Introduction: Navigating the Global Market for tractor Truck Model

In the competitive landscape of the global market for tractor truck models, international B2B buyers face the significant challenge of sourcing reliable and efficient vehicles that meet their operational needs. This guide delves into the diverse world of tractor truck models, providing insights into various types, applications, and the critical factors to consider when selecting the right vehicle for your business. From understanding the intricacies of supplier vetting to evaluating cost implications, this comprehensive resource equips you with the necessary knowledge to navigate the complexities of the market.

As businesses expand their reach across continents—from Africa to South America, the Middle East, and Europe—making informed purchasing decisions becomes paramount. This guide addresses key considerations, such as performance specifications, regulatory compliance, and after-sales support, ensuring you select a tractor truck model that aligns with your operational goals. We also explore emerging trends in technology and sustainability, providing a forward-looking perspective that can enhance your fleet’s efficiency and environmental impact.

Whether you are a seasoned buyer or new to the industry, this guide empowers you to make strategic decisions that drive your business forward. With actionable insights and expert recommendations, you will be better positioned to choose the right tractor truck model that not only meets your immediate needs but also supports your long-term growth objectives.

Understanding tractor Truck Model Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conventional Tractors | Long hood, engine in front, high visibility | Long-haul freight, heavy loads | Pros: Excellent stability, easier maintenance. Cons: Larger turning radius, less maneuverable in tight spaces. |

| Cabover Tractors | Engine above the cab, compact design | Urban deliveries, short-haul transport | Pros: Better maneuverability, shorter length. Cons: Reduced driver comfort, engine heat can affect cab. |

| Heavy-Duty Tractors | High horsepower, robust chassis | Construction, mining, heavy freight | Pros: Superior towing capacity, durability. Cons: Higher fuel consumption, more expensive to maintain. |

| Medium-Duty Tractors | Balanced load capacity, versatile designs | Local deliveries, regional transport | Pros: Cost-effective, versatile for various loads. Cons: Limited in heavy-duty applications, lower power. |

| Specialty Tractors | Custom features for specific industries | Agriculture, logging, waste management | Pros: Tailored for specific tasks, improved efficiency. Cons: Limited resale value, specialized parts can be costly. |

What are the Key Characteristics of Conventional Tractors?

Conventional tractors are characterized by their long hood and engine placement in front of the cab, which provides enhanced visibility and cooling. These models are ideal for long-haul freight and heavy loads, making them a staple in logistics and transportation sectors. Buyers should consider factors such as fuel efficiency, maintenance costs, and the type of cargo they intend to transport, as these factors can significantly impact operational costs.

How Do Cabover Tractors Differ from Conventional Models?

Cabover tractors feature a compact design with the engine situated above the cab, allowing for a shorter overall length. This design is particularly advantageous for urban deliveries and short-haul transport, where maneuverability is critical. B2B buyers should evaluate the comfort level for drivers and the specific routes the trucks will operate on, as these factors will influence productivity and driver satisfaction.

What Makes Heavy-Duty Tractors Suitable for Challenging Environments?

Heavy-duty tractors are built with high horsepower and robust chassis, making them suitable for demanding applications such as construction, mining, and heavy freight. Their superior towing capacity and durability are significant advantages for companies requiring reliable performance under tough conditions. However, potential buyers should be aware of higher fuel consumption and maintenance costs associated with these powerful machines.

Why Choose Medium-Duty Tractors for Versatile Operations?

Medium-duty tractors offer a balanced load capacity with versatile designs, making them suitable for local deliveries and regional transport. They are often more cost-effective than their heavy-duty counterparts while still providing sufficient power for various loads. B2B buyers should consider their operational needs, as these tractors can serve multiple purposes, reducing the need for a diverse fleet.

What Benefits Do Specialty Tractors Provide for Specific Industries?

Specialty tractors are designed with custom features tailored to specific industries, such as agriculture, logging, or waste management. These tractors improve efficiency for specialized tasks but may have limited resale value and require specific parts that can be costly. Buyers should assess the long-term operational benefits against the initial investment, ensuring that the chosen model aligns with their business needs and growth plans.

Key Industrial Applications of tractor Truck Model

| Industry/Sector | Specific Application of tractor Truck Model | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Transportation | Long-haul freight transport using tractor trucks | Increased efficiency in transporting goods over long distances | Reliability of the truck model, fuel efficiency, and maintenance support |

| Agriculture | Transporting agricultural products and machinery | Enhanced productivity in moving crops and equipment | Load capacity, terrain adaptability, and service availability |

| Construction | Hauling construction materials and equipment | Streamlined project timelines through efficient material delivery | Durability, towing capacity, and compliance with local regulations |

| Oil and Gas | Transporting heavy equipment and materials | Cost savings through effective logistics management | Weight limits, fuel consumption, and specialized equipment compatibility |

| Mining | Moving extracted materials and heavy machinery | Improved operational efficiency in remote locations | Off-road capability, fuel efficiency, and service network accessibility |

How Are Tractor Truck Models Used in Logistics and Transportation?

In the logistics and transportation sector, tractor truck models are essential for long-haul freight transport. These trucks provide a reliable means to move large quantities of goods across vast distances, which is crucial for supply chain efficiency. Buyers in this sector should consider the reliability and fuel efficiency of the trucks, as well as the availability of maintenance services, particularly in regions like Africa and South America where infrastructure can be challenging.

