Introduction: Navigating the Global Market for manual Transmission Cargo Truck

In an era where automatic transmissions dominate the automotive landscape, sourcing manual transmission cargo trucks presents a unique challenge for international B2B buyers. These vehicles, known for their durability and control, are particularly sought after in regions such as Africa, South America, the Middle East, and Europe, where rugged terrain and diverse operational needs demand reliable performance. This guide serves as a comprehensive resource, meticulously detailing the types of manual transmission cargo trucks available, their applications across various industries, and essential factors for supplier vetting.

Buyers will gain insights into the cost implications of acquiring these trucks, alongside the benefits of manual transmissions, such as enhanced fuel efficiency and lower maintenance costs. Additionally, we explore the latest market trends, helping businesses understand the evolving landscape of manual transmission vehicles.

By empowering B2B buyers with actionable information and strategic considerations, this guide aims to facilitate informed purchasing decisions that align with operational needs and budgetary constraints. Whether you’re in Brazil seeking versatile transport solutions or in Saudi Arabia looking to optimize logistics, our insights will help navigate the complexities of the global market for manual transmission cargo trucks, ensuring you make choices that drive your business forward.

Understanding manual Transmission Cargo Truck Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flatbed Cargo Truck | Open bed design for transporting oversized loads | Construction, agriculture, logistics | Pros: Versatile load capacity; easy loading/unloading. Cons: Limited weather protection for cargo. |

| Box Truck | Enclosed cargo area for security and protection | Delivery services, moving companies | Pros: Provides weather protection; secure storage. Cons: Limited height for taller cargo. |

| Dump Truck | Equipped with a hydraulic lift for easy unloading | Construction, waste management | Pros: Efficient unloading; ideal for loose materials. Cons: Heavier and may have limited payload capacity. |

| Refrigerated Truck | Insulated cargo area with refrigeration system | Food transportation, pharmaceuticals | Pros: Maintains temperature-sensitive cargo; versatile. Cons: Higher maintenance costs; limited cargo space. |

| Tow Truck | Designed for towing other vehicles or heavy equipment | Automotive services, roadside assistance | Pros: Essential for recovery operations; versatile. Cons: May require specialized training to operate. |

What Are the Key Characteristics of Flatbed Cargo Trucks?

Flatbed cargo trucks feature an open bed without sides or a roof, making them ideal for transporting large or awkwardly shaped items. Their design allows for easy loading and unloading from multiple angles, which is particularly beneficial in construction and agricultural sectors. B2B buyers should consider the load capacity and dimensions to ensure compatibility with their typical cargo types.

How Do Box Trucks Serve Businesses?

Box trucks, also known as cube vans, provide an enclosed cargo space that offers protection from the elements. This makes them suitable for businesses that require safe transport of goods, such as delivery services and moving companies. When purchasing, buyers should evaluate the truck’s payload capacity and interior dimensions to match their specific shipping needs.

Why Choose Dump Trucks for Construction?

Dump trucks are essential for construction and waste management applications due to their ability to unload materials quickly and efficiently. They are equipped with a hydraulic lift that allows for the dumping of loose materials like gravel, sand, and debris. Buyers should assess the truck’s payload capacity and hydraulic system reliability to ensure optimal performance on job sites.

What Are the Advantages of Refrigerated Trucks?

Refrigerated trucks are specialized vehicles designed to transport temperature-sensitive goods, such as food and pharmaceuticals. Their insulated cargo areas and refrigeration systems help maintain specific temperature ranges, making them crucial for businesses in the food supply chain. B2B buyers should consider the truck’s refrigeration capacity and energy efficiency when making a purchase.

How Do Tow Trucks Benefit Automotive Services?

Tow trucks are equipped to recover and transport vehicles that are disabled or involved in accidents. They are vital for automotive services and roadside assistance companies. Buyers should focus on the truck’s towing capacity and the type of towing equipment it includes, as these factors will determine its effectiveness in various recovery situations.

Key Industrial Applications of manual Transmission Cargo Truck

| Industry/Sector | Specific Application of manual Transmission Cargo Truck | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Transporting building materials to job sites | Enhanced control in rugged terrains; lower maintenance costs | Durability, fuel efficiency, and load capacity |

| Agriculture | Hauling produce and equipment between farms | Versatile use in various terrains; lower operational costs | Availability of parts, ease of repair, and service support |

| Logistics and Distribution | Delivering goods in urban and rural areas | Improved driver engagement and control during delivery | Fuel consumption, reliability, and driver training needs |

| Mining | Transporting minerals and heavy equipment | Better handling in off-road conditions; cost-effective | Load capacity, terrain adaptability, and safety features |

| Emergency Services | Rapid response for fire and rescue operations | High reliability and control in critical situations | Speed of delivery, serviceability, and operational flexibility |

How is Manual Transmission Cargo Truck Used in the Construction Industry?

In the construction sector, manual transmission cargo trucks are vital for transporting heavy building materials and equipment to various job sites. Their ability to offer enhanced control over gear changes allows operators to navigate challenging terrains often found on construction sites. This is particularly beneficial in regions with rough roads, where automatic transmissions may struggle. Buyers in this sector should prioritize trucks with high durability and load capacity to ensure they can handle the demands of their projects.

What Role Does Manual Transmission Cargo Truck Play in Agriculture?

