FTR Intel – Tractor/Trailer vs. Straight Truck

Domain: help.ftrintel.com

Registered: 2013 (12 years)

Introduction: The difference between Tractor/Trailer and Straight Truck lies in their construction and functionality. A Tractor/Trailer unit consists of a truck tractor (a power unit with engine and transmission) combined with a semitrailer, which attaches via a ‘fifth wheel’. This setup allows for separate movement of the tractor and trailer. In contrast, a Straight Truck is a single piece of equipment where t…

5. Used Tractor Units – DAF, MAN, Mercedes, Renault, Iveco, Scania, Volvo

Domain: grctrucks.com

Registered: 2019 (6 years)

Introduction: Used tractor units for sale from reputable brands including DAF, MAN, Mercedes, Renault, Iveco, Scania, and Volvo. Available configurations: 4×2, 6×2 mid-lift, 6×2 twin-steer, and 6×2 rear-lift. Power outputs range from 400bhp to 750bhp, with load capacities of up to 40 tonnes for five-axle combinations and 44 tonnes for six-axle configurations. Popular models include DAF XF, Iveco Stralis, MAN TG…

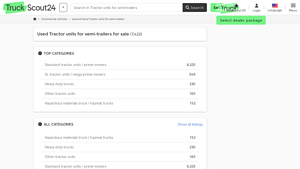

6. TruckScout24 – Used Tractor Units

Domain: truckscout24.com

Registered: 2000 (25 years)

Introduction: Used Tractor units for semi-trailers for sale on TruckScout24.com

Key Product Details:

1. **General Information**:

– Total Listings: 7,422

– Categories: Standard tractor units, XL tractor units, Heavy duty trucks, Other tractor units, Hazardous materials trucks

– Dealers in this category: 410

2. **Example Listings**:

– **Listing 1**:

– Manufacturer: MAN

– Model: TGA 25.480…

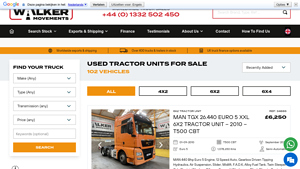

7. Used Tractor Units – Top Brands Available

Domain: walkermovements.com

Registered: 2001 (24 years)

Introduction: Used Tractor Units for Sale in the UK. Total available: 102 vehicles. Key features include various makes such as Scania, DAF, Iveco, Renault, Mercedes-Benz, MAN, Volvo, Hino, Isuzu, and Mitsubishi. Transmission options include Manual and Semi-Automatic. Price range: £0-£30,001+. Examples of available units include: 1. MAN TGX 26.440 EURO 5 XXL 6X2 (2010) – £6,250, 1,078,650 Kms, 440 Bhp, Semi-Auto…

8. ProLogistik – Tractor Units

Domain: prologistik.com

Registered: 1998 (27 years)

Introduction: A tractor unit is the towing unit of a semi-trailer truck, also known as an articulated lorry. It consists of a short truck chassis with a driver’s cab and does not have its own loading area, making it significantly shorter than a traditional truck. The tractor unit features a fifth wheel coupling that connects to the semi-trailer, which has a kingpin for this purpose. The fifth wheel coupling inc…

Strategic Sourcing Conclusion and Outlook for truck Tractor Units

How Can Strategic Sourcing Enhance Your Procurement of Truck Tractor Units?

In the dynamic landscape of truck tractor units, strategic sourcing emerges as a pivotal approach for international B2B buyers. By focusing on quality manufacturers and reliable suppliers, businesses can ensure that their fleets are equipped with durable and efficient vehicles, essential for optimizing logistics and transportation operations. Leveraging online marketplaces such as Mascus and Autoline enables buyers to access a vast array of options, from new to used units, catering to varying budgets and specifications.

The importance of understanding market trends, including pricing fluctuations and technological advancements, cannot be overstated. Buyers should prioritize relationships with suppliers who offer transparency and support, as this fosters a collaborative environment that can lead to better deals and enhanced service levels. Moreover, engaging with local distributors in regions such as Africa, South America, and the Middle East can provide invaluable insights into regional demands and regulations.

Looking ahead, the future of truck tractor unit procurement is promising, with innovations in fuel efficiency and sustainability shaping the industry. Now is the time for international B2B buyers to take proactive steps in their sourcing strategies, ensuring they are well-positioned to capitalize on emerging opportunities and navigate challenges in the global marketplace. Embrace strategic sourcing to drive your business forward.