Introduction: Navigating the Global Market for new Condition Refrigerated Truck

In today’s global marketplace, sourcing new condition refrigerated trucks poses a significant challenge for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. With the increasing demand for efficient transportation of perishable goods, understanding the intricacies of refrigerated truck procurement is crucial. This guide serves as a comprehensive resource, detailing various types of refrigerated trucks, their applications, and the vital features that enhance performance and reliability.

From reefer vans to heavy-duty trucks, we delve into the specifications that matter most, including insulation materials, refrigeration units, and fuel types. Additionally, we provide insights into the supplier vetting process, ensuring that buyers can identify reputable manufacturers and distributors. The guide also addresses cost considerations, helping you navigate the financial aspects of acquiring these essential vehicles.

By arming B2B buyers with the knowledge to make informed purchasing decisions, this resource empowers businesses to enhance their logistics capabilities and ensure the safe transport of temperature-sensitive products. Whether you are in the food industry, pharmaceuticals, or any sector reliant on refrigerated transport, understanding these elements will lead to better procurement strategies and ultimately, a more successful operation.

Understanding new Condition Refrigerated Truck Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Reefer Van | Insulated cargo area, compact size, often built on a chassis like a Sprinter. | Urban deliveries of perishable goods. | Pros: Maneuverable in city traffic; Cons: Limited cargo capacity compared to larger trucks. |

| Reefer Box Truck | Larger, enclosed cargo area, typically with a rigid frame and insulated walls. | Distribution of food and pharmaceuticals. | Pros: Greater volume and weight capacity; Cons: Less maneuverable than vans. |

| Multi-Temperature Reefer | Equipped with multiple temperature zones, often with advanced monitoring systems. | Transporting different products requiring varying temperatures. | Pros: Versatile for diverse cargo; Cons: More complex systems may require specialized training. |

| Straight Truck Reefer | Built on a single chassis, with a fixed body for larger loads, often used for heavy-duty applications. | Long-haul transportation of bulk perishables. | Pros: High load capacity; Cons: Limited flexibility in routing. |

| Truck and Trailer Reefer | Combination of a truck with a refrigerated trailer, ideal for extensive logistics operations. | Large-scale distribution networks. | Pros: Maximum cargo flexibility; Cons: Requires more space and driving skill. |

What Are the Key Characteristics of Reefer Vans?

Reefer vans are compact, insulated vehicles designed for urban deliveries of perishable goods. These vehicles are built on chassis like the Mercedes-Benz Sprinter, making them highly maneuverable in tight city environments. Ideal for businesses such as florists or small food distributors, they can be outfitted with refrigeration units that maintain optimal temperature conditions. Buyers should consider the limited cargo capacity when choosing this type, as it may not be suitable for larger shipments.

How Do Reefer Box Trucks Meet Diverse B2B Needs?

Reefer box trucks feature a larger, enclosed cargo area with insulated walls, making them suitable for transporting food products, pharmaceuticals, and other temperature-sensitive items. Their rigid frame allows for significant volume and weight capacity, making them a preferred choice for businesses needing to distribute large quantities of goods efficiently. However, their size can be a drawback in urban settings where maneuverability is crucial. Buyers should evaluate their delivery routes and volume needs when considering this option.

What Advantages Do Multi-Temperature Reefers Offer?

Multi-temperature reefers are specialized refrigerated trucks equipped with separate temperature zones, allowing for the transport of various products that require different storage conditions. This versatility makes them particularly valuable for companies in the food and pharmaceutical sectors. While they provide significant operational flexibility, the complexity of their systems may necessitate additional training for drivers and maintenance personnel. Companies should assess their product range and the need for temperature control when considering this investment.

Why Choose a Straight Truck Reefer for Long-Haul Transport?

Straight truck reefers are built on a single chassis with a fixed body, making them ideal for heavy-duty applications and long-haul transportation of bulk perishables. Their high load capacity allows businesses to maximize shipments, reducing the number of trips required. However, their fixed nature can limit routing flexibility, which may impact delivery efficiency. Companies should weigh the benefits of capacity against the need for flexible logistics solutions when selecting this type.

How Do Truck and Trailer Reefers Enhance Logistics Operations?

Truck and trailer reefers combine a truck with a refrigerated trailer, offering maximum cargo flexibility and capacity, making them suitable for extensive logistics operations. This configuration allows businesses to transport large quantities of goods over long distances efficiently. However, they require more space for parking and maneuvering, and drivers need specialized skills to handle the combination effectively. Organizations should consider their logistical requirements and driver capabilities when opting for this type of refrigerated truck.

Key Industrial Applications of new Condition Refrigerated Truck

| Industry/Sector | Specific Application of new Condition Refrigerated Truck | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Transporting fresh produce and dairy products | Ensures product freshness, reduces spoilage rates | Temperature control capabilities, payload capacity, fuel efficiency |

| Pharmaceuticals | Delivering temperature-sensitive medical supplies | Maintains drug efficacy, complies with regulations | Insulation quality, refrigeration unit reliability, tracking systems |

| Floral Industry | Shipping cut flowers and plants | Extends product life, enhances customer satisfaction | Customization options, humidity control, delivery timing |

| E-commerce and Retail | Distributing perishable goods to online customers | Expands market reach, improves service reliability | Vehicle size, load optimization, route planning technology |

| Seafood Industry | Transporting fresh and frozen seafood | Preserves quality, meets health regulations | Refrigeration technology, compliance with food safety standards |

In the Food and Beverage sector, new condition refrigerated trucks are essential for transporting fresh produce and dairy products. These vehicles are equipped with advanced temperature control systems that ensure the integrity of perishable goods during transit. This is particularly critical in regions with fluctuating climates, such as parts of Africa and South America, where maintaining a consistent temperature can significantly reduce spoilage rates. Buyers should consider the truck’s insulation quality and payload capacity to optimize their logistics.