Agricultural businesses utilize manual transmission cargo trucks to efficiently haul produce, fertilizers, and equipment between farms and markets. The versatility of these trucks allows them to operate on both paved and unpaved roads, making them ideal for rural settings. For international buyers, especially in developing regions, considerations should include the availability of spare parts and ease of repair, as these factors directly impact operational downtime and maintenance costs.

How are Manual Transmission Cargo Trucks Beneficial for Logistics and Distribution?

In logistics and distribution, manual transmission cargo trucks are used for delivering goods in both urban and rural environments. The ability to engage drivers more actively in the shifting process can lead to better fuel efficiency and reduced operational costs. Buyers should consider the reliability of the trucks and their fuel consumption ratings, as these will influence the overall cost-effectiveness of their logistics operations.

Why are Manual Transmission Cargo Trucks Essential in Mining Operations?

Manual transmission cargo trucks are crucial in mining operations for transporting minerals and heavy machinery across rugged terrains. Their design allows for better handling in off-road conditions, making them a cost-effective choice for mining companies. When sourcing trucks for this application, businesses should focus on load capacity, terrain adaptability, and safety features to ensure they meet the unique challenges of the mining environment.

How Do Manual Transmission Cargo Trucks Support Emergency Services?

Emergency services rely on manual transmission cargo trucks for rapid response in fire and rescue operations. The high reliability and control provided by manual transmissions are critical in high-stakes situations where quick maneuverability is essential. Buyers in this sector should prioritize the speed of delivery, serviceability, and operational flexibility of the trucks to ensure they can respond effectively to emergencies.

3 Common User Pain Points for ‘manual Transmission Cargo Truck’ & Their Solutions

Scenario 1: Limited Availability of Manual Transmission Options

The Problem: Many international B2B buyers, particularly in regions such as Africa and South America, face the challenge of a dwindling selection of manual transmission cargo trucks. As manufacturers increasingly phase out manual options, buyers find it increasingly difficult to source vehicles that meet their operational needs. This limitation can severely impact logistics and transportation businesses that rely on manual transmission trucks for their performance and durability in rugged terrains.

The Solution: To navigate this challenge, B2B buyers should consider establishing direct relationships with manufacturers known for producing manual transmission trucks, such as Ford and Toyota. Engaging in direct negotiations can sometimes lead to custom orders or exclusive deals that might not be available through typical dealership channels. Additionally, buyers should explore the used truck market, as older models may still be available with manual transmissions. Utilizing online platforms that specialize in commercial vehicle listings can help identify these options. It’s also beneficial to attend industry trade shows where manufacturers showcase their latest models, providing an opportunity to inquire about manual transmission availability directly.

Scenario 2: Driver Training and Skill Gap

The Problem: Another significant pain point for B2B buyers is the skill gap among drivers when it comes to operating manual transmission cargo trucks. In regions where automatic vehicles dominate, finding qualified drivers who are proficient in manual shifting can be a challenge. This can lead to operational inefficiencies, higher training costs, and potential safety risks if untrained personnel attempt to operate these trucks.

The Solution: To mitigate this issue, companies should invest in comprehensive training programs specifically tailored for manual transmission vehicles. Partnering with local driving schools or hiring experienced trainers can facilitate effective learning. Training should not only cover the mechanics of driving a manual but also include safety protocols and best practices for handling cargo trucks in various conditions. Additionally, creating a mentorship program where experienced manual drivers guide newer employees can enhance skill retention and confidence in operating these vehicles. Implementing a structured training schedule ensures that all drivers are adequately prepared before they take the trucks on the road, thus improving overall safety and efficiency.

Scenario 3: Maintenance Complexity and Costs

The Problem: Manual transmission cargo trucks can present unique maintenance challenges that may not be familiar to all service technicians, especially in regions where automatics are more prevalent. This can lead to higher repair costs and longer downtimes if technicians lack the necessary expertise to troubleshoot and resolve issues effectively. B2B buyers may feel uncertain about the long-term viability of their investment due to these potential maintenance hurdles.

The Solution: To address this concern, buyers should prioritize sourcing manual transmission trucks from manufacturers that offer comprehensive service and support packages. This includes extended warranties and access to manufacturer-trained technicians who specialize in manual transmissions. Establishing a relationship with a reputable service center that understands the intricacies of manual systems can also be beneficial. Furthermore, buyers should consider investing in preventive maintenance programs that emphasize regular checks and fluid changes, as these can significantly extend the lifespan of the transmission and reduce the likelihood of costly repairs. Keeping detailed maintenance records and utilizing telematics for real-time monitoring can help anticipate issues before they escalate, ensuring that the fleet remains operational with minimal downtime.

Strategic Material Selection Guide for manual Transmission Cargo Truck

What Materials Are Commonly Used in Manual Transmission Cargo Trucks?

When selecting materials for manual transmission cargo trucks, several factors must be considered, including durability, cost, manufacturing complexity, and compliance with international standards. Here, we analyze four common materials used in the construction of manual transmission systems, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Steel Perform in Manual Transmission Systems?

Steel is a prevalent choice for various components in manual transmission systems due to its high strength and durability. Key properties include excellent tensile strength and resistance to wear, which are critical for handling the high torque and stress experienced during operation. However, steel can be prone to corrosion if not properly treated or coated, which may impact longevity.

Pros: Steel offers a high strength-to-weight ratio and is relatively cost-effective. It is also widely available and compatible with various manufacturing processes.

