Introduction: Navigating the Global Market for mini electric truck lsv

Navigating the complexities of sourcing mini electric truck LSVs (Low-Speed Vehicles) can be a daunting task for international B2B buyers. With the growing demand for sustainable logistics solutions across diverse markets such as Africa, South America, the Middle East, and Europe, businesses face the challenge of selecting the right vehicle that meets both operational needs and regulatory requirements. This comprehensive guide is designed to empower you with the knowledge needed to make informed purchasing decisions, covering various types of mini electric trucks, their applications in urban and industrial settings, and essential factors to consider when vetting suppliers.

In the following sections, we will explore the distinct features of different LSV models, such as their payload capacities, battery options, and customization possibilities. Additionally, we will provide insights into the cost structures associated with these vehicles, allowing you to budget effectively for your fleet expansion. As you navigate through this guide, you will gain valuable tools for evaluating potential suppliers, ensuring that you partner with reputable manufacturers who can deliver reliable and efficient solutions tailored to your specific business requirements.

By understanding the landscape of mini electric truck LSVs, you can position your company to capitalize on the benefits of eco-friendly transportation while enhancing your operational efficiency. Whether you’re in the bustling urban centers of Vietnam or the expansive markets of Saudi Arabia, this guide serves as your roadmap to making strategic investments in the future of mobility.

Understanding mini electric truck lsv Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Club Car Urban LSV | Compact design, customizable configurations, up to 2204 lbs payload | Last-mile delivery, facilities maintenance | Pros: Versatile, eco-friendly; Cons: Higher initial investment. |

| MAX-EV LSV | Permanent magnetic motor, lithium-ion battery options, 4WD | Urban logistics, construction sites | Pros: Robust performance, zero emissions; Cons: Limited cargo space in smaller models. |

| Electric Utility Vehicle (EUV) | Various seating configurations, off-road capabilities | Agriculture, landscaping, tourism | Pros: Adaptable for different terrains; Cons: May require specialized training for operation. |

| Low-Speed Utility Vehicles (LSVs) | Street-legal features, typically lower speed limits | Urban transport, parks, campuses | Pros: Safe for urban environments; Cons: Speed limitations may affect efficiency. |

| Utility Carts | Simplified design, often with flatbeds or open cargo areas | Warehousing, event logistics | Pros: Cost-effective, easy to maneuver; Cons: Less powerful for heavy loads. |

What are the Key Characteristics of Club Car Urban LSV?

The Club Car Urban LSV stands out for its compact design and high payload capacity of up to 2204 lbs. It is particularly well-suited for last-mile delivery and facilities maintenance, thanks to its customizable configurations that can be tailored to specific business needs. B2B buyers should consider the vehicle’s eco-friendliness and versatility, although the initial investment may be higher compared to traditional options.

How Does the MAX-EV LSV Cater to Diverse Needs?

The MAX-EV LSV features a permanent magnetic motor and offers a range of lithium-ion battery options, making it a robust choice for urban logistics and construction. Its four-wheel-drive capability enhances performance across varied terrains, making it suitable for diverse applications. Buyers should weigh its strong performance and zero emissions against the potential limitations in cargo space, particularly in the shorter models.

Why are Electric Utility Vehicles (EUVs) Ideal for Various Industries?

Electric Utility Vehicles (EUVs) are characterized by their adaptability, with various seating configurations and off-road capabilities. They are commonly used in agriculture, landscaping, and tourism, where terrain can vary significantly. B2B buyers should consider the versatility of EUVs for different environments, but should also note that some models may require specialized training for safe operation.

What Advantages Do Low-Speed Utility Vehicles (LSVs) Offer in Urban Settings?

Low-Speed Utility Vehicles (LSVs) are designed with street-legal features, making them ideal for urban transport, parks, and campuses. Their safety features and lower speed limits make them suitable for crowded areas. B2B buyers should appreciate the safety benefits in urban settings, but they may find that speed limitations could impact operational efficiency for time-sensitive tasks.

How Do Utility Carts Serve Specific Business Functions?

Utility Carts are often characterized by a simplified design, featuring flatbeds or open cargo areas. They are particularly effective in warehousing and event logistics, where maneuverability and cost-effectiveness are crucial. While these carts are easy to operate and maintain, potential buyers should consider their limitations in terms of power and capacity for heavier loads.

Key Industrial Applications of mini electric truck lsv

| Industry/Sector | Specific Application of mini electric truck lsv | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Urban Logistics | Last-Mile Delivery | Enhanced efficiency in urban environments, reducing delivery times and costs. | Compliance with local regulations for street-legal operation, battery range for urban distances. |

| Facilities Management | On-Site Maintenance and Transportation | Cost-effective and eco-friendly transport for maintenance crews and equipment. | Durability for varied terrain, payload capacity for tools and equipment. |

| Agriculture | Crop Transport and Supply Chain Logistics | Sustainable transport solutions that reduce carbon footprint and operational costs. | Terrain adaptability, battery performance in remote areas, and cargo space for agricultural products. |

| Hospitality and Events | Guest Transportation and Service Support | Improved guest experience with quiet, eco-friendly transport options within resorts or event venues. | Comfort features, seating capacity, and customization for specific service needs. |

| Construction | Tool and Material Transport | Efficient movement of tools and materials on construction sites, reducing manual labor costs. | Load capacity, off-road capability, and durability against harsh environments. |

How Are Mini Electric Trucks Used in Urban Logistics for Last-Mile Delivery?

