Introduction: Navigating the Global Market for independent fourwheel electric vehicle chassis

Navigating the complexities of sourcing independent four-wheel electric vehicle chassis can be a formidable challenge for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. As the demand for electric vehicles surges, companies face increasing pressure to identify reliable suppliers who can deliver innovative, customizable chassis solutions that meet specific operational requirements. This guide aims to provide a comprehensive overview of the independent four-wheel electric vehicle chassis market, exploring various types, applications, and key features that differentiate suppliers.

From understanding the modularity and scalability of chassis designs to assessing cost implications and supplier vetting processes, this resource equips buyers with the insights needed to make informed purchasing decisions. With a focus on performance, safety, and operational efficiency, the guide also addresses critical aspects such as maintenance and technological advancements in chassis control systems. By leveraging this information, B2B buyers can enhance their procurement strategies, ensuring that they not only meet current market demands but also position themselves for future growth in the electric vehicle sector.

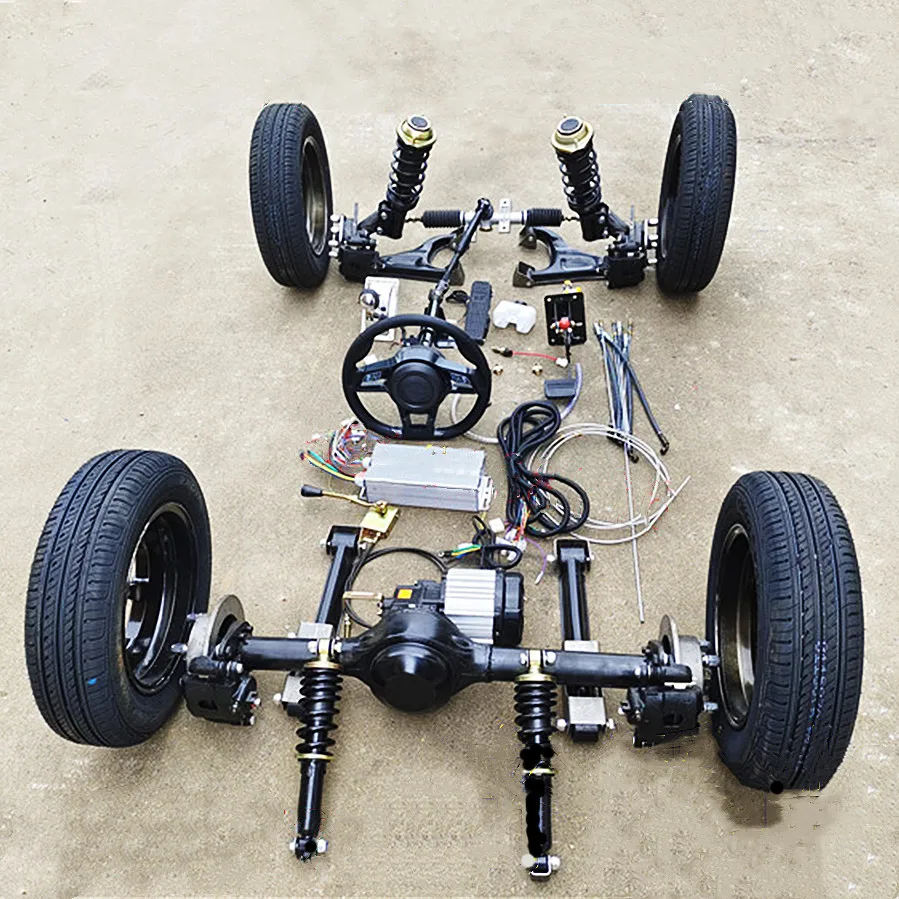

Understanding independent fourwheel electric vehicle chassis Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Modular Electric Vehicle Platform | Fully modular design, customizable for mission-specific applications, high load capacity | Commercial fleets, logistics | Pros: Versatile, reduced TCO, design freedom. Cons: Complexity in integration. |

| X-by-Wire Chassis | Independent control of steering, braking, and drive; eliminates mechanical components | Autonomous vehicles, specialized transport | Pros: Enhanced maneuverability, safety features. Cons: Higher initial investment. |

| Integrated Chassis Control | Hierarchical control structure with Model Predictive Control for optimized performance | Performance vehicles, high-load applications | Pros: Maximizes tire adhesion, improved stability. Cons: Requires advanced software expertise. |

| Four-Wheel Independent Steering | Each wheel can steer independently, improving handling in tight spaces | Urban delivery, emergency services | Pros: Superior agility, enhanced safety. Cons: Potentially higher maintenance costs. |

| Battery-Electric Vehicle Chassis | Designed to accommodate various battery types, optimized for energy efficiency | Public transport, fleet vehicles | Pros: Flexibility in battery choice, lower emissions. Cons: Limited range in some configurations. |

What are the key characteristics of Modular Electric Vehicle Platforms for B2B buyers?

Modular Electric Vehicle Platforms, such as those offered by REE Automotive, provide a fully customizable architecture that allows businesses to tailor vehicles to specific operational needs. This flexibility is particularly valuable for commercial fleets in sectors like logistics, where optimizing load capacity and reducing total cost of ownership (TCO) are crucial. Buyers should consider the initial complexity of integration and potential training needs for staff, as the modular design may require specialized knowledge for effective implementation.

How does X-by-Wire technology enhance vehicle performance for businesses?

X-by-Wire technology offers independent control over steering, braking, and driving functions, providing significant advantages in maneuverability and safety. This system is ideal for autonomous vehicles and specialized transport applications, allowing for enhanced performance in challenging environments. B2B buyers should weigh the initial investment against long-term benefits, such as improved safety and reduced maintenance needs, which can lead to lower operational costs over time.