The Pharmaceuticals industry relies heavily on refrigerated trucks for delivering temperature-sensitive medical supplies, including vaccines and biologics. These trucks help maintain the efficacy of drugs, which is vital for patient safety and regulatory compliance. For international buyers, especially in the Middle East and Europe, it is crucial to assess the insulation quality and reliability of the refrigeration unit. Additionally, tracking systems that monitor temperature during transit can provide added assurance of compliance with stringent health regulations.

In the Floral Industry, refrigerated trucks are used to ship cut flowers and plants, extending their shelf life and enhancing customer satisfaction. The ability to maintain a controlled environment during transit is essential, particularly in regions with high temperatures. Buyers should look for customization options that cater to their specific needs, such as humidity control features and the ability to manage delivery timing effectively.

The rise of E-commerce and Retail has made refrigerated trucks vital for distributing perishable goods to online customers. These vehicles enable businesses to expand their market reach while improving service reliability. For international buyers, considerations such as vehicle size and load optimization are critical, as they can impact delivery efficiency and cost-effectiveness. Technologies that facilitate route planning can also enhance operational efficiency.

Finally, in the Seafood Industry, new condition refrigerated trucks are crucial for transporting fresh and frozen seafood products. These vehicles help preserve quality and ensure compliance with health regulations, which is especially important in markets with strict food safety standards. Buyers should focus on the type of refrigeration technology used and ensure that it meets local compliance requirements, particularly in regions like Europe where regulations are stringent.

3 Common User Pain Points for ‘new Condition Refrigerated Truck’ & Their Solutions

Scenario 1: Ensuring Temperature Consistency During Transportation

The Problem: One of the most pressing concerns for B2B buyers of refrigerated trucks is maintaining the required temperature for perishable goods throughout the entire transportation process. Variability in temperature can lead to spoilage, resulting in significant financial losses and damage to a company’s reputation. In regions with extreme weather, such as the Middle East or South America, the challenge intensifies, as external temperatures can fluctuate widely. Buyers often worry about the reliability of the refrigeration unit and the insulation quality of the truck, fearing that even slight deviations can compromise their cargo.

The Solution: To address this issue, buyers should prioritize sourcing trucks equipped with advanced refrigeration systems that offer real-time temperature monitoring capabilities. Investing in units from reputable brands like Thermo King or Carrier can provide peace of mind, as these systems are designed to maintain consistent temperatures and alert drivers to any deviations. Additionally, prospective buyers should examine the insulation materials and construction of the truck, ensuring that they meet industry standards for thermal efficiency. Opting for features like dual-zone temperature control can be beneficial for transporting various types of perishables simultaneously. Lastly, conducting regular maintenance checks on the refrigeration unit will ensure optimal performance and longevity.

Scenario 2: Navigating Compliance with Local Regulations

The Problem: B2B buyers often face challenges understanding and complying with local regulations concerning the transport of temperature-sensitive goods. Different regions, especially in Europe and Africa, have unique compliance standards regarding food safety and vehicle specifications. Failure to adhere to these regulations can result in hefty fines, legal issues, and disrupted business operations. Buyers may feel overwhelmed by the complexity of ensuring their refrigerated trucks meet all necessary criteria before entering new markets.

The Solution: To navigate this regulatory landscape, buyers should conduct thorough research into the specific regulations applicable to their target markets. Consulting with local authorities or industry associations can provide valuable insights into compliance requirements. Additionally, buyers should consider working with suppliers who have expertise in international logistics, as they can offer guidance on appropriate truck specifications and documentation needed for cross-border transport. Including features that facilitate compliance, such as temperature data loggers and easy-to-clean interiors, can also enhance the truck’s suitability for various markets. Collaborating with legal advisors familiar with transportation regulations will further safeguard against potential pitfalls.

Scenario 3: Managing Operational Costs Effectively

The Problem: The total cost of ownership (TCO) is a significant concern for businesses investing in new refrigerated trucks. Buyers often struggle with the balance between purchasing high-quality vehicles that ensure reliability and managing operational costs, including fuel efficiency, maintenance, and insurance. In regions with volatile fuel prices, particularly in parts of Africa and South America, the pressure to keep operational expenses low while ensuring reliable service can create anxiety for decision-makers.

The Solution: To mitigate these concerns, buyers should perform a comprehensive analysis of the TCO before making a purchase. This includes evaluating different models based on fuel efficiency ratings, which can vary significantly across brands and configurations. Buyers should also inquire about the availability of alternative fuel options, such as biodiesel or electric refrigerated trucks, which can lead to long-term savings and reduced environmental impact. Furthermore, investing in telematics systems can optimize routing and driving behaviors, leading to lower fuel consumption and maintenance costs. Establishing a proactive maintenance schedule can help prevent costly repairs and downtime, ensuring the truck remains operational and efficient throughout its lifespan.

