Introduction: Navigating the Global Market for crane Lifting Equipment

In an increasingly interconnected world, sourcing crane lifting equipment can pose significant challenges for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, such as Brazil and Germany. With diverse regulations, varying standards, and a multitude of suppliers, the quest for reliable lifting solutions can be daunting. This guide aims to simplify the process by providing an in-depth exploration of crane lifting equipment, including types, applications, and best practices for supplier vetting.

From below-the-hook devices to advanced hoisting systems, understanding the full spectrum of lifting equipment is essential for ensuring operational efficiency and safety. This comprehensive resource will delve into the various lifting technologies available, including their specific applications in different industries. Additionally, we will cover critical factors such as cost considerations, compliance with international safety standards, and tips for evaluating suppliers to make informed purchasing decisions.

By leveraging the insights and strategies outlined in this guide, B2B buyers will be empowered to navigate the complexities of the global crane lifting equipment market. Whether you are enhancing your current operations or venturing into new projects, this resource is designed to equip you with the knowledge needed to make confident, strategic investments in lifting solutions that meet your unique business needs.

Understanding crane Lifting Equipment Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Below-the-Hook Devices | Versatile attachments like lifting beams, magnets, and clamps | Manufacturing, construction, logistics | Pros: Increased load stability, versatile applications. Cons: Requires careful selection based on load type. |

| Lifting Beams | Connects to load via a single point; ideal for low headroom | Warehousing, assembly lines | Pros: Space-efficient, easy to use. Cons: Limited to single load points, may require additional safety measures. |

| Spreader Bars | Multiple connection points to distribute load evenly | Heavy machinery, shipping, construction | Pros: Reduces bending and shearing risk, enhances load control. Cons: Bulkier than other options, requires more space. |

| Lifting Magnets | Utilizes magnetic force for lifting ferrous materials | Steel processing, manufacturing | Pros: Quick load handling, no mechanical parts. Cons: Limited to magnetic materials, requires power supply. |

| Coil Lifters | Specifically designed for lifting coils through inner diameter | Metal processing, manufacturing | Pros: Safe handling of coils, reduces risk of damage. Cons: Limited to specific shapes and sizes. |

What Are Below-the-Hook Devices and Their Applications?

Below-the-hook devices are essential attachments that facilitate safe and efficient lifting of various loads. These devices can include lifting beams, magnets, and clamps, each designed to accommodate specific types of materials and configurations. Their versatility makes them suitable for a wide range of applications, from manufacturing to logistics. When purchasing, buyers should consider the load type, weight capacity, and compatibility with existing crane systems to ensure optimal performance and safety.

How Do Lifting Beams Enhance Material Handling?

Lifting beams are characterized by their single-point connection to loads, making them particularly effective in environments with low headroom. Commonly used in warehousing and assembly lines, they enable the safe lifting of heavy materials without compromising space. Buyers should evaluate the beam’s weight capacity and construction material to match their operational demands, ensuring that the chosen lifting beam can handle the required loads efficiently.

Why Choose Spreader Bars for Heavy Loads?

Spreader bars are designed with multiple connection points that distribute the load evenly, enhancing stability during lifting operations. They are particularly beneficial in industries such as heavy machinery and shipping, where the risk of bending or shearing is significant. When selecting a spreader bar, buyers should assess the bar’s load capacity and ensure it complies with safety standards, as this will directly impact operational efficiency and safety.

What Advantages Do Lifting Magnets Offer?

Lifting magnets leverage magnetic force to lift ferrous materials quickly and efficiently. This technology eliminates the need for mechanical components, making it a preferred choice in steel processing and manufacturing. However, buyers should consider the power requirements and the limitations regarding the types of materials that can be lifted. Proper assessment of the operational environment is crucial to ensure the magnet’s effectiveness and safety.

How Are Coil Lifters Specialized for Specific Loads?

Coil lifters are tailored for the lifting of coils through their inner diameters, making them indispensable in metal processing and manufacturing sectors. Their design reduces the risk of damaging coils during handling, thus protecting valuable materials. When purchasing coil lifters, it is essential for buyers to confirm compatibility with the specific coil dimensions and weights they handle, ensuring safe and efficient operations.

Key Industrial Applications of crane Lifting Equipment

| Industry/Sector | Specific Application of crane Lifting Equipment | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Heavy material lifting and placement | Enhanced project efficiency and safety | Load capacity, compliance with local regulations, durability |

| Manufacturing | Assembly line support and material handling | Improved workflow and reduced labor costs | Type of lifting device, customization options, maintenance support |

| Shipping and Logistics | Container handling and loading/unloading operations | Increased throughput and reduced turnaround times | Compatibility with existing equipment, lifting capacity, safety features |

| Oil and Gas | Equipment installation and maintenance | Enhanced operational uptime and safety in hazardous environments | Certification for hazardous areas, load monitoring solutions, reliability |

| Mining | Transporting heavy machinery and materials | Optimized resource extraction and reduced downtime | Robustness for extreme conditions, lifting capacity, supplier reliability |

How is Crane Lifting Equipment Utilized in the Construction Industry?

In the construction sector, crane lifting equipment is essential for transporting and placing heavy materials such as steel beams, concrete panels, and prefabricated components. This equipment addresses challenges related to safety and efficiency, allowing construction teams to lift loads that would otherwise require extensive manual effort. Buyers in this field should prioritize equipment with high load capacities and compliance with local safety regulations to ensure both worker safety and project timelines.

What Role Does Crane Lifting Equipment Play in Manufacturing?