Why is Integrated Chassis Control important for high-performance applications?

Integrated Chassis Control systems utilize advanced algorithms to optimize vehicle performance by managing the distribution of control forces among the wheels. This technology is particularly beneficial for performance vehicles and applications requiring high load capacity. Businesses should consider the need for sophisticated software and technical expertise for implementation, as these systems can significantly enhance stability and handling, thus improving overall operational efficiency.

What advantages do Four-Wheel Independent Steering systems offer?

Four-Wheel Independent Steering systems allow each wheel to steer independently, providing exceptional agility and handling in tight urban environments. This feature is especially useful for applications like urban delivery and emergency services, where quick maneuverability is essential. B2B buyers should evaluate the potential for increased maintenance costs due to the complexity of the system against the benefits of improved safety and operational efficiency.

How do Battery-Electric Vehicle Chassis impact sustainability in fleet operations?

Battery-Electric Vehicle Chassis are designed to accommodate a variety of battery chemistries, enhancing energy efficiency and reducing emissions. These systems are particularly suited for public transport and fleet vehicles, where sustainability goals are increasingly prioritized. Buyers should consider the flexibility in battery sourcing and the potential for reduced operational costs, but also be mindful of range limitations that may affect vehicle deployment strategies.

Key Industrial Applications of independent fourwheel electric vehicle chassis

| Industry/Sector | Specific Application of Independent Four-Wheel Electric Vehicle Chassis | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Transportation | Last-Mile Delivery Vehicles | Enhanced maneuverability in urban settings, reduced operational costs | Compatibility with local infrastructure, battery range, TCO |

| Agriculture | Electric Utility Vehicles for Farming | Reduced emissions, lower running costs, and improved efficiency | Terrain adaptability, load capacity, service support |

| Mining and Heavy Industry | Electric Haul Trucks | Increased payload capacity, lower maintenance costs | Robustness for harsh environments, battery management systems |

| Construction | Modular Electric Cranes | Versatile designs for various construction tasks, reduced noise | Customization options, weight distribution, power requirements |

| Public Transport | Electric Buses | Lower emissions, improved passenger comfort, and operational efficiency | Compliance with local regulations, charging infrastructure |

How Are Independent Four-Wheel Electric Vehicle Chassis Utilized in Logistics and Transportation?

In logistics and transportation, independent four-wheel electric vehicle chassis are increasingly used for last-mile delivery vehicles. These vehicles benefit from superior maneuverability and adaptability in congested urban environments, addressing the challenge of navigating narrow streets and tight corners. Businesses can expect reduced operational costs due to lower fuel consumption and maintenance needs. For international buyers, it’s crucial to consider the compatibility of these vehicles with local infrastructure and their battery range to meet delivery demands.

What Role Do Independent Four-Wheel Electric Vehicle Chassis Play in Agriculture?

In the agriculture sector, independent four-wheel electric vehicle chassis are utilized in electric utility vehicles designed for farming tasks. These vehicles provide a sustainable alternative to traditional fuel-powered machines, significantly reducing emissions and operational costs. Additionally, they enhance efficiency by allowing farmers to transport goods and equipment swiftly across various terrains. Buyers from regions like Africa and South America should focus on terrain adaptability and load capacity to ensure these vehicles can handle the specific challenges of their agricultural environments.

How Are Independent Four-Wheel Electric Vehicle Chassis Transforming Mining and Heavy Industry?

The mining and heavy industry sectors leverage independent four-wheel electric vehicle chassis for electric haul trucks. These trucks offer increased payload capacity and lower maintenance costs compared to conventional vehicles. Their design allows for better maneuverability in challenging terrains, enhancing productivity. When sourcing these vehicles, companies should prioritize robustness for harsh environments and effective battery management systems to ensure reliability and efficiency during operations.

What Benefits Do Independent Four-Wheel Electric Vehicle Chassis Provide in Construction?

In the construction industry, modular electric cranes powered by independent four-wheel electric vehicle chassis offer versatile designs tailored for various tasks. These cranes operate with reduced noise and emissions, aligning with growing environmental regulations. The adaptability of these chassis allows for customization based on specific construction needs. Buyers should consider customization options, weight distribution, and power requirements to ensure optimal performance on job sites.

How Are Independent Four-Wheel Electric Vehicle Chassis Enhancing Public Transport Solutions?

Independent four-wheel electric vehicle chassis are revolutionizing public transport by enabling the development of electric buses. These buses contribute to lower emissions and offer improved passenger comfort and operational efficiency. The shift towards electric public transport aligns with global sustainability goals, making it an attractive investment for municipalities. Key sourcing considerations include compliance with local regulations and the availability of charging infrastructure to support fleet operations effectively.

3 Common User Pain Points for ‘independent fourwheel electric vehicle chassis’ & Their Solutions

Scenario 1: Managing Diverse Fleet Needs with Modular Chassis Solutions

The Problem:

B2B buyers, especially fleet operators in regions such as Africa and South America, often face challenges when managing diverse vehicle needs. Different operational demands may require varying vehicle configurations, from delivery vans to specialized utility vehicles. Traditional vehicle platforms can be inflexible, leading to high costs and inefficiencies when trying to adapt a single vehicle type to multiple applications. This results in prolonged lead times for new vehicles, increased maintenance costs, and challenges in optimizing fleet performance.