In urban logistics, mini electric trucks serve as a vital component for last-mile delivery, particularly in densely populated areas where traditional vehicles face challenges. These trucks can navigate tight spaces and operate at lower speeds, making them ideal for urban environments. They significantly reduce delivery times and costs by enabling swift transport of goods. Buyers should prioritize models that comply with local street regulations, possess a sufficient battery range for urban deliveries, and offer customization options for cargo needs.

What Role Do Mini Electric Trucks Play in Facilities Management?

In facilities management, mini electric trucks are utilized for on-site maintenance and transportation of crews and equipment. Their electric nature allows for quiet operation, which is crucial in sensitive environments such as hospitals or corporate offices. They provide a cost-effective solution, reducing fuel expenses and maintenance costs associated with traditional vehicles. Businesses should consider durability for varied terrain, payload capacity, and features that enhance ease of use for maintenance tasks.

How Can Mini Electric Trucks Enhance Agricultural Operations?

In the agricultural sector, mini electric trucks are increasingly being used for crop transport and supply chain logistics. They provide a sustainable transport solution that aligns with the growing emphasis on eco-friendly practices. These vehicles can efficiently move produce from fields to markets, reducing the carbon footprint associated with traditional transport methods. Buyers should focus on battery performance in remote areas, terrain adaptability, and cargo space to accommodate agricultural products.

What Benefits Do Mini Electric Trucks Offer in Hospitality and Events?

Mini electric trucks are becoming popular in the hospitality industry for guest transportation and service support. Their quiet, eco-friendly design enhances the guest experience, allowing for smooth transportation within resorts or event venues. They can be customized to meet specific service needs, such as adding seating or storage for catering supplies. Buyers should look for comfort features, seating capacity, and the ability to adapt the vehicle for various service requirements.

How Are Mini Electric Trucks Used in Construction for Tool and Material Transport?

In the construction industry, mini electric trucks are essential for the efficient transport of tools and materials on-site. They help reduce manual labor costs and improve safety by allowing for quick movement of heavy items. Their off-road capabilities make them suitable for rugged construction environments. Buyers should prioritize load capacity, durability against harsh conditions, and maneuverability to navigate tight spaces on construction sites.

3 Common User Pain Points for ‘mini electric truck lsv’ & Their Solutions

Scenario 1: Navigating Urban Delivery Challenges with Mini Electric Trucks

The Problem: In densely populated urban areas, businesses often struggle with last-mile delivery logistics. Traditional delivery vehicles can be cumbersome, difficult to maneuver, and often restricted in certain zones due to environmental regulations. For B2B buyers in cities across Europe and South America, the challenge lies in finding a vehicle that is both efficient and compliant with local traffic laws while being capable of navigating tight streets and small loading docks.

The Solution: Mini electric trucks like the Club Car Urban LSV are specifically designed for urban environments. Their compact size, combined with a top speed of up to 25 mph, allows for quick and efficient delivery without the risk of traffic violations. When sourcing these vehicles, it’s crucial to inquire about their compliance with local regulations, including features like seat belts, lights, and turn signals, which are essential for street-legal operation. Buyers should also consider customizing the vehicle with features such as a backup camera and in-dash storage, which enhances safety and usability. By choosing a mini electric truck that meets local requirements, businesses can streamline their delivery processes while adhering to city regulations, ultimately improving service efficiency.

Scenario 2: Ensuring Reliability in Diverse Climate Conditions

The Problem: B2B buyers in regions with extreme weather conditions, such as the Middle East’s heat or Northern Europe’s cold, face the challenge of ensuring vehicle reliability throughout the year. These environments can severely affect the performance of electric vehicles, leading to concerns about battery life, vehicle functionality, and overall dependability during operations.

The Solution: To mitigate these concerns, it’s essential to select mini electric trucks equipped with advanced battery management systems and climate control features. For instance, the MAX-EV LSV offers options for battery heating, which enhances performance in cold climates, and has lithium-ion batteries that can withstand high temperatures. When sourcing these vehicles, buyers should prioritize those with proven durability in harsh conditions and ask about warranty offerings that cover extreme weather usage. Additionally, regular maintenance checks should be scheduled to ensure that battery and motor systems remain in optimal condition. By investing in reliable mini electric trucks tailored for diverse climates, businesses can ensure uninterrupted operations, regardless of external conditions.

Scenario 3: Maximizing Payload Efficiency for Diverse Operations

The Problem: Many businesses require vehicles that can handle a variety of payloads, from transporting equipment to delivering goods. However, standard trucks may not offer the necessary versatility or efficiency, leading to potential losses in productivity and increased operational costs. Buyers in industries such as logistics and facility management are particularly affected by the inability to adapt their vehicles for multiple uses.

The Solution: Mini electric trucks like the Club Car Urban offer customizable cargo options that can cater to a variety of business needs. Buyers should explore models that allow for different bed configurations, such as pickup beds or van boxes, and assess their payload capacities, which can reach up to 2,200 lbs. Additionally, consider options like adjustable seats and lockable storage to enhance the vehicle’s adaptability. When evaluating potential purchases, request demonstrations to see how easily the vehicle can switch between configurations. By selecting a mini electric truck with flexible design features, businesses can optimize their operations, reduce the need for multiple vehicles, and ultimately improve their bottom line.

Strategic Material Selection Guide for mini electric truck lsv

What Are the Key Materials for Mini Electric Truck LSVs?

