Introduction: Navigating the Global Market for electric truck pickup freezer

In today’s rapidly evolving logistics landscape, sourcing electric truck pickup freezers has become a pivotal challenge for businesses aiming to enhance their delivery efficiency while adhering to stringent environmental regulations. As global demand for sustainable transport solutions rises, the need for reliable, zero-emission refrigeration options has never been more critical. This comprehensive guide delves into the diverse types of electric truck pickup freezers available, their applications across various sectors, and essential considerations for supplier vetting.

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Nigeria—will find actionable insights on navigating the complexities of this market. We will cover factors such as cost analysis, performance metrics, and compliance with regional regulations, enabling businesses to make informed purchasing decisions. With a focus on reliability and innovation, this guide empowers organizations to select the right electric truck pickup freezer solutions tailored to their unique operational needs, ensuring they remain competitive in an increasingly eco-conscious world. By leveraging the information presented here, companies can streamline their logistics, reduce their carbon footprint, and enhance customer satisfaction—all while positioning themselves as leaders in sustainable practices.

Understanding electric truck pickup freezer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fully Electric Reefer Units | Zero emissions, battery-powered, compatible with Class 8 trucks | Food distribution, pharmaceutical transport | Pros: Cost-effective, eco-friendly; Cons: Initial investment may be high. |

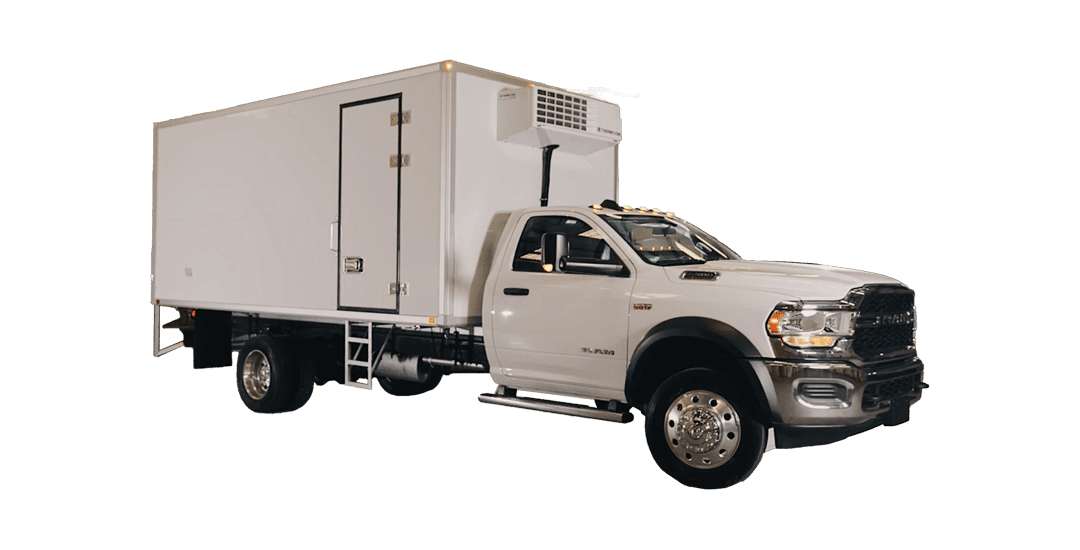

| Direct-Drive Electric Refrigeration | Operates off the vehicle’s engine, low noise levels, emissions-free | Urban deliveries, last-mile logistics | Pros: Efficient for short routes; Cons: Dependent on vehicle operation. |

| Compact Electric Reefer Units | Designed for small trucks/vans, compact size, high refrigeration capacity | Grocery delivery, small-scale food transport | Pros: Space-saving, ideal for tight urban environments; Cons: Limited cooling capacity. |

| ePower and ePTO Systems | Integrates with electric trucks for auxiliary power | Utility services, specialized transport needs | Pros: Versatile power options; Cons: Requires compatible truck models. |

| Mobile Trailer Refrigeration Units | Larger capacity, suitable for extended transport, battery or generator powered | Long-haul food transport, event catering | Pros: High volume capacity; Cons: Requires larger investment and space. |

What Are Fully Electric Reefer Units and Their Advantages for B2B Buyers?

Fully electric reefer units represent a significant advancement in sustainable transport refrigeration. These systems operate entirely on battery power, ensuring zero emissions during operation. They are particularly suited for businesses involved in food distribution and pharmaceutical transport, where compliance with stringent regulations is essential. B2B buyers should consider the long-term cost savings on fuel and maintenance, despite the higher initial investment. The reliability of these units, combined with their eco-friendly nature, positions them as a viable option for forward-thinking fleets.

How Do Direct-Drive Electric Refrigeration Units Benefit Urban Delivery?

Direct-drive electric refrigeration units utilize the vehicle’s engine to power the refrigeration system, making them efficient for urban deliveries and last-mile logistics. Their low noise levels are particularly advantageous in noise-sensitive areas, allowing for nighttime operations without disturbing residents. B2B buyers should evaluate their operational routes and vehicle compatibility, as these units are best suited for short-distance deliveries. While they provide reliable cooling, their dependency on the vehicle’s operation can limit their utility during downtime.

Why Choose Compact Electric Reefer Units for Small-Scale Transport?

Compact electric reefer units are specifically designed for smaller trucks and vans, making them ideal for grocery delivery and small-scale food transport. Their compact size allows for efficient use of space, which is crucial in urban environments where maneuverability is key. However, buyers must consider their cooling capacity, as these units may not be suitable for larger loads. The investment in compact units can yield high returns in urban settings where space and efficiency are paramount.