Manufacturers utilize crane lifting equipment for various applications, including assembly line support and material handling. This equipment streamlines operations by enabling the quick and safe movement of heavy parts and machinery, thus improving overall workflow. International buyers should consider the specific types of lifting devices that best fit their production processes, as well as options for customization to meet unique operational requirements.

How is Crane Lifting Equipment Applied in Shipping and Logistics?

In shipping and logistics, crane lifting equipment is vital for the efficient handling of containers during loading and unloading operations. This equipment significantly increases throughput and reduces turnaround times, which is crucial in competitive markets. Buyers should focus on sourcing equipment that is compatible with existing handling systems and has the necessary lifting capacity to meet their operational demands while ensuring safety features are in place.

What are the Key Applications of Crane Lifting Equipment in the Oil and Gas Industry?

In the oil and gas sector, crane lifting equipment is used for the installation and maintenance of heavy machinery and infrastructure in often hazardous environments. This equipment enhances operational uptime and safety, which are critical in this high-stakes industry. Buyers must ensure that any lifting equipment sourced is certified for use in hazardous areas and equipped with load monitoring solutions to maintain safety standards.

How is Crane Lifting Equipment Essential in Mining Operations?

Mining operations rely heavily on crane lifting equipment for transporting heavy machinery and materials, such as ore and waste rock. This equipment optimizes resource extraction and minimizes downtime, which is vital for profitability in the sector. Buyers should prioritize sourcing robust equipment that can withstand extreme conditions, along with ensuring that the lifting capacity meets the demanding nature of mining operations.

3 Common User Pain Points for ‘crane Lifting Equipment’ & Their Solutions

Scenario 1: Inadequate Load Handling Capabilities

The Problem: In many industrial settings, B2B buyers often face challenges with lifting equipment that is not adequately designed for their specific load requirements. This can lead to unsafe lifting practices, inefficient operations, and even equipment failure. For instance, a construction company in Brazil might purchase a crane that is rated for a certain weight but fails to handle the dynamic loads experienced on site, leading to potential accidents and costly downtimes. This scenario reflects a broader issue where mismatched equipment capabilities result in operational disruptions and safety hazards.

The Solution: To mitigate these risks, it is essential to conduct a comprehensive assessment of the lifting needs before purchasing crane lifting equipment. Buyers should engage in detailed conversations with suppliers to understand the full range of available options, focusing on load ratings and dynamic load considerations. Additionally, employing below-the-hook lifting devices such as lifting beams and spreader bars can help distribute loads more evenly, enhancing stability and safety. Regular training for operators on the equipment’s limitations and proper usage can further ensure that lifting operations remain within safe parameters.

Scenario 2: Compliance with Safety Standards and Regulations

The Problem: B2B buyers in regions like the Middle East and Europe often struggle to keep up with varying safety regulations and standards for crane lifting equipment. Non-compliance can result in hefty fines, legal liabilities, and jeopardized employee safety. For example, a logistics company in Germany may invest in state-of-the-art lifting equipment but later discover that it does not meet local OSHA or ASME standards, leading to operational delays and increased costs due to necessary modifications or replacements.

The Solution: To navigate this complex landscape, buyers should prioritize sourcing equipment from reputable manufacturers who can provide documentation of compliance with relevant standards. Conducting thorough research on local regulations is crucial; this may involve consulting with industry experts or legal advisors specializing in safety compliance. Moreover, establishing a regular maintenance and inspection schedule for lifting equipment not only ensures compliance but also prolongs the equipment’s lifespan. Utilizing load monitoring devices, such as load cells, can help track compliance in real-time, providing data that can be invaluable during inspections.

Scenario 3: Difficulty in Finding the Right Equipment for Specialized Applications

The Problem: Many B2B buyers encounter challenges when seeking crane lifting equipment tailored to specialized applications. For instance, a manufacturing plant in South America may require unique below-the-hook attachments to handle custom loads, but standard options often do not meet their specific needs. This can lead to increased downtime as they search for suitable solutions or attempt to adapt existing equipment, ultimately impacting productivity and profitability.

The Solution: To address this issue, buyers should engage with suppliers who offer customizable lifting solutions. This could involve collaborating with manufacturers to design bespoke lifting devices that suit their operational needs. Conducting a thorough needs assessment that includes load types, sizes, and environmental conditions will help in specifying the right equipment. Furthermore, suppliers should provide extensive product support, including guidance on installation and usage, to ensure that specialized equipment is utilized effectively. Leveraging technology such as CAD software for design visualization can also streamline the customization process, making it easier for buyers to communicate their specific requirements.

Strategic Material Selection Guide for crane Lifting Equipment

What Are the Key Materials Used in Crane Lifting Equipment?

In the world of crane lifting equipment, the choice of materials plays a critical role in determining the performance, safety, and longevity of the products. Understanding the properties, advantages, and limitations of these materials is essential for B2B buyers, particularly those operating in diverse environments such as Africa, South America, the Middle East, and Europe. Below are analyses of four common materials used in crane lifting equipment.

How Does Steel Perform in Crane Lifting Equipment?

Steel is the most commonly used material in crane lifting equipment due to its exceptional strength and durability. Key properties include high tensile strength and excellent resistance to deformation under load. Steel can withstand high temperatures and pressures, making it suitable for heavy-duty applications.

Pros: Steel is highly durable and can endure harsh environmental conditions. It is also relatively cost-effective and widely available, which makes it a preferred choice for many applications.