What Role Do Tractor Trucks Play in Agriculture?

In agriculture, tractor trucks are used to transport products from farms to markets, as well as to move heavy agricultural machinery. This application significantly enhances productivity by ensuring timely delivery of goods. Buyers must focus on load capacity and terrain adaptability, especially in rural areas where road conditions may vary. Additionally, ensuring access to service and parts is vital for maintaining operational continuity.

How Are Tractor Trucks Utilized in Construction Projects?

The construction industry relies on tractor truck models for hauling materials and equipment to and from job sites. This capability streamlines project timelines and reduces downtime caused by material shortages. Key considerations for buyers include the truck’s durability and towing capacity, as well as compliance with local regulations regarding heavy vehicle operation. Buyers in Europe and the Middle East should also consider regional environmental standards when selecting models.

Why Are Tractor Trucks Important for Oil and Gas Operations?

In the oil and gas sector, tractor trucks are crucial for transporting heavy equipment and materials to remote drilling sites. Their ability to manage heavy loads efficiently leads to significant cost savings and improved logistics management. Buyers should assess weight limits and fuel consumption, particularly in regions with vast distances between operational sites, such as parts of Africa and the Middle East.

How Do Tractor Trucks Support Mining Operations?

Tractor truck models are vital in mining for moving extracted materials and heavy machinery within and outside mining sites. They improve operational efficiency, particularly in remote locations where access can be difficult. Buyers should prioritize off-road capability and fuel efficiency, as well as the accessibility of service networks, to ensure sustained operations in challenging environments typical of mining operations in South America and Africa.

3 Common User Pain Points for ‘tractor Truck Model’ & Their Solutions

Scenario 1: Navigating the Complexity of Model Specifications

The Problem:

B2B buyers often face the daunting task of selecting the right tractor truck model that meets specific operational requirements. With numerous models available, each with distinct specifications, features, and performance metrics, it can be overwhelming. This is especially true in markets like Africa and South America, where varying terrains and regulatory standards necessitate tailored solutions. Misjudging the specifications can lead to inefficiencies, increased operational costs, and even legal complications.

The Solution:

To effectively navigate the complexity of model specifications, B2B buyers should adopt a systematic approach. Start by clearly defining the operational needs, including load capacity, fuel efficiency, and terrain compatibility. Engaging with manufacturers and suppliers to request detailed product specifications and performance data is crucial. Additionally, utilizing advanced simulation tools that provide insights into how different models perform under specific conditions can be highly beneficial. Establishing a checklist based on these criteria will help streamline the selection process, ensuring that the chosen tractor truck model aligns perfectly with the intended use case.

Scenario 2: Overcoming Supply Chain Disruptions

The Problem:

Supply chain disruptions pose a significant challenge for B2B buyers of tractor truck models, particularly in regions like the Middle East and Europe, where geopolitical factors can impact availability. Delays in delivery can lead to operational downtime, affecting business continuity and customer satisfaction. Buyers often find themselves struggling to source models on time, leading to a cascade of logistical challenges.

The Solution:

To mitigate supply chain disruptions, B2B buyers should establish a multi-supplier strategy. This involves identifying and engaging with multiple manufacturers and suppliers, both locally and internationally, to ensure a diversified supply chain. Building strong relationships with suppliers can enhance communication and responsiveness, allowing buyers to quickly adapt to changes in availability. Additionally, investing in inventory management systems can help track demand and supply fluctuations, enabling more informed purchasing decisions. Finally, considering alternative models or configurations that have shorter lead times can provide flexibility and reduce the risk of operational delays.

Scenario 3: Ensuring Post-Purchase Support and Maintenance

The Problem:

After purchasing a tractor truck model, B2B buyers often encounter challenges related to post-purchase support and maintenance. Inadequate support can lead to increased downtime and higher repair costs, particularly if parts are not readily available or if the buyer is unfamiliar with the maintenance requirements of the specific model. This issue is exacerbated in regions where technical support might not be as accessible, leading to frustration and operational inefficiencies.

The Solution:

To ensure robust post-purchase support, B2B buyers should prioritize sourcing from manufacturers that offer comprehensive service packages. Before finalizing a purchase, inquire about warranty terms, availability of spare parts, and the extent of technical support offered. Establishing a partnership with a local dealer or service center can provide timely assistance and facilitate easier access to parts. Furthermore, implementing a proactive maintenance schedule based on the manufacturer’s guidelines can help prevent issues before they arise. Training in-house maintenance staff on the specific model can also empower teams to address minor issues effectively, reducing reliance on external support and minimizing downtime.

Strategic Material Selection Guide for tractor Truck Model

What Are the Key Materials Used in Tractor Truck Models?

When selecting materials for tractor truck models, it is crucial to consider their properties, advantages, disadvantages, and the specific needs of international B2B buyers. Here, we analyze four common materials used in the construction of tractor truck models: steel, aluminum, plastic, and composite materials.

How Does Steel Perform in Tractor Truck Models?