In the development of mini electric trucks (LSVs), material selection plays a crucial role in ensuring performance, durability, and compliance with international standards. Here, we analyze four common materials used in the construction of these vehicles, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Steel Contribute to Mini Electric Truck LSV Durability?

Steel is a primary material for the chassis and structural components of mini electric trucks. Its high tensile strength and excellent durability make it an ideal choice for withstanding the stresses of daily use. Steel components can typically handle high temperatures and pressures, making them suitable for various operational conditions.

Pros: Steel is relatively cost-effective and widely available, making it an economical choice for manufacturers. It also offers good corrosion resistance when treated, enhancing the vehicle’s lifespan.

Cons: The weight of steel can impact the overall efficiency of electric vehicles, potentially reducing range. Additionally, steel requires more complex manufacturing processes, such as welding and machining, which can increase production time.

Impact on Application: Steel’s robustness makes it suitable for heavy-duty applications, including cargo transport and utility services. However, it may require additional coatings or treatments in humid or corrosive environments, common in regions like South America and Africa.

What Role Does Aluminum Play in Weight Reduction for Mini Electric Truck LSVs?

Aluminum is increasingly used in mini electric trucks due to its lightweight nature and resistance to corrosion. This material is particularly advantageous for electric vehicles, as reducing weight can significantly improve energy efficiency and extend range.

Pros: Aluminum offers excellent strength-to-weight ratios, making it suitable for components like body panels and frames. It also has inherent corrosion resistance, reducing the need for protective coatings.

Cons: The primary drawback of aluminum is its higher cost compared to steel, which can impact the overall production budget. Additionally, aluminum can be more challenging to work with, requiring specialized welding techniques.

Impact on Application: Aluminum’s lightweight properties enhance performance in urban environments, where agility and efficiency are essential. International buyers should consider compliance with local standards regarding aluminum alloys, which can vary by region.

How Does Composite Material Enhance Performance in Mini Electric Truck LSVs?

Composite materials, often made from a combination of plastics and fibers, are gaining traction in the production of mini electric trucks. These materials are known for their lightweight and high-strength characteristics, making them suitable for various applications, including body panels and interior components.

Pros: Composites offer excellent resistance to corrosion and environmental degradation, making them ideal for outdoor applications. They also provide design flexibility, allowing for innovative shapes and features.

Cons: The primary limitation of composites is their higher manufacturing complexity and cost. Additionally, they may not have the same impact resistance as metals, which can be a concern in rugged applications.

Impact on Application: Composites can significantly reduce vehicle weight, enhancing energy efficiency. Buyers in regions like the Middle East should consider local regulations regarding composite materials, as standards can differ.

Why Is Plastic a Viable Option for Mini Electric Truck LSV Components?

Plastics are commonly used in various components of mini electric trucks, including dashboards, storage compartments, and exterior trims. Their versatility and ease of manufacturing make them a popular choice.

Pros: Plastics are lightweight and can be produced at a lower cost than metals, allowing for cost-effective manufacturing. They also offer good resistance to chemicals and moisture.

Cons: The durability of plastics can be a concern, particularly in extreme temperatures or heavy-use scenarios. They may also be less environmentally friendly, depending on the type of plastic used.

Impact on Application: Plastics can enhance the aesthetic appeal and functionality of mini electric trucks. International buyers should be aware of regulations regarding plastic materials, particularly in regions with strict environmental standards.

Summary Table of Material Selection for Mini Electric Truck LSVs

| Material | Typical Use Case for mini electric truck lsv | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chassis and structural components | High strength and durability | Heavy weight impacts efficiency | Medium |

| Aluminum | Body panels and frames | Lightweight and corrosion-resistant | Higher cost and manufacturing complexity | High |

| Composite | Body panels and interior components | Lightweight and design flexibility | Higher cost and impact resistance | High |

| Plastic | Dashboards, storage compartments | Cost-effective and lightweight | Durability concerns in extreme conditions | Low |

This guide provides essential insights for B2B buyers in selecting the right materials for mini electric trucks, considering performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for mini electric truck lsv

What Are the Key Stages in the Manufacturing Process of Mini Electric Trucks (LSVs)?

The manufacturing process for mini electric trucks, particularly Low-Speed Vehicles (LSVs), involves several critical stages that ensure the final product meets both performance and safety standards. Understanding these stages can help B2B buyers evaluate potential suppliers effectively.

1. Material Preparation: What Materials Are Used in LSV Manufacturing?

The first step in the manufacturing process is material preparation. This includes sourcing high-quality materials such as steel for the chassis, aluminum for lightweight components, and durable plastics for interior and exterior parts. Advanced electric drivetrains typically utilize specialized materials for efficiency and weight reduction. Suppliers often employ just-in-time (JIT) manufacturing to minimize waste and ensure that materials are available as needed, thus streamlining production.

2. Forming: How Are Components Shaped and Fabricated?

Once materials are prepared, the next stage is forming. This involves various techniques such as stamping, bending, and welding to create the chassis and body of the LSV. For example, steel sheets may be stamped into specific shapes that will be assembled later. Advanced robotic systems are frequently used to ensure precision and reduce human error. Additionally, laser cutting technology may be employed for intricate designs, enhancing the vehicle’s aesthetics while maintaining structural integrity.