What Are the Benefits of ePower and ePTO Systems in Electric Trucks?

ePower and ePTO systems are innovative solutions that provide additional power for refrigeration and other body applications in electric trucks. These systems enable businesses to operate various equipment without relying on traditional fuel sources, supporting a cleaner and more sustainable operation. B2B buyers should assess the compatibility of their fleet with these systems, as they offer versatility in applications, from refrigeration to hydraulic power. While they enhance operational efficiency, the requirement for specific truck models may limit their adoption.

How Do Mobile Trailer Refrigeration Units Support Long-Haul Transportation?

Mobile trailer refrigeration units are designed for larger-scale operations, providing significant capacity for long-haul food transport and event catering. These units can be powered by batteries or generators, offering flexibility based on operational needs. B2B buyers should consider the total cost of ownership, including initial investment and ongoing maintenance. While they provide ample space for perishable goods, the need for additional space and investment may be a barrier for smaller businesses.

Key Industrial Applications of electric truck pickup freezer

| Industry/Sector | Specific Application of Electric Truck Pickup Freezer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Distribution | Transporting perishable goods like fresh produce and dairy products | Ensures product freshness and reduces spoilage costs | Battery capacity, cooling efficiency, and range |

| Pharmaceutical Logistics | Delivering temperature-sensitive medications and vaccines | Maintains strict temperature control, ensuring compliance | Regulatory compliance, monitoring systems, and reliability |

| Grocery Delivery Services | Last-mile delivery of frozen and chilled items | Enhances customer satisfaction with quality and freshness | Size compatibility, noise levels, and battery runtime |

| Catering and Events | On-site food preparation and service for events | Provides flexibility in food service and reduces waste | Power requirements, mobility, and insulation quality |

| Construction and Utilities | Transporting materials that require refrigeration | Prevents material degradation and extends usability | Durability, operational range, and maintenance support |

How is Electric Truck Pickup Freezer Used in Food Distribution?

In the food distribution sector, electric truck pickup freezers are essential for transporting perishable goods like fresh produce, dairy, and meats. These units ensure that products remain at optimal temperatures throughout transit, significantly reducing spoilage and waste. For international buyers in regions such as Africa and South America, considerations include the truck’s battery capacity and cooling efficiency, as these factors directly impact the freshness of goods upon delivery.

What Role Does Electric Truck Pickup Freezer Play in Pharmaceutical Logistics?

Pharmaceutical logistics relies heavily on electric truck pickup freezers to deliver temperature-sensitive medications and vaccines. Maintaining a strict temperature range is critical to ensure the efficacy of these products. B2B buyers in the Middle East and Europe must focus on regulatory compliance and advanced monitoring systems to guarantee that medications are transported safely and effectively, avoiding costly penalties or product recalls.

How Does Electric Truck Pickup Freezer Enhance Grocery Delivery Services?

In grocery delivery services, electric truck pickup freezers facilitate the last-mile delivery of frozen and chilled items. By maintaining the cold chain, these trucks enhance customer satisfaction through the delivery of fresh products. For B2B buyers, factors like size compatibility with delivery routes and low noise levels are vital, particularly in urban areas with strict noise regulations, ensuring operations remain unobtrusive during nighttime deliveries.

Why is Electric Truck Pickup Freezer Important for Catering and Events?

Catering businesses benefit from electric truck pickup freezers by enabling on-site food preparation and service for events. These units provide the flexibility needed to transport various food items while minimizing waste through effective temperature management. Buyers should consider power requirements and mobility, ensuring that the unit can handle diverse catering needs while maintaining high standards of food safety.

How Does Electric Truck Pickup Freezer Support Construction and Utilities?

In the construction and utilities sector, electric truck pickup freezers are used to transport materials that require refrigeration, such as certain chemicals and food products for job sites. This prevents degradation and extends the usability of materials, which is crucial for project timelines. B2B buyers should prioritize durability, operational range, and maintenance support when sourcing these units, ensuring they can withstand challenging environments while performing reliably.

3 Common User Pain Points for ‘electric truck pickup freezer’ & Their Solutions

Scenario 1: Ensuring Consistent Temperature Control During Transit

The Problem: B2B buyers often face challenges with maintaining precise temperature control while transporting perishable goods in electric truck pickup freezers. Fluctuations in temperature can lead to spoilage, impacting product quality and business reputation. This is particularly critical for companies in the food and pharmaceutical sectors, where compliance with health regulations is mandatory and any lapse can result in significant financial loss and legal repercussions.

The Solution: To address this issue, buyers should invest in electric truck pickup freezers equipped with advanced temperature monitoring systems. These systems provide real-time data on the internal conditions of the freezer, allowing operators to respond promptly to any deviations. When sourcing these units, look for features such as smart temperature control and alerts that notify drivers of any temperature changes during transit. Additionally, implementing regular maintenance checks and battery management systems will help ensure that the refrigeration units operate efficiently, maintaining optimal temperatures throughout the delivery process.

Scenario 2: Navigating Regulatory Compliance and Environmental Standards

The Problem: In regions like Europe, Africa, and South America, buyers of electric truck pickup freezers face stringent regulations regarding emissions and energy efficiency. Non-compliance can result in fines and hinder market entry, particularly in urban areas with strict environmental policies. The complexity of these regulations can be overwhelming, especially for businesses looking to expand their operations internationally.

The Solution: To navigate these regulatory challenges, buyers should conduct thorough research into the specific compliance requirements of their target markets. When selecting electric truck pickup freezers, choose models that are certified to meet local and international emissions standards, such as those set by the EPA or CARB. Engaging with suppliers who have a strong understanding of the regulatory landscape can also provide valuable insights. Consider establishing partnerships with local distributors who can offer ongoing support and ensure that your fleet remains compliant with evolving regulations, thereby mitigating potential risks and enhancing your market position.