Cons: The primary drawback is its susceptibility to rust and corrosion, particularly in humid or saline environments. Additionally, the weight of steel can affect the overall vehicle performance.

Impact on Application: Steel’s compatibility with high-temperature and high-pressure applications makes it suitable for manual transmissions. However, corrosion resistance treatments may be necessary for trucks operating in harsh environments.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local corrosion resistance standards. Familiarity with ASTM and DIN standards can aid in selecting the right steel grades.

What Role Does Aluminum Play in Manual Transmission Construction?

Aluminum is increasingly used in manual transmission systems due to its lightweight properties, which enhance fuel efficiency and vehicle performance. Key properties include good corrosion resistance and thermal conductivity, making it suitable for heat dissipation.

Pros: Aluminum is lightweight and offers excellent corrosion resistance. It also allows for more complex shapes during manufacturing, which can be advantageous for design flexibility.

Cons: The main limitation of aluminum is its lower tensile strength compared to steel, which may require thicker components to achieve the same performance, potentially offsetting weight savings.

Impact on Application: Aluminum is particularly effective in applications where weight reduction is crucial, such as in fuel-efficient cargo trucks. However, its lower strength may limit its use in high-stress components.

Considerations for International Buyers: Buyers should look for compliance with international aluminum standards, such as JIS and ASTM, to ensure quality and performance.

How Does Composite Material Enhance Transmission Performance?

Composite materials, often a blend of plastics and fibers, are becoming more common in manual transmission components. They offer unique properties, including lightweight characteristics and resistance to corrosion.

Pros: Composites are highly customizable and can be engineered for specific performance characteristics. They are also resistant to many chemicals, which is beneficial in environments where exposure to various fluids is common.

Cons: The primary disadvantage is the higher manufacturing complexity and cost associated with composite materials, which may deter budget-conscious buyers.

Impact on Application: Composites can significantly reduce weight and improve fuel efficiency, making them suitable for modern cargo trucks. However, their performance under extreme temperatures may be a concern.

Considerations for International Buyers: Understanding local regulations regarding composite materials is crucial, especially in regions with stringent automotive standards.

What Advantages Does Cast Iron Offer in Manual Transmissions?

Cast iron is traditionally used in manual transmission cases and housings due to its excellent wear resistance and ability to dampen vibrations. Key properties include high compressive strength and good thermal stability.

Pros: Cast iron is durable and provides excellent performance in high-stress applications. It is also relatively inexpensive and easy to cast into complex shapes.

Cons: The main drawback is its weight, which can negatively impact fuel efficiency. Additionally, cast iron is prone to cracking under extreme stress if not manufactured correctly.

Impact on Application: Cast iron’s strength and durability make it suitable for housing and structural components in manual transmissions, where it can withstand significant mechanical loads.

Considerations for International Buyers: Compliance with international standards for cast iron, such as ASTM, is essential for ensuring quality and performance in diverse operating environments.

Summary Table of Material Selection for Manual Transmission Cargo Trucks

| Material | Typical Use Case for manual Transmission Cargo Truck | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Gears, shafts, and structural components | High strength and cost-effective | Susceptible to corrosion | Medium |

| Aluminum | Housing and lightweight components | Lightweight and corrosion-resistant | Lower tensile strength compared to steel | Medium |

| Composite | Specialized components (e.g., housings) | Customizable and resistant to chemicals | Higher manufacturing complexity and cost | High |

| Cast Iron | Transmission cases and housings | Durable and excellent wear resistance | Heavy and prone to cracking | Low |

This guide provides a comprehensive overview of material options for manual transmission cargo trucks, equipping international B2B buyers with the insights needed to make informed decisions based on their specific operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for manual Transmission Cargo Truck

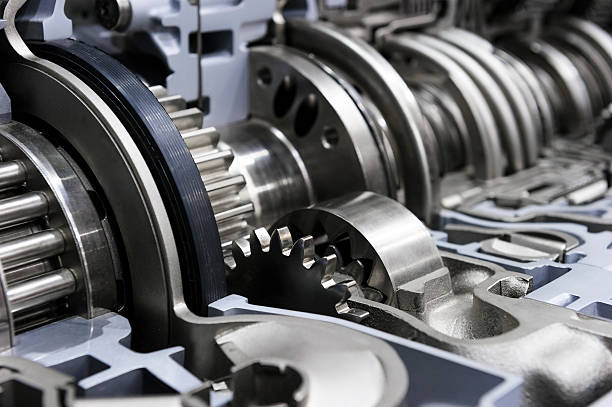

What Are the Main Stages in the Manufacturing Process of Manual Transmission Cargo Trucks?

The manufacturing process of manual transmission cargo trucks is a complex sequence of stages designed to ensure both functionality and durability. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality materials, such as steel for the chassis and aluminum for the transmission casing. Suppliers must adhere to international standards to ensure that materials meet specific strength and durability requirements. This stage may involve processes like cutting, machining, and treatment to enhance material properties.

-

Forming: In this stage, the prepared materials are shaped into components using various techniques. Common methods include stamping, forging, and casting. For instance, the transmission housing may be cast using aluminum alloy, which offers a balance of weight and strength. Precision in forming is crucial, as any defects can lead to functional failures in the transmission system.