3. Assembly: What Does the Assembly Process Entail?

The assembly stage is where the various components are brought together. This includes attaching the electric drivetrain, battery systems, and other essential features like brakes and suspension. Most manufacturers follow an assembly line model, which enhances efficiency and allows for quick adjustments based on real-time quality checks. Key components such as wiring harnesses and electronic controls are integrated into the assembly process to facilitate a seamless operation of the electric vehicle.

4. Finishing: How Is the Final Product Prepared for Market?

The finishing stage involves painting, polishing, and applying any necessary protective coatings to enhance durability and aesthetic appeal. Manufacturers often use eco-friendly paints and finishes to align with the sustainability goals of electric vehicles. Additionally, this stage may include installing safety features such as seat belts and lights to ensure the vehicle complies with street-legal requirements.

What Quality Assurance Practices Are Essential for Mini Electric Trucks?

Quality assurance (QA) is a fundamental aspect of manufacturing mini electric trucks. It ensures that vehicles meet international safety and performance standards, which is crucial for B2B buyers across diverse markets.

1. What International Standards Should Buyers Be Aware Of?

B2B buyers should look for manufacturers that adhere to internationally recognized quality standards such as ISO 9001, which focuses on quality management systems. Additionally, industry-specific certifications like CE marking for compliance with European standards, and API standards for performance and safety, are vital indicators of a manufacturer’s commitment to quality.

2. What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several critical checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, random samples may be taken to check for defects or deviations from specifications.

- Final Quality Control (FQC): Once assembly is complete, a thorough inspection of the finished product is conducted to ensure it meets all operational and safety standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

1. What Methods Are Available for Supplier Audits?

B2B buyers can verify a supplier’s QC practices through various methods. Conducting on-site audits is one of the most effective ways to assess a manufacturer’s capabilities. These audits can cover everything from the manufacturing process to the handling of materials and employee training.

2. How Important Are Quality Reports and Third-Party Inspections?

Requesting detailed quality reports can provide insights into a manufacturer’s QC processes. These reports should outline testing methodologies, results, and any corrective actions taken. Additionally, engaging third-party inspectors for independent assessments can add a layer of assurance regarding the quality and compliance of the vehicles being manufactured.

What Are the Quality Control Nuances for International Buyers?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of QC is critical. Different regions may have varying regulatory requirements, which can affect compliance. Buyers should ensure that suppliers are not only compliant with their local regulations but also with international standards that may apply to their target markets.

1. How Do Regulatory Variations Impact Quality Control?

Regulatory variations can impact everything from vehicle design to safety features. For example, LSVs intended for the European market must comply with stricter emissions standards compared to those in other regions. Buyers should collaborate closely with suppliers to ensure that vehicles meet the necessary regulations for their specific markets.

2. What Role Does Documentation Play in QC Verification?

Comprehensive documentation is crucial for verifying QC practices. B2B buyers should request documentation that includes certificates of compliance, testing results, and maintenance logs. This documentation serves not only as proof of quality but also as a resource for future maintenance and service needs.

By understanding the manufacturing processes and quality assurance practices associated with mini electric trucks, B2B buyers can make informed decisions and ensure they are partnering with reliable suppliers that prioritize quality and compliance in their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mini electric truck lsv’

To assist B2B buyers in procuring mini electric trucks (LSVs), this checklist provides a structured approach to ensure a successful sourcing process. By following these steps, you can effectively evaluate options, negotiate contracts, and make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the mini electric truck that align with your operational needs. Consider aspects such as payload capacity, range, speed, and specific features like cargo bed configurations and additional safety requirements. This clarity will aid in communicating your needs to potential suppliers and ensure you receive suitable options.

Step 2: Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers of mini electric trucks. Look for manufacturers with a proven track record in producing LSVs, especially those that cater to your region (e.g., Africa, South America, the Middle East, and Europe). Supplier reputation can be assessed through online reviews, industry awards, and client testimonials.

Step 3: Evaluate Supplier Certifications

Before moving forward, verify that suppliers hold the necessary certifications for LSVs in your intended market. Compliance with local regulations and standards, such as safety features and emissions guidelines, is crucial. Look for certifications from recognized industry bodies, which indicate that the vehicles meet quality and safety benchmarks.

Step 4: Request Detailed Quotes

Contact shortlisted suppliers to request detailed quotes. Ensure that the quotes include not only the base price of the vehicles but also additional costs such as shipping, taxes, and any optional features. A comprehensive understanding of total costs will help you budget accurately and compare offers effectively.

Step 5: Assess After-Sales Support and Warranty

Inquire about the after-sales support and warranty options provided by the supplier. Reliable after-sales service is essential for maintenance and repairs, which can minimize downtime. Look for warranties that cover critical components and ensure that the supplier has a local service network or can provide remote support.

Step 6: Conduct a Test Drive

Whenever possible, arrange for a test drive of the mini electric truck. This hands-on experience allows you to evaluate the vehicle’s performance, comfort, and handling. Pay attention to the ease of operation, visibility, and any additional features that may enhance your operational efficiency.

Step 7: Negotiate Terms and Finalize the Purchase

Once you’ve selected a supplier, negotiate the purchase terms. Discuss payment options, delivery timelines, and any customization requests. Clear communication during this phase can help avoid misunderstandings later and ensure that both parties are aligned on expectations.

By following this step-by-step checklist, B2B buyers can streamline their sourcing process for mini electric trucks, ensuring they choose the right vehicle that meets their operational requirements while maximizing value.

Comprehensive Cost and Pricing Analysis for mini electric truck lsv Sourcing

What Are the Key Cost Components for Mini Electric Truck LSVs?