Strategic Material Selection Guide for new Condition Refrigerated Truck

When selecting materials for new condition refrigerated trucks, it is crucial to consider their properties, advantages, disadvantages, and how they align with international standards. This guide analyzes four common materials used in refrigerated truck construction: aluminum, stainless steel, fiberglass, and polyurethane foam. Each material has unique characteristics that can significantly impact the performance and longevity of the vehicle, especially in diverse climates and regulatory environments.

What Are the Key Properties of Aluminum in Refrigerated Trucks?

Aluminum is widely used in the construction of refrigerated trucks due to its lightweight nature and excellent thermal conductivity. It typically has a temperature rating of up to 200°F and is highly resistant to corrosion, making it suitable for various weather conditions. Its low density contributes to better fuel efficiency, which is a critical factor for B2B buyers looking to reduce operational costs.

Pros and Cons of Aluminum: The primary advantage of aluminum is its balance between weight and strength, leading to enhanced payload capacity. However, it can be more expensive than other materials, and its susceptibility to dents may require additional protective measures. For international buyers, compliance with standards like ASTM B209 can be essential for ensuring quality.

How Does Stainless Steel Compare in Terms of Durability?

Stainless steel is another popular choice for refrigerated trucks, particularly for structural components and interiors. It boasts high corrosion resistance and can withstand extreme temperatures, making it ideal for transporting perishable goods. Its pressure rating is generally higher than aluminum, which adds to its durability.

Pros and Cons of Stainless Steel: The key advantage of stainless steel is its strength and longevity, which can lead to lower maintenance costs over time. However, it is heavier than aluminum, which may affect fuel efficiency. Buyers in regions with strict regulations, such as Germany and other EU countries, will find that stainless steel often meets the necessary compliance standards.

What Role Does Fiberglass Play in Insulation?

Fiberglass is primarily used for insulation in refrigerated trucks. It has excellent thermal resistance, typically able to maintain temperatures below 0°F, making it suitable for transporting sensitive goods like pharmaceuticals. Fiberglass is also lightweight, which contributes to overall vehicle efficiency.

Pros and Cons of Fiberglass: The main advantage of fiberglass is its superior insulation properties, which can significantly reduce energy costs. However, it can be prone to cracking under extreme stress and may require more complex manufacturing processes. For international buyers, ensuring compliance with insulation standards like JIS A 9511 can be crucial.

Why is Polyurethane Foam Essential for Thermal Efficiency?

Polyurethane foam is often used as insulation material in refrigerated trucks due to its high R-value, which indicates its effectiveness in thermal resistance. It can maintain low temperatures effectively, making it ideal for transporting perishable items.

Pros and Cons of Polyurethane Foam: The key advantage of polyurethane foam is its lightweight and high insulation efficiency, which can lead to reduced energy consumption. However, it may not be as durable as other materials and can be affected by moisture. Buyers should consider local regulations regarding insulation materials, particularly in regions with stringent environmental standards.

Summary Table of Material Selection for Refrigerated Trucks

| Material | Typical Use Case for new Condition Refrigerated Truck | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Truck body and structural components | Lightweight and fuel-efficient | Prone to dents, higher cost | Medium |

| Stainless Steel | Structural components, interiors | High strength and corrosion resistance | Heavier, potentially higher maintenance | High |

| Fiberglass | Insulation for temperature control | Excellent thermal resistance | Prone to cracking, complex manufacturing | Medium |

| Polyurethane Foam | Insulation for refrigerated compartments | High R-value, energy-efficient | Less durable, moisture sensitivity | Medium |

This analysis provides essential insights for international B2B buyers, enabling them to make informed decisions regarding material selection for new condition refrigerated trucks. Understanding the properties and implications of each material can lead to better performance, compliance with local standards, and ultimately, enhanced operational efficiency.

In-depth Look: Manufacturing Processes and Quality Assurance for new Condition Refrigerated Truck

What Are the Main Stages of Manufacturing a New Condition Refrigerated Truck?

The manufacturing of new condition refrigerated trucks involves several critical stages that ensure the final product meets the high standards required for transporting perishable goods. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality materials, which are crucial for insulation and durability. Common materials used include reinforced steel for the truck chassis, composite materials for the refrigerated box, and specialized insulation that provides thermal efficiency. Quality checks are conducted on these materials to ensure they meet specifications before proceeding.

-

Forming: In this stage, the materials are shaped into the necessary components. Advanced techniques such as CNC machining, laser cutting, and pressing are employed to create precise parts that fit together seamlessly. For the refrigerated box, panels are often formed using vacuum forming or injection molding techniques, which enhance insulation properties.

-

Assembly: Once the components are prepared, assembly begins. This involves integrating the refrigeration unit, which is a critical aspect of the refrigerated truck. Typically, manufacturers use modular assembly lines where teams focus on specific tasks, ensuring efficiency. During assembly, quality checkpoints are established to verify that components fit correctly and function as intended.

-

Finishing: The finishing stage includes painting and applying protective coatings to the truck body. This not only enhances aesthetic appeal but also protects against corrosion, especially for trucks that will operate in harsh environments. Final inspections are conducted to ensure that the truck meets all regulatory standards and customer specifications before delivery.