The Solution:

To effectively manage diverse fleet needs, B2B buyers should consider sourcing independent four-wheel electric vehicle chassis that offer modularity and scalability, such as those provided by REE Automotive. These chassis are designed to accommodate mission-specific applications, allowing fleet operators to customize their vehicles according to precise requirements without the need for bespoke designs. When specifying these chassis, buyers should focus on platforms that allow for quick reconfiguration of components, including battery placement and control systems, to enhance operational flexibility. Engaging with manufacturers that provide robust modular systems can also facilitate quicker turnaround times for vehicle development, ensuring that the fleet can adapt to changing market demands swiftly.

Scenario 2: Reducing Total Cost of Ownership in Electric Vehicle Operations

The Problem:

B2B buyers often grapple with the total cost of ownership (TCO) associated with electric vehicle operations. The initial investment in electric vehicles may be high, and the ongoing costs related to maintenance, battery replacement, and energy consumption can further strain budgets. This is particularly concerning for businesses in the Middle East and Africa, where economic pressures necessitate careful financial planning. The challenge is to ensure that the operational efficiencies gained through electric vehicles translate into tangible cost savings.

The Solution:

To mitigate TCO, buyers should prioritize independent four-wheel electric vehicle chassis equipped with advanced technologies aimed at operational efficiency. For instance, selecting platforms that integrate smart monitoring systems and AI for preventative maintenance can significantly reduce unexpected downtime and associated repair costs. Buyers should also look for chassis that boast high energy efficiency features, such as minimized aerodynamic drag and optimized battery placement. When negotiating with suppliers, it is essential to request detailed analysis and case studies demonstrating how their chassis have led to lower TCO in similar operational contexts. By doing this, businesses can not only justify their investment but also project long-term savings effectively.

Scenario 3: Ensuring Safety and Compliance in Electric Vehicle Design

The Problem:

For international B2B buyers, particularly in Europe and emerging markets, ensuring safety and compliance with industry regulations is a critical concern when investing in electric vehicle chassis. The complexities of x-by-wire technology, which includes drive-by-wire and steer-by-wire systems, may raise apprehensions regarding reliability and regulatory compliance. Furthermore, as safety standards evolve, buyers must be confident that the chassis they choose will meet these requirements without incurring significant redesign costs or delays.

The Solution:

To address safety and compliance issues, buyers should seek independent four-wheel electric vehicle chassis that are designed with redundancies and robust safety features. Platforms that are compliant with international safety standards, such as ISO 26262 for functional safety, should be prioritized. Buyers should engage manufacturers who offer detailed documentation and certifications regarding their chassis’ safety features and compliance status. Additionally, it’s advisable to conduct thorough due diligence by consulting with industry experts or utilizing third-party assessments to validate safety claims. By investing in chassis with proven safety records and comprehensive support for compliance, buyers can confidently navigate regulatory landscapes while ensuring the safety of their fleets.

Strategic Material Selection Guide for independent fourwheel electric vehicle chassis

What Are the Key Materials for Independent Four-Wheel Electric Vehicle Chassis?

Selecting the right materials for independent four-wheel electric vehicle (EV) chassis is crucial for optimizing performance, durability, and cost-effectiveness. Below, we analyze four common materials used in the construction of these chassis, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Aluminum Influence Performance in EV Chassis?

Aluminum is a widely used material in the automotive industry due to its lightweight properties and corrosion resistance. It typically has a temperature rating of up to 600°C and exhibits good strength-to-weight ratios, making it suitable for electric vehicle applications where weight reduction is critical for enhancing range and efficiency.

Pros: Aluminum offers high durability and resistance to corrosion, which is essential for vehicles operating in diverse climates, particularly in regions like Africa and the Middle East. Its manufacturing processes, such as extrusion and casting, are well-established, allowing for complex shapes and designs.

Cons: The primary drawback of aluminum is its cost, which can be higher than traditional steel. Additionally, while it is strong, it may not be as impact-resistant as some other materials, making it less suitable for heavy-duty applications without proper design considerations.

Impact on Application: Aluminum’s lightweight nature supports energy efficiency, crucial for EVs. However, its lower tensile strength compared to steel may require design adjustments to ensure structural integrity.

What Role Does Steel Play in Chassis Construction?

Steel remains a popular choice for chassis construction due to its exceptional strength and durability. It can withstand high pressure and has a temperature rating of approximately 400°C. Different grades of steel, such as high-strength low-alloy (HSLA) steel, are often used to enhance performance.

Pros: Steel is cost-effective and readily available, making it a preferred choice for manufacturers. Its high tensile strength ensures excellent structural integrity, which is vital for safety and performance.

Cons: The downside of steel is its weight, which can negatively impact the overall efficiency of electric vehicles. Additionally, steel is prone to corrosion, necessitating protective coatings or treatments, especially in humid or coastal environments.

Impact on Application: Steel’s strength makes it suitable for heavy-duty applications, but its weight must be managed to avoid compromising the vehicle’s range.

How Does Composite Material Enhance Chassis Design?

Composite materials, such as carbon fiber reinforced polymer (CFRP), are increasingly being explored for EV chassis due to their superior strength-to-weight ratio and corrosion resistance. Composites can withstand temperatures up to 300°C and offer excellent fatigue resistance.

Pros: The primary advantage of composites is their lightweight nature, which significantly contributes to vehicle efficiency. They also provide excellent design flexibility, allowing for innovative shapes and structures.

Cons: The manufacturing complexity of composites can lead to higher costs and longer production times. Additionally, the recyclability of composite materials is a concern, as they are not as easily recyclable as metals.

Impact on Application: Composites can enhance performance and efficiency, but their cost and production challenges may limit their use in mass-market vehicles.

What Benefits Does Magnesium Offer for Chassis Applications?

Magnesium is another lightweight material that is gaining traction in the automotive sector. It has a temperature rating of around 400°C and is known for its excellent strength-to-weight ratio, making it suitable for applications where reducing weight is paramount.