When sourcing mini electric truck low-speed vehicles (LSVs), understanding the cost structure is crucial for international B2B buyers. Key cost components include:

-

Materials: The choice of materials significantly impacts cost. High-quality, lightweight materials like aluminum or specialized composites are often preferred for their durability and efficiency, yet they come at a premium. Additionally, battery technology (e.g., lithium-ion vs. lead-acid) is a major factor, with advanced batteries increasing the upfront cost but enhancing overall performance and lifespan.

-

Labor: Labor costs vary widely depending on the region of manufacturing. Countries with lower labor costs can offer competitive pricing, but this may come with trade-offs in quality. Skilled labor is essential for assembling sophisticated electric drivetrains and ensuring compliance with safety standards.

-

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, maintenance, and administrative expenses. Efficient production techniques can reduce overhead, allowing manufacturers to pass savings onto buyers.

-

Tooling: Initial setup costs for molds and production equipment can be substantial, especially for customized models. Buyers should consider how tooling costs are amortized over production runs, as larger orders often lead to lower per-unit tooling costs.

-

Quality Control (QC): Robust QC processes are essential for ensuring the reliability and safety of LSVs. While rigorous testing can increase production costs, it also mitigates risks related to recalls or warranty claims, which can be financially burdensome.

-

Logistics: Shipping costs are a critical factor for international buyers. Factors such as freight methods, distance, and local tariffs can significantly impact the total landed cost of vehicles. Understanding Incoterms is vital to clarify responsibilities and risks associated with shipping.

-

Margin: Manufacturers often build a profit margin into their pricing, which can vary based on brand reputation, market demand, and competition. Buyers should be aware of the typical margins in the industry to gauge whether a quote is reasonable.

How Do Price Influencers Affect Mini Electric Truck LSV Pricing?

Several price influencers can affect the final cost of mini electric trucks:

-

Volume/MOQ: Purchasing in larger quantities can lead to economies of scale, lowering the unit price. Suppliers may offer better pricing or additional benefits such as customized features for bulk orders.

-

Specifications and Customization: Custom features, such as specialized cargo beds or enhanced battery options, can increase the price. Buyers should clearly define their specifications to ensure accurate quotes.

-

Materials and Quality Certifications: The choice of materials and compliance with industry standards (like ISO certifications) can affect pricing. Higher-quality components often lead to a higher upfront cost but can enhance reliability and reduce maintenance costs over time.

-

Supplier Factors: The reputation and reliability of suppliers play a significant role in pricing. Established suppliers with a track record of quality may charge a premium, but this can be offset by lower risks and better service.

What Are the Best Negotiation Tips for International B2B Buyers?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant savings:

-

Understand Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, parts, and energy consumption. This holistic view can provide leverage in negotiations.

-

Leverage Competitive Quotes: Obtaining multiple quotes can empower buyers during negotiations. Presenting competitors’ pricing can encourage suppliers to offer better terms.

-

Negotiate Payment Terms: Flexible payment terms can improve cash flow. Consider options like deferred payments or financing through the supplier, which can ease the immediate financial burden.

-

Be Aware of Pricing Nuances: Prices may vary significantly based on local economic conditions, currency fluctuations, and import duties. Understanding these factors can help buyers negotiate better deals.

What Are the Pricing Nuances for International Buyers?

Buyers should be mindful of various nuances when sourcing mini electric trucks:

-

Currency Fluctuations: International transactions can be affected by changes in exchange rates. Locking in prices or negotiating in a stable currency can mitigate risks.

-

Import Tariffs and Duties: Different countries impose varying tariffs on imported vehicles, which can significantly impact total costs. Buyers should research these tariffs in advance.

-

Compliance with Local Regulations: Ensure that the vehicles meet local regulations for street-legal operation, as this can affect both cost and usability.

Disclaimer on Indicative Prices

Prices for mini electric trucks LSVs can vary widely based on configuration, supplier, and market conditions. The figures mentioned in this analysis are indicative and should be validated through direct quotes from manufacturers or suppliers. Always perform due diligence to ensure the best value for your investment.

Alternatives Analysis: Comparing mini electric truck lsv With Other Solutions

When considering options for urban logistics and utility transportation, B2B buyers often evaluate various solutions to determine the best fit for their operational needs. The mini electric truck LSV (Low-Speed Vehicle) presents a compelling option, but it’s essential to compare it against alternative technologies to make an informed decision. Below is a detailed comparison of the mini electric truck LSV against two viable alternatives: traditional gasoline utility vehicles and electric cargo bicycles.

Comparison Table

| Comparison Aspect | Mini Electric Truck LSV | Traditional Gasoline Utility Vehicle | Electric Cargo Bicycle |

|---|---|---|---|

| Performance | Top speed of 25 mph, payload of up to 2,204 lbs | Higher speed (up to 70 mph), larger payload capacity | Lower speed (up to 20 mph), limited payload (up to 400 lbs) |

| Cost | Starting at $19,950 | Typically $25,000 – $40,000 | Ranges from $1,500 to $5,000 |

| Ease of Implementation | Requires charging infrastructure, can operate on streets | Established fueling infrastructure, immediate availability | Minimal setup, charging can be done at home or workplace |

| Maintenance | Lower maintenance costs, fewer moving parts | Higher costs due to more complex engines | Very low maintenance, mainly tire and brake checks |

| Best Use Case | Urban delivery, facilities maintenance | Construction, heavy hauling, long-distance travel | Short-distance deliveries, urban commuting |

Detailed Breakdown of Alternatives

Traditional Gasoline Utility Vehicle

Traditional gasoline utility vehicles offer robust performance with higher speed and larger payload capacities, making them suitable for construction and heavy hauling tasks. However, they come with higher upfront costs and ongoing maintenance expenses due to their complex mechanical systems. Additionally, they contribute to carbon emissions, which may conflict with sustainability goals. For B2B buyers focused on extensive logistics requiring speed and heavy lifting, these vehicles remain a strong option, albeit with higher operational costs.