Cons: However, steel is prone to corrosion if not properly treated, which can be a significant drawback in humid or coastal environments. Additionally, the manufacturing complexity can increase costs if specialized treatments or alloys are required.

Impact on Application: Steel’s compatibility with various lifting applications makes it versatile, but buyers must consider the need for protective coatings or treatments to prevent rust and degradation.

Considerations for International Buyers: Compliance with international standards such as ASTM A36 or DIN 17100 is crucial, especially in regions like Germany, where stringent regulations are enforced.

What Role Does Aluminum Play in Crane Lifting Equipment?

Aluminum is increasingly popular in crane lifting applications due to its lightweight nature and resistance to corrosion. Its key properties include a high strength-to-weight ratio and excellent resistance to oxidation.

Pros: The primary advantage of aluminum is its low weight, which allows for easier handling and reduced energy consumption during lifting operations. It is also naturally resistant to corrosion, making it ideal for outdoor applications.

Cons: On the downside, aluminum has a lower tensile strength compared to steel, which may limit its use in extremely heavy lifting scenarios. Its higher cost can also be a consideration for budget-conscious buyers.

Impact on Application: Aluminum is particularly well-suited for applications requiring portability and ease of use, such as in construction sites or temporary installations.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM B221 for aluminum structural shapes, particularly in regions like Brazil, where local regulations may vary.

How Does Synthetic Fiber Compare in Crane Lifting Equipment?

Synthetic fiber materials, such as nylon and polyester, are commonly used in lifting slings and straps. Their key properties include high flexibility, lightweight, and resistance to abrasion.

Pros: Synthetic fibers are incredibly lightweight and offer excellent shock absorption, which can be beneficial in reducing the impact on loads during lifting. They also resist moisture and some chemicals, making them suitable for various environments.

Cons: However, synthetic fibers have lower temperature and UV resistance compared to metals, which can limit their use in extreme conditions. They are also generally less durable than steel or aluminum over long-term use.

Impact on Application: These materials are best suited for applications where weight and flexibility are prioritized, such as in the lifting of delicate or finished products.

Considerations for International Buyers: Compliance with standards such as ASME B30.9 is essential, especially in regions with strict safety regulations like Europe.

What Are the Advantages of Using Composite Materials in Crane Lifting Equipment?

Composite materials, often made from a combination of fibers and resins, are emerging in crane lifting equipment due to their unique properties. They offer high strength while being lightweight and resistant to corrosion.

Pros: The main advantage of composites is their ability to withstand harsh environments without the risk of rust or corrosion. They are also customizable, allowing for tailored solutions for specific applications.

Cons: The primary limitation is the higher cost associated with manufacturing composite materials, which can be a barrier for some buyers. Additionally, they may not be as widely accepted or understood in traditional lifting applications.

Impact on Application: Composites are ideal for specialized applications where weight and corrosion resistance are critical, such as in offshore or chemical handling environments.

Considerations for International Buyers: Buyers should be aware of the varying acceptance of composite materials in different regions and ensure compliance with relevant standards.

Summary Table of Material Selection for Crane Lifting Equipment

| Material | Typical Use Case for crane Lifting Equipment | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty lifting applications | Exceptional strength and durability | Prone to corrosion without treatment | Medium |

| Aluminum | Portable lifting solutions | Lightweight and corrosion-resistant | Lower tensile strength than steel | High |

| Synthetic Fiber | Delicate or finished product lifting | Lightweight and flexible | Lower durability over time | Medium |

| Composite | Specialized lifting in harsh environments | Corrosion-resistant and customizable | Higher manufacturing costs | High |

This guide provides B2B buyers with a comprehensive understanding of the materials used in crane lifting equipment, enabling informed decisions that align with their operational needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for crane Lifting Equipment

What Are the Key Stages in the Manufacturing Process of Crane Lifting Equipment?

The manufacturing process of crane lifting equipment is intricate and involves several critical stages to ensure safety, efficiency, and reliability. Understanding these stages helps B2B buyers make informed decisions when sourcing equipment.

Material Preparation: What Materials Are Used and How Are They Prepared?

The first step in manufacturing crane lifting equipment is material preparation. Common materials used include high-strength steel, aluminum, and occasionally composite materials, depending on the application. The preparation process involves selecting quality raw materials, cutting them to specified dimensions, and treating them to enhance durability, such as through galvanization or powder coating. This ensures that the materials can withstand the stresses they will encounter during use.

Forming: How Are Crane Components Shaped?

Forming is the next stage, where materials are shaped into components. Techniques such as forging, casting, and machining are commonly employed. For example, forging is used to create strong and durable components like hooks and lugs, while casting may be used for more complex shapes. Machining processes, including milling and turning, are employed to achieve precise dimensions and tolerances required for safe operation. This stage is crucial as it directly impacts the structural integrity and performance of the lifting equipment.

Assembly: What Assembly Techniques Are Commonly Used?

Once the components are formed, the assembly process begins. This involves integrating various parts, such as hoists, pulleys, and lifting devices, into a cohesive unit. Techniques such as welding, bolting, and riveting are employed to secure components. During assembly, attention is paid to ensure that all connections are robust and that the equipment meets design specifications. A well-assembled crane lifting device is essential for maintaining safety standards and operational efficiency.

Finishing: What Finishing Processes Enhance Durability?