Pros: Magnesium is one of the lightest structural metals available, which can lead to significant improvements in vehicle efficiency. It also has good machinability, allowing for intricate designs.

Cons: Magnesium is more susceptible to corrosion than aluminum and steel, requiring protective coatings. Additionally, its cost can be higher, and it may not be as widely available as other materials.

Impact on Application: While magnesium can enhance performance through weight reduction, its corrosion susceptibility must be managed, particularly in regions with high humidity or saline environments.

Summary Table of Material Selection for EV Chassis

| Material | Typical Use Case for independent fourwheel electric vehicle chassis | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight chassis components for improved range | Excellent corrosion resistance | Higher cost compared to steel | Medium |

| Steel | Structural frames and components for heavy-duty applications | High strength and durability | Heavier, prone to corrosion | Low |

| Composite | Advanced lightweight structures for performance-focused designs | Superior strength-to-weight ratio | High manufacturing complexity | High |

| Magnesium | Lightweight components for efficiency-focused applications | Extremely lightweight | Susceptible to corrosion | Medium |

This guide provides a comprehensive overview of material options for independent four-wheel electric vehicle chassis, assisting international B2B buyers in making informed decisions that align with their specific operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for independent fourwheel electric vehicle chassis

What Are the Key Stages in Manufacturing Independent Four-Wheel Electric Vehicle Chassis?

The manufacturing process of independent four-wheel electric vehicle (EV) chassis involves several critical stages, each essential for ensuring the final product meets performance and safety standards. Understanding these stages can help B2B buyers assess the capabilities of potential suppliers.

Material Preparation: How Are Chassis Materials Selected and Processed?

Material selection is the foundation of chassis manufacturing. Common materials include high-strength steel, aluminum, and composite materials that offer a balance between weight, strength, and cost. The preparation process typically involves cutting, shaping, and treating materials to enhance durability and corrosion resistance.

Techniques such as laser cutting and CNC machining are frequently employed to achieve precise dimensions. Additionally, advanced surface treatments, such as anodizing for aluminum components, improve resistance to wear and environmental factors. Buyers should inquire about the material certifications and sourcing practices to ensure compliance with international quality standards.

Forming: What Techniques Are Used to Shape the Chassis Components?

Forming processes play a pivotal role in creating the structural elements of the chassis. Techniques such as stamping, bending, and hydroforming are commonly used to create complex shapes and features. Hydroforming, in particular, allows for the production of lightweight components with high strength-to-weight ratios, critical for electric vehicles aiming for energy efficiency.

The forming stage also includes the integration of modular components like the REEcorner® system, which consolidates various functionalities into compact units. This modular approach not only streamlines production but also enhances flexibility in design. B2B buyers should look for suppliers that utilize state-of-the-art forming technologies, as these can significantly impact the performance and longevity of the chassis.

Assembly: How Are Chassis Components Brought Together?

The assembly stage involves the integration of various components, including the chassis frame, suspension systems, and electrical systems. Advanced techniques such as robotic welding and automated assembly lines are increasingly common, ensuring high precision and repeatability.

Quality control measures are integrated throughout the assembly process, with checkpoints to verify alignment, fit, and functionality. Given the complexity of independent four-wheel systems, it is crucial that assembly processes are adaptable to accommodate various configurations for different vehicle applications. Buyers should evaluate a supplier’s assembly capabilities, including their ability to customize solutions based on specific requirements.

Finishing: What Quality Enhancements Are Applied to the Final Product?

Finishing processes, including painting, coating, and surface treatments, are essential for protecting the chassis from environmental damage and enhancing aesthetics. Techniques such as powder coating provide a durable finish that resists chipping and corrosion, which is especially important for vehicles operating in diverse climates.

Moreover, finishing processes also involve the installation of sensors and electronic components essential for modern electric vehicles. This integration is vital for performance monitoring and predictive maintenance capabilities. Buyers should request information on the finishing techniques employed, as these can affect both the operational lifespan and maintenance requirements of the chassis.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance (QA) is integral to the manufacturing of independent four-wheel electric vehicle chassis, ensuring that each component meets stringent safety and performance standards.

What International and Industry-Specific Standards Guide Quality Assurance?

International standards, such as ISO 9001, provide a framework for quality management systems, emphasizing customer satisfaction and continuous improvement. In addition to ISO standards, industry-specific certifications like CE marking for compliance with European safety regulations and API for performance standards in the oil and gas industry are critical.

B2B buyers should ensure that potential suppliers are certified and regularly audited against these standards, as compliance can significantly impact the reliability and safety of the chassis.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to monitor and verify quality. These typically include:

- Incoming Quality Control (IQC): Assessment of raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing stages to catch defects early, minimizing waste and rework.

- Final Quality Control (FQC): Comprehensive testing of the finished chassis to verify functionality, safety, and compliance with design specifications.

Common testing methods include dimensional inspections, functional tests, and stress testing to evaluate the chassis’s performance under various conditions.

How Can B2B Buyers Verify Supplier Quality Assurance Processes?

B2B buyers must take proactive steps to verify the quality assurance processes of potential suppliers. Here are several strategies to consider:

-

Conduct Supplier Audits: Regular audits can provide insights into a supplier’s quality management practices, manufacturing capabilities, and adherence to international standards.

-

Request Quality Assurance Documentation: Suppliers should provide detailed documentation, including quality control reports, certifications, and compliance records. This transparency is crucial for establishing trust.

-

Engage Third-Party Inspectors: Utilizing independent third-party inspectors can provide an objective assessment of a supplier’s quality assurance processes and the integrity of their products.