Steel is a staple material in the manufacturing of tractor truck models due to its high strength and durability. Key properties include excellent temperature and pressure ratings, making it suitable for heavy-duty applications. Steel is also highly resistant to deformation under stress, which is essential for maintaining the structural integrity of the truck.

Pros: Steel’s durability and strength make it ideal for components that experience high stress, such as the chassis and frame. It is generally cost-effective, especially for large-scale production.

Cons: However, steel is prone to corrosion if not properly treated, which can be a significant drawback in humid or coastal environments. Additionally, the manufacturing complexity can be higher due to the need for welding and finishing processes.

Impact on Application: Steel is compatible with various media, including fuels and lubricants, but may require protective coatings to prevent rusting, especially in regions with high moisture levels.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local regulations regarding emissions and safety standards, such as ASTM or DIN. The availability of corrosion-resistant coatings may also influence material choice.

What Are the Benefits of Using Aluminum in Tractor Truck Models?

Aluminum is another popular choice, particularly for components that require a lightweight yet strong material. Its key properties include excellent corrosion resistance and a good strength-to-weight ratio, making it ideal for fuel-efficient designs.

Pros: The lightweight nature of aluminum contributes to better fuel efficiency and handling. It is also easier to manufacture into complex shapes, which can be advantageous for design flexibility.

Cons: The primary drawback is the higher cost of aluminum compared to steel, which can impact the overall budget for manufacturers. Additionally, aluminum may not perform as well under high-stress conditions compared to steel.

Impact on Application: Aluminum is compatible with a variety of media, making it suitable for fuel tanks and body panels. However, care must be taken to avoid galvanic corrosion when in contact with other metals.

Considerations for International Buyers: Buyers should consider the availability of aluminum and its cost implications in their respective markets. Compliance with international standards for recycling and sustainability may also be a factor.

How Do Plastics Contribute to Tractor Truck Models?

Plastics are increasingly used in tractor truck models, particularly for interior components and lightweight exterior panels. Key properties include resistance to corrosion and a wide range of temperature tolerances.

Pros: Plastics are lightweight, which can significantly reduce the overall weight of the vehicle, enhancing fuel efficiency. They are also cost-effective and can be molded into complex shapes easily.

Cons: However, plastics can be less durable than metals, especially under high-stress conditions. They may also degrade over time when exposed to UV light unless treated.

Impact on Application: Plastics are suitable for components that do not bear heavy loads, such as dashboards and fairings. However, their use in structural components may be limited.

Considerations for International Buyers: Buyers should be aware of the regulations regarding the use of plastics in their regions, especially concerning environmental impact and recyclability.

What Role Do Composites Play in Tractor Truck Models?

Composite materials, such as fiberglass and carbon fiber, are becoming more prevalent in high-performance tractor truck models. Their key properties include high strength, low weight, and excellent resistance to corrosion.

Pros: Composites offer superior performance in terms of weight savings and strength, making them ideal for specialized applications. They also provide excellent thermal and electrical insulation.

Cons: The primary limitation is the high cost of composite materials, which can make them less accessible for budget-sensitive projects. Additionally, manufacturing processes can be complex and time-consuming.

Impact on Application: Composites are particularly suitable for body panels and components requiring high strength-to-weight ratios. However, they may not be compatible with all media, necessitating careful selection based on application.

Considerations for International Buyers: Buyers should evaluate the availability and cost of composites in their markets. Compliance with international standards for material performance and safety is crucial.

Summary of Material Selection for Tractor Truck Models

| Material | Typical Use Case for tractor Truck Model | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chassis and frame | High strength and durability | Prone to corrosion | Medium |

| Aluminum | Fuel tanks and body panels | Lightweight and corrosion-resistant | Higher cost than steel | High |

| Plastic | Interior components | Cost-effective and lightweight | Less durable under stress | Low |

| Composites | High-performance body panels | Superior strength-to-weight ratio | High cost and complex manufacturing | High |

This guide should assist international B2B buyers in making informed decisions regarding material selection for tractor truck models, considering both performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for tractor Truck Model

What Are the Key Stages in the Manufacturing Process of Tractor Truck Models?

The manufacturing process for tractor truck models involves several critical stages that ensure the final product meets the expectations of durability, functionality, and aesthetics. Understanding these stages can provide B2B buyers with insights into the quality and reliability of the models they intend to purchase.

Material Preparation: What Materials Are Used and How Are They Processed?

The first stage in manufacturing tractor truck models typically involves material preparation. Common materials include high-grade steel, aluminum, and various plastics, each chosen for their specific properties such as strength, weight, and resistance to wear. The material selection is crucial as it impacts the overall performance and longevity of the trucks.

After selecting the materials, they undergo processes such as cutting, bending, and shaping. Advanced machinery, including CNC (Computer Numerical Control) machines, is often employed to ensure precision. This level of accuracy is vital, as even minor deviations can affect the assembly and performance of the final product.

How Are Tractor Truck Models Formed During Manufacturing?

The forming stage involves several techniques that create the various components of the tractor truck. Processes such as stamping, injection molding, and die casting are commonly used. Stamping is particularly important for producing flat panels and structural components, while injection molding is ideal for creating intricate plastic parts.