-

Assembly: The assembly stage is where the individual components come together to form the manual transmission system. Skilled technicians follow stringent assembly protocols to ensure that every part fits perfectly. This process often involves the use of specialized tools and jigs to maintain alignment and prevent misassembly. Moreover, the integration of the transmission with the truck’s drivetrain requires careful calibration to ensure optimal performance.

-

Finishing: The finishing stage includes processes like painting, coating, and surface treatment to enhance durability and aesthetics. Protective coatings may be applied to the transmission to resist corrosion, which is particularly important for trucks operating in harsh environments. Quality checks are conducted throughout this stage to ensure that the final product meets the required specifications.

Which Quality Assurance Standards Are Relevant for Manual Transmission Cargo Trucks?

Quality assurance is paramount in the manufacturing of manual transmission cargo trucks, especially for international B2B buyers who require reliability and compliance with various standards. Relevant standards include:

-

ISO 9001: This international standard specifies requirements for a quality management system (QMS) and is applicable to any organization, regardless of its size or industry. Manufacturers of manual transmission cargo trucks must demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

-

CE Marking: For products sold within the European Economic Area, CE marking signifies compliance with safety, health, and environmental protection standards. This is particularly relevant for B2B buyers in Europe, as it ensures that the trucks meet EU regulations.

-

API Standards: For trucks that may be used in oil and gas industries, adherence to American Petroleum Institute (API) standards may be necessary. These standards cover various aspects, including the design and manufacturing of transmission components that must withstand extreme conditions.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that each component meets the required standards before proceeding to the next stage. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint involves the inspection of raw materials and components upon arrival at the manufacturing facility. Suppliers must provide certification that materials meet specified standards, and any substandard materials are rejected.

-

In-Process Quality Control (IPQC): Throughout the forming and assembly stages, in-process inspections are performed. These inspections help identify any defects early in the manufacturing process, allowing for immediate corrective actions. Techniques such as dimensional checks, visual inspections, and functional tests are employed.

-

Final Quality Control (FQC): At the end of the manufacturing process, final inspections are conducted to ensure that the entire truck, including the manual transmission, meets all specifications and quality standards. This may involve performance testing, where the transmission is evaluated under load conditions to ensure it operates smoothly and reliably.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential to ensure product reliability. Here are several actionable steps:

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control systems. Audits should assess compliance with international standards and the effectiveness of their QMS.

-

Requesting Quality Reports: Buyers can request detailed quality reports that outline the results of IQC, IPQC, and FQC inspections. These reports should include data on defect rates, corrective actions taken, and compliance with applicable standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control measures. These agencies can conduct assessments at various stages of the manufacturing process, ensuring adherence to both local and international standards.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing manual transmission cargo trucks, international B2B buyers should be aware of several nuances related to quality control:

-

Cultural Differences: Different regions may have varying approaches to quality management. Buyers should consider these cultural factors when evaluating suppliers to ensure compatibility in quality expectations.

-

Regulatory Compliance: Different markets have distinct regulatory requirements. Buyers must ensure that the supplier’s products comply with the regulations of the destination country, which may require additional testing or certifications.

-

Supply Chain Transparency: Transparency in the supply chain is vital for international buyers. Understanding where materials are sourced and how they are processed can impact the overall quality of the final product. Buyers should seek suppliers who are willing to share this information.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing manual transmission cargo trucks, ensuring they receive reliable and compliant products tailored to their specific operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘manual Transmission Cargo Truck’

In the competitive landscape of cargo transportation, selecting the right manual transmission cargo truck is crucial for operational efficiency and cost-effectiveness. This guide provides a step-by-step checklist to help international B2B buyers navigate the sourcing process, ensuring they make informed decisions tailored to their specific needs.

Step 1: Define Your Technical Specifications

Begin by clearly outlining your technical requirements for the manual transmission cargo truck. Consider factors such as load capacity, engine power, fuel type, and transmission type. This foundational step is essential as it ensures that the trucks you evaluate align with your operational needs and comply with local regulations.

- Load Capacity: Determine the maximum weight you need to transport.

- Engine Power: Assess the horsepower and torque required for your routes.

Step 2: Research Market Availability

Investigate the current market to identify available manual transmission cargo truck models. With a shrinking selection in the industry, knowing which manufacturers still offer manual options will save you time and effort.

- Manufacturer Options: Focus on brands known for robust manual transmission offerings, such as Ford, Jeep, and Toyota.

- Regional Availability: Ensure that the selected models are available in your target markets, such as Africa, South America, the Middle East, and Europe.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, conduct thorough evaluations of potential suppliers. This step is vital to ensuring reliability and quality in your sourcing decisions.

- Request Documentation: Ask for company profiles, product specifications, and certifications.

- Check References: Seek testimonials from other buyers in similar industries to assess supplier performance.

Step 4: Assess Total Cost of Ownership (TCO)

Calculate the total cost of ownership to understand the long-term financial implications of your purchase. This includes not just the initial price of the truck but also ongoing costs such as maintenance, fuel, and insurance.

- Maintenance Costs: Investigate the reliability of the manual transmission system and its associated upkeep.

- Fuel Efficiency: Consider how the truck’s fuel consumption will impact your operational budget over time.

Step 5: Verify Compliance with Local Regulations

Ensure that the manual transmission cargo truck complies with local regulations in your target markets. This is crucial to avoid legal issues and ensure smooth operations.