The final manufacturing stage is finishing, which includes surface treatments and protective coatings. Processes such as painting, powder coating, and anodizing are applied to enhance corrosion resistance and aesthetic appeal. This not only prolongs the lifespan of the equipment but also ensures compliance with industry standards for safety and performance. Proper finishing is especially important in environments that may expose equipment to harsh conditions, such as coastal or industrial settings.

What Quality Assurance Measures Are Necessary for Crane Lifting Equipment?

Quality assurance (QA) is a critical aspect of the manufacturing process for crane lifting equipment, ensuring that products meet international and industry-specific standards. For B2B buyers, understanding these measures is essential for selecting reliable suppliers.

Which International Standards Should Buyers Be Aware Of?

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with ISO 9001 ensures that a manufacturer is committed to continuous improvement and customer satisfaction. Additionally, industry-specific standards such as CE marking in Europe, which indicates compliance with safety and environmental protection standards, and API (American Petroleum Institute) standards for equipment used in the oil and gas industry, are crucial for ensuring product reliability and safety.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): This is the initial inspection of raw materials and components to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): During the manufacturing process, inspections are conducted to monitor quality and compliance with specifications. This ensures that any defects are identified and rectified early.

- Final Quality Control (FQC): After assembly, the finished product undergoes thorough testing and inspection to verify that it meets all safety and performance criteria.

What Common Testing Methods Are Used to Ensure Quality?

Various testing methods are employed to ensure the quality and safety of crane lifting equipment. Common methods include:

- Load Testing: This involves applying a load greater than the maximum working load limit (WLL) to ensure the equipment can safely handle expected loads.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, magnetic particle inspection, and dye penetrant testing are used to detect internal and surface defects without damaging the equipment.

- Visual Inspections: Regular visual checks are conducted to identify any signs of wear, damage, or non-compliance with safety standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is crucial for ensuring that the equipment meets required standards. Here are several strategies to consider:

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting supplier audits is an effective way to assess quality control practices. Buyers can request to visit manufacturing facilities to observe processes firsthand. During the audit, it is essential to review documentation related to quality management systems, including inspection reports, certifications, and compliance records.

How Can Buyers Request Quality Reports and Certifications?

Buyers should request quality reports and certifications from suppliers. These documents provide insight into the manufacturing processes and the results of quality testing. Certifications from recognized organizations lend credibility and assurance that the equipment meets international standards.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can further validate a supplier’s claims regarding quality control. Independent inspectors can conduct thorough evaluations of the manufacturing process and the final product, ensuring compliance with industry standards. This adds an additional layer of assurance for buyers, especially those operating in regions with stringent regulatory requirements.

What Are the Specific Quality Control Considerations for International Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances. Understanding local regulations and market expectations is vital.

How Do Regional Regulations Impact Quality Assurance?

Each region may have unique regulations regarding the safety and performance of lifting equipment. Buyers must familiarize themselves with local requirements, such as those set by OSHA in the United States or equivalent agencies in their respective countries. Compliance with these regulations is crucial for ensuring that equipment can be legally used in their operations.

What Are the Challenges of Sourcing Quality Equipment Internationally?

Sourcing crane lifting equipment from international suppliers can present challenges, including language barriers, varying standards, and shipping logistics. Buyers should consider these factors when evaluating suppliers and ensure that they have clear communication regarding quality expectations.

In conclusion, understanding the manufacturing processes and quality assurance measures for crane lifting equipment is essential for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and quality control, buyers can make informed decisions that prioritize safety and efficiency in their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘crane Lifting Equipment’

In the competitive landscape of industrial operations, sourcing the right crane lifting equipment is essential for maximizing efficiency and ensuring safety. This guide provides a structured approach for B2B buyers to navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Understanding your specific lifting requirements is the first step in the procurement process. Identify the types of loads you will be lifting, their weights, dimensions, and any unique handling needs. This clarity will help you select equipment that meets your operational demands while ensuring compliance with safety regulations.

- Consider Load Types: Different loads may require specialized lifting devices, such as below-the-hook attachments or lifting beams.

- Evaluate Capacity Requirements: Ensure that the equipment’s working load limit (WLL) exceeds the maximum weight you intend to lift.

Step 2: Research Available Equipment Options

With technical specifications in hand, explore the various types of crane lifting equipment available in the market. This includes hoists, lifting beams, spreader bars, and below-the-hook devices.

- Assess Versatility: Look for equipment that can handle multiple types of loads or can be adapted for different applications.

- Check Compliance Standards: Ensure that the equipment meets relevant industry standards, such as OSHA and ASME, for safety and performance.

Step 3: Evaluate Potential Suppliers

Before making a purchase, it’s critical to assess potential suppliers. A thorough vetting process will help you identify trustworthy partners who can meet your needs.

- Request Documentation: Ask for company profiles, certifications, and case studies demonstrating their experience in your industry.

- Seek References: Contact previous clients to gauge their satisfaction and reliability of the supplier’s equipment and service.

Step 4: Verify Supplier Certifications

Ensure that your chosen supplier holds necessary certifications and complies with local regulations. This step is vital for maintaining safety and legal compliance in your operations.

- Check for ISO Certifications: Suppliers with ISO certifications indicate a commitment to quality management and continuous improvement.

- Review Equipment Testing Procedures: Confirm that the equipment undergoes rigorous testing to ensure it meets specified safety standards.

Step 5: Assess After-Sales Support and Warranty Options

The procurement process does not end with the purchase. Evaluate the after-sales support and warranty options offered by the supplier.

- Understand Warranty Terms: A robust warranty can protect your investment and ensure that you have support in case of equipment failure.