Forming techniques are chosen based on the component’s requirements. For example, heavy-duty components may be stamped from steel sheets, while lighter, more complex parts might be molded from plastic. The choice of technique not only affects the quality but also the cost-effectiveness of the manufacturing process.

What Is Involved in the Assembly Stage of Tractor Truck Models?

Once the individual components are formed, the assembly stage begins. This phase typically involves several steps, including the integration of the chassis, engine, transmission, and other key systems. Skilled workers or automated systems carefully fit these components together to create a functional truck model.

Quality control checkpoints are established during assembly to ensure that each component meets the required specifications. Issues identified during this stage can lead to rework or replacement, ensuring that the final product is up to standard before moving to the finishing stage.

How Is the Finishing Process Conducted for Tractor Truck Models?

The finishing stage is where the tractor truck models receive their final touches. This includes painting, detailing, and the application of protective coatings. Advanced techniques such as powder coating are often employed to provide a durable finish that can withstand harsh environments.

In addition to aesthetics, the finishing process also includes functional enhancements, such as the installation of lights, decals, and branding elements. This stage is critical for ensuring that the models not only look good but also function as intended in various operating conditions.

What Quality Assurance Practices Are Essential in the Manufacturing of Tractor Truck Models?

Quality assurance (QA) is a fundamental aspect of the manufacturing process, ensuring that products meet established standards and customer expectations. For B2B buyers, understanding these QA practices is essential for verifying the reliability of their suppliers.

Which International Standards Are Relevant for Tractor Truck Model Manufacturing?

Manufacturers of tractor truck models often adhere to international quality standards, such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards indicates a commitment to quality and continuous improvement.

Additionally, industry-specific certifications may be relevant, such as CE marking for products sold in Europe or API standards for those targeting the oil and gas sectors. These certifications assure buyers that the products meet rigorous safety and quality requirements.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control is typically structured around several checkpoints, including Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC ensures that raw materials and components meet specified standards before they enter the production line.

- IPQC monitors the manufacturing process to identify defects during production, allowing for immediate corrective actions.

- FQC is the final assessment that checks the completed models for overall quality and performance before shipment.

These checkpoints are critical for maintaining high standards and minimizing defects in the final product.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For B2B buyers, verifying the quality assurance practices of suppliers is crucial to ensure they receive reliable products. Here are several actionable steps that buyers can take:

What Methods Can Be Used to Assess Supplier Quality?

- Audits and Inspections: Conducting regular audits of suppliers’ manufacturing facilities can provide insights into their quality management systems and adherence to standards.

- Reviewing Quality Reports: Requesting detailed quality reports, including defect rates and corrective actions taken, can help buyers assess a supplier’s reliability.

- Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased evaluation of the supplier’s quality assurance processes.

What Are the Specific Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Variations in regulations, standards, and market expectations can affect product compliance.

Additionally, understanding local certification requirements and potential logistical challenges in transporting goods can help mitigate risks associated with quality assurance. Establishing clear communication channels with suppliers to address these nuances is also essential for ensuring product quality and reliability.

Conclusion: Ensuring Quality in Tractor Truck Model Manufacturing

By comprehensively understanding the manufacturing processes and quality assurance practices involved in tractor truck models, B2B buyers can make informed decisions. This knowledge not only aids in selecting reliable suppliers but also enhances the overall procurement process, ensuring that buyers receive high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tractor Truck Model’

Introduction

Navigating the procurement of tractor truck models requires a structured approach to ensure that your investment meets your operational needs and standards. This checklist is designed to guide international B2B buyers through the essential steps to source high-quality tractor truck models effectively. By following this guide, you can streamline your purchasing process and minimize risks associated with supplier selection.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly define the technical specifications for the tractor truck models you need. This includes parameters such as size, weight capacity, engine specifications, and intended use (e.g., long-haul, short-haul).

- Consider Regional Requirements: Different regions may have specific regulations or preferences regarding truck specifications, so ensure your requirements align with local standards.

Step 2: Conduct Market Research

Conduct thorough market research to identify potential suppliers and understand the current market landscape. Investigate manufacturers known for producing tractor truck models that meet your specifications.

- Utilize Trade Shows and Online Platforms: Attend industry trade shows and leverage online platforms to gather insights about different suppliers and their offerings.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

- Assess Supplier Stability: Look for suppliers with a solid track record of reliability and customer satisfaction, as this can significantly impact your supply chain stability.

Step 4: Verify Certifications and Compliance

Ensure that potential suppliers have the necessary certifications and comply with international standards. This is critical for ensuring product quality and safety.

- Check for ISO Certifications: Look for suppliers with ISO or equivalent certifications, which indicate adherence to quality management systems.

Step 5: Request Samples or Prototypes

Request samples or prototypes of the tractor truck models you are considering. This allows you to assess the quality and functionality before making a large purchase.

- Evaluate Performance and Durability: Pay attention to aspects such as build quality, ease of maintenance, and performance under different conditions during your evaluation.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations to agree on pricing, payment terms, and delivery schedules.

- Consider Total Cost of Ownership: Factor in not just the purchase price but also long-term costs such as maintenance, fuel efficiency, and potential downtime.

Step 7: Finalize the Purchase Agreement

Carefully review and finalize the purchase agreement, ensuring all terms are clearly defined and agreed upon. This document should outline specifications, delivery timelines, warranties, and service agreements.