- Emissions Standards: Check if the vehicle meets the environmental regulations specific to your region.

- Safety Certifications: Confirm that the trucks have the necessary safety ratings and certifications.

Step 6: Conduct On-Site Inspections

If possible, conduct on-site inspections of the trucks before finalizing your purchase. This step allows you to assess the quality and condition of the vehicles firsthand.

- Test Drive: Experience the manual transmission’s performance and handling capabilities.

- Inspect Build Quality: Look for signs of durability and craftsmanship that align with your operational demands.

Step 7: Negotiate Terms and Finalize the Purchase

Once you’ve selected a supplier and model, negotiate the purchase terms to secure the best deal. This final step is important to ensure you get favorable pricing and support.

- Warranty and Support: Discuss warranty coverage and after-sales support options.

- Payment Terms: Clarify payment schedules and financing options to ease your procurement process.

By following this checklist, B2B buyers can confidently navigate the sourcing process for manual transmission cargo trucks, ensuring they select the right vehicle to meet their business needs effectively.

Comprehensive Cost and Pricing Analysis for manual Transmission Cargo Truck Sourcing

What Are the Key Cost Components in Manual Transmission Cargo Truck Sourcing?

When sourcing manual transmission cargo trucks, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality steel, aluminum for lightweight designs, and durable plastics for interior components can enhance performance but may increase costs.

-

Labor: Labor costs vary by region, influenced by local wage standards and the skill level required for assembly. Countries with a skilled labor force may offer competitive prices but require higher wages.

-

Manufacturing Overhead: This encompasses costs related to factory operations, utilities, and administrative expenses. Efficient production processes can minimize overhead, affecting the final price.

-

Tooling: The cost of specialized tools and machinery used in the production process is a crucial factor. Custom tooling may be necessary for specific configurations, which can increase initial investment.

-

Quality Control (QC): Implementing stringent QC measures ensures the trucks meet safety and performance standards. While this may increase costs, it is essential for maintaining product reliability and buyer satisfaction.

-

Logistics: Transportation costs for delivering trucks from the manufacturer to the buyer can vary widely based on distance, shipping methods, and fuel prices. Buyers should factor in these costs when evaluating overall expenditure.

-

Margin: Suppliers typically apply a margin to cover risks and profit. Understanding the supplier’s margin expectations can aid in negotiations.

How Do Price Influencers Affect Manual Transmission Cargo Truck Costs?

Several factors can influence the pricing of manual transmission cargo trucks:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounts, as manufacturers benefit from economies of scale. Buyers should consider combining orders to meet MOQ requirements for better pricing.

-

Specifications and Customization: Custom features or specifications can drive up costs. Buyers need to balance their requirements with budget constraints, as bespoke modifications may lead to longer lead times and higher prices.

-

Materials and Quality Certifications: Trucks made with premium materials or those that meet specific quality certifications can command higher prices. Buyers should assess whether the investment aligns with their operational needs.

-

Supplier Factors: The reputation and reliability of suppliers play a crucial role in pricing. Established suppliers with a track record of quality and service may charge higher prices but provide greater assurance.

-

Incoterms: Understanding the terms of shipping and delivery is vital. Incoterms dictate who bears the shipping costs and risks, which can significantly affect the total landed cost of the trucks.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Manual Transmission Cargo Trucks?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, employing effective strategies can enhance cost-efficiency:

-

Negotiation: Leverage volume purchases and long-term partnerships to negotiate better pricing and terms. Building a relationship with suppliers can lead to improved pricing over time.

-

Total Cost of Ownership (TCO): Assess the TCO, which includes purchase price, operating costs, maintenance, and resale value. A slightly higher initial investment in quality can lead to lower operational costs and better longevity.

-

Pricing Nuances for International Buyers: Currency fluctuations, tariffs, and trade agreements can influence prices. Buyers should stay informed about geopolitical factors that may affect costs.

-

Research and Benchmarking: Conduct thorough market research to understand average pricing and specifications. Benchmarking against competitors can provide leverage during negotiations.

Disclaimer on Indicative Prices

Prices for manual transmission cargo trucks can vary significantly based on the aforementioned factors. The indicative prices may not reflect actual market conditions or specific supplier quotes. Buyers should conduct due diligence and obtain formal quotes to ensure accurate budgeting.

Alternatives Analysis: Comparing manual Transmission Cargo Truck With Other Solutions

Understanding Alternatives in Cargo Truck Solutions

In the evolving landscape of cargo transportation, the choice of vehicle significantly impacts operational efficiency, cost management, and overall productivity. While manual transmission cargo trucks have their unique advantages, it is essential for B2B buyers to explore alternative solutions that may better align with their business needs. This analysis will compare manual transmission cargo trucks with automatic transmission cargo trucks and electric cargo vehicles, highlighting key aspects that influence decision-making.