- Inquire About Maintenance Services: Reliable suppliers often provide maintenance services to ensure the longevity and performance of your equipment.

Step 6: Compare Pricing and Payment Terms

While price shouldn’t be the sole determining factor, it is essential to compare costs among different suppliers.

- Request Detailed Quotes: Ensure that quotes include all potential costs, such as shipping, installation, and training.

- Negotiate Payment Terms: Look for flexible payment options that can accommodate your financial planning.

Step 7: Finalize the Purchase and Document Everything

Once you’ve selected a supplier and agreed on terms, finalize the purchase. Ensure that all agreements are documented and clearly outline the expectations for delivery and installation.

- Create a Purchase Order: This formalizes the transaction and serves as a reference for both parties.

- Maintain Open Communication: Keep lines of communication open with your supplier to address any concerns that may arise during the delivery and installation process.

By following these steps, B2B buyers can effectively navigate the procurement of crane lifting equipment, ensuring that they select the right solutions to meet their operational needs while adhering to safety standards.

Comprehensive Cost and Pricing Analysis for crane Lifting Equipment Sourcing

What Are the Key Cost Components in Crane Lifting Equipment Manufacturing?

When sourcing crane lifting equipment, understanding the cost structure is crucial for B2B buyers. The primary cost components typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly impacts cost. High-strength steel or specialized alloys used in lifting devices can increase expenses but provide enhanced durability and safety.

-

Labor: Labor costs vary based on region and the skill level required for manufacturing. For instance, countries with lower labor costs may offer more competitive pricing, but this can come at the expense of quality.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help keep these costs down.

-

Tooling: The initial investment in tooling can be substantial, especially for customized equipment. Buyers should consider whether the supplier has the necessary tools for their specific needs.

-

Quality Control: Ensuring that lifting equipment meets safety standards is non-negotiable. Investment in QC processes can lead to higher upfront costs but reduce long-term liabilities.

-

Logistics: Transportation costs can vary significantly based on distance and the mode of shipping. International buyers should consider these expenses when evaluating total costs.

-

Margin: The supplier’s profit margin can fluctuate based on competition and market demand. Understanding the typical margins in the industry can help buyers negotiate better prices.

What Influences the Pricing of Crane Lifting Equipment?

Several factors can influence the pricing of crane lifting equipment, particularly for international buyers.

-

Volume/MOQ: Larger orders often lead to discounts due to economies of scale. Buyers should assess their needs to determine optimal order quantities.

-

Specifications and Customization: Customized solutions typically come with higher price tags. Buyers should weigh the benefits of customization against standard options.

-

Materials and Quality Certifications: Equipment that meets specific certifications (e.g., OSHA, ASME) may command higher prices due to the assurance of quality and safety.

-

Supplier Factors: The reputation, reliability, and financial stability of the supplier can impact pricing. Established suppliers may charge a premium but offer better service and reliability.

-

Incoterms: Understanding International Commercial Terms (Incoterms) is vital. They dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect the total cost.

What Tips Can Help Buyers Navigate Crane Lifting Equipment Pricing?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, here are actionable tips to maximize cost efficiency:

-

Negotiate: Always approach pricing discussions with an understanding of your desired price point and the factors influencing it. Suppliers may offer flexibility on pricing, especially for bulk orders.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, operational efficiency, and potential downtime costs. Investing in higher-quality equipment may reduce TCO over time.

-

Understand Pricing Nuances: Factors like currency fluctuations, import tariffs, and regional economic conditions can affect pricing. Staying informed about these variables can aid in better budgeting.

-

Research Multiple Suppliers: Diversifying your supplier base can provide leverage in negotiations and ensure competitive pricing. It also allows for comparisons in quality and service.

Disclaimer on Indicative Pricing

Prices for crane lifting equipment can vary widely based on specifications, supplier, and market conditions. The figures presented in this analysis are indicative and should not be considered final quotes. Buyers are encouraged to conduct thorough market research and supplier evaluations to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing crane Lifting Equipment With Other Solutions

Exploring Alternative Lifting Solutions to Crane Lifting Equipment

In the realm of industrial lifting, crane lifting equipment stands out for its efficiency and versatility. However, various alternative solutions can also meet the needs of businesses engaged in material handling. This section compares crane lifting equipment with two viable alternatives: Forklifts and Hoists. Understanding these alternatives can help businesses select the most suitable lifting technology based on their specific operational requirements.

| Comparison Aspect | Crane Lifting Equipment | Forklifts | Hoists |

|---|---|---|---|

| Performance | High load capacity and stability for heavy items | Moderate load capacity; ideal for palletized goods | High precision in lifting, suitable for various loads |

| Cost | Higher initial investment; ongoing maintenance costs | Lower initial cost; varying maintenance expenses | Generally lower cost; minimal maintenance required |

| Ease of Implementation | Requires significant space and setup | Easy to operate; minimal training needed | Simple installation; often portable |

| Maintenance | Regular maintenance needed; parts can be costly | Routine servicing; parts are widely available | Low maintenance; fewer moving parts |

| Best Use Case | Heavy-duty lifting in construction and manufacturing | Moving goods within warehouses and distribution centers | Precision lifting in construction, manufacturing, and maintenance |

Forklifts: Pros and Cons

Forklifts are widely used for material handling in warehouses and manufacturing settings. Their primary advantage lies in their ability to transport goods over short distances quickly and efficiently. They are easy to operate, requiring minimal training, which makes them accessible for many employees. However, forklifts have a limited load capacity compared to cranes, making them unsuitable for extremely heavy or oversized items. Additionally, they require a flat, stable surface to operate effectively, which may limit their application in uneven terrains.