- Include Contingency Clauses: Consider including clauses that address potential issues such as delays or defects to protect your investment.

By following this step-by-step checklist, you can enhance your procurement process, ensuring that the tractor truck models you acquire are aligned with your business needs and operational goals.

Comprehensive Cost and Pricing Analysis for tractor Truck Model Sourcing

What Are the Key Cost Components in Tractor Truck Model Sourcing?

When sourcing tractor truck models, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: This encompasses the raw materials used in manufacturing, such as steel and plastics, which can fluctuate based on global market conditions. High-quality materials may increase costs but also enhance durability and performance.

-

Labor: Labor costs vary significantly depending on the region and the skill level required for manufacturing. Countries with lower labor costs can provide competitive pricing, but this may impact quality.

-

Manufacturing Overhead: This includes costs related to facilities, equipment maintenance, and utilities. Efficient manufacturing processes can help minimize these overheads.

-

Tooling: The initial investment in tooling for specific designs can be substantial. Custom models may require unique tooling, which increases upfront costs but can be amortized over larger production runs.

-

Quality Control (QC): Implementing robust quality control processes ensures that products meet specified standards, which can add to overall costs but is crucial for maintaining reputation and reducing returns.

-

Logistics: Transportation and shipping costs are influenced by distance, weight, and chosen shipping methods. International logistics can add complexity and costs, particularly with customs and duties.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market conditions and competition.

How Do Price Influencers Impact Tractor Truck Model Costs?

Several factors can influence the pricing of tractor truck models, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to better pricing due to economies of scale. Negotiating MOQ can significantly affect the overall cost.

-

Specifications and Customization: Custom features or specifications can drive up costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Materials: The choice of materials directly affects pricing. Premium materials can enhance performance but come at a higher cost. Buyers should assess the trade-off between cost and quality.

-

Quality Certifications: Products that meet international quality standards may command higher prices but offer assurance of performance and safety. This is particularly important in regulated markets.

-

Supplier Factors: The reputation, reliability, and financial stability of the supplier can influence pricing. Established suppliers may offer better warranties and support but may also charge a premium.

-

Incoterms: The terms of shipment can significantly affect the total landed cost. Understanding Incoterms helps buyers clarify responsibilities regarding shipping, insurance, and customs duties.

What Buyer Tips Can Enhance Cost-Efficiency in Tractor Truck Model Sourcing?

International B2B buyers can adopt several strategies to ensure cost-effectiveness when sourcing tractor truck models:

-

Negotiate Terms: Always negotiate payment terms, lead times, and delivery schedules. Flexibility can lead to better pricing or improved service.

-

Consider Total Cost of Ownership (TCO): Look beyond initial purchase prices to include maintenance, operational costs, and potential resale value. This holistic view helps in making informed purchasing decisions.

-

Research Local Market Conditions: Understanding regional market dynamics can provide leverage in negotiations. Factors such as local demand, competition, and economic conditions can impact pricing.

-

Evaluate Supplier Relationships: Building long-term relationships with suppliers can lead to better terms, pricing, and priority service. Loyalty may yield discounts or exclusive offers.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures due to local economies, tariffs, and taxes. Familiarize yourself with these nuances to avoid unexpected costs.

Disclaimer on Indicative Prices

Prices for tractor truck models can vary significantly based on the factors discussed above. Buyers should consider these variables when budgeting and negotiating, as costs may fluctuate based on market conditions and supplier capabilities. Always seek updated quotes and detailed breakdowns to ensure transparency and accuracy in pricing.

Alternatives Analysis: Comparing tractor Truck Model With Other Solutions

Understanding Alternatives to the Tractor Truck Model

In the realm of logistics and transportation, the tractor truck model is a widely recognized solution for heavy hauling and freight transport. However, it is crucial for B2B buyers to explore various alternatives to make informed decisions that align with their operational needs and budget constraints. This analysis will compare the tractor truck model with two viable alternatives: the box truck and the flatbed truck.

Comparison Table

| Comparison Aspect | Tractor Truck Model | Box Truck | Flatbed Truck |

|---|---|---|---|

| Performance | High towing capacity, suitable for long hauls | Moderate load capacity, ideal for local deliveries | Excellent for oversized loads, versatile for various cargo |

| Cost | Higher initial investment, ongoing fuel costs | Lower initial cost, efficient for short routes | Moderate cost, varying based on size and load |

| Ease of Implementation | Requires specialized training for drivers | Easier for general drivers to operate | Requires specialized knowledge for securing loads |

| Maintenance | Regular maintenance needed; complex systems | Generally lower maintenance needs | Higher wear and tear due to exposure to elements |

| Best Use Case | Long-distance freight transport | Urban deliveries, moving services | Construction, heavy machinery transport |

What Are the Pros and Cons of Box Trucks?

Box trucks, also known as cube trucks, are a popular alternative for businesses requiring transportation of goods in urban environments. They offer a closed cargo space that protects items from the elements, making them ideal for local deliveries. The initial cost of box trucks is generally lower than that of tractor trucks, and they are easier to maneuver in tight spaces. However, their load capacity is limited compared to tractor trucks, making them less suitable for heavy or oversized freight. Additionally, while maintenance is typically lower, box trucks may not be as durable for long hauls.