How Is Quality Assurance Implemented in Refrigerated Truck Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the final product adheres to international standards and industry-specific regulations.

-

What International Standards Are Relevant?

International standards such as ISO 9001 are essential in establishing a quality management system that focuses on continuous improvement and customer satisfaction. Compliance with these standards demonstrates a commitment to quality and reliability, making it easier for B2B buyers to trust the manufacturer. -

What Industry-Specific Certifications Should Buyers Look For?

For refrigerated trucks, certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) are important indicators of safety and performance. CE marking ensures that the product meets European health, safety, and environmental protection standards, while API standards apply to certain components like engines and refrigeration units.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are established at various stages of manufacturing to catch defects early and ensure compliance with standards.

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components upon arrival at the manufacturing facility. Tests may include dimensional checks, material composition analysis, and visual inspections to ensure they meet specifications.

-

In-Process Quality Control (IPQC): During the assembly phase, IPQC involves continuous monitoring of the manufacturing process. This can include checking the fit and function of components as they are assembled, as well as conducting tests on refrigeration units to ensure they operate within the required temperature ranges.

-

Final Quality Control (FQC): Before a refrigerated truck is delivered, a comprehensive final inspection is conducted. This includes functional tests of the refrigeration system, visual inspections for paint quality, and verification of compliance with international and industry-specific standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers need to have confidence in their suppliers’ QC processes, especially when purchasing refrigerated trucks for international markets. Here are several methods to ensure quality:

-

Conduct Supplier Audits: Periodic audits of the manufacturing facility can provide insights into the supplier’s QC processes. Buyers should assess whether the supplier adheres to international standards and maintains proper documentation of their QA procedures.

-

Request QC Reports: Suppliers should be able to provide detailed QC reports that outline the results of inspections and tests conducted throughout the manufacturing process. These reports can help buyers understand the reliability of the products they are purchasing.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s QC processes. Inspectors can verify compliance with standards and evaluate the overall quality of the refrigerated trucks before shipment.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

For B2B buyers operating in diverse markets such as Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certification is crucial.

-

Regional Standards and Regulations: Different regions may have varying standards and regulations for refrigerated trucks. Buyers should familiarize themselves with local requirements, such as the European Union’s stringent environmental and safety regulations, or specific certifications needed in African markets.

-

Cultural and Logistical Considerations: Cultural differences may influence communication and expectations regarding quality. Buyers should establish clear lines of communication with suppliers and consider logistical challenges that may affect delivery timelines and product integrity.

-

Building Long-Term Relationships: Establishing a long-term relationship with suppliers can facilitate better understanding and adherence to quality standards. Regular feedback and collaboration on quality improvements can enhance the reliability of the supply chain.

Conclusion

Manufacturing new condition refrigerated trucks is a complex process that requires meticulous attention to detail at every stage, from material preparation to finishing. By understanding the manufacturing processes and quality assurance measures in place, B2B buyers can make informed decisions when selecting suppliers. With the right knowledge of international standards and QC practices, buyers can ensure they are investing in reliable, high-quality refrigerated trucks suitable for their specific market needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘new Condition Refrigerated Truck’

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure new condition refrigerated trucks. Given the complexities involved in sourcing refrigerated transport solutions, this guide aims to streamline the process, ensuring that buyers make informed decisions that align with their logistical needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital to ensure that the refrigerated truck meets your operational requirements. Consider factors such as the size of the truck, the type of refrigeration unit, and the insulation materials.

– Capacity Needs: Assess the volume and weight of the perishable goods you intend to transport to choose an appropriately sized truck.

– Temperature Range: Determine the required temperature range for your products to select a truck with a compatible refrigeration system.

Step 2: Research Regulatory Compliance

Before proceeding with a purchase, it’s essential to understand the regulatory standards in your region. Refrigerated trucks must comply with local laws regarding the transport of perishable goods.

– Certification Requirements: Check for necessary certifications such as HACCP (Hazard Analysis Critical Control Point) compliance, which ensures food safety.

– Import Regulations: If sourcing from international suppliers, familiarize yourself with import regulations that may affect your purchase.

Step 3: Evaluate Potential Suppliers

Conduct a thorough evaluation of potential suppliers to ensure they have a proven track record in delivering quality refrigerated trucks.

– Request Documentation: Ask for company profiles, product catalogs, and customer references to gauge their reliability and service quality.

– Industry Experience: Look for suppliers with experience in your specific industry or region, as they are more likely to understand your unique needs.

Step 4: Inspect the Truck Features

When considering a refrigerated truck, inspect key features that enhance functionality and efficiency.

– Refrigeration Unit: Evaluate the type of refrigeration system (e.g., diesel, electric) and its energy efficiency ratings.

– Additional Features: Consider features such as liftgates for easy loading and unloading, as well as cargo control systems to secure your goods during transit.

Step 5: Verify Warranty and After-Sales Support

A robust warranty and reliable after-sales support are critical components of your purchase decision.

– Warranty Coverage: Confirm the duration and coverage of the warranty for both the truck and the refrigeration unit, including parts and labor.

– Service Availability: Assess the availability of local service centers for maintenance and repairs to minimize downtime.