Hoists: Pros and Cons

Hoists are another alternative that offers precise lifting capabilities, often used in conjunction with a support structure. They are particularly beneficial for lifting heavy objects in tight spaces, where cranes might not fit. Hoists tend to be more cost-effective than cranes, both in terms of initial purchase and maintenance. However, their load capacity can vary significantly, and they may not be suitable for moving materials over long distances as they lack mobility. The installation can also be site-specific, potentially limiting flexibility in operations.

Making the Right Choice for Your Lifting Needs

Selecting the right lifting solution for your business hinges on understanding the specific requirements of your operations. Consider factors such as the weight and size of the loads, the environment where lifting will occur, and the overall budget. Crane lifting equipment excels in heavy-duty scenarios where stability and capacity are paramount. On the other hand, forklifts offer flexibility and ease of use for general material handling, while hoists provide precision in specialized applications. By evaluating these aspects, B2B buyers can make informed decisions that align with their operational goals and enhance productivity in their facilities.

Essential Technical Properties and Trade Terminology for crane Lifting Equipment

What Are the Essential Technical Properties of Crane Lifting Equipment?

When selecting crane lifting equipment, understanding its technical specifications is crucial for ensuring safety, efficiency, and compliance with industry standards. Here are some key properties to consider:

-

Load Capacity

Load capacity refers to the maximum weight that a crane or lifting device can safely handle. It is essential for buyers to understand the load requirements of their specific applications to prevent accidents and equipment failure. Exceeding load capacity can lead to catastrophic incidents, making this a critical specification in the procurement process. -

Material Grade

The material grade indicates the type and quality of materials used in the construction of lifting equipment, which affects durability and performance. Common materials include carbon steel, alloy steel, and stainless steel. Buyers should assess the environmental conditions where the equipment will be used, as certain materials offer better corrosion resistance or strength, impacting the longevity and reliability of the equipment. -

Working Load Limit (WLL)

WLL is the maximum load that a lifting device is rated to safely lift under specific conditions. This specification is vital for ensuring that all components of the lifting system, including slings, hooks, and rigging hardware, are compatible and can safely handle the intended loads. Understanding WLL helps in selecting appropriate lifting devices and avoiding overloading scenarios. -

Tolerance and Precision

Tolerance refers to the allowable deviation in dimensions and weight that the equipment can handle. For cranes and lifting devices, precision is crucial for maintaining safety and operational efficiency. Buyers should consider applications that require high precision, such as those in manufacturing or assembly lines, where even minor deviations can lead to significant operational issues. -

Proof Testing Standards

Proof testing involves subjecting lifting equipment to loads beyond its rated capacity to ensure safety and reliability. Equipment certified to OSHA and ASME standards typically undergoes proof testing to confirm its integrity. Buyers should look for equipment that has been tested and certified to industry standards, as this assures compliance and enhances safety.

Which Trade Terms Are Commonly Used in Crane Lifting Equipment Procurement?

Understanding trade terminology is essential for navigating the procurement process effectively. Here are some key terms frequently encountered in the industry:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be sold under another company’s brand. In the context of crane lifting equipment, working with OEMs ensures that buyers receive high-quality products that meet specific performance standards. This term is important for buyers seeking reliability and brand assurance in their lifting solutions. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of goods that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers, as it affects inventory management and purchasing decisions. Suppliers may have different MOQs based on product type, which can influence procurement strategies, especially for smaller operations. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price offers from suppliers for specific products or services. This term is significant in the procurement process, as it helps buyers compare prices, terms, and conditions from different vendors, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for international B2B buyers, as they clarify shipping responsibilities, costs, and risks, ensuring smooth logistics and compliance with global trade practices. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. It is an important consideration for B2B buyers, as it affects project timelines and operational efficiency. Understanding lead times helps in planning and ensures that necessary equipment is available when needed.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when procuring crane lifting equipment, ultimately enhancing operational safety and efficiency.

Navigating Market Dynamics and Sourcing Trends in the crane Lifting Equipment Sector

What Are the Key Market Dynamics and Trends in the Crane Lifting Equipment Sector?

The crane lifting equipment sector is experiencing notable growth, driven by several global factors. The ongoing expansion of industries such as construction, manufacturing, and logistics, particularly in emerging markets like Africa and South America, is fueling demand for efficient material handling solutions. Increased urbanization and infrastructure development in these regions necessitate advanced lifting equipment to meet higher productivity standards. Additionally, technological advancements, including automation and IoT integration, are reshaping sourcing strategies. For instance, cranes equipped with smart sensors can provide real-time data on load weights and equipment performance, thus enhancing safety and operational efficiency.

Another emerging trend is the rising importance of below-the-hook lifting devices, which provide versatility and safety in lifting applications. These devices, including lifting beams, clamps, and tongs, are essential for secure load handling and are increasingly being designed with customizable features to cater to specific industry needs. International buyers, particularly from regions like Europe, are also prioritizing suppliers that offer comprehensive service packages, including maintenance and training, to ensure that equipment operates at optimal levels.

How Is Sustainability and Ethical Sourcing Shaping the Crane Lifting Equipment Market?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the crane lifting equipment sector. The environmental impact of manufacturing processes and the materials used is under scrutiny, prompting companies to seek suppliers who adopt eco-friendly practices. The use of recycled materials in the production of lifting equipment not only reduces waste but can also lead to cost savings in the long term.