Comparison Table

| Comparison Aspect | Manual Transmission Cargo Truck | Automatic Transmission Cargo Truck | Electric Cargo Vehicle |

|---|---|---|---|

| Performance | Offers direct control, ideal for rugged terrain and heavy loads | Generally smoother operation, may lag in performance under heavy loads | Instant torque, excellent for urban deliveries |

| Cost | Typically lower purchase and repair costs | Higher initial investment, but lower operational costs due to fuel efficiency | High upfront costs, but potential savings on fuel and maintenance |

| Ease of Implementation | Requires skilled drivers familiar with manual operation | Easier to operate, less training required for drivers | Infrastructure investment needed for charging stations |

| Maintenance | More frequent maintenance due to wear on clutch systems | Generally lower maintenance needs, fewer moving parts | Minimal maintenance, but battery replacement can be costly |

| Best Use Case | Off-road applications, remote areas, and heavy-duty tasks | Urban logistics, highway driving, and general freight | Urban deliveries, eco-conscious companies, short-haul routes |

Detailed Breakdown of Alternatives

Automatic Transmission Cargo Truck

Automatic transmission trucks are designed for ease of use, making them a popular choice for logistics companies. The primary advantage is that they require less driver training and can lead to increased driver comfort and productivity. However, they may be less efficient in terms of power delivery when carrying heavy loads, which could impact performance in specific scenarios. Additionally, while they typically incur higher upfront costs, their fuel efficiency can lead to savings over time, especially in urban settings.

Electric Cargo Vehicle

Electric cargo vehicles represent a growing trend in the logistics sector, particularly among businesses focused on sustainability. These vehicles offer instant torque, making them excellent for stop-and-go urban environments. They also benefit from lower operational costs due to reduced fuel expenses and minimal maintenance needs. However, the high initial investment and the necessity for charging infrastructure can be significant barriers for some businesses. Moreover, the range limitations of electric vehicles may restrict their use for long-distance transport.

Conclusion: Choosing the Right Cargo Truck Solution

When selecting the appropriate cargo truck solution, B2B buyers should carefully evaluate their specific operational requirements, budget constraints, and long-term goals. Manual transmission cargo trucks may excel in performance and cost-effectiveness in rugged environments, while automatic transmission trucks provide ease of use and comfort for diverse applications. Electric cargo vehicles offer a sustainable alternative that can significantly reduce operational costs but require careful consideration of initial investments and infrastructure needs. By aligning vehicle capabilities with business objectives, companies can enhance efficiency and drive growth in their logistics operations.

Essential Technical Properties and Trade Terminology for manual Transmission Cargo Truck

What Are the Key Technical Properties of Manual Transmission Cargo Trucks?

Understanding the essential technical specifications of manual transmission cargo trucks is crucial for B2B buyers. These specifications not only affect the performance and reliability of the vehicles but also influence operational costs and maintenance schedules.

1. Transmission Type

Manual transmission trucks typically feature a 6-speed or 7-speed gearbox. The number of gears affects the vehicle’s torque output and fuel efficiency. A higher gear count generally allows for smoother acceleration and improved fuel economy, which can lead to lower operational costs over time.

2. Gross Vehicle Weight Rating (GVWR)

GVWR is a critical specification that defines the maximum weight a truck can safely carry, including its own weight. For cargo trucks, this rating influences the choice of chassis and suspension systems, impacting durability and load capacity. Buyers must ensure that the GVWR aligns with their logistical needs to prevent overloading and potential legal issues.

3. Engine Power and Torque

The engine’s horsepower (HP) and torque ratings are vital for determining a truck’s hauling capabilities. A higher torque rating is particularly important for manual transmission vehicles as it directly influences the truck’s ability to move heavy loads, especially at lower speeds. Buyers should evaluate these ratings based on the types of cargo they plan to transport.

4. Drivetrain Configuration

Manual transmission cargo trucks can have various drivetrain configurations such as two-wheel drive (2WD) or four-wheel drive (4WD). The choice between these configurations will affect the truck’s performance in different terrains, particularly in regions with challenging road conditions, such as parts of Africa and South America.

5. Material Composition

The materials used in the construction of the truck’s body and chassis, such as high-strength steel or aluminum alloys, play a significant role in durability and weight. A lighter truck can improve fuel efficiency, while robust materials enhance longevity and resistance to wear and tear, essential for long-haul operations.

6. Fuel Type

Most manual transmission cargo trucks run on diesel due to its efficiency and torque characteristics. However, understanding the fuel type is vital for operational costs and availability, particularly in regions where fuel supply can be inconsistent.

What Are Common Trade Terms in the Manual Transmission Cargo Truck Industry?

Familiarity with industry terminology can streamline procurement processes and negotiations for B2B buyers, ensuring better communication with suppliers and manufacturers.

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. When purchasing trucks, understanding whether parts are OEM can assure buyers of quality and compatibility, which is crucial for maintenance and repairs.

2. MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of goods that a supplier is willing to sell. Knowing the MOQ can help buyers manage inventory levels effectively, especially when dealing with parts or accessories for manual transmission trucks.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where buyers invite suppliers to submit price quotes for specific products or services. Utilizing RFQs can help buyers compare offers from multiple suppliers, ensuring competitive pricing and better decision-making.

4. Incoterms (International Commercial Terms)

These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) relating to international commercial law. Understanding Incoterms is crucial for B2B transactions, as they clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to the delivery of goods. In the context of manual transmission cargo trucks, shorter lead times can be a competitive advantage, enabling businesses to respond quickly to market demands.

6. Aftermarket

The aftermarket refers to the market for parts and accessories that are not provided by the original manufacturer. Understanding the availability and quality of aftermarket options can enhance maintenance strategies and reduce downtime for fleet operations.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions, optimizing their investments in manual transmission cargo trucks for various operational needs.

Navigating Market Dynamics and Sourcing Trends in the manual Transmission Cargo Truck Sector

What Are the Key Market Trends Influencing the Manual Transmission Cargo Truck Sector?