Step 6: Compare Pricing and Financing Options

Gather pricing information from multiple suppliers to ensure you receive a competitive deal.

– Total Cost of Ownership: Look beyond the initial purchase price; consider maintenance, fuel efficiency, and potential resale value.

– Financing Solutions: Explore financing options that may be available, such as leasing or installment plans, to better manage cash flow.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier and a specific truck, ensure that all terms are clearly outlined in the purchase agreement.

– Review Terms: Carefully review payment terms, delivery schedules, and any additional costs before signing.

– Legal Considerations: Consider involving legal counsel to review the contract to safeguard your interests.

By following these steps, B2B buyers can effectively navigate the process of sourcing new condition refrigerated trucks, ensuring they meet their operational needs while adhering to regulatory requirements and budget constraints.

Comprehensive Cost and Pricing Analysis for new Condition Refrigerated Truck Sourcing

What Are the Key Cost Components in Sourcing New Refrigerated Trucks?

When sourcing new condition refrigerated trucks, understanding the cost structure is paramount. The primary cost components include:

-

Materials: The quality and type of materials used in the truck’s construction significantly affect pricing. High-quality insulation, refrigeration units, and durable chassis materials can lead to higher initial costs but provide better long-term performance and reliability.

-

Labor: Labor costs vary based on geographic location and the skill level required for assembly. Regions with higher wage standards may present increased labor costs, which can impact the final price of the truck.

-

Manufacturing Overhead: This includes factory expenses such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can lower overhead, but any inefficiencies can inflate costs.

-

Tooling: Customization often requires specialized tools and equipment, particularly if the truck needs unique specifications. The more complex the customization, the higher the tooling costs.

-

Quality Control (QC): Implementing rigorous quality control measures ensures product reliability but adds to the overall cost. Investing in QC can prevent costly recalls and warranty claims in the long run.

-

Logistics: Shipping costs can vary widely depending on the origin and destination. Factors such as distance, mode of transport, and fuel prices can influence logistics expenses.

-

Margin: Supplier profit margins also play a role. Established brands with strong reputations may command higher margins, reflecting their perceived value.

How Do Price Influencers Affect the Cost of Refrigerated Trucks?

Several factors can influence the pricing of refrigerated trucks:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk typically allows for negotiated discounts. Buyers should assess their current and future needs to determine the best order volume.

-

Specifications and Customization: Custom features, such as specific refrigeration units or unique body configurations, can drive up costs. Buyers should carefully evaluate which specifications are essential for their operations.

-

Materials and Quality Certifications: The choice of materials directly affects durability and efficiency. Trucks with certifications for energy efficiency or environmental standards may have higher upfront costs but lower operational costs over time.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may offer better after-sales support, warranty terms, and reliability, justifying a higher price.

-

Incoterms: International shipping terms can affect total costs. Buyers should understand their responsibilities for shipping, insurance, and tariffs to accurately calculate the total landed cost.

What Buyer Tips Can Enhance Cost Efficiency in Refrigerated Truck Sourcing?

B2B buyers can leverage several strategies to ensure cost-effective sourcing:

-

Negotiation: Engage in thorough negotiations with suppliers. Understand the market rates and be prepared to discuss pricing based on volume, payment terms, and delivery schedules.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront price. Consider factors such as maintenance, fuel efficiency, and resale value, which can significantly affect long-term costs.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import tariffs, and regional regulations that can impact pricing. Staying informed about local market conditions can aid in making better purchasing decisions.

-

Research and Comparison: Conduct thorough market research to compare different suppliers and models. Utilize online platforms to gather insights on pricing and features, ensuring informed decisions.

Conclusion

Sourcing new condition refrigerated trucks involves a complex interplay of costs and pricing influencers. By understanding the cost components, recognizing price influencers, and employing strategic buying tips, international B2B buyers can navigate the market effectively and make informed purchasing decisions. Always keep in mind that prices can vary significantly based on numerous factors, so it’s crucial to seek detailed quotations and understand the full context of any pricing discussions.

Alternatives Analysis: Comparing new Condition Refrigerated Truck With Other Solutions

Introduction: Exploring Alternatives to New Condition Refrigerated Trucks

In the realm of transporting perishable goods, selecting the right method or vehicle is crucial for maintaining product quality and ensuring efficiency. While new condition refrigerated trucks are a popular choice, several alternative solutions can also meet the needs of businesses across various industries. This analysis compares refrigerated trucks against two viable alternatives: portable refrigeration units and refrigerated shipping containers, providing B2B buyers with comprehensive insights to inform their purchasing decisions.