Electric Cargo Bicycle

Electric cargo bicycles are an eco-friendly alternative ideal for short-distance deliveries and urban commuting. With significantly lower upfront costs and minimal maintenance requirements, they appeal to businesses looking to reduce operational expenses. However, their limited speed and payload capacity make them less suitable for larger deliveries or longer routes. They excel in environments where maneuverability is essential, such as congested city streets, but may not fulfill the needs of businesses requiring more substantial hauling capabilities.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right transportation solution for your business involves assessing specific operational requirements, including payload capacity, range, and environmental considerations. For urban logistics where maneuverability and sustainability are priorities, the mini electric truck LSV offers a balanced approach with decent performance and lower emissions. In contrast, businesses needing to transport heavier loads over longer distances may find traditional gasoline vehicles more suitable despite their higher costs. Meanwhile, electric cargo bicycles can serve niche markets focused on short distances and eco-friendliness. Ultimately, understanding your operational needs will guide you in choosing the best solution for your logistics strategy.

Essential Technical Properties and Trade Terminology for mini electric truck lsv

What Are the Essential Technical Properties of Mini Electric Trucks (LSVs)?

Understanding the technical specifications of mini electric trucks, particularly Low-Speed Vehicles (LSVs), is crucial for international B2B buyers. These specifications not only dictate the vehicle’s performance but also its suitability for specific applications across various industries.

1. Motor Power and Efficiency

The motor power, typically expressed in kilowatts (kW), indicates the vehicle’s efficiency and performance. For instance, models like the MAX-EV LSV feature motors with power ratings ranging from 8 kW to 24 kW. A higher power rating usually translates to better acceleration and load-carrying capacity, making it essential for businesses that require reliable transportation for goods.

2. Battery Capacity and Range

Battery capacity, measured in kilowatt-hours (kWh), directly affects the vehicle’s range on a single charge. The MAX-EV LSV, for example, offers battery options that enhance its range from approximately 28-32 miles to an estimated 35-45 miles with improved battery technology. A longer range is critical for logistics and delivery services, ensuring that vehicles can cover greater distances without frequent recharging.

3. Payload Capacity

Payload capacity indicates the maximum weight that a vehicle can safely transport, often expressed in pounds or kilograms. Mini electric trucks like the Club Car Urban can carry payloads of up to 2,204 lbs. This property is vital for businesses in sectors such as construction and logistics, where transporting heavy materials is common.

4. Speed Limitations

LSVs are designed to operate at lower speeds, typically around 25 mph, to comply with road regulations. This speed limitation is significant for urban environments, where traffic conditions and safety regulations must be considered. Understanding these limitations helps businesses plan their logistics effectively.

5. Construction Material and Durability

The materials used in the construction of mini electric trucks, such as galvanized steel for the chassis, influence durability and maintenance costs. Vehicles built from high-grade materials tend to withstand harsh operating conditions, making them a better investment for businesses that operate in diverse environments.

What Trade Terminology Should B2B Buyers Know When Considering Mini Electric Trucks (LSVs)?

Familiarizing yourself with industry-specific terminology can facilitate smoother negotiations and ensure informed decision-making.

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of LSVs, understanding OEM partnerships can help buyers assess the quality and reliability of components used in the vehicle.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers, especially when planning inventory and budgeting for initial purchases. This term can significantly impact procurement strategies.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and availability for specific products. For mini electric trucks, submitting an RFQ allows buyers to compare offers from different manufacturers, ensuring they receive competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Understanding these terms helps buyers navigate shipping costs, insurance, and delivery responsibilities, which are essential in global transactions involving LSVs.

5. TCO (Total Cost of Ownership)

TCO encompasses all costs associated with purchasing and operating a vehicle over its lifespan, including acquisition, maintenance, fuel, and depreciation. Evaluating TCO is vital for B2B buyers to ensure they are making financially sound investments.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when selecting mini electric trucks that align with their operational needs and market conditions.

Navigating Market Dynamics and Sourcing Trends in the mini electric truck lsv Sector

What Are the Key Trends Shaping the Mini Electric Truck LSV Market?

The global market for mini electric trucks, specifically Low-Speed Vehicles (LSVs), is on an upward trajectory driven by several key factors. Increasing urbanization, particularly in regions like Africa, South America, the Middle East, and Europe, has created a pressing need for efficient, eco-friendly transportation solutions. As cities become more congested, the demand for vehicles that can navigate tight spaces while providing utility is rising. Additionally, heightened regulatory pressures aimed at reducing carbon footprints are pushing businesses to consider electric options over traditional combustion engines.

Emerging technologies are also influencing sourcing trends. For instance, advancements in battery technology, such as lithium-ion systems with higher energy density and faster charging capabilities, are making mini electric trucks more viable for a broader range of applications. Furthermore, the integration of smart technologies like fleet management systems and telematics is enhancing operational efficiencies, allowing businesses to monitor vehicle performance and optimize routes in real-time.