The manual transmission cargo truck market is experiencing notable shifts driven by evolving consumer preferences and technological advancements. While automatic transmissions have gained popularity due to ease of use, manual transmissions still appeal to specific segments, particularly in emerging markets like Africa and South America, where affordability and durability remain paramount. The demand for manual transmission trucks is bolstered by their perceived reliability and lower maintenance costs, making them suitable for rugged terrains often encountered in these regions.

Additionally, the rise of digital sourcing platforms is changing how international buyers procure manual transmission cargo trucks. B2B buyers can now leverage online marketplaces to access a wider range of options, compare specifications, and evaluate pricing models. This shift towards e-commerce is particularly significant for buyers in developing regions, where traditional dealership access may be limited. Furthermore, the integration of telematics and fleet management technologies is enhancing operational efficiency, allowing companies to monitor vehicle performance and optimize their logistics.

How Are Sustainability and Ethical Sourcing Shaping the Manual Transmission Cargo Truck Market?

Sustainability has become a critical focus in the manual transmission cargo truck sector, driven by increasing regulatory pressures and consumer demand for environmentally responsible practices. Manufacturers are now prioritizing sustainable materials and production methods to minimize the environmental impact of their vehicles. This includes using recycled metals, eco-friendly paints, and energy-efficient manufacturing processes.

Moreover, ethical sourcing has gained prominence as buyers become more conscious of their supply chains. Establishing partnerships with suppliers who adhere to ethical labor practices and environmental standards is essential for B2B buyers seeking to enhance their corporate social responsibility (CSR) profiles. Certifications such as ISO 14001 for environmental management and adherence to the Global Reporting Initiative (GRI) can serve as benchmarks for evaluating suppliers. By prioritizing sustainability and ethical sourcing, companies not only meet regulatory requirements but also appeal to an increasingly environmentally aware customer base.

What Is the Historical Context of Manual Transmission in Cargo Trucks?

The manual transmission has a rich history in the cargo truck sector, dating back to the early 20th century when trucks first began to be used for commercial purposes. Early models featured rudimentary gear systems that required significant driver skill and effort. Over the decades, advancements in technology led to improvements in gear design and shift mechanisms, enhancing the driving experience.

However, the introduction of automatic transmissions in the latter half of the century changed the landscape dramatically. Automatics offered convenience and ease of operation, leading to a decline in manual transmission popularity. Despite this trend, manual transmissions have remained a staple in many commercial vehicles, particularly in markets where cost efficiency and control are prioritized. The enduring appeal of manual transmission trucks lies in their simplicity and lower upfront costs, making them an attractive option for businesses operating in challenging environments.

In summary, the manual transmission cargo truck sector is navigating a complex landscape characterized by market dynamics, sustainability imperatives, and historical evolution. For B2B buyers, understanding these factors is crucial for making informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of manual Transmission Cargo Truck

-

1. How do I choose the right manual transmission cargo truck for my business needs?

When selecting a manual transmission cargo truck, consider factors such as payload capacity, engine type, fuel efficiency, and the terrain where the truck will operate. Evaluate your specific business requirements, including delivery routes and the type of cargo you will transport. Additionally, inspect the available trim levels that offer manual transmission options, as they may differ significantly in features and performance. It’s also advisable to conduct a cost-benefit analysis to ensure that the chosen truck aligns with your budget and operational needs. -

2. What advantages do manual transmission cargo trucks offer compared to automatic ones?

Manual transmission cargo trucks often provide better control over gear selection, which can enhance performance in rugged terrains or when carrying heavy loads. They typically have lower purchase and maintenance costs, offering a more budget-friendly option for businesses. Additionally, manual trucks may deliver superior fuel efficiency, especially in hilly or off-road conditions, making them a viable choice for businesses that prioritize operational cost savings. Furthermore, many drivers prefer the tactile engagement of manual shifting, which can lead to improved driving experience. -

3. What are the common customization options available for manual transmission cargo trucks?

Customization options for manual transmission cargo trucks can include modifications to the cargo area, such as shelving, partitions, and loading ramps tailored to your specific business needs. You may also consider engine upgrades, enhanced suspension systems, and specialized tires for improved performance. Additionally, features like GPS tracking, safety enhancements, and comfort upgrades can be integrated based on your operational requirements. Collaborating with manufacturers or dealers who offer customization services can help you design a truck that fits your unique business model. -

4. What is the typical minimum order quantity (MOQ) for manual transmission cargo trucks in international trade?

Minimum order quantities can vary significantly based on the manufacturer and your location. Generally, for manual transmission cargo trucks, MOQs may range from one unit for smaller dealers to several units for larger manufacturers. It’s essential to communicate your specific needs with suppliers to negotiate favorable terms. In many cases, suppliers are willing to accommodate smaller orders, especially if you establish a long-term relationship or demonstrate potential for future purchases. -

5. How can I ensure the quality of manual transmission cargo trucks from international suppliers?

To ensure quality, conduct thorough research on potential suppliers, focusing on their reputation, production standards, and certifications. Request samples or visit their manufacturing facilities if possible. It’s beneficial to verify customer reviews and seek references from other businesses that have purchased from them. Additionally, consider arranging for third-party inspections or audits to assess quality control processes before finalizing your order. Establishing clear quality assurance protocols in your purchase agreement can further safeguard your investment. -