Comparison Table

| Comparison Aspect | New Condition Refrigerated Truck | Portable Refrigeration Units | Refrigerated Shipping Containers |

|---|---|---|---|

| Performance | High, with consistent temperature control for various cargo sizes | Moderate, suitable for specific applications and limited capacity | High, ideal for bulk transport over longer distances |

| Cost | High initial investment; operational costs vary based on fuel and maintenance | Lower initial cost, but rental fees can accumulate over time | Moderate to high initial investment; shipping costs depend on distance and logistics |

| Ease of Implementation | Requires specific training and a driver’s license; operational logistics to consider | Quick setup; portable and easy to deploy | Complex logistics; requires transport to and from shipping ports |

| Maintenance | Regular maintenance required for both the truck and refrigeration unit | Minimal maintenance; units are often rented or leased | Requires maintenance of the shipping container and refrigeration system |

| Best Use Case | Ideal for local and regional deliveries of fresh goods | Best for short-term events or temporary needs; suitable for catering and outdoor events | Optimal for international shipping and long-distance transport of bulk perishable goods |

Detailed Breakdown of Alternatives

1. Portable Refrigeration Units

Portable refrigeration units offer a flexible alternative to refrigerated trucks, particularly for businesses that require temporary cold storage solutions. They are easy to set up and can be rented for short durations, making them ideal for events like catering services or festivals. However, their capacity is limited compared to trucks, which may restrict the volume of goods transported. Additionally, while initial costs are lower, rental fees can add up, potentially making them less cost-effective for long-term use.

2. Refrigerated Shipping Containers

Refrigerated shipping containers are another robust alternative, especially for businesses involved in international trade. These containers maintain a stable temperature and are designed for bulk shipments, making them suitable for transporting large quantities of perishable goods over long distances. However, the logistics surrounding their use can be complicated, requiring coordination with shipping lines and consideration of port facilities. Moreover, the initial investment can be substantial, and ongoing shipping costs can vary based on distance and logistics.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right solution for transporting perishable goods, B2B buyers must consider several factors, including performance requirements, budget constraints, and operational logistics. New condition refrigerated trucks provide reliable, high-capacity transport for local deliveries, while portable refrigeration units offer flexibility for short-term needs. Refrigerated shipping containers excel in bulk transport for international shipping but come with complex logistics. Ultimately, understanding the specific demands of your business and the nature of the products being transported will guide you to the optimal choice that balances cost, efficiency, and reliability.

Essential Technical Properties and Trade Terminology for new Condition Refrigerated Truck

What Are the Key Technical Properties of New Condition Refrigerated Trucks?

When investing in new condition refrigerated trucks, understanding their technical properties is crucial for ensuring the right fit for your logistics needs. Here are some essential specifications to consider:

-

Insulation Material

The insulation material used in refrigerated trucks significantly affects temperature retention. Common materials include polyurethane foam and polystyrene, which offer high thermal resistance. This property is vital as it prevents temperature fluctuations that can compromise the quality of perishable goods, thereby safeguarding your investment and meeting health regulations. -

Refrigeration Unit Capacity

The capacity of the refrigeration unit, typically measured in BTUs (British Thermal Units), indicates how much heat the unit can remove from the cargo area within an hour. A higher BTU rating is essential for transporting larger volumes of perishable goods over longer distances, especially in warmer climates. This specification directly impacts operational efficiency and ensures that products remain at optimal temperatures throughout transit. -

Payload Capacity

The payload capacity refers to the maximum weight the truck can carry, including both the vehicle’s weight and the cargo. This property is crucial for B2B buyers to ensure compliance with local regulations and to optimize transport costs. Understanding payload limits helps businesses avoid penalties and ensures that they maximize their delivery efficiency. -

Chassis Material and Design

The chassis material, often steel or aluminum, affects the truck’s weight, durability, and maintenance costs. A lightweight chassis can enhance fuel efficiency, while a robust design ensures longevity and resilience against wear and tear. Buyers should consider the trade-off between weight and strength to select a truck that meets their operational demands. -

Temperature Range

Refrigerated trucks can maintain various temperature ranges, from deep freezing (-20°C) to cool storage (0°C to 4°C). Knowing the required temperature range for your specific cargo type is vital for selecting the appropriate vehicle. This property ensures that your products remain safe and compliant with international shipping standards.

Which Trade Terminology Should B2B Buyers Understand for Refrigerated Trucks?

Navigating the purchase of new refrigerated trucks involves familiarity with specific industry terminology. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. For refrigerated trucks, understanding which OEMs supply the refrigeration units or chassis can help buyers assess quality and compatibility, ensuring they invest in reliable components. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. In the context of refrigerated trucks, knowing the MOQ can influence purchasing decisions, especially for fleet buyers who need multiple units. This term is critical for budgeting and inventory planning. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers requesting price quotes for specific products or services. For refrigerated trucks, an RFQ helps buyers compare costs and features across different manufacturers, ensuring they secure the best value for their investment. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping costs and risk transfer. Familiarity with these terms helps buyers navigate logistics and understand their obligations, which is essential when importing refrigerated trucks from different countries. -

Cold Chain Logistics

This term refers to the supply chain process that maintains a specific temperature range for perishable goods from production to consumption. Understanding cold chain logistics is crucial for businesses involved in the transport of food and pharmaceuticals, as it ensures product integrity and compliance with safety standards. -

Thermo King / Carrier Transicold

These are leading brands of refrigeration units commonly used in refrigerated trucks. Familiarity with these brands allows buyers to evaluate the reliability and performance of the refrigeration systems, which is vital for ensuring the success of temperature-sensitive deliveries.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, optimizing their operations while ensuring compliance and efficiency in transporting perishable goods.

Navigating Market Dynamics and Sourcing Trends in the new Condition Refrigerated Truck Sector

What Are the Key Trends Shaping the New Condition Refrigerated Truck Market?