How Do Flatbed Trucks Compare?

Flatbed trucks provide a versatile solution for transporting a wide range of cargo, particularly oversized or irregularly shaped items that cannot fit into a standard trailer. Their open design allows for easy loading and unloading, making them a preferred choice in construction and heavy machinery transport. However, flatbed trucks require drivers with specialized skills to secure loads properly, and they are exposed to weather conditions, leading to potential wear and tear. While their initial costs can be moderate, the maintenance may vary significantly depending on usage.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting between the tractor truck model and its alternatives, B2B buyers must consider their specific operational requirements, including load type, delivery routes, and budget constraints. The tractor truck model excels in performance and capacity for long hauls, while box trucks are ideal for local deliveries with a lower cost of entry. Flatbed trucks offer unique advantages for specialized cargo but require more skilled handling. By carefully evaluating these factors, buyers can choose the most suitable solution that aligns with their business goals and enhances their logistics efficiency.

Essential Technical Properties and Trade Terminology for tractor Truck Model

What Are the Key Technical Properties of Tractor Truck Models?

When evaluating tractor truck models, understanding their essential technical properties is crucial for B2B buyers. Here are several critical specifications that impact performance, durability, and operational efficiency:

-

Payload Capacity

– Definition: This refers to the maximum weight a tractor truck can safely carry, including the weight of the cargo and any additional equipment.

– B2B Importance: Knowing the payload capacity helps businesses determine the right truck for their logistics needs, ensuring compliance with legal weight limits and optimizing transport efficiency. -

Engine Power (Horsepower)

– Definition: Engine power, often measured in horsepower (HP), indicates the engine’s ability to perform work, affecting acceleration and load handling.

– B2B Importance: Higher horsepower allows for better performance under heavy loads, making it essential for businesses in sectors like construction and freight transport, where efficiency is paramount. -

Torque Rating

– Definition: Torque is the rotational force produced by the engine, usually expressed in foot-pounds (ft-lbs). It affects the vehicle’s ability to start moving and climb inclines.

– B2B Importance: A higher torque rating is vital for heavy-duty applications, enabling the truck to handle steep grades and heavy loads without straining the engine. -

Fuel Efficiency (MPG)

– Definition: Fuel efficiency, measured in miles per gallon (MPG), indicates how far a truck can travel on a gallon of fuel.

– B2B Importance: For businesses looking to minimize operational costs, fuel efficiency is a key consideration. Improved MPG can lead to significant savings over time, making it an attractive feature for fleet managers. -

Towing Capacity

– Definition: This specification indicates the maximum weight a tractor truck can tow safely, which includes trailers and additional cargo.

– B2B Importance: Understanding towing capacity is essential for logistics and transport companies that often haul heavy trailers. It ensures that the chosen vehicle can meet the demands of specific jobs without compromising safety.

Which Trade Terminology Should B2B Buyers Know?

Familiarity with industry jargon is equally important for B2B buyers when navigating the procurement of tractor truck models. Here are some common terms to understand:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer.

– B2B Importance: Knowing about OEMs helps buyers identify reliable manufacturers for replacement parts or upgrades, ensuring compatibility and quality. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– B2B Importance: Understanding MOQ is crucial for buyers to gauge the cost-effectiveness of large purchases. It can also influence inventory management strategies. -

RFQ (Request for Quotation)

– Definition: An RFQ is a formal document requesting price quotes from suppliers for specific products or services.

– B2B Importance: Utilizing RFQs allows businesses to compare pricing and terms across different suppliers, aiding in informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions.

– B2B Importance: Understanding Incoterms helps businesses clarify shipping responsibilities, costs, and risks, which is critical when purchasing tractor trucks from overseas suppliers. -

Lead Time

– Definition: Lead time refers to the amount of time from placing an order to the delivery of the product.

– B2B Importance: Knowing the lead time is vital for planning and logistics, as it directly impacts inventory levels and project timelines.

By grasping these technical properties and industry terms, B2B buyers can make more informed decisions when selecting tractor truck models that meet their operational requirements and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the tractor Truck Model Sector

What Are the Key Market Dynamics and Trends in the Tractor Truck Model Sector?

The tractor truck model sector is experiencing significant growth, driven by several global factors. Increased demand for freight transport, particularly in emerging markets like Africa, South America, and Southeast Asia, is pushing B2B buyers to explore innovative sourcing options. The expansion of e-commerce and logistics industries is another catalyst, necessitating efficient transportation solutions. Moreover, advancements in technology—such as telematics, automation, and electric vehicles—are reshaping the landscape, allowing businesses to optimize fleet management and reduce operational costs.

B2B buyers should also be aware of the emerging trend towards customization in tractor truck models. As market competition intensifies, companies are increasingly looking for tailored solutions that meet specific operational needs. Digital platforms for sourcing and procurement are becoming more prevalent, enabling buyers to compare models, features, and pricing efficiently. Furthermore, the rise of online marketplaces is facilitating direct interactions between manufacturers and buyers, streamlining the purchasing process and enhancing transparency.

How Are Sustainability and Ethical Sourcing Shaping the Tractor Truck Model Market?