6. What payment terms should I negotiate when sourcing manual transmission cargo trucks?

When negotiating payment terms, consider options like letters of credit, bank transfers, or installment payments. Aim for terms that provide financial security while ensuring timely delivery. Common arrangements include a deposit upfront, with the balance due upon delivery or after a specified inspection period. It’s crucial to discuss these terms openly with your supplier to find a mutually beneficial agreement. Always document payment terms in a formal contract to avoid any misunderstandings. -

7. What logistics considerations should I be aware of when importing manual transmission cargo trucks?

Logistics considerations include shipping methods, customs regulations, and import duties specific to your country. Determine whether you will use container shipping or roll-on/roll-off services based on cost and convenience. Familiarize yourself with the documentation required for customs clearance, including bills of lading and import permits. Partnering with a reliable logistics provider can streamline the process, helping you navigate the complexities of international shipping and ensuring your trucks arrive safely and on time. -

8. How can I effectively vet suppliers of manual transmission cargo trucks?

To effectively vet suppliers, start by researching their industry experience and reputation. Look for certifications and memberships in relevant trade organizations as indicators of credibility. Request information about their production capabilities, quality control processes, and after-sales support. Engaging in direct communication can also provide insights into their responsiveness and professionalism. Additionally, consider visiting their facility or seeking feedback from past clients to assess their reliability and commitment to customer satisfaction.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Manual Transmission Cargo Truck Manufacturers & Suppliers List

1. Reddit – Automated Manual Transmissions in Semi Trucks

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Automated Manual Transmissions in Semi Trucks, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Jeep – 2024 Gladiator

Domain: carbuzz.com

Registered: 2003 (22 years)

Introduction: 1. 2024 Jeep Gladiator: Midsize pickup, off-road focused, automatic transmission from 2025, features include off-road tires, front and rear locking differentials, removable doors and roof, wireless smartphone mirroring, adventure guides from Trails app.

2. 2019 Nissan Frontier: Previous generation, available with manual transmission until 2019, options for four-cylinder with five-speed manual or …

3. Eaton Cummins – Automated Manual Transmissions

Domain: eatoncummins.com

Registered: 2017 (8 years)

Introduction: Automated Manual Transmissions (AMTs) are a standard feature in long-haul and over-the-road trucks, providing a hybrid approach that combines a manual gearbox with electronic control for clutch engagement and gear changes. Key products include the Endurant HD series and Endurant XD series. AMTs improve fuel efficiency, reduce greenhouse gas emissions, and ensure consistent performance across drive…

4. Freightliner – Box Truck Listings

Domain: commercialtrucktrader.com

Registered: 2004 (21 years)

Introduction: Freightliner Box Truck – Straight Truck for sale. Key models include: BUSINESS CLASS M2 106, FL70, FL60. Listings include various years and conditions with prices ranging from $5,900 to $31,500. Notable features include: 6-speed manual transmission, GVW class 6 and 7, engines from Cummins and Caterpillar, liftgates, and varying mileage. Locations include MI, TX, NC, CO, and more.

5. Volvo – VNL 760

Domain: munichtruckrepair.com

Registered: 2017 (8 years)

Introduction: The Ultimate Guide to Choosing Trucks With Manual Transmission: Pros, Cons, and Top Models. Key models highlighted include: 1. Volvo VNL Series – Known for exceptional build quality and advanced features, with manual transmission variants like the VNL 760. 2. Freightliner Cascadia – An adaptable workhorse offering reliability and innovative technology with manual transmission options. 3. Kenworth …

6. Freightliner – Commercial Trucks

Domain: freightliner.com

Registered: 1997 (28 years)

Introduction: Freightliner offers a range of commercial trucks designed for various applications, including On-Highway, Medium Duty, Severe Duty, Electric, and Natural Gas models. Key features include high uptime, reliability, fuel efficiency, and low cost of ownership. The trucks are suitable for both fleet operations and owner-operators, with options for customization to enhance comfort and performance. Addit…

Strategic Sourcing Conclusion and Outlook for manual Transmission Cargo Truck

Why is Strategic Sourcing Essential for Manual Transmission Cargo Trucks?

In the evolving landscape of manual transmission cargo trucks, strategic sourcing remains a pivotal approach for international B2B buyers. As the availability of manual options dwindles, understanding market dynamics and supplier capabilities becomes essential. Buyers should prioritize partnerships with manufacturers who not only offer a range of models—such as the Ford Bronco, Jeep Wrangler, and Toyota Tacoma—but also demonstrate reliability and adaptability to regional market demands.

What Key Insights Should B2B Buyers Consider?

The trend towards automatics in the industry signals a potential scarcity of manual transmission options. Therefore, it’s crucial for buyers in Africa, South America, the Middle East, and Europe to act swiftly to secure inventory that meets their operational needs. The benefits of manual transmissions, including lower maintenance costs and enhanced driver control, should be emphasized when negotiating with suppliers.

How Can You Position Your Business for Future Success?

Looking ahead, international buyers must leverage their purchasing power to foster long-term relationships with trusted suppliers. This proactive approach not only enhances supply chain stability but also positions businesses to adapt to emerging trends. Engage with manufacturers now to explore customized solutions that align with your specific operational requirements. Embrace the opportunity to lead in this niche market, ensuring your fleet remains competitive and efficient.