The global refrigerated truck market is currently experiencing significant transformations driven by several factors. The demand for cold chain logistics is surging, particularly in developing regions like Africa and South America, where the need for efficient transportation of perishable goods is critical. This demand is fueled by the growth of the food and pharmaceutical sectors, which require stringent temperature controls to maintain product integrity. Additionally, technological advancements in refrigeration units and telematics are enhancing operational efficiencies, allowing businesses to monitor conditions in real-time, thus reducing spoilage and improving delivery performance.

Emerging trends in sourcing include the increasing preference for electric and hybrid refrigerated trucks. As sustainability becomes a priority for many businesses, manufacturers are investing in alternative fuel technologies to meet regulatory requirements and consumer expectations. Moreover, the rise of e-commerce is driving the need for last-mile delivery solutions, pushing companies to adopt smaller, more agile refrigerated vans alongside traditional larger trucks. For international B2B buyers, understanding these trends is essential for making informed sourcing decisions and aligning with suppliers that offer innovative solutions tailored to their market needs.

How Is Sustainability Influencing the Sourcing of New Condition Refrigerated Trucks?

Sustainability is a critical consideration in the sourcing of new refrigerated trucks, with environmental impacts and ethical supply chains taking center stage. The refrigeration process traditionally relies on fossil fuels, contributing to greenhouse gas emissions. However, the industry is pivoting towards greener alternatives, such as electric and hybrid models that produce fewer emissions. B2B buyers are increasingly prioritizing suppliers who can demonstrate commitment to sustainability through their product offerings.

Moreover, the importance of ethical supply chains cannot be overstated. International buyers are scrutinizing the sourcing of materials used in truck production, favoring suppliers that adhere to ethical practices, such as fair labor standards and responsible sourcing of raw materials. Certifications like ISO 14001 for environmental management and LEED for sustainable building practices are becoming essential for suppliers aiming to establish credibility in the market. By opting for trucks that are manufactured sustainably, businesses not only reduce their carbon footprint but also enhance their brand reputation and appeal to a growing base of environmentally-conscious consumers.

What Is the Evolution of Refrigerated Trucks and Its Relevance for Today’s B2B Buyers?

The evolution of refrigerated trucks can be traced back to the early 20th century when the first ice-cooled transport vehicles were introduced. Over the decades, technological advancements have revolutionized the sector, transitioning from basic ice-box trucks to highly sophisticated vehicles equipped with advanced refrigeration systems. The introduction of insulated truck bodies and more efficient cooling units has significantly improved temperature control during transit.

For today’s B2B buyers, understanding this evolution is crucial as it highlights the progress made in efficiency, reliability, and sustainability. Modern refrigerated trucks are designed to cater to specific industry needs, offering customizable features such as temperature monitoring systems and specialized cargo configurations. This historical context enables buyers to appreciate the continuous innovation in the sector and the importance of investing in new condition refrigerated trucks that meet contemporary demands for quality and environmental responsibility.

Frequently Asked Questions (FAQs) for B2B Buyers of new Condition Refrigerated Truck

-

How do I choose the right refrigerated truck for my business needs?

Choosing the right refrigerated truck involves assessing your specific requirements, such as the type of goods you transport, the required temperature range, and the volume of cargo. Consider the truck’s dimensions, insulation quality, and refrigeration system. Additionally, evaluate the fuel type and efficiency, as these factors impact operational costs. Consulting with suppliers about your needs can help ensure you select a truck that balances capacity, reliability, and cost-effectiveness. -

What are the key features to look for in a new refrigerated truck?

When sourcing a new refrigerated truck, prioritize features such as robust insulation, an efficient refrigeration unit, and a reliable temperature control system. Look for trucks with user-friendly monitoring tools for real-time temperature tracking. Additional features like liftgates for easy loading and unloading, cargo control systems for safety, and durable construction materials can enhance functionality. Ensure the truck meets local regulatory requirements for transporting perishable goods. -

What payment terms should I expect when purchasing a refrigerated truck internationally?

Payment terms can vary widely depending on the supplier and the specifics of the transaction. Common terms include upfront payments, payment upon delivery, or installment plans. For international purchases, consider using letters of credit or escrow services to protect your investment. Always clarify payment methods, currency, and any applicable taxes or duties before finalizing the deal to avoid surprises. -

How can I verify the credibility of a refrigerated truck supplier?

To vet a refrigerated truck supplier, check their business credentials, including registration, licenses, and industry certifications. Look for customer reviews and testimonials to assess their reputation. Engage in direct communication to gauge their responsiveness and willingness to provide additional information. Request references from past clients, particularly those in your region, to verify their reliability and service quality. -

What are the minimum order quantities (MOQ) for refrigerated trucks?

Minimum order quantities for refrigerated trucks can vary based on the manufacturer and the model. Some suppliers may require a minimum purchase for bulk orders to offer competitive pricing. If you are a smaller business, inquire about flexibility in MOQ or whether they provide options for single-unit purchases. Establishing a relationship with suppliers can also lead to more favorable terms. -

What logistics considerations should I keep in mind when importing refrigerated trucks?

When importing refrigerated trucks, consider logistics factors such as shipping methods, customs clearance, and transportation routes. Ensure you understand the import regulations of your country, including necessary documentation and tariffs. Partnering with a logistics provider experienced in handling refrigerated goods can streamline the process. Additionally, plan for the transportation of the truck from the port to your operational site, accounting for any special handling requirements. -

How can I customize my refrigerated truck to meet specific business needs?