International buyers are increasingly focusing on suppliers who can demonstrate a commitment to sustainable practices and innovation. The competitive landscape is becoming more dynamic as manufacturers roll out models with customizable features and configurations to meet specific industry needs, from last-mile delivery to facility maintenance.

How Important Is Sustainability and Ethical Sourcing for Mini Electric Truck LSVs?

Sustainability is not just a buzzword; it has become a crucial factor in the purchasing decisions of B2B buyers in the mini electric truck LSV sector. The environmental impact of transportation has spurred businesses to seek out vehicles that produce zero tailpipe emissions. By investing in electric utility vehicles, companies can significantly reduce their carbon footprint and contribute to global sustainability goals.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are increasingly looking for manufacturers that prioritize responsible sourcing of materials, ensuring that components are produced in an environmentally friendly manner and that labor practices meet international standards. Certifications such as ISO 14001 for environmental management and adherence to the Global Reporting Initiative (GRI) guidelines can serve as indicators of a manufacturer’s commitment to sustainability.

Incorporating ‘green’ materials into the production of mini electric trucks also enhances their marketability. Manufacturers that utilize recycled or sustainably sourced materials can appeal to a growing segment of environmentally conscious buyers, making their offerings more attractive in a competitive landscape.

What Is the Evolution of the Mini Electric Truck LSV Market?

The mini electric truck LSV market has evolved significantly over the past two decades, transitioning from niche utility vehicles to essential components of urban logistics. Initially, these vehicles were primarily used in specific sectors like golf courses or gated communities. However, as urban landscapes have changed, so too has the demand for versatile, street-legal vehicles capable of fulfilling a variety of roles.

The introduction of regulations promoting cleaner transportation options has accelerated this evolution. Today’s mini electric trucks are designed with advanced features that enhance safety, comfort, and efficiency. Modern models offer customizable options such as varied cargo configurations, advanced battery systems, and smart technology integration, making them suitable for diverse applications—from last-mile delivery to facility maintenance.

The growing interest in electric vehicles, supported by government incentives and changing consumer preferences, is likely to propel further innovation in this sector, making it an attractive space for international B2B buyers looking for sustainable and efficient transportation solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of mini electric truck lsv

-

How do I choose the right mini electric truck LSV for my business needs?

Choosing the right mini electric truck LSV depends on your specific operational requirements. Consider factors like payload capacity, range, speed, and terrain adaptability. For instance, if your business involves last-mile delivery in urban areas, opt for models with agile handling and compact designs. Additionally, assess customization options such as cargo configurations and features like backup cameras or heating systems, which can enhance functionality based on your climate and usage scenarios. -

What are the key features to look for in a mini electric truck LSV?

Key features to consider include payload capacity, battery range, speed, and safety elements like seatbelts and mirrors. Look for electric trucks that offer customizable cargo options and various bed configurations to suit your specific needs. Other important features may include a robust electric drivetrain, backup cameras, and advanced braking systems. Also, consider the vehicle’s compliance with local regulations to ensure it meets street-legal requirements in your target market. -

What is the average lead time for ordering mini electric trucks LSV?

Lead times for mini electric truck LSV orders can vary based on the manufacturer, customization options, and the current demand. Typically, you can expect a lead time of 8 to 12 weeks for standard models. Custom configurations may take longer due to additional production steps. It’s advisable to communicate directly with suppliers to get precise timelines and plan your procurement process accordingly. -

What are the minimum order quantities (MOQ) for mini electric trucks LSV?

Minimum order quantities (MOQ) can differ significantly among manufacturers. Some may offer single-unit sales, while others may require bulk purchases, often starting at 5 to 10 units to qualify for wholesale pricing. For international buyers, negotiating MOQs can be crucial, especially if you are testing market demand. Always inquire about flexibility in MOQs, particularly if you are entering a new market. -

How can I vet suppliers of mini electric trucks LSV?

To vet suppliers, start by researching their reputation in the industry. Look for customer reviews, case studies, and testimonials to gauge their reliability and product quality. Additionally, request references from other clients, especially those in your target region. Ensure that the supplier adheres to international quality standards and has a track record of timely deliveries. Engaging in a direct conversation about their production processes and after-sales support can also provide valuable insights. -

What payment terms should I expect when purchasing mini electric trucks LSV?

Payment terms can vary widely based on the supplier and your relationship with them. Common terms include a deposit upon order confirmation (often 30-50%) with the balance due before shipment. Some suppliers may offer financing options or installment plans, especially for larger orders. Always clarify terms in writing and consider negotiating favorable conditions, such as extended payment periods or discounts for upfront payments. -

What are the logistics considerations for importing mini electric trucks LSV?

Logistics for importing mini electric trucks LSV involve multiple steps, including shipping, customs clearance, and local distribution. Choose a freight forwarder experienced in handling vehicle imports to manage the complexities of international shipping. Ensure you understand the regulations and tariffs in your destination country, which can impact overall costs. Additionally, consider the availability of local infrastructure for transport and storage upon arrival. -

What quality assurance measures should I check for when sourcing mini electric trucks LSV?