Moreover, certifications such as ISO 14001 for environmental management and the use of green materials are increasingly influencing purchasing decisions. Buyers are looking for vendors who demonstrate transparency in their supply chains, ensuring that their sourcing practices do not compromise ethical standards. This shift not only helps mitigate environmental risks but also aligns with corporate social responsibility initiatives that many companies are now prioritizing. As a result, suppliers who can offer sustainable products and practices are likely to gain a competitive edge in the market.

How Has the Crane Lifting Equipment Sector Evolved Over Time?

The evolution of the crane lifting equipment sector has been marked by significant technological advancements and changing industry needs. Initially, cranes were primarily mechanical devices, but the introduction of electric, pneumatic, and hydraulic systems has transformed their functionality and efficiency. Over the years, the focus has shifted towards enhancing safety features, with stricter regulations and standards necessitating the implementation of advanced monitoring systems.

Furthermore, the globalization of supply chains has allowed for a broader range of materials and technologies to be integrated into lifting equipment, making them more versatile and capable of handling complex lifting tasks. As industries continue to evolve, the demand for innovative, reliable, and efficient lifting solutions remains paramount, shaping the future landscape of the crane lifting equipment sector.

Through understanding these dynamics and trends, international B2B buyers can make informed decisions that align with their operational goals and sustainability commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of crane Lifting Equipment

-

How do I choose the right lifting equipment for my project?

Selecting the appropriate lifting equipment depends on various factors, including the weight and type of load, the lift height, and the working environment. Start by assessing the specifications of your load, such as its dimensions and weight distribution. Next, consider the lifting method: mechanical, hydraulic, or pneumatic systems may be suitable depending on the application. Additionally, ensure that the equipment adheres to local safety standards and regulations. Consulting with an expert or supplier can provide valuable insights tailored to your specific needs. -

What is the best below-the-hook lifting device for heavy loads?

For heavy loads, lifting beams or spreader bars are often the best choices as they distribute weight evenly and enhance stability during lifting. Lifting beams connect to a single lifting point, making them ideal for low headroom applications. Conversely, spreader bars feature multiple connection points, reducing the risk of load shearing or bending. When selecting a device, consider the load’s weight, dimensions, and handling requirements to ensure safety and efficiency. -

How can I ensure the quality and safety of the crane lifting equipment I purchase?

To ensure quality and safety, verify that the equipment meets relevant industry standards, such as OSHA and ASME certifications. Request proof of testing, such as load testing results, and check for compliance with safety regulations in your region. Additionally, source equipment from reputable suppliers with a history of reliability and positive customer feedback. Regular maintenance and inspections post-purchase are crucial to ensuring long-term safety and performance. -

What factors should I consider when vetting international suppliers?

When vetting international suppliers, assess their reputation, experience, and product offerings. Look for established companies with positive reviews and testimonials from other B2B clients, particularly in your industry. Evaluate their compliance with international quality standards and certifications. Consider their logistical capabilities, including shipping options and lead times. Engaging in direct communication can also provide insights into their customer service and support. -

Are customization options available for crane lifting equipment?

Yes, many suppliers offer customization options for crane lifting equipment to meet specific project requirements. Customization can include alterations in size, material, lifting capacity, and design features. When seeking customization, discuss your needs with the supplier early in the process. Be sure to inquire about the additional costs and lead times associated with custom orders to plan your project timeline effectively. -

What are the typical minimum order quantities (MOQs) for crane lifting equipment?

Minimum order quantities (MOQs) can vary significantly among suppliers and depend on the type of equipment being purchased. Standard lifting devices may have lower MOQs, while specialized or custom equipment might require higher quantities to justify production costs. Always clarify MOQs with potential suppliers before placing an order. Understanding these terms can help in budgeting and project planning, especially for larger purchases. -

What payment terms should I expect when sourcing internationally?

Payment terms for international purchases can differ widely based on the supplier’s policies and the nature of the transaction. Common terms include upfront payments, deposits, or letters of credit. It’s crucial to discuss payment options early in negotiations to ensure mutual understanding. Be aware of potential additional fees related to currency conversion, international banking, or customs duties. Always review the supplier’s payment terms to avoid any surprises during the transaction process. -

How can I manage logistics and shipping for crane lifting equipment?

Effective logistics management for crane lifting equipment involves coordinating with your supplier to understand shipping options, timelines, and costs. Discuss preferred shipping methods—such as air, sea, or land—and select the one that balances cost and urgency. Ensure that the supplier provides necessary shipping documentation, including customs paperwork, to facilitate a smooth import process. Partnering with a reliable freight forwarder can also help navigate international shipping complexities and ensure timely delivery to your site.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 10 Crane Lifting Equipment Manufacturers & Suppliers List

1. Lifting 365 – Industrial Lifting Equipment

Domain: us.lifting365.com

Registered: 2017 (8 years)

Introduction: Industrial Lifting Equipment includes a variety of products such as hoists, beam trolleys, clamps, manual and electric winches, davit cranes, lifting jacks, lifting magnets, and magnetic tools. The range features 106 products designed for efficiency and safety in material handling. Key products include MAG-MATE® Weld-On Padeyes, Vestil Polyester Lifting Slings, OZ Beam Clamp, and various safety aw…

2. Crane Depot – Below-the-Hook Lifting Devices

Domain: cranedepot.com

Registered: 2013 (12 years)