Customization options for refrigerated trucks often include alterations to the insulation, refrigeration unit specifications, and cargo area configurations. Discuss your requirements with the supplier, as many manufacturers offer tailored solutions to fit unique operational needs. Consider adding features such as shelving, temperature monitoring systems, or branding elements. Ensure that any modifications comply with local regulations and standards for transporting perishable goods. -

What quality assurance measures should I look for in refrigerated trucks?

Quality assurance in refrigerated trucks is critical for maintaining the integrity of perishable goods. Look for suppliers that adhere to industry standards and certifications, such as ISO or HACCP. Request details on the truck’s manufacturing process, materials used, and testing procedures. Inquire about warranties and service agreements that cover potential defects or issues after purchase, as these can provide additional peace of mind in your investment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 New Condition Refrigerated Truck Manufacturers & Suppliers List

1. Mercedes-Benz – 2023 Sprinter 4500 Reefer Truck

Domain: commercialtrucktrader.com

Registered: 2004 (21 years)

Introduction: New 2023 Reefer/Refrigerated Trucks for Sale. Key makes include Mercedes-Benz and Isuzu. Notable models: 2023 Mercedes-Benz Sprinter 4500 with Thermo King V520 Max, High Output Turbo Diesel, and 9-Speed transmission. 2023 Isuzu FTR with 20′ Thermo King T1090R-50 refrigerator van body, powered by a 260 hp Cummins engine. Prices range from $86,353 to $193,239. Available colors include Arctic White. …

2. Liberty Isuzu – Refrigerated Commercial Trucks

Domain: libertyisuzutrucks.com

Registered: 2010 (15 years)

Introduction: Liberty Isuzu Refrigerated Commercial Trucks are designed for transporting temperature-sensitive commodities across various industries, including food, pharmaceuticals, floriculture, catering, seafood, and baking. Key features include: 1. Dependable Temperature Control: Equipped with advanced refrigeration equipment for consistent temperature maintenance. 2. Increased Durability and Lower Maintena…

3. Penske – Non-CDL Refrigerated Trucks

Domain: pensketruckrental.com

Registered: 1999 (26 years)

Introduction: For businesses requiring reliable refrigerated transportation without the need for a commercial driver’s license (CDL), the 18 to 26 ft. refrigerated truck – non-CDL is the perfect choice. Key Features Include: Refrigerated Capacity: Our non-CDL reefer trucks provide a spacious cargo area with up to an 8,000 lb. payload capacity and up to 1,600 cu. ft. of loading space. It ensures your temperature…

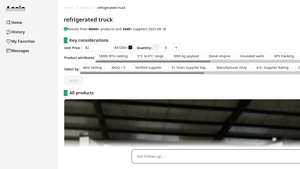

4. Accio – Premium Refrigerated Trucks

Domain: accio.com

Registered: 1997 (28 years)

Introduction: Premium Refrigerated Trucks for Sale – Reliable Cold Chain Transport Solutions. Products include: 5 Ton Freezer Refrigerator Truck ($2,450-2,500), DF4x2 163PH 16m³ Refrigerated Truck ($22,080-22,500), Foton Poultry Van Truck ($3,999-4,999), Dongfeng 4.2-Meter Refrigerator Truck ($3,000-3,600), BYD T5 Electric Refrigerator Truck ($10,200-14,800), 6.8-Meter Dongfeng Tianjin Diesel Refrigerated Truck…

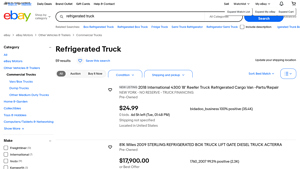

5. International – 2018 4300 Reefer Truck

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Refrigerated Truck listings on eBay include various models and conditions. Examples include: 2018 International 4300 18′ Reefer Truck (Parts/Repair) priced at $24.99, 2009 Sterling Refrigerated Box Truck with Lift Gate (Diesel) priced at $17,900.00, 2014 International DuraStar 4300 21′ S/A Refrigerated Box Truck (Repair) starting at $3,150.00, 2021 Isuzu NRR 16FT Reefer Box Truck with Carrier Supr…

Strategic Sourcing Conclusion and Outlook for new Condition Refrigerated Truck

In summary, the strategic sourcing of new condition refrigerated trucks is essential for businesses aiming to enhance their logistics and supply chain efficiency. These vehicles, designed to maintain specific temperature controls for perishable goods, offer significant advantages including improved product integrity, reduced spoilage, and compliance with health regulations. Buyers must consider key factors such as insulation quality, refrigeration unit efficiency, and total cost of ownership to make informed purchasing decisions.

As the global market continues to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for reliable refrigerated transport is set to increase. Strategic sourcing not only enables companies to secure the best vehicles suited to their operational needs but also fosters partnerships with manufacturers and suppliers that can offer ongoing support and innovation.

Looking ahead, B2B buyers are encouraged to leverage data-driven insights and market trends to enhance their procurement strategies. By prioritizing quality and efficiency in their sourcing decisions, businesses can position themselves for success in the competitive landscape of refrigerated logistics. Engage with trusted suppliers today to explore the best options that align with your operational goals and customer expectations.