When sourcing mini electric trucks LSV, inquire about the supplier’s quality assurance protocols. Look for certifications such as ISO 9001 or specific automotive standards. Request details on their testing processes, including safety, performance, and durability tests, to ensure that the vehicles meet industry benchmarks. Understanding the warranty and after-sales support is also crucial, as it reflects the supplier’s commitment to product quality and customer satisfaction.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Mini Electric Truck Lsv Manufacturers & Suppliers List

1. Westward Industries – MAX-EV LSV

Domain: westwardindustries.com

Registered: 1999 (26 years)

Introduction: Product Name: MAX-EV LSV

Type: Low Speed Electric Utility Vehicle

Seating Capacity: 2 and 4-seater options

Starting Price: $19,950 (USD, may exclude freight and local taxes)

Payload Capacity: Up to 1,500 lbs

Battery Options: 8kWh to 32kWh Lithium-Ion batteries

Estimated Range: 35-45 miles (8kWh), up to 120 miles (20kWh)

Top Speed: 25 mph (for on-road models), 52 mph (for higher models)

Features:

…

2. Club Car – Urban LSV

Domain: clubcar.com

Registered: 1996 (29 years)

Introduction: Club Car Urban is available in two versions: XR (non street legal) and LSV (street legal). The LSV model includes features such as 3-point seatbelts, mirrors, tail lights, brake lights, turn signals, a horn, an in-dash storage compartment, and a backup camera system. It has a top speed of 25 mph and a payload capacity of up to 1,400 lbs with lithium battery options. The XR model has a payload capa…

3. Vantage – Electric Low-Speed Vehicles

Domain: vantagevehicle.com

Registered: 2001 (24 years)

Introduction: Vantage’s electric low-speed vehicles (LSVs) provide eco-friendly transport solutions for various businesses and facilities. Key features include: 1. Zero emissions, contributing to cleaner air and reduced environmental impact. 2. Street-legal operation up to 25 mph, suitable for urban and industrial environments. 3. Powered by 100% lithium electric charging systems, requiring no specialized conne…

4. ScooterCarz – Truck Golf Car 4 Seater LSV

Domain: scootercarz.com

Registered: 2020 (5 years)

Introduction: {“Product Name”: “Truck Golf Car 4 Seater LSV Low Speed Vehicle”, “Model”: “60v Coco Truck Golf Cart”, “Dimensions”: “2400 x 1200 x 1620mm / 94″ x 47″ x 64″”, “Ground Clearance”: “10””, “Motor Power”: “1500 Watt”, “Range”: “Approximately Up To 35 Miles Per Charge (Depends On Weight and Terrain)”, “Controller”: “24 tubes”, “Tire Size”: “400-10”, “Body Structure”: “Two Doors & Four Seats”, “Brake Ty…

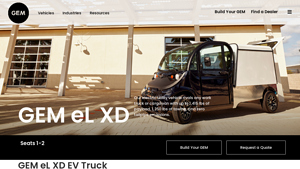

5. GEM – eL XD Electric Utility Vehicle

Domain: gemcar.com

Registered: 1998 (27 years)

Introduction: GEM eL XD Electric Utility Vehicle

– Payload Capacity: 1,415 lbs

– Towing Capacity: 1,250 lbs

– Range: Up to 78 miles between charges

– Seating: 1-2 passengers

– Dimensions: Length 146 in, Width 55.5 in, Height 73 in

– Bed Dimensions: 70 in long, 48 in wide

– Turning Radius: 194 in

– Wheelbase: 114 in

– Ground Clearance: 8 in

– Dry Weight: 1,585 lbs

– Gross Vehicle Weight (GVW): 3,000 lbs

– Motor …

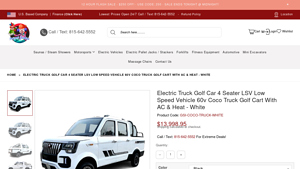

6. Coco – Electric Truck Golf Car 4 Seater LSV

Domain: importjunkies.com

Registered: 2022 (3 years)

Introduction: {“Product Name”: “Electric Truck Golf Car 4 Seater LSV Low Speed Vehicle 60v Coco Truck Golf Cart With AC & Heat – White”, “Product Code”: “GSI-COCO-TRUCK-WHITE”, “Regular Price”: “$13,998.95”, “Dimensions”: “3900x1450x1650mm / 154x57x65in”, “Motor”: “4000W”, “Controller”: “30 Tubes”, “Tire”: “145 Vacuum”, “Brake”: “Four Wheel Disc Brake”, “Drive Way”: “RWD”, “Maximum Cruising Range”: “70-130km / …

Strategic Sourcing Conclusion and Outlook for mini electric truck lsv

In the evolving landscape of electric utility vehicles, mini electric trucks (LSVs) represent a strategic opportunity for businesses aiming to enhance operational efficiency while adhering to sustainability goals. With their compact design, robust performance, and versatile applications, these vehicles are ideal for urban logistics, facilities maintenance, and last-mile delivery services. The Club Car Urban and Westward MAX-EV showcase the adaptability and innovation within this segment, offering customizable options to meet specific business needs.

For international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe, strategic sourcing of mini electric trucks is essential. It enables businesses to capitalize on the growing demand for eco-friendly transportation solutions while ensuring compliance with local regulations. As the market continues to expand, leveraging partnerships with reputable manufacturers will provide access to the latest technology and competitive pricing.

Looking ahead, now is the time to invest in mini electric trucks to future-proof your logistics operations. Engage with suppliers to explore tailored solutions that align with your sustainability objectives, operational requirements, and budget constraints. Embrace the shift towards electric mobility—your business and the planet will benefit.