-

Evaluate Quality Metrics: Inquire about key performance indicators (KPIs) that the supplier uses to measure quality. Metrics such as defect rates, return rates, and customer satisfaction scores can provide a clearer picture of their reliability.

What Are the Unique Quality Control Considerations for International Buyers?

For B2B buyers in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Variations in regulatory requirements, market conditions, and cultural expectations can influence quality assurance practices.

Buyers should familiarize themselves with local standards and regulations that may impact the quality of the chassis. Additionally, building strong relationships with suppliers can facilitate better communication and understanding of quality expectations, ultimately leading to successful partnerships.

By comprehensively understanding the manufacturing processes and quality assurance measures in the production of independent four-wheel electric vehicle chassis, B2B buyers can make informed decisions that ensure they partner with reliable and capable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘independent fourwheel electric vehicle chassis’

Introduction

This guide provides a practical checklist for B2B buyers seeking to procure independent four-wheel electric vehicle chassis. As the market for electric vehicles (EVs) continues to grow, understanding the specific requirements and ensuring the right sourcing strategy is essential. This checklist will help streamline your procurement process and ensure that you select the most suitable chassis for your operational needs.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for the chassis. Consider factors such as load capacity, modularity, and integration capabilities with existing systems. This step is crucial to ensure that the chassis meets your operational demands and aligns with your vehicle design goals.

- Key Considerations:

- Type of electric powertrain (BEV or FCEV)

- Desired performance metrics (speed, range, etc.)

Step 2: Assess Compliance and Safety Standards

Verify that potential chassis suppliers comply with relevant industry standards and safety regulations. This includes certifications such as ISO 26262 for functional safety and ISO 21434 for cybersecurity. Ensuring compliance mitigates risks and enhances the reliability of your fleet.

- What to Look For:

- Documentation of certifications

- Evidence of safety testing and performance data

Step 3: Evaluate Supplier Capabilities

Before making a commitment, it’s vital to thoroughly vet suppliers. Request detailed company profiles, including their production capabilities, technology used, and previous projects. Engaging with suppliers who have experience in your specific market can provide valuable insights and reassurance.

- Specific Actions:

- Ask for references from similar projects

- Review case studies that highlight their expertise

Step 4: Analyze Modularity and Scalability Options

Consider the modularity of the chassis design, as it can significantly affect your vehicle’s adaptability for various applications. A chassis that supports modular designs allows for easy customization and upgrades, which can be beneficial for fleet operators aiming to diversify their offerings.

- Key Features to Evaluate:

- Flexibility in component integration

- Options for future upgrades or expansions

Step 5: Inquire About Maintenance and Support Services

Effective maintenance strategies are critical for minimizing downtime and maximizing fleet efficiency. Inquire about the supplier’s maintenance services, including the availability of spare parts and support for preventative maintenance technologies.

- Important Aspects:

- Turnaround time for parts replacement

- Availability of remote diagnostics and support

Step 6: Request Detailed Pricing and TCO Analysis

Understanding the total cost of ownership (TCO) is essential for budgeting and financial planning. Request a comprehensive breakdown of costs associated with the chassis, including initial purchase price, maintenance, and potential operational savings over time.

- Areas to Consider:

- Cost savings from energy efficiency

- Long-term maintenance costs vs. upfront pricing

Step 7: Conduct a Pilot Test or Prototype Evaluation

If possible, arrange for a pilot test of the chassis or evaluate a prototype. This hands-on experience can provide critical insights into performance, handling, and compatibility with your operational requirements. It’s an essential step before full-scale procurement.

- What to Observe:

- Handling and maneuverability under various conditions

- Compatibility with your specific vehicle applications

By following this checklist, B2B buyers can make informed decisions when sourcing independent four-wheel electric vehicle chassis, ensuring that they select the right solutions for their specific needs.

Comprehensive Cost and Pricing Analysis for independent fourwheel electric vehicle chassis Sourcing

What Are the Key Cost Components in Sourcing Independent Four-Wheel Electric Vehicle Chassis?

When sourcing independent four-wheel electric vehicle (EV) chassis, understanding the cost structure is vital for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Lightweight materials, such as aluminum or advanced composites, may offer better performance but come at a higher price. Conversely, traditional steel may reduce initial costs but could lead to higher operational expenses due to weight.

-

Labor: Labor costs vary depending on the location of the manufacturing facility. Regions with higher labor costs might offer superior craftsmanship and advanced skills, while lower-cost regions may compromise on quality.

-

Manufacturing Overhead: This encompasses indirect costs related to production, including utilities, rent, and administrative expenses. A facility’s efficiency can influence these costs, making it essential to assess potential suppliers’ operational efficiency.

-

Tooling: The initial investment in specialized tooling for manufacturing can be substantial. Custom chassis designs will typically require bespoke tooling, which can significantly affect the overall project budget.

-

Quality Control (QC): Implementing robust QC processes ensures that the chassis meet safety and performance standards. However, these processes add to the overall cost. Buyers should consider the long-term benefits of quality assurance against upfront costs.

-

Logistics: Shipping costs depend on the distance from the manufacturing site to the buyer’s location, as well as the logistics infrastructure in place. Import duties, taxes, and tariffs can also add to the final price, particularly for international transactions.

-

Margin: Supplier margins can vary based on competition, market demand, and perceived value. Understanding the typical margins within the industry can help buyers negotiate better deals.

How Do Price Influencers Affect the Cost of EV Chassis?

Several factors can influence the pricing of independent four-wheel EV chassis:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often yield better unit prices. Suppliers may offer discounts for bulk purchases, so it is essential to assess your needs accurately.