Sustainability is no longer a mere trend; it has become a critical consideration for B2B buyers in the tractor truck model sector. The environmental impact of logistics and transportation is under scrutiny, prompting companies to seek solutions that minimize their carbon footprint. This shift has led to the adoption of electric and hybrid tractor truck models, which are gaining traction due to their lower emissions and operational costs.

Moreover, ethical sourcing is becoming increasingly important as buyers prioritize suppliers who demonstrate a commitment to sustainable practices. Certifications such as ISO 14001 for environmental management and adherence to green materials are now key factors in the decision-making process. Buyers should evaluate their supply chains to ensure that their partners uphold ethical standards, fostering a more sustainable ecosystem. By choosing suppliers that prioritize sustainability, businesses not only enhance their brand image but also meet the growing expectations of environmentally conscious consumers.

What Is the Evolution of the Tractor Truck Model Sector?

The tractor truck model sector has a rich history that reflects broader technological advancements and changing market demands. Initially, tractor trucks were primarily utilitarian vehicles designed for heavy-duty hauling. Over the decades, they have evolved into sophisticated machines equipped with advanced technologies for safety, efficiency, and comfort. The introduction of computerized systems for diagnostics and performance monitoring has transformed fleet management, allowing businesses to optimize operations.

In recent years, the focus has shifted towards sustainability and innovation, with manufacturers investing heavily in research and development of electric and hybrid models. This evolution is not just about meeting regulatory standards but also responding to a market that increasingly values eco-friendly solutions. As B2B buyers navigate this dynamic landscape, understanding the historical context of tractor truck models can provide valuable insights into current trends and future directions.

Frequently Asked Questions (FAQs) for B2B Buyers of tractor Truck Model

-

How do I choose the right tractor truck model for my business needs?

Selecting the appropriate tractor truck model involves assessing your operational requirements, including load capacity, fuel efficiency, and terrain adaptability. Consider the type of cargo you plan to transport and the distances involved. Research various models to evaluate their specifications, and consult with suppliers for insights on performance in different environments. Additionally, reviewing customer feedback and industry reports can provide valuable context to help make an informed decision. -

What are the key factors to consider when vetting suppliers for tractor trucks?

When vetting suppliers, focus on their reputation, experience in the industry, and compliance with international standards. Request references from previous clients and assess their responsiveness to inquiries. Evaluate their production capacity and delivery timelines to ensure they can meet your demand. Additionally, inquire about their quality assurance processes and after-sales support, which are crucial for maintaining operational efficiency. -

What customization options are typically available for tractor truck models?

Customization options vary by manufacturer but often include modifications to engine specifications, cab configurations, and trailer types. You may also request features like advanced safety systems, enhanced fuel management technology, or specialized cargo handling equipment. Discuss your specific needs with potential suppliers to understand the range of customization available and any associated costs or lead times. -

What is the minimum order quantity (MOQ) for tractor trucks when sourcing from suppliers?

Minimum order quantities (MOQs) can differ significantly based on the supplier and the tractor truck model. Some manufacturers may have an MOQ as low as one unit, while others may require bulk orders to ensure production efficiency. It’s essential to communicate your purchasing intentions upfront to negotiate favorable terms. Understanding your budget and future needs can also influence your decision on the order size. -

What payment terms should I expect when sourcing tractor trucks internationally?

Payment terms can vary by supplier, but common arrangements include upfront deposits followed by balance payments upon delivery or after a specified period. Letters of credit and escrow services are often used for larger transactions to protect both parties. Always clarify the payment schedule, acceptable payment methods, and any potential financing options with your supplier to avoid misunderstandings. -

How can I ensure quality assurance for my tractor truck purchases?

To ensure quality assurance, request detailed specifications and certifications from your supplier that demonstrate compliance with industry standards. Inquire about their manufacturing processes, testing protocols, and warranty policies. If possible, arrange for an inspection of the trucks before shipment or utilize third-party inspection services. Establishing a clear agreement on quality expectations in your contract will also protect your interests. -

What logistics considerations should I take into account when importing tractor trucks?

When importing tractor trucks, consider shipping methods, customs regulations, and potential tariffs in your destination country. Engage a reliable freight forwarder familiar with heavy equipment transportation to navigate the complexities of international logistics. Ensure you have all necessary documentation, including bills of lading and import permits, to facilitate a smooth customs clearance process. Proper planning can help mitigate delays and additional costs. -

How can I effectively manage after-sales support and service for my tractor truck fleet?

Effective management of after-sales support involves establishing clear communication channels with your supplier or manufacturer for ongoing service needs. Ensure you understand warranty coverage and the availability of replacement parts. Building a relationship with local service providers can also facilitate timely maintenance and repairs. Regular training for your operators on best practices for maintenance will help maximize the lifespan of your tractor trucks.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Tractor Truck Model Manufacturers & Suppliers List

1. AMT – Kenworth W925 Conventional

Domain: autoworldstore.com

Registered: 2009 (16 years)

Introduction: [{‘name’: ‘AMT Kenworth W925 Conventional’, ‘scale’: ‘1:25’, ‘price’: ‘$49.99’}, {‘name’: ‘AMT Peterbilt 359 Wrecker’, ‘scale’: ‘1:25’, ‘price’: ‘$51.99’, ‘availability’: ‘Out of Stock’}, {‘name’: ‘AMT White Freightliner 2-in-1 SD-DD Cabover Tractor (75th Anniversary)’, ‘scale’: ‘1:25’, ‘price’: ‘$51.99’}, {‘name’: ‘AMT Mack R685ST Semi Tractor’, ‘scale’: ‘1:25’, ‘price’: ‘$51.99’}, {‘name’: “AMT …

2. MegaHobby – Trucks and Trailers

Domain: megahobby.com

Registered: 1999 (26 years)

Introduction: Trucks and Trailers category includes model trucks, jeeps, pickups, vans, SUVs, and civil construction vehicles.