Introduction: Below-the-Hook lifting devices are used for attaching a load to a hoist, consisting of interrelated parts like slings and hooks, by holding and securing a load to ensure safe and steady mobility. These devices can be mechanical, electronic, pneumatic, or hydraulic. Crane Depot offers a variety of below-the-hook lifting devices including coil hooks, lifting beams, crane scales, lifting magnets, pal…

3. US Cargo Control – Rigging and Lifting Hardware

Domain: uscargocontrol.com

Registered: 2005 (20 years)

Introduction: Lifting and Rigging Hardware, Rigging Supplies, Lifting Slings (Nylon, Polyester Round, Wire Rope, Chain), Rigging Supplies & Hardware (Lifting Beams, Spreader Bars, Plasma® Rope, High Performance Roundslings, Wire Rope Chain & Accessories), Material Handling Netting, Straightpoint Load Monitoring Loadcells, Sling Protection, Outrigger Pads, Snatch Blocks, Wire Rope Pulleys, Crosby® Rigging Produc…

4. Harrington – Material Handling Equipment

Domain: harringtonhoists.com

Registered: 1998 (27 years)

Introduction: This company, Harrington – Material Handling Equipment, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Internet Rigging – Below-the-Hook Equipment

Domain: internetrigging.com

Registered: 2022 (3 years)

Introduction: This company, Internet Rigging – Below-the-Hook Equipment, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Lifting Equipment Store – 2 Ply Webbing Sling

Domain: liftingequipmentstore.us

Registered: 2018 (7 years)

Introduction: Lifting Slings and Straps for Rigging & Cranes. Types of slings include Round Slings, Webbing Slings, Chain Slings & Lifting Chains, Wire Rope Slings, and Synthetic Rope Slings. Key products include: 2 Ply Webbing Sling (from $11.80, made to order, ships in 1 day), Green Round Sling (5,300lbs, from $10.46, made to order, ships in 1 day), Red Round Sling (13,200lbs, from $20.75, made to order, ship…

7. Lift-All – Custom Lifting Devices

Domain: lift-all.com

Registered: 1996 (29 years)

Introduction: Lifting Devices include Custom Lifting Devices, Beams, Coil Lifters, Gantry Cranes, Pipe Lifters, Manhole Lifters, Barrier Grabs, and Beam/Girder Clamps. All products meet or exceed applicable U.S. Government Standards including OSHA, ASME B30.20, B30.9 & B30.17. Custom lifting devices can be designed for specific applications. Key products include:

– Beams: Multiple pick points for balance, avai…

8. Airpes – Lifting Equipment Solutions

Domain: airpes.com

Registered: 2002 (23 years)

Introduction: Types of lifting equipment include: 1. Overhead cranes or bridge cranes – designed for material handling in manufacturing facilities, moving loads along a fixed path. 2. Gantry cranes – consist of two vertical legs and a cross beam, adaptable for various jobs, both large and small. 3. Hoists – used for lifting awkwardly shaped or heavy objects, available in chain, wire rope, pneumatic, electric, o…

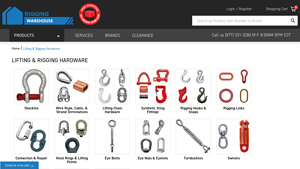

9. Rigging Warehouse – Lifting & Rigging Hardware

Domain: riggingwarehouse.com

Registered: 2006 (19 years)

Introduction: Lifting & Rigging Hardware includes various subcategories such as Shackles, Wire Rope, Cable & Strand Terminations, Lifting Chain Hardware, Synthetic Sling Fittings, Rigging Hooks & Snaps, Rigging Links, Connection & Repair Links, Hoist Rings & Lifting Points, Eye Bolts, Eye Nuts & Eyelets, Turnbuckles, Swivels, Lag Type Hardware, Miscellaneous Rigging Hardware, and Load Insulating Products. Key p…

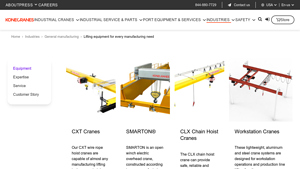

10. Konecranes – Lifting Equipment Solutions

Domain: konecranes.com

Registered: 1999 (26 years)

Introduction: Konecranes offers a variety of lifting equipment for general manufacturing needs, including: Industrial cranes, Workstation lifting systems, Electric chain hoists, Workstation cranes, Jib cranes, Manual products, Overhead cranes, C-series electric chain hoist cranes, Rope hoist cranes, Gantry cranes, Portable cranes, Wall mounted console cranes, Built up cranes, Custom cranes, Hazardous Environmen…

Strategic Sourcing Conclusion and Outlook for crane Lifting Equipment

In today’s competitive landscape, strategic sourcing of crane lifting equipment is paramount for businesses aiming to enhance operational efficiency and safety. Key considerations include evaluating below-the-hook lifting devices, rigging hardware, and the specific needs of your material handling applications. By partnering with reliable suppliers, you can ensure compliance with international safety standards while optimizing your procurement process.

Investing in high-quality lifting solutions not only minimizes risks but also improves productivity. As industries across Africa, South America, the Middle East, and Europe continue to grow, the demand for advanced lifting technology is set to rise. This presents a significant opportunity for international B2B buyers to leverage superior products that meet their operational requirements.

As you navigate your sourcing journey, consider the long-term benefits of forming strategic partnerships with reputable manufacturers and suppliers. By doing so, you will not only secure a competitive edge but also foster innovation in your operations. Now is the time to take action—explore the vast array of crane lifting equipment available and invest in solutions that drive your business forward.