Scenario 3: Managing Cost Efficiency and Operational Reliability

The Problem: Many businesses are concerned about the upfront investment and ongoing operational costs associated with electric truck pickup freezers. Buyers often worry that the initial capital outlay for these units will not yield a favorable return, especially when compared to traditional diesel refrigeration systems. The perception of higher maintenance and charging infrastructure costs can deter investment in electric solutions.

The Solution: To alleviate these concerns, it’s crucial to perform a total cost of ownership analysis that considers not just the purchase price but also the long-term savings from reduced fuel expenses and lower maintenance costs. Electric truck pickup freezers typically have fewer moving parts than diesel units, leading to lower maintenance requirements and costs. Additionally, buyers should explore available government incentives and grants for electric vehicle adoption, which can offset initial costs. Partnering with suppliers who offer comprehensive support, including financing options and charging infrastructure solutions, can further enhance cost efficiency and operational reliability, making the transition to electric refrigeration a financially sound decision.

Strategic Material Selection Guide for electric truck pickup freezer

What Are the Key Materials for Electric Truck Pickup Freezers?

When selecting materials for electric truck pickup freezers, it is crucial to consider properties such as thermal insulation, structural integrity, weight, and resistance to environmental factors. Here, we analyze four common materials used in the construction of these units, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Aluminum Perform in Electric Truck Pickup Freezers?

Key Properties: Aluminum is lightweight, has excellent thermal conductivity, and is resistant to corrosion. It can withstand a range of temperatures, making it suitable for refrigeration applications.

Pros & Cons: The main advantages of aluminum include its low weight, which enhances fuel efficiency, and its corrosion resistance, making it ideal for humid or coastal environments. However, aluminum can be more expensive than other materials and may require specialized manufacturing techniques, which can increase production costs.

Impact on Application: Aluminum’s thermal conductivity allows for efficient temperature maintenance within the freezer, crucial for perishable goods. However, care must be taken to ensure that the aluminum is adequately insulated to prevent heat transfer.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider aluminum’s cost-effectiveness against local availability and manufacturing capabilities. Compliance with international standards such as ASTM for material quality is essential.

What Role Does Stainless Steel Play in Electric Truck Pickup Freezers?

Key Properties: Stainless steel is known for its strength, durability, and resistance to corrosion and staining. It performs well under high pressure and maintains structural integrity at various temperatures.

Pros & Cons: The primary advantage of stainless steel is its long lifespan and robustness, making it ideal for heavy-duty applications. However, it is heavier than aluminum, which can affect the overall weight of the truck. Additionally, stainless steel can be more costly due to its manufacturing complexity.

Impact on Application: Stainless steel is particularly suitable for environments where hygiene is critical, such as food transport. Its resistance to corrosion ensures that it can withstand exposure to various cleaning agents and environmental conditions.

Considerations for International Buyers: Buyers in the Middle East and Europe should ensure compliance with local health and safety regulations, as stainless steel is often preferred in food-grade applications. Understanding local sourcing options can help mitigate costs.

How Effective Is Polyurethane Foam for Insulation in Freezers?

Key Properties: Polyurethane foam is an excellent insulator, providing high thermal resistance. It is lightweight and can be molded into various shapes, making it versatile for different designs.

Pros & Cons: The key advantage of polyurethane foam is its superior insulation properties, which help maintain low temperatures efficiently. However, it can be sensitive to moisture and may degrade if not properly sealed, leading to potential thermal loss.

Impact on Application: Effective insulation is critical for electric truck freezers to maintain the cold chain, especially in warmer climates. Properly applied polyurethane foam can significantly reduce energy consumption.

Considerations for International Buyers: Buyers should be aware of local environmental regulations regarding foam materials, as some regions may have restrictions on certain chemicals used in production. Compliance with standards such as DIN can also be necessary.

Why Is Composite Material a Good Choice for Electric Truck Freezers?

Key Properties: Composite materials, often a combination of plastics and other materials, offer a balance of strength, weight, and thermal insulation. They are customizable and can be engineered for specific applications.

Pros & Cons: Composites are lightweight and can be designed for specific thermal properties, making them suitable for electric truck freezers. However, they may not have the same durability as metals and can be more expensive to produce due to complex manufacturing processes.

Impact on Application: Composites can provide excellent insulation while reducing overall vehicle weight, enhancing fuel efficiency. However, their longevity under harsh conditions should be assessed.

Considerations for International Buyers: For buyers in emerging markets like Nigeria, understanding the local supply chain for composite materials is essential. Compliance with international standards for safety and performance is also crucial.

Summary Table of Material Selection for Electric Truck Pickup Freezers

| Material | Typical Use Case for Electric Truck Pickup Freezer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Structural components and outer casing | Lightweight and corrosion-resistant | Higher cost and manufacturing complexity | Medium |

| Stainless Steel | Interior surfaces and structural reinforcements | Durable and hygienic | Heavier and more expensive | High |

| Polyurethane Foam | Insulation for temperature control | Superior thermal insulation | Moisture sensitivity can lead to degradation | Medium |

| Composite Material | Custom components and lightweight structures | Customizable thermal properties | Potentially less durable than metals | High |

This guide provides a comprehensive overview of the strategic material selection for electric truck pickup freezers, ensuring B2B buyers make informed decisions that align with their operational needs and regional regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for electric truck pickup freezer

What Are the Main Stages in the Manufacturing Process of Electric Truck Pickup Freezers?

The manufacturing process of electric truck pickup freezers involves several critical stages that ensure product quality and performance. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality materials, including advanced insulating materials, stainless steel for durability, and components such as compressors and evaporators. Suppliers must provide documentation verifying the material properties, which is essential for compliance with international standards.

-

Forming: In this stage, raw materials are shaped into components. Techniques such as CNC machining and laser cutting are commonly used to create precise parts. This is vital for ensuring the structural integrity of the freezer units. Manufacturers often utilize automated processes to enhance accuracy and reduce human error.

-

Assembly: After forming, components are assembled into a cohesive unit. This stage may include integrating the refrigeration system, electrical components, and insulation. Manufacturers often employ modular assembly techniques, allowing for efficient assembly and easier maintenance. Quality control checkpoints during this stage include visual inspections and functional tests to ensure proper installation.

-

Finishing: The final stage involves applying protective coatings, painting, or surface treatments to enhance durability and aesthetics. This step may also include final assembly checks and testing of the cooling performance. Manufacturers should adhere to strict environmental standards during this phase, particularly regarding the disposal of waste materials.

How Do Manufacturers Ensure Quality Control in Electric Truck Pickup Freezers?

Quality control (QC) is a vital aspect of the manufacturing process, ensuring that electric truck pickup freezers meet both international standards and customer expectations.

-

International Standards Compliance: Manufacturers typically adhere to ISO 9001 for quality management systems. This certification indicates that the manufacturer has established a framework for consistent quality and continuous improvement. Additionally, industry-specific certifications such as CE marking for compliance with European safety and environmental standards are crucial, particularly for buyers in Europe.

-

Quality Checkpoints: QC checkpoints are established at various stages of the manufacturing process:

– Incoming Quality Control (IQC): This involves checking the quality of incoming materials and components against specifications. Suppliers must provide certificates of compliance and test reports.

– In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are performed to identify defects early. This may include dimensional checks and functional tests.

– Final Quality Control (FQC): After assembly, the final product undergoes rigorous testing, including thermal performance tests, noise level assessments, and safety inspections. -

Common Testing Methods: Manufacturers utilize a range of testing methods to ensure product reliability. These may include:

– Thermal Cycle Testing: Evaluates the freezer’s ability to maintain specified temperatures under varying conditions.

– Vibration Testing: Ensures that components can withstand the stresses of transport and operation.

– Electrical Safety Testing: Verifies that the electrical components comply with safety standards, reducing the risk of failures.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control?

For B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability and compliance.

-

Conduct Supplier Audits: Regular audits of potential suppliers can provide insight into their manufacturing processes and quality control systems. Buyers should look for evidence of compliance with international standards and certifications.

-

Request Quality Assurance Documentation: Buyers should ask for detailed quality assurance documentation, including certificates of compliance, test reports, and records of past inspections. This information can help assess the supplier’s commitment to quality.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an impartial assessment of the supplier’s manufacturing practices. Inspectors can verify compliance with international standards and provide reports on the condition of the products before shipment.

-

Understand Regional Certifications: Different regions may have specific certifications that are crucial for compliance. For instance, in Europe, CE marking is vital, while in the Middle East, local certifications might be required. Buyers should be aware of these requirements to ensure that products meet local regulations.

How Do Quality Control and Certification Nuances Affect International B2B Buyers?

International B2B buyers must navigate various quality control and certification nuances that can impact their purchasing decisions.

-

Regional Regulations: Each region has unique regulations regarding emissions, safety, and performance standards. For example, buyers in Saudi Arabia may need to consider local environmental regulations when sourcing electric truck freezers. Understanding these requirements is crucial for compliance and avoiding costly penalties.

-

Cultural Differences in Quality Standards: Different markets may have varying perceptions of quality. Buyers should familiarize themselves with local expectations and standards to ensure that the products meet their specific needs.

-

Supply Chain Considerations: The complexity of international supply chains can complicate quality assurance. Buyers should evaluate the entire supply chain, from raw material sourcing to final product delivery, to identify potential quality issues and ensure consistent product quality.

-

Post-Purchase Support: Quality assurance doesn’t end with the purchase. Buyers should consider the manufacturer’s capacity for post-purchase support, including warranty services and parts availability. A strong support system can mitigate risks associated with product performance and maintenance.

In conclusion, understanding the manufacturing processes and quality assurance measures for electric truck pickup freezers is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they select reliable, high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric truck pickup freezer’

Introduction

This sourcing guide serves as a practical checklist for B2B buyers interested in procuring electric truck pickup freezers. With a growing emphasis on sustainability and compliance with stringent emissions regulations, selecting the right electric refrigeration system is essential for businesses that transport perishable goods. This checklist will help you navigate the procurement process efficiently and effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring the electric truck pickup freezer meets your operational needs. Consider the size of the freezer, temperature range, and power requirements.

- Capacity Needs: Assess the volume of goods you need to transport and the required cooling capacity.

- Temperature Range: Determine the specific temperature range necessary for your products, such as deep freezing or refrigerated transport.

Step 2: Research Compliance Requirements

Understanding local and international compliance standards is vital for seamless operations. Regulations regarding emissions and energy efficiency can vary significantly by region.

- Local Regulations: Investigate specific regulations in your target markets, particularly in regions like Europe or the Middle East, where standards are increasingly stringent.

- Certification: Ensure that the equipment has the necessary certifications (e.g., EPA, CARB) to avoid legal complications and enhance your brand’s reputation.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s important to thoroughly vet potential suppliers. This will ensure you partner with a reputable company that can provide reliable products and support.

- Supplier Background: Request company profiles, including years in business, customer testimonials, and case studies.

- Product Range: Look for suppliers that offer a variety of electric truck freezer models to match your specific needs.

Step 4: Assess Energy Efficiency and Operating Costs

Energy consumption is a significant factor in the total cost of ownership for electric truck freezers. Evaluate the energy efficiency of each option to determine potential savings over time.

- Energy Ratings: Check for energy efficiency ratings or certifications that indicate lower operating costs.

- Fuel Savings: Calculate estimated savings based on fuel costs compared to traditional diesel-powered units.

Step 5: Verify Warranty and Support Services

A robust warranty and reliable support services are essential for minimizing downtime and maintaining operational efficiency.

- Warranty Terms: Review the warranty coverage, including duration and what it encompasses (parts, labor, etc.).

- Technical Support: Ensure that the supplier offers comprehensive technical support, including installation and maintenance services.

Step 6: Request Demonstrations or Trials

Before finalizing your purchase, request a demonstration or trial of the electric truck pickup freezer. This allows you to assess performance in real-world conditions.

- Performance Evaluation: Evaluate the unit’s cooling efficiency, noise levels, and ease of use.

- Compatibility Check: Ensure that the freezer integrates well with your existing fleet and logistics operations.

Step 7: Finalize the Purchase Agreement

Once you’ve conducted thorough evaluations and are satisfied with your selected supplier, proceed to finalize the purchase agreement.

- Terms and Conditions: Pay close attention to payment terms, delivery schedules, and any additional fees.

- After-Sales Support: Confirm details regarding after-sales support and service agreements to ensure ongoing operational efficiency.

Following this step-by-step checklist will help you make informed decisions when sourcing electric truck pickup freezers, ultimately enhancing your logistics capabilities and supporting your sustainability goals.

Comprehensive Cost and Pricing Analysis for electric truck pickup freezer Sourcing

What Are the Key Cost Components of Electric Truck Pickup Freezers?

When sourcing electric truck pickup freezers, understanding the cost structure is essential for effective budgeting and financial planning. The primary cost components include:

-

Materials: The choice of materials significantly affects the overall cost. High-quality insulation, advanced lithium-ion batteries, and durable casing materials are essential for optimal performance and longevity. Sourcing these materials from reputable suppliers can mitigate risks associated with quality and reliability.

-

Labor: Labor costs encompass the wages of skilled workers involved in the assembly and quality control of the freezers. Investing in skilled labor can lead to better craftsmanship and fewer defects, ultimately reducing long-term operational costs.

-

Manufacturing Overhead: This includes indirect costs related to production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help keep these costs down, impacting the final pricing of the units.

-

Tooling: Tooling costs pertain to the initial investment in specialized tools and equipment necessary for production. This cost can vary based on the complexity of the freezer designs and whether custom tooling is required.

-

Quality Control (QC): Rigorous quality control processes ensure that each unit meets performance and safety standards. Investing in comprehensive QC can prevent costly recalls and enhance customer satisfaction.

-

Logistics: Transportation and handling costs must be factored into the final price. Efficient logistics can reduce delivery times and costs, which is particularly important for international buyers.

-

Margin: Suppliers typically include a profit margin that reflects their business strategy and market conditions. Understanding the margin can help buyers negotiate better deals.

How Do Price Influencers Affect Electric Truck Pickup Freezer Pricing?

Several factors influence the pricing of electric truck pickup freezers, particularly in the context of international B2B transactions:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact pricing. Higher volumes often lead to discounts, while smaller orders may incur higher per-unit costs. Buyers should evaluate their needs against potential savings.

-

Specifications and Customization: Customized units tailored to specific operational needs may come at a premium. Buyers should clearly communicate their requirements to avoid unexpected costs.

-

Materials: The type of materials used directly correlates with the freezer’s efficiency, durability, and cost. Opting for higher-grade materials can enhance performance but may increase upfront costs.

-

Quality and Certifications: Units that meet international quality standards and certifications may command higher prices. However, these units often provide better reliability and compliance with regulatory requirements.

-

Supplier Factors: The reputation and reliability of suppliers play a critical role in pricing. Established suppliers may offer better quality and service but at a higher cost. Newer suppliers might provide competitive pricing but could pose risks in quality and support.

-

Incoterms: Understanding Incoterms is crucial for international buyers as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. This knowledge can help avoid unexpected costs.

What Are Some Buyer Tips for Cost-Efficiency in Sourcing Electric Truck Pickup Freezers?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, effective sourcing strategies can lead to significant cost savings:

-

Negotiation: Engage in thorough negotiations with suppliers. Understanding the cost components allows buyers to negotiate better terms and pricing. Leverage volume commitments to secure discounts.

-

Total Cost of Ownership (TCO): Evaluate the total cost of ownership rather than just the initial purchase price. Consider maintenance, energy consumption, and potential downtime when assessing overall costs.

-

Research Local Regulations: Be aware of local regulations and standards that may influence costs. Compliance with these regulations can affect pricing, especially for units with emissions standards.

-

Consider Alternative Suppliers: Explore multiple suppliers to compare prices and offerings. This can provide leverage in negotiations and ensure you find the best value for your investment.

-

Stay Informed on Market Trends: Keeping abreast of industry trends, such as advancements in battery technology and refrigeration efficiency, can help buyers make informed decisions that align with their operational needs.

Disclaimer on Pricing

Prices for electric truck pickup freezers can vary widely based on numerous factors, including specifications, supplier relationships, and market conditions. It is advisable for buyers to seek multiple quotes and conduct thorough due diligence before making purchasing decisions.

Alternatives Analysis: Comparing electric truck pickup freezer With Other Solutions

When considering solutions for transporting perishable goods, businesses must evaluate various technologies to find the most efficient and sustainable option. The electric truck pickup freezer represents a modern approach, but it’s essential to compare it with other alternatives to determine the best fit for specific operational needs. This analysis will focus on the electric truck pickup freezer and its alternatives: diesel-powered reefer units and hybrid refrigeration systems.

| Comparison Aspect | Electric Truck Pickup Freezer | Diesel-Powered Reefer Units | Hybrid Refrigeration Systems |

|---|---|---|---|

| Performance | Excellent cooling, zero emissions, up to 10 hours runtime per charge | High cooling capacity, longer operational range, but emits pollutants | Good cooling performance, flexibility in power sources, lower emissions than diesel |

| Cost | Higher upfront cost, lower operating costs (up to $5,000/year savings) | Lower initial investment, higher fuel and maintenance costs | Moderate initial cost, fuel savings over time, potential tax incentives |

| Ease of Implementation | Requires charging infrastructure; installation can be complex | Widely available, straightforward installation | Requires both electric and fuel infrastructure; moderate complexity |

| Maintenance | Lower maintenance due to fewer moving parts, 5-year warranty | Higher maintenance needs due to engine wear and tear | Moderate maintenance, dependent on hybrid components |

| Best Use Case | Ideal for urban deliveries, tight emissions regulations, and night operations | Suitable for long-haul transport and areas without charging infrastructure | Versatile for varied applications, suitable for both urban and rural settings |

What Are the Pros and Cons of Diesel-Powered Reefer Units?

Diesel-powered reefer units have been the traditional choice for cold chain logistics. Their primary advantage lies in their strong cooling capacity and the ability to operate over long distances without the need for recharging. They are generally less expensive upfront compared to electric solutions. However, they contribute to greenhouse gas emissions and are subject to stringent regulations in many regions, which can increase operational costs over time. Maintenance can also be a significant factor due to the mechanical complexity of diesel engines.

How Do Hybrid Refrigeration Systems Compare?

Hybrid refrigeration systems combine electric and diesel power, offering a compromise between the two technologies. They can operate on electric power in urban settings, reducing emissions, and switch to diesel for long-haul routes, thus providing flexibility. The initial investment can be moderate, and many regions offer tax incentives for adopting greener technologies. However, managing two power sources can increase complexity in operations and maintenance.

How Can B2B Buyers Choose the Right Solution?

Selecting the right refrigeration solution depends on various factors, including operational geography, regulatory environment, and budget constraints. Businesses operating in urban areas with strict emissions regulations may find electric truck pickup freezers to be the most beneficial, despite their higher initial costs. Conversely, companies engaged in long-distance logistics may prefer the reliability of diesel-powered units. Hybrid systems serve as a versatile option, appealing to operations that require both flexibility and efficiency. Ultimately, buyers should conduct a thorough analysis of their specific needs and potential return on investment to make an informed decision.

Essential Technical Properties and Trade Terminology for electric truck pickup freezer

What Are the Key Technical Properties of Electric Truck Pickup Freezers?

When evaluating electric truck pickup freezers, several critical technical specifications are essential for ensuring optimal performance, reliability, and compliance with industry standards. Here are some key properties to consider:

-

Cooling Capacity (BTU/hr or kW)

The cooling capacity indicates the amount of heat the freezer can remove from the cargo area per hour. Typically measured in BTU/hr or kilowatts (kW), this specification is crucial for B2B buyers as it determines the unit’s ability to maintain the required temperature for perishable goods. Understanding the cooling capacity helps businesses select the right unit based on the type and volume of products they transport. -

Battery Life and Runtime

Electric truck freezers are powered by batteries, which influence their operational efficiency. The runtime specifies how long the unit can operate on a single charge, often ranging from 8 to 10 hours. This property is particularly important for logistics companies that require long-distance transportation without frequent recharging. A longer runtime can enhance productivity and reduce downtime. -

Temperature Range

The temperature range indicates the lowest and highest temperatures the freezer can achieve. For instance, a unit may operate effectively between -20°C to +5°C. This range is vital for businesses dealing with various perishable items, such as seafood, meat, or pharmaceuticals, as it ensures compliance with health regulations and maintains product quality during transit. -

Construction Material

The materials used in the construction of the freezer significantly impact durability and insulation efficiency. Common materials include stainless steel for the interior and high-density polyurethane for insulation. Choosing the right materials can enhance the unit’s longevity and reduce energy consumption, which is essential for lowering operational costs. -

Power Consumption (kWh)

Power consumption indicates how much energy the freezer uses during operation. Measured in kilowatt-hours (kWh), this specification is important for calculating operational costs. Lower energy consumption translates to reduced electricity bills, making the freezer a more economical choice for businesses in regions with high energy prices. -

Noise Level (dB)

The noise level, measured in decibels (dB), is a critical consideration for urban deliveries or nighttime operations. Units that operate below 55dB are often preferred, as they comply with local noise regulations and ensure minimal disturbance in residential areas.

What Are Common Trade Terms Related to Electric Truck Pickup Freezers?

Understanding industry terminology is vital for effective communication and negotiation in the B2B sector. Here are some common trade terms associated with electric truck pickup freezers:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of electric truck freezers, knowing the OEM can help buyers assess the quality and reliability of the components used in the refrigeration system. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding the MOQ is essential for managing inventory levels and ensuring that purchasing decisions align with operational needs. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. This process helps businesses compare prices and negotiate terms effectively before making a purchase decision. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and obligations, ensuring a smoother logistics process. -

Cold Chain Logistics

Cold chain logistics refers to the transportation and storage of perishable goods under controlled temperature conditions. This concept is critical for businesses involved in food and pharmaceutical distribution, as it ensures product safety and compliance with health regulations. -

Regenerative Braking

This technology allows electric trucks to recover energy during braking and use it to recharge the battery. Understanding regenerative braking is essential for buyers looking to enhance the efficiency of their electric trucks, potentially extending the operational range of the freezer units.

These technical properties and trade terminologies are crucial for B2B buyers involved in the procurement of electric truck pickup freezers, enabling informed decision-making and effective supply chain management.

Navigating Market Dynamics and Sourcing Trends in the electric truck pickup freezer Sector

What Are the Key Market Trends Driving the Electric Truck Pickup Freezer Sector?

The electric truck pickup freezer market is experiencing transformative changes driven by several global dynamics. A significant driver is the escalating demand for sustainable transport solutions, particularly in regions like Africa, South America, the Middle East, and Europe. As countries tighten emissions regulations, businesses are compelled to transition away from diesel-powered refrigeration systems. This shift aligns with the broader sustainability goals embraced by many governments, aiming for a reduction in greenhouse gas emissions.

Emerging technologies play a crucial role in shaping the market. Innovations in battery technology, such as lithium-ion and lithium iron phosphate batteries, are enhancing the efficiency and operational lifespan of electric refrigeration units. These advancements allow for extended runtimes, with some units capable of providing cooling for over ten hours on a single charge. Moreover, the rise of smart temperature control systems is enabling precise cargo management, which is vital for preserving perishable goods.

For international B2B buyers, the market dynamics also highlight the growing importance of cost-effectiveness. Electric freezer units can substantially reduce operating costs by up to $5,000 annually compared to traditional diesel reefers. The quiet operation of these units makes them particularly appealing for urban deliveries, where noise restrictions are often in place. As competition intensifies, companies that invest in electric truck pickup freezers are likely to gain a competitive edge by enhancing their service offerings and meeting evolving regulatory requirements.

How Does Sustainability Influence Sourcing in the Electric Truck Pickup Freezer Market?

Sustainability is no longer a mere trend; it has become a critical factor in sourcing decisions within the electric truck pickup freezer sector. The environmental impact of traditional refrigeration methods, particularly diesel-powered units, has led to a surge in demand for greener alternatives. B2B buyers are increasingly prioritizing products that contribute to reducing their carbon footprint and enhancing their sustainability profiles.

Ethical sourcing practices are also gaining traction. Companies are seeking suppliers that demonstrate commitment to sustainable practices, including the use of recycled materials and adherence to environmentally friendly manufacturing processes. Certifications like ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming essential for suppliers aiming to stand out in a competitive market.

Furthermore, the emphasis on sustainability extends to the entire supply chain. Buyers are now considering the lifecycle of products, from production through to disposal. Those involved in the electric truck pickup freezer sector must ensure that their supply chains are transparent and that they prioritize suppliers who align with their environmental values. This trend not only meets regulatory demands but also resonates with consumers increasingly inclined to support eco-friendly businesses.

What Is the Historical Context of the Electric Truck Pickup Freezer Market?

The evolution of the electric truck pickup freezer market can be traced back to the growing awareness of environmental issues in the late 20th century. Initially dominated by diesel-powered refrigeration units, the sector began to shift in the early 2000s as technology advanced and the negative impacts of fossil fuels became more apparent. The introduction of electric vehicles (EVs) into the broader transportation landscape set the stage for innovations in electric refrigeration solutions.

As governments worldwide implemented stricter emissions regulations, the demand for electric truck freezer units gained momentum. Key players in the market responded by developing all-electric refrigeration systems that not only comply with environmental standards but also provide significant operational cost savings. This historical trajectory illustrates a clear trend towards sustainability and efficiency, which continues to define the electric truck pickup freezer sector today.

By understanding these market dynamics, sustainability considerations, and historical context, international B2B buyers can make informed decisions that align with both their operational needs and environmental responsibilities.

Frequently Asked Questions (FAQs) for B2B Buyers of electric truck pickup freezer

-

How do I ensure the quality of electric truck pickup freezers when sourcing from international suppliers?

To ensure the quality of electric truck pickup freezers, it’s crucial to conduct thorough supplier vetting. Start by requesting certifications such as ISO 9001 or CE for compliance with international quality standards. Consider visiting the supplier’s facility if feasible or utilizing third-party inspection services. Additionally, seek samples or pilot units to evaluate performance before committing to larger orders. Establish clear quality assurance protocols and contractual agreements that specify quality standards and penalties for non-compliance. -

What is the best electric truck pickup freezer for transporting perishable goods in hot climates?

The optimal electric truck pickup freezer for hot climates should offer high cooling efficiency and reliability. Look for units that feature advanced insulation, efficient compressors, and smart temperature control systems to maintain consistent temperatures. Models with lithium-ion battery technology provide extended runtime and quick recharging, essential for long-distance deliveries. Brands like Thermo King and BatteryAir offer solutions designed specifically for high ambient temperatures, ensuring your perishable goods remain fresh during transit. -

What are the minimum order quantities (MOQ) for electric truck pickup freezers?

Minimum order quantities (MOQ) can vary significantly between suppliers, often influenced by production capabilities and material costs. Typically, MOQs for electric truck pickup freezers range from 5 to 50 units. It’s advisable to negotiate these terms based on your needs, especially if you’re entering new markets. Some manufacturers may offer lower MOQs for first-time buyers or trial orders, so don’t hesitate to ask for flexibility, particularly if you’re looking to test the product’s performance in your specific environment. -

What payment terms are common when sourcing electric truck pickup freezers internationally?

Common payment terms for international B2B transactions include a mix of upfront deposits (usually 30-50%) and balance payments upon shipment or delivery. Other options may involve letters of credit (LC) or payment through escrow services for added security. It’s important to clarify these terms with your supplier and ensure they align with your cash flow needs. Be aware of currency exchange rates and potential transaction fees that could affect the total cost of your order. -

How can I customize electric truck pickup freezers to fit my specific operational needs?

Customization options for electric truck pickup freezers often include adjustments to size, cooling capacity, and additional features such as temperature monitoring systems. When discussing customization with suppliers, provide detailed specifications regarding your operational requirements, including the types of goods you transport and typical environmental conditions. Many manufacturers are willing to collaborate on bespoke solutions, but be prepared for potential increases in lead time and cost. -

What logistics considerations should I keep in mind when importing electric truck pickup freezers?

When importing electric truck pickup freezers, consider logistics factors such as shipping methods, customs regulations, and lead times. Ensure your supplier provides a clear understanding of the shipping process and delivery timelines. Work with logistics partners experienced in handling large equipment to navigate potential challenges, including customs clearance and import tariffs. Additionally, assess the need for insurance during transit to safeguard your investment against damage or loss. -

Are electric truck pickup freezers compliant with international environmental regulations?

Most modern electric truck pickup freezers are designed to comply with international environmental regulations, including emissions standards set by bodies such as the EPA and CARB. When sourcing, verify that the units meet the regulatory requirements of your target market, particularly if you operate in regions with stringent emissions laws. Suppliers should provide documentation confirming compliance, which is crucial for avoiding penalties and ensuring smooth operations. -

What after-sales support should I expect from suppliers of electric truck pickup freezers?

After-sales support is vital when investing in electric truck pickup freezers. Reputable suppliers typically offer comprehensive support, including installation, maintenance, and troubleshooting assistance. Check if they provide warranties on the units, as well as training for your team on operating and maintaining the equipment. Ensure that you have access to local service centers or support channels to address any issues promptly, minimizing downtime and ensuring the longevity of your investment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Electric Truck Pickup Freezer Manufacturers & Suppliers List

1. Thermo King – All-Electric Transport Refrigeration Units

Domain: thermoking.com

Registered: 1997 (28 years)

Introduction: Thermo King offers a complete line of transport refrigeration units for trucks and vans, including:

1. **All-Electric Solutions**:

– **e1000**: Fully electric transport refrigeration unit for Class 5 – 7 trucks with zero emissions.

– **e200**: Electric truck refrigeration unit that helps comply with CO2 emission regulations.

– **B-100**: Compact all-electric reefer unit with high refrige…

2. Facebook – Compact Electric Refrigerator/Freezer

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: smaller (30-40L), cost efficient, durable single zone electric refrigerator/freezer for off-road truck camper

3. Alpicool – 50L Refrigerator/Freezer

Domain: f150gen14.com

Registered: 2019 (6 years)

Introduction: Electric fridge options discussed include a ~55L fridge for the F150, specifically mentioned are: 1. Alpicool 50L refrigerator/freezer – stored in the bed under a tonneau cover, powered by Pro-power on-board generator during the day and Jackery Power Station at night. 2. Dometic CFX3-75 – dual-zone fridge/freezer, powered by EcoFlow delta charged via solar panel while camping and 12v A/C while on …

4. International – eMV™ Series Electric Truck

Domain: international.com

Registered: 1998 (27 years)

Introduction: eMV™ Series Electric Truck

– Type: Electric powered medium-duty truck

– Peak Power: 342 hp

– Torque: 1,737 lb-ft

– Typical Range: 135 miles*

– Battery: 210 kWh Lithium Iron Phosphate (LFP) Battery**

– Regenerative Braking: 3 levels

– Acceleration: Equal to or better than diesel

– Battery Thermal Management System (BTMS)

– Maintenance: Lower compared to diesel

– Charging Solutions: Available from I…

5. Ford – Maverick Truck Power Capabilities

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Ford Maverick truck can be used to power small appliances during outages, such as mini fridges, but is not designed to function as a full generator like the F150 with Pro Power Onboard. The truck has a standard 120V outlet capable of handling 400W (3.3A). Users suggest that while it may be possible to run a mini fridge, the starting watts of a full-size fridge exceed the inverter’s capacity. Some …

6. Qingling Isuzu – EVK100 4×2 Electric Refrigerated Truck

Domain: qinglingisuzu.com

Registered: 2017 (8 years)

Introduction: {“model”:”EVK100 4×2 Electric Refrigerated Truck LHD”,”type”:”Refrigerated Truck”,”dimensions”:{“overall”:”5995x2200x3200 mm”,”box_inner”:”4080x2100x2100 mm”},”curb_weight”:”3940 Kg”,”GVW”:”7300 kg”,”wheelbase”:”3360 mm”,”drive_type”:”Motor Direct Driving Motor”,”motor”:{“model”:”YTD060W23″,”type”:”Permanent magnet synchronous motor”,”rated_power”:”60 kw”,”peak_power”:”110 kw”,”rated_torque”:”310 …

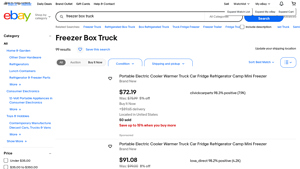

7. eBay – Portable Car Freezer

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Freezer Box Truck listings on eBay include various portable electric coolers and refrigerators suitable for cars, trucks, and RVs. Key products include: 1. 16QT Portable Car Freezer – $159.99, free delivery, brand new. 2. 25QT 12V/24V Console Fridge Freezer – $70.89, $14.99 delivery, brand new. 3. MJ30 Portable Refrigerator – $209.99, free delivery, brand new. 4. PT45 48QT Dual Zone Car Freezer – …

Strategic Sourcing Conclusion and Outlook for electric truck pickup freezer

In the evolving landscape of logistics and transportation, the adoption of electric truck pickup freezers offers a transformative approach for businesses. Key takeaways highlight the significant operational cost savings, compliance with stringent environmental regulations, and the enhanced reliability that these innovative refrigeration solutions provide. By strategically sourcing electric freezer units, companies can not only reduce their carbon footprint but also improve their bottom line—potentially cutting fuel expenses by thousands annually.

As the demand for sustainable practices escalates, international buyers from regions like Africa, South America, the Middle East, and Europe should prioritize partnerships with manufacturers who offer cutting-edge, electric refrigeration technology. This alignment not only supports regulatory compliance but also positions businesses as leaders in eco-friendly logistics.

Looking ahead, the momentum towards electrification in transport refrigeration is undeniable. Companies that invest in these solutions today will gain a competitive edge, ensuring they are well-prepared to meet the challenges of tomorrow’s market. Now is the time to embrace this shift—explore options, engage with suppliers, and take proactive steps towards a sustainable future in perishable goods transport.