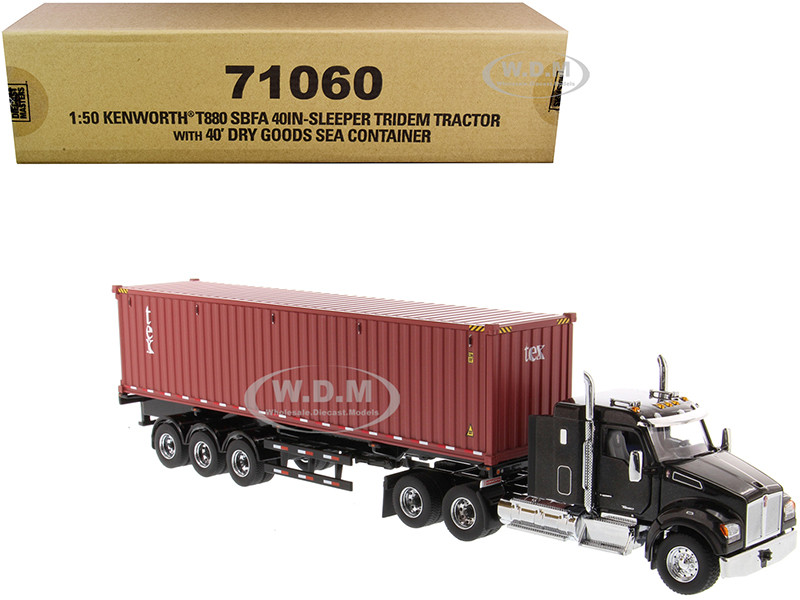

3. Diecast Direct – Tractor Trailers

Domain: diecastdirect.com

Registered: 1997 (28 years)

Introduction: Tractor Trailers: Diecast Direct, Inc. offers a variety of diecast models including different types of tractor trailers such as Auto Haulers, Cement Trucks, Dump Trucks, Flatbed Trailers, Garbage Trucks, Lowboy Trailers, Semi Tractors, Tankers, and more. The site features products from various manufacturers including ACME Trading Co., Action Racing Collectables, First Gear, Greenlight Collectibles…

4. Peterbilt – Trucks for Every Application

Domain: peterbilt.com

Registered: 1996 (29 years)

Introduction: This company, Peterbilt – Trucks for Every Application, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Awesome Diecast – Diecast Model Tractor Trailers

Domain: awesomediecast.com

Registered: 2006 (19 years)

Introduction: Diecast Model Tractor Trailers – Replica Trailers available in various scales including 1:18, 1:43, 1:50, 1:64, and 1:87. The product category includes a wide selection of tractor trailers, with options for articulated trucks, delivery trucks, cement trucks, and more. The site offers worldwide shipping and a customer account feature for enhanced shopping experience.

6. Hobbylinc – Model Truck Kits

Domain: hobbylinc.com

Registered: 1997 (28 years)

Introduction: Model Truck Kits available from Hobbylinc include 100 kits from 11 manufacturers. Key details include:

– Scale options: 1/20-1/29 (91), 1/30-1/39 (5), 1/70-1/79 (1), Military (3)

– Popular brands: AMT/ERTL (30), Aoshima (1), Bandai Models (1), Heller (3), Hobby Boss (1), Italeri (51), Moebius Models (2), MPC by Ertl (1), Revell of Germany (2), Revell-Monogram (6), Trumpeter (2)

– Price discounts: …

Strategic Sourcing Conclusion and Outlook for tractor Truck Model

In conclusion, strategic sourcing for tractor truck models is essential for international B2B buyers seeking to enhance their supply chain efficiency and operational effectiveness. The diverse range of models available—from classic American trucks to modern European designs—offers buyers the flexibility to choose vehicles that align with their specific logistical needs and regional requirements. By leveraging strategic sourcing practices, businesses can negotiate better pricing, ensure quality standards, and foster long-term relationships with suppliers, which is crucial in navigating competitive markets across Africa, South America, the Middle East, and Europe.

As the demand for efficient transportation solutions continues to grow, buyers are encouraged to stay informed about the latest innovations in tractor truck technology and sustainability practices. Engaging with reputable manufacturers and suppliers will not only enhance procurement strategies but also contribute to a more sustainable and resilient supply chain.

Looking ahead, it is an opportune time for businesses to invest in strategic sourcing initiatives. By doing so, they can secure a competitive advantage and position themselves effectively in the evolving global marketplace. Start exploring your options today to ensure your fleet is equipped for the challenges of tomorrow.