-

Specifications and Customization: Custom designs tailored to specific applications can significantly raise costs. Buyers should weigh the benefits of customization against the potential for increased expenses.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO standards) can enhance performance and safety but come at a premium. Buyers should evaluate the importance of certifications based on their operational requirements.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their experience and reliability, while newer entrants may offer lower prices to gain market share.

-

Incoterms: The choice of Incoterms (International Commercial Terms) can influence the final price. Terms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and risks, impacting overall expenses.

What Tips Can Help Buyers Negotiate Better Pricing?

To optimize sourcing strategies, buyers should consider the following tips:

-

Negotiation: Engage suppliers in negotiations to explore various pricing structures. Establishing long-term relationships can lead to favorable terms and discounts.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO) beyond just the initial purchase price. Consider maintenance, operational costs, and potential downtime, which can significantly impact overall expenses.

-

Pricing Nuances for International Buyers: Understanding local market conditions, currency fluctuations, and regional economic factors is crucial for international buyers. Engaging local experts can provide insights into pricing norms and potential hidden costs.

-

Flexible Specifications: If possible, maintain some flexibility in chassis specifications. This can open up opportunities for cost savings if suppliers can offer alternative materials or designs that meet your needs at a lower price.

Disclaimer

Prices mentioned in this analysis are indicative and can vary significantly based on market conditions, supplier negotiations, and specific project requirements. Always conduct thorough market research and supplier assessments to ensure the best value for your investment.

Alternatives Analysis: Comparing independent fourwheel electric vehicle chassis With Other Solutions

Understanding the Importance of Alternatives in Electric Vehicle Chassis

When evaluating the best solutions for electric vehicle (EV) chassis, particularly independent four-wheel designs, it is essential to consider alternative technologies. Each alternative may offer unique advantages or drawbacks, influencing a B2B buyer’s decision based on specific operational needs, cost constraints, and performance expectations. Below, we compare independent four-wheel electric vehicle chassis against two viable alternatives: traditional rigid chassis designs and modular electric vehicle platforms.

| Comparison Aspect | Independent Fourwheel Electric Vehicle Chassis | Traditional Rigid Chassis Design | Modular Electric Vehicle Platform |

|---|---|---|---|

| Performance | High maneuverability and stability with independent control of each wheel. | Limited maneuverability; better for high-speed stability. | Excellent adaptability for various applications; optimized for specific missions. |

| Cost | Higher initial investment due to advanced technology. | Lower initial costs but potentially higher long-term maintenance. | Competitive pricing with potential for reduced TCO through modularity. |

| Ease of Implementation | Complex integration; may require specialized training for installation. | Simpler integration with established manufacturing processes. | Streamlined implementation due to modular design; less training required. |

| Maintenance | Advanced maintenance needs; requires skilled technicians. | Easier maintenance with readily available parts. | Reduced downtime with modular components; quick replacements. |

| Best Use Case | Ideal for urban environments requiring high maneuverability and flexibility. | Best for heavy-duty applications where stability is prioritized. | Suitable for fleets needing customized vehicles for diverse operations. |

What Are the Advantages and Disadvantages of Traditional Rigid Chassis Designs?

Traditional rigid chassis designs have been the backbone of vehicle manufacturing for decades. Their primary advantage lies in their structural integrity and simplicity, which often leads to lower initial costs. These chassis are well-suited for heavy-duty applications where stability is paramount, such as long-haul trucks or commercial vehicles requiring consistent performance over varied terrains. However, they often lack the maneuverability and flexibility of independent four-wheel systems, making them less ideal for urban environments or applications requiring frequent directional changes.

How Do Modular Electric Vehicle Platforms Compare?

Modular electric vehicle platforms are gaining traction in the industry due to their adaptability and efficiency. These platforms allow for the quick assembly of various vehicle configurations tailored to specific mission requirements, significantly reducing development costs and time to market. Their modular design facilitates easier maintenance and repairs, often resulting in lower total cost of ownership (TCO) over time. However, while they provide excellent flexibility, they may not offer the same level of performance as independent four-wheel systems in terms of precise wheel control and stability during complex maneuvers.

Conclusion: How Should B2B Buyers Choose the Right Electric Vehicle Chassis Solution?

In selecting the optimal chassis solution for electric vehicles, B2B buyers must weigh their specific operational needs against the strengths and weaknesses of each alternative. Independent four-wheel electric vehicle chassis provide exceptional performance and flexibility for urban and complex driving conditions, albeit at a higher upfront cost and maintenance requirement. Conversely, traditional rigid chassis designs offer simplicity and cost-effectiveness, while modular platforms present a balanced approach with adaptability and reduced downtime. Ultimately, the decision should align with the buyer’s operational goals, budget constraints, and the intended application of the vehicles within their fleet.

Essential Technical Properties and Trade Terminology for independent fourwheel electric vehicle chassis

What Are the Key Technical Properties of Independent Four-Wheel Electric Vehicle Chassis?

Understanding the technical specifications of independent four-wheel electric vehicle (EV) chassis is vital for B2B buyers, especially when evaluating options for fleet operations or manufacturing. Here are several critical properties that significantly impact performance, safety, and operational efficiency:

-

Modularity

Modularity refers to the design flexibility of the chassis, allowing various configurations to suit specific applications. A modular chassis can accommodate different body types, battery sizes, and drive systems without requiring a complete redesign. This is crucial for OEMs looking to minimize development costs and time while maximizing adaptability for various market needs. -

Weight Distribution

Proper weight distribution enhances vehicle stability and handling. Independent chassis systems allow for precise control over weight allocation across the four wheels, improving traction and safety. For fleet operators, a well-distributed weight can lead to better tire longevity and lower maintenance costs, ultimately affecting the Total Cost of Ownership (TCO). -

X-by-Wire Technology

This term describes the use of electronic controls for steering, braking, and acceleration instead of traditional mechanical linkages. Implementing x-by-wire technology enhances responsiveness and precision, allowing for advanced features such as autonomous driving capabilities. For buyers, this translates to improved vehicle performance and safety, making it a key consideration in procurement. -

Energy Efficiency Metrics

Energy efficiency is critical in electric vehicle design, impacting range and operational costs. Buyers should consider metrics such as aerodynamic drag coefficients and energy consumption rates. A chassis designed for optimal energy efficiency can significantly reduce charging frequency and operational downtime, enhancing fleet productivity. -

Safety Compliance Standards

Compliance with industry safety standards, such as ISO 26262 for functional safety, is essential. This ensures that the chassis design incorporates fail-operational systems, which maintain functionality even during component failures. For B2B buyers, understanding these standards is crucial for ensuring the safety and reliability of their vehicle fleets. -

Serviceability

The ease with which a chassis can be maintained and repaired is another vital property. Features such as modular components that can be replaced quickly (often within an hour) reduce downtime and maintenance costs. Buyers should look for chassis designs that prioritize serviceability, as this can lead to significant savings in operational efficiency.

What Are Common Trade Terms Used in the Independent Four-Wheel Electric Vehicle Chassis Industry?

Familiarity with industry-specific terminology can facilitate smoother negotiations and procurement processes. Here are some key terms every B2B buyer should know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of electric vehicle chassis, OEMs often provide the core components that are integrated into the final vehicle design. Understanding OEM relationships can help buyers identify reliable suppliers and potential partnerships. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest amount of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory planning, particularly in the context of chassis components that may require large upfront investments. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to invite them to submit price quotes for specific products or services. For buyers in the EV chassis sector, issuing an RFQ helps to gather competitive pricing and assess supplier capabilities before making purchasing decisions. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and responsibilities, which is crucial for international procurement of chassis components. -

TCO (Total Cost of Ownership)

TCO is a financial estimate intended to help buyers assess the direct and indirect costs of a product over its lifecycle. In the context of electric vehicle chassis, understanding TCO can guide buyers in making informed decisions that go beyond initial purchase price, considering maintenance, energy consumption, and resale value. -

Aftermarket Support

This term refers to services provided after the initial sale, including repairs, maintenance, and parts supply. Buyers should evaluate the level of aftermarket support offered by suppliers to ensure that they can maintain their fleet’s operational efficiency over time.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance the efficiency and effectiveness of their electric vehicle operations.

Navigating Market Dynamics and Sourcing Trends in the independent fourwheel electric vehicle chassis Sector

What Are the Current Market Dynamics and Key Trends in the Independent Four-Wheel Electric Vehicle Chassis Sector?

The independent four-wheel electric vehicle (EV) chassis sector is witnessing significant transformation driven by technological advancements, regulatory pressures, and shifting consumer expectations. Globally, the push for sustainable transportation solutions is prompting OEMs and fleet operators to explore modular platforms that offer customization and scalability. This trend is particularly relevant for international B2B buyers in emerging markets such as Africa, South America, the Middle East, and Europe, where the demand for electric mobility is on the rise.

Key technology trends include the integration of x-by-wire systems, which provide independent control over steering, braking, and driving functions. This allows for enhanced vehicle performance and safety features, such as improved electronic stability control and reduced total cost of ownership (TCO). Furthermore, modular platforms, like the REEcorner® technology, enable businesses to tailor vehicles for specific applications, increasing operational efficiency and reducing development costs. As competition intensifies, international buyers must prioritize partnerships with manufacturers that can deliver innovative, scalable solutions that meet local market demands.

Additionally, the rise of data-driven vehicle systems is reshaping how fleet operators manage their assets. Advanced data collection and analytics facilitate proactive maintenance, optimizing vehicle uptime and performance. Buyers must stay informed about these emerging technologies to leverage the benefits they offer in terms of cost savings and operational improvements.

How Important Is Sustainability and Ethical Sourcing in B2B for the Electric Vehicle Chassis Sector?

Sustainability is no longer just a buzzword; it has become a critical component of business strategy in the independent four-wheel electric vehicle chassis sector. For international B2B buyers, particularly in regions grappling with environmental challenges, sourcing components with minimal ecological impact is imperative. This includes selecting materials that are recyclable, responsibly sourced, and certified by recognized environmental standards.

Ethical supply chains are equally important, as they not only mitigate risks associated with labor practices but also enhance brand reputation. Buyers should seek partnerships with manufacturers who demonstrate commitment to sustainability through certifications such as ISO 14001 or adherence to sustainability standards like the Global Reporting Initiative (GRI). Furthermore, the integration of green technologies in chassis manufacturing, such as low-emission production processes and sustainable material selection, can significantly reduce the overall carbon footprint of electric vehicles.

Incorporating these principles into sourcing strategies not only aligns with regulatory requirements but also caters to the growing consumer demand for environmentally responsible products. This alignment can provide a competitive edge in the marketplace, fostering loyalty among increasingly eco-conscious customers.

What Is the Evolution of the Independent Four-Wheel Electric Vehicle Chassis Sector?

The evolution of the independent four-wheel electric vehicle chassis sector has been marked by a shift from traditional mechanical designs to advanced modular platforms. Early models were limited by rigid architectures that constrained design flexibility and vehicle performance. However, the advent of electric mobility has spurred innovation, allowing for the development of chassis systems that prioritize versatility and efficiency.

The introduction of x-by-wire technologies has been a game-changer, enabling independent control of vehicle functions and enhancing safety and maneuverability. This evolution is complemented by the growing demand for sustainable and customizable transportation solutions, particularly in developing regions. As the industry continues to mature, it is essential for B2B buyers to understand these historical shifts to make informed sourcing decisions that align with current market dynamics and future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of independent fourwheel electric vehicle chassis

-

How do I evaluate the quality of independent four-wheel electric vehicle chassis?

To evaluate the quality of independent four-wheel electric vehicle chassis, consider several factors: manufacturing standards, compliance with international safety regulations, and the technology used in the chassis design. Request certifications and test reports from potential suppliers, and assess their production capabilities through site visits or third-party inspections. Additionally, reviews and testimonials from other B2B clients can provide insights into the supplier’s reliability and product performance. -

What are the key features to look for in independent four-wheel electric vehicle chassis?

Key features to consider include modularity, weight capacity, energy efficiency, and advanced control systems like x-by-wire technology. Assess the chassis for its adaptability to various body designs and its ability to incorporate different powertrain configurations, such as battery-electric or fuel-cell systems. Also, prioritize safety features, such as fail-operational systems and compliance with ISO standards, which ensure reliability and operational integrity. -

What customization options are available for independent four-wheel electric vehicle chassis?

Customization options typically include modifications to chassis dimensions, weight distribution, and component integration (such as battery placement). Suppliers may also offer specialized designs to accommodate specific vocational applications, ensuring that the chassis meets your operational requirements. Engage with manufacturers early in the procurement process to discuss your specific needs and explore available customization options. -

What is the minimum order quantity (MOQ) for independent four-wheel electric vehicle chassis?

The minimum order quantity for independent four-wheel electric vehicle chassis varies by supplier and often depends on factors such as production capacity and customization requirements. Generally, MOQs can range from a few units to several dozen. It’s advisable to negotiate with suppliers to find a quantity that aligns with your operational needs while also ensuring cost-effectiveness. -

What payment terms are common when sourcing independent four-wheel electric vehicle chassis?

Payment terms can vary significantly among suppliers, but common practices include a percentage upfront (usually 30-50%) with the balance due upon delivery or after satisfactory inspection. Some suppliers may offer flexible financing options or letter of credit arrangements, especially for larger orders. Always clarify payment terms before finalizing agreements to avoid misunderstandings. -

How can I ensure timely delivery of independent four-wheel electric vehicle chassis?

To ensure timely delivery, establish clear timelines with your suppliers and incorporate penalties for delays in your contracts. Utilize logistics tracking systems to monitor shipment progress and maintain regular communication with your supplier regarding production schedules. Additionally, consider suppliers with a proven track record of meeting deadlines and those who have established logistics networks in your region. -

What quality assurance processes should I expect from suppliers of independent four-wheel electric vehicle chassis?

Expect suppliers to implement rigorous quality assurance processes, including regular inspections, testing of materials, and adherence to international standards such as ISO 9001. Inquire about their quality control protocols, such as incoming material inspections, in-process audits, and final product testing. Additionally, request access to quality documentation and certifications to verify compliance. -

What are the best practices for vetting suppliers of independent four-wheel electric vehicle chassis?

Best practices for vetting suppliers include conducting thorough background checks, reviewing their financial stability, and assessing their production capabilities. Request references from previous clients and visit their facilities if possible. It’s also beneficial to evaluate their responsiveness and customer service during initial communications, as this can indicate their level of commitment to your partnership.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 Independent Fourwheel Electric Vehicle Chassis Manufacturers & Suppliers List

1. REE.auto – Modular Electric Vehicle Platform

Domain: ree.auto

Registered: 2019 (6 years)

Introduction: REEcorner technology is a modular electric vehicle platform that integrates critical vehicle components into a compact module. Key features include:

– Fully modular, software-defined electric vehicle platforms for commercial use.

– High volumetric efficiency with 36% more load capacity for a given footprint.

– Energy efficiencies with minimum aerodynamic drag and energy consumption.

– Operational …

2. SAGE Journals – In-Wheel Motor Control Technology

Domain: journals.sagepub.com

Registered: 1989 (36 years)

Introduction: The paper discusses longitudinal/lateral integrated control technology for in-wheel motor automotive chassis, focusing on the in-wheel motor-driven electric vehicle (IWMEV) which offers high controllable degrees of freedom, fast motor response, high system integration, and a compact vehicle structure. Key technologies mentioned include: longitudinal anti-lock braking system (ABS), electronic brake…

3. Inderscience – FWIC-EV Technology

Domain: inderscienceonline.com

Registered: 2014 (11 years)

Introduction: This company, Inderscience – FWIC-EV Technology, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for independent fourwheel electric vehicle chassis

As the electric vehicle (EV) market continues to evolve, the strategic sourcing of independent four-wheel electric vehicle chassis presents significant opportunities for B2B buyers across diverse regions such as Africa, South America, the Middle East, and Europe. Key takeaways from this guide emphasize the importance of modularity and scalability in chassis design, which allows for tailored solutions that meet specific operational needs. The REEcorner® technology, for instance, showcases how integrated systems can enhance energy efficiency, reduce total cost of ownership, and improve vehicle performance.

Investing in advanced chassis solutions not only supports operational efficiencies but also aligns with the global shift towards sustainable transportation. Buyers should prioritize partnerships with manufacturers that offer cutting-edge technologies, such as x-by-wire systems and AI-driven maintenance, ensuring their fleets remain competitive and adaptable.

Looking ahead, B2B buyers are encouraged to leverage these insights to inform their sourcing strategies. Embracing innovation and customization will be crucial as the demand for electric vehicles rises. By strategically sourcing independent four-wheel electric vehicle chassis, businesses can position themselves at the forefront of this transformative industry, driving both profitability